Merida Procraft Sattel User manual

Installation and operating

instructions

Saddle/Seatpost

Thank you for purchasing a MERIDA component.

About these instructions

Carefully read and follow these installation and operating

instructions before use. Keep these instructions for future

reference.

These instructions are valid for the following

MERIDA components:

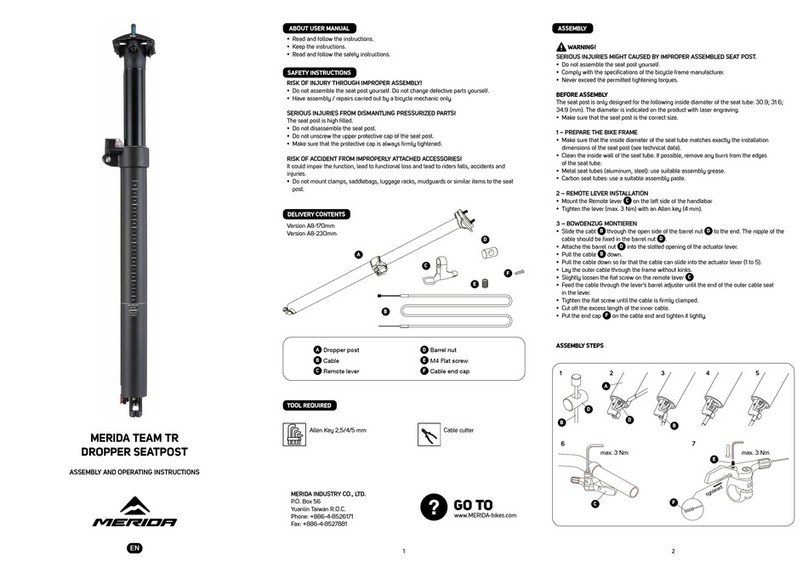

1. Suspension seatpost

2. Reducing sleeves

3. Classic seatpost

4. MERIDA EXPERT CC seatpost

5. Quick release

6. Saddle

Special features

The material is very durable and has a low weight. Have

your bicycle inspected by your dealer following accidents

or other incidents.

1. Intended use

The majority of MERIDA components are designed for

use on racing, trekking, and mountain bikes, and their

typical use.

Before your first ride

Never modify MERIDA components. Do not file or drill

and holes in components as this damages their structure

and voids the warranty.

Only use MERIDA parts with each other to achieve

optimum function and component durability.

Carbon

After being overstressed, a previously damaged carbon

component may fail without warning.

If your MERIDA carbon component has been exposed to

such high stress, take your bicycle to your MERIDA

dealer. For safety reasons, carbon components can

never be repaired and must always be replaced

immediately.

Carbon components must never be exposed to high

temperatures. Therefore, never have them painted.

Avoid storage near to heat sources. Carbon components

have a limited life cycle. Therefore, replace them at

regular intervals, as a precaution.

Ensure that clamp areas of carbon parts are completely

free of grease and lubricant.

2. MERIDA Saddles

Assembly

To mount the saddle, loosen the fixing bolts of the saddle

clamp just a few turns. If the saddle rails are too far apart,

do not force the rails into the clamp grooves.

Position the surface of the saddle parallel to the ground.

Gently tighten the bolts of the saddle clamp. You will find

the next steps in “SETTING THE CORRECT SEAT

POSITION”.

MERIDA EXPERT CC seatpost special features

With this model, the individual components must be

mounted in the correct combination and orientation.

See also “SETTING THE FORE-AFT POSITION AND

TILT OF SADDLE.”

3. MERIDA seatposts

MERIDA seatposts differ mainly in terms of the clamping

mechanism. The diameter of the post and its length are

important – see also “SETTING THE CORRECT SEAT

POSITION” in this regard.

Assembly

The difference between the (greater) internal diameter of

the seat tube and the (smaller) external diameter of the

seatpost should be between 0.05 mm and 0.1 mm.

If necessary, deburr the seat tube.

If a MERIDA aluminum seatpost is mounted in a frame

made of aluminum, titanium, or steel, the inside of the

seat tube must be greased.

With carbon components, the inside of the seat tube and

the post itself must be completely free of lubricants. Use

a special carbon assembly paste for the assembly.

Now slowly slide the post into the seat tube, no farther

than is necessary.

Do not rotate the post in the frame.

Slide the seatpost at least so far that the marking for the

minimum insertion depth (min. insertion, stop, etc.) is

inside the seat tube. For frames with seat tubes that

extend upward, the seatpost may need to be lowered

farther. Refer to the bicycle/frame manufacturer’s

instructions.

Special features of MERIDA EXPERT CC

seatposts

During assembly, make sure that the label “in front” is

pointing in the direction of motion.

Danger

Indicates essential safety instructions.

Danger

Replace the component following

a heavy impact.

Danger

If the component shows external signs

of damage, you should no longer ride

using this component.

Danger

Each of the following instructions must

be strictly observed. Non-observance

of these instructions may lead to the

failure of the components.

Note

The seatpost must glide smoothly into

the frame. However, it must not be

able to tilt back and forth.

1

2

3

4

5

6

Danger

Never mount pannier racks or trailer

coupling on carbon posts.

Flange Yoke (rear ange)

Long boltShort bolt

Direction of motion

Mounting bracket

Note

The seatpost must glide smoothly into

the frame. However, it must not be

able to tilt back and forth.

Note

The seatpost must glide smoothly

into the frame. However, it must not

be able to tilt back and forth.

Danger

If a clamping surface is made of

carbon, neither the frame nor the post

may come into contact with lubricants!

Use a special carbon assembly paste

for the assembly.

in

front

1

4. MERIDA reducing sleeves

for seatposts

Reducing sleeves for seatposts compensate for

differences in diameter between the seatpost and seat

tube in the frame.

If using a metallic frame and seatpost, lubricate the inside

of the frame and the inside of the reducing sleeve before

mounting the seatpost.

If carbon components are involved in clamping, no

grease may be applied there. Use special carbon

assembly paste when clamping carbon components!

Slide the reducing sleeve into the frame so that the slot is

congruent with that of the frame. Then see “MERIDA

SEATPOSTS/ASSEMBLY”.

5. Adjusting MERIDA suspension

seatposts

The suspension seatpost is prepared for a weight of

approx. 75–85 kg. To adjust the suspension, it must be

removed from the frame.

Carefully read the bicycle manufacturer’s user manual,

and follow the instructions in the chapter “MERIDA

seatposts/assembly”.

If the post is too soft, screw in the bolt in a clockwise

direction. The suspension will get harder.

If the post is too hard, screw the bolt counter-clockwise.

The suspension will get softer.

After mounting, check that the post compresses approx.

10 mm when you are sitting in your riding position.

6. Setting the correct seat position

Setting the saddle height

Pedaling determines the required saddle height. The

balls of the big toes should be above the center of the

pedal axle. The leg must not extend fully at the lowest

point of the pedal stroke.

Check the saddle height by sitting on the saddle and

placing your heel on the pedal in the lowest position. In

this position, the leg should be fully stretched. The hips

must remain straight. To adjust the saddle height, you

have to loosen the saddle clamping bolts or the quick

release.

Use a suitable tool to loosen the seatpost clamping bolt,

turning it 2–3 times counter-clockwise. Now slide the

seatpost to the desired position. Obtain a longer seatpost

if necessary. Align the saddle so that it is point straight

ahead again. Tighten the seat tube clamp in half-turns,

and check that the post is held securely by trying to rotate

the saddle. Sufficiently tightening the clamping bolt or

quick release should not require much force.

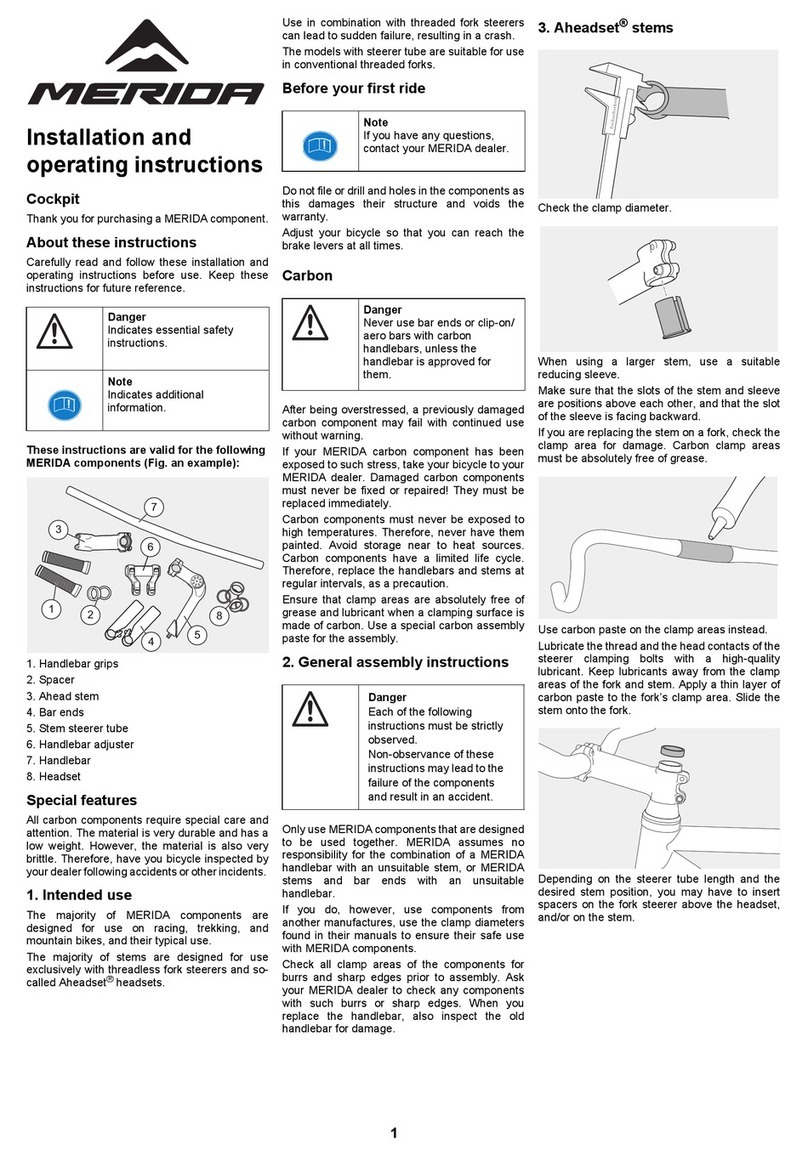

Setting the fore-aft position and tilt of saddle

For seatposts with 2-bolt yoke clamps, loosen both fixing

bolts and move the saddle forward and backward to the

desired longitudinal position. Then tighten the bolts until

both clamps touch the saddle rails. The brackets should

not clamp, otherwise there is a risk of breakage.

Tightening the front bolt lowers the saddle point, while

tightening the rear one lifts it. If the adjustment range is

not sufficient, loosening the front bolt at the same time as

tightening the rear one will also elevate it. Loosening the

rear bolt and tightening the front one lowers the saddle

point. Retighten the bolts evenly and alternately with a

torque wrench, paying attention to the torque specified

on the component.

MERIDA EXPERT CC seatpost

This MERIDA EXPERT CC seatpost has a weight-

optimized clamp, so the individual components must be

mounted in the correct combination and orientation.

Tighten the bolts of the seatpost.

For seatposts with 1 or 2-bolt patented clamps, loosen

the clamping bolts and move the saddle forward or

backward, or the saddle point up or down.

The clamps may be within the marks on the saddle rails.

The brackets must not clamp on the bends. There is a

danger of breakage.

Now tighten the bolts until both clamps touch the saddle

rails. Increase the torque using a torque wrench until the

maximum torque specified on the component is reached.

7. Handling quick releases

The hand lever transforms the closing motion into

clamping force via an eccentric cam.

The binder nut sets the tension on a threaded rod.

Open the quick release and the text “Open” can be seen.

Move the lever back to the clamping position and the text

“Close” appears. The lever should move easily at first.

During the second half of the movement, the leverage

should increase considerably. Finally, the lever should be

very difficult to move.

In its final position, the lever must be parallel to the

bicycle, resting close to the frame.

Check that it is sitting correctly by pressing on the end of

the closed lever and trying to rotate it.

If the clamping lever moves, the component is not

securely held in place. You will need to open it again and

increase the pretension. To do this, screw the binder nut

on the other side a half-turn clockwise. Repeat the

closing process and check the grip again.

Finally, take hold of the front and back of the saddle, and

try to rotate it.

Note

Read “HANDLING QUICK

RELEASES”. Only tighten the bolt in

the clamp so far/close the quick

release so that the post does not slip

when you are mounting the saddle.

After mounting the saddle, proceed as

described in the chapter “SETTING

THE CORRECT SEAT POSITION”.

Note

Before mounting a suspension

seatpost, follow the setting instructions

in the chapter “ADJUSTING MERIDA

SUSPENSION SEATPOSTS”.

Danger

Seat tube and seatpost diameters that

do not match exactly can cause the

seatpost or frame to break.

Note

Mark the position of the seatpost in the

frame.

Danger

Only unscrew the adjusting bolt

enough so that it sits flush with the

post.

Danger

Never ride a bike where the maximum

seatpost length marking is visible.

Danger

Insufficiently tightened quick releases

can cause components to come loose.

6Nm6Nm

Torque

specication

2

8. Care and maintenance

Clean the components regularly with water and a soft

cloth. For stubborn stains, you can add some readily

available dish soap to warm water. Do not use any harsh

cleaning agents.

Rub the metallic surfaces and carbon with commercially

available hard wax at least two times per year. Polish the

post once the wax has dried.

After cleaning, the plastic saddle cover can be

maintained with a colorless plastic care product (e.g.

cockpit spray).

Mount the component once per year. Grease the parts

again, with the exception of carbon parts.

Maintain the interior of the suspension post every 60–

100 hours of operation/yearly. Replace the grease, and

check seals, guides, and spring elements.

Check the torque values of all bolts after the first 100–

300 km (60–180 miles), and then again every 2,000 km

(1,200 miles).

9. Warranty and guarantee

Statutory warranty rights apply within the first two years.

This regulation only applies in states that have ratified the

EU bill.

The components are subject to natural wear, depending

on use and external conditions.

We also grant a manufacturer’s guarantee on all

MERIDA components (from the date of purchase, to the

first purchaser) of 5 years on material and workmanship.

In case of defects, please contact your MERIDA dealer.

In a guarantee case where the respective higher-quality

model is unavailable, MERIDA INDUSTRY CO., LTD.

reserves the right to deliver the respective current

successor model in the available color.

Assembly and/or conversion costs and any accessories

(due to altered dimensions) will not be refunded in a

guarantee case.

The manufacturer guarantee is only valid for the first

purchaser upon presentation of proof of purchase

showing the purchase date, dealer address, and model

name.

The intended use is a prerequisite for the guarantee. The

guarantee does not cover labor and transportation costs,

or any follow-up costs caused by defects. Competition

use in the context of road races, triathlon, or the MTB

sections of cross-country races are covered by the

guarantee. Other visible fall damage resulting from jumps

or other types of overstress is likewise not covered by the

guarantee. The guarantee does not cover damage

caused by wear, neglect, crashes, overstressing caused

by overloading, improper installation and care, or the

modification of components.

In the interest of a long life and durability of the

components, the manufacturer’s installation instructions

and the prescribed maintenance intervals must be

adhered to exactly. Failure to comply with the installation

instructions and inspection intervals will void the

guarantee.

The upper material of the saddle becomes rough when

exposed to sunlight, and wears out during use due to

mechanical stress. Regular cleaning and care have

a positive impact on wear.

10. Technical specifications

Saddles

Diameter of wires or tubes

of the saddle rails: 7 mm

Reducing sleeves for seatposts

Your dealer will inform you about the diameters available

in the current MERIDA catalog.

Seat posts

Available diameters –

depending on the model: 27.2–34.9 mm

Minimum insertion depth:

The minimum insertion depth is marked on every post.

The marking must always be lowered into the frame.

For the maximum torque of the seat tube clamp, see the

frame manufacturer’s instructions.

Note

When cleaning, pay attention to any

damage to the materials.

Note

If there is any doubt, always adhere

to the values specified on the

component.

If you have any questions, please contact:

MERIDA INDUSTRY CO., LTD.

P.O. Box 56

Yuanlin Taiwan R.O.C.

Phone: +886-4-8526171

Fax: +886-4-8527881

www.merida-bikes.com

5th Edition, February 2017

© No part of this document may be reprinted, translated,

reproduced, or otherwise used, e.g. on electronic media

without prior written consent.

Graphics, text, and design

2W Technische Informations GmbH & Co.KG

www.2wgmbh.de

3

Table of contents

Other Merida Bicycle Accessories manuals

Popular Bicycle Accessories manuals by other brands

Specialized

Specialized Elite CylcoComputer user manual

Sigma

Sigma BC 16.16 manual

Playcore

Playcore Dero Setbacks installation instructions

VDO Cyclecomputing

VDO Cyclecomputing x3dw instruction manual

Cateye

Cateye RAPID X2 manual

buratti meccanica

buratti meccanica Clorofilla Trail Use and maintenance manual