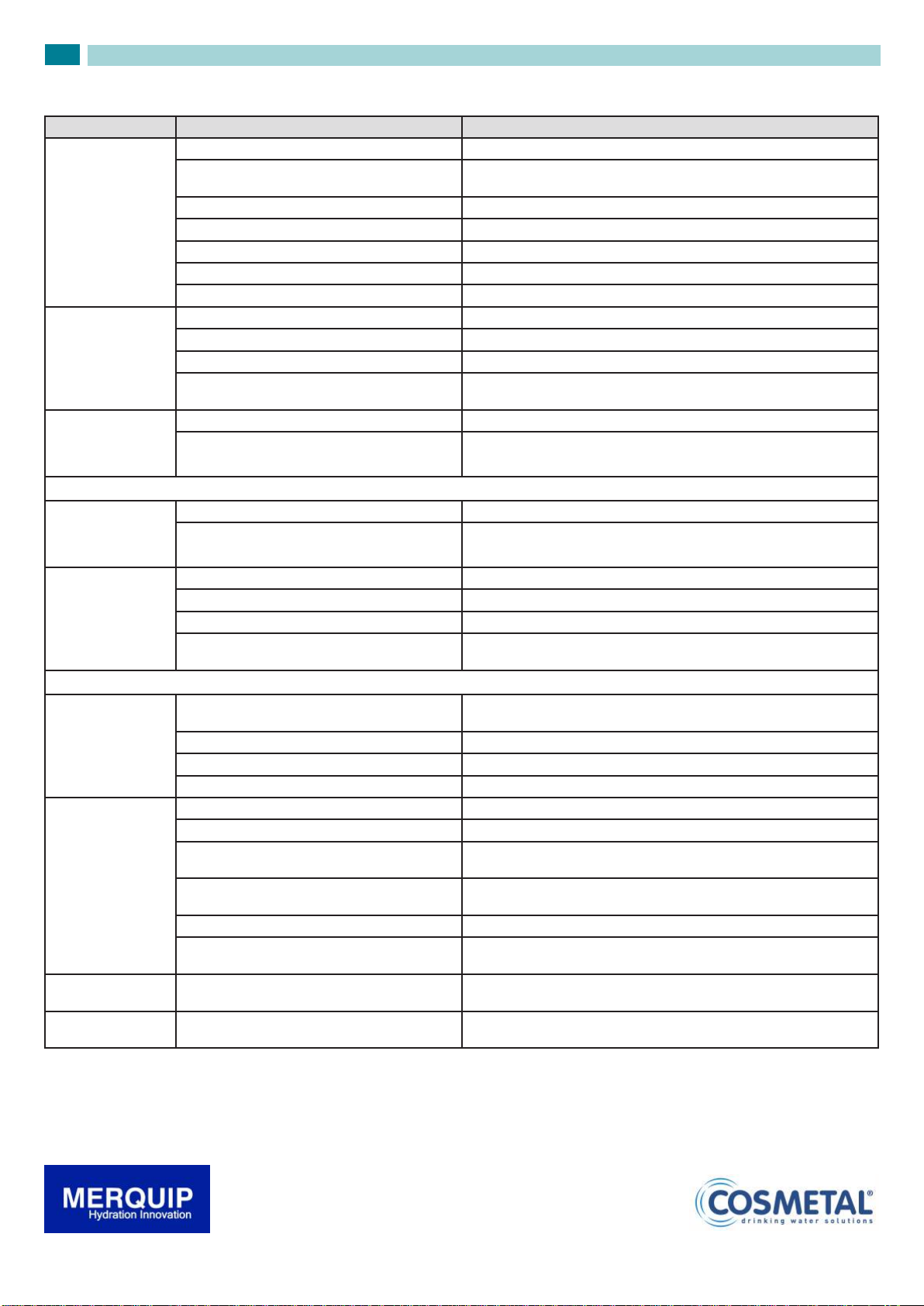

9.2

COOLING SYSTEM

GB

ANOMALY POSSIBLE CAUSE INTERVENTION

Ithe compressor will

not start

- power failure - check that there is voltage in the plug

- thermostat on the off position, or set to the mi-

nimum

-

adjust the thermostat position

- faulty thermostat - replace the thermosta

t

- the over-load protection of the compressor is faulty

- replace it

- the starting relay is faulty

- replace it

- the starting capacitor is faulty

- replace it

- the compressor is faulty

- replace it

the water is cold but

the appliance is ope-

rating excessively or

non-stop

- little ventilation

- place the appliance away from the wall

-

the condenser is dirty or covered

- clean the condenser or free it of its obstacles

-

the thermostat is on maximum cold position

- adjust it

-

the room temperature is higher than 32°C

- it is normal that the appliance works at a continuously high room tempe-

rature

the compressor

works continuously,

but the water is not

cold

- gas leak from the cooling system - contact a specialised technician (refrigerationist)

- the compressor is faulty

- replace the compressor

COOLING SYSTEM

too much noise com-

ing from the appli-

ance, but it is work-

ing normally

- the machine is not levelled

- level the appliance using the adjustable feet

- a few pipes are touching some parts inside the ap-

pliance, thus causing it to vibrate

- adjust the position of the pipes, making sure they do not touch any other

parts

l’acqua fredda esce

piano o non esce

- low pressure of the inlet water

- take steps to increase the pressure (autoclave)

- faulty solenoid valve

- replace it

- cloggedwaterlter

- replace it

- the temperature adjuster is faulty and causes

complete freezing of the ice compartment

- make the ice melt.

replace the temperature adjuster

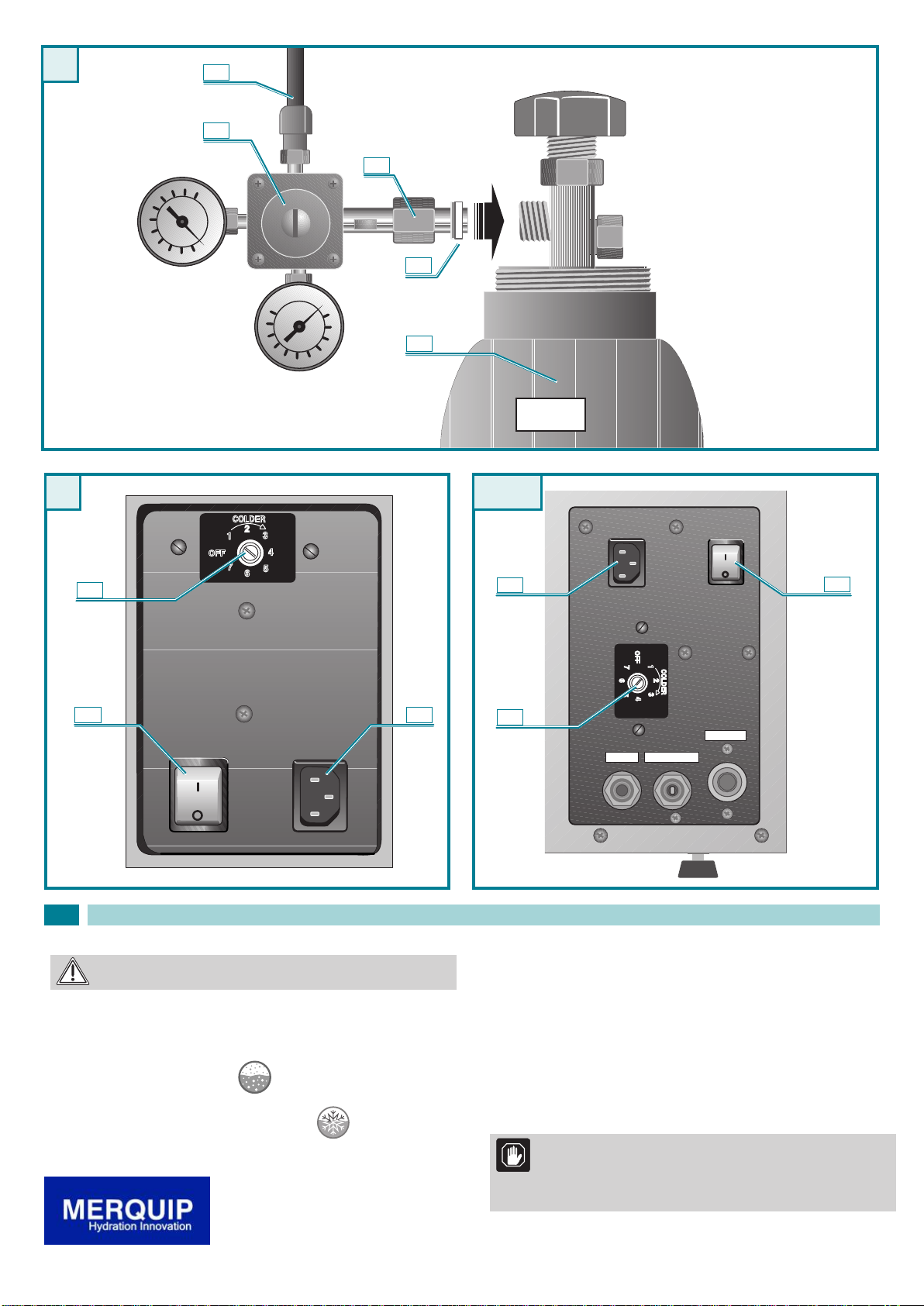

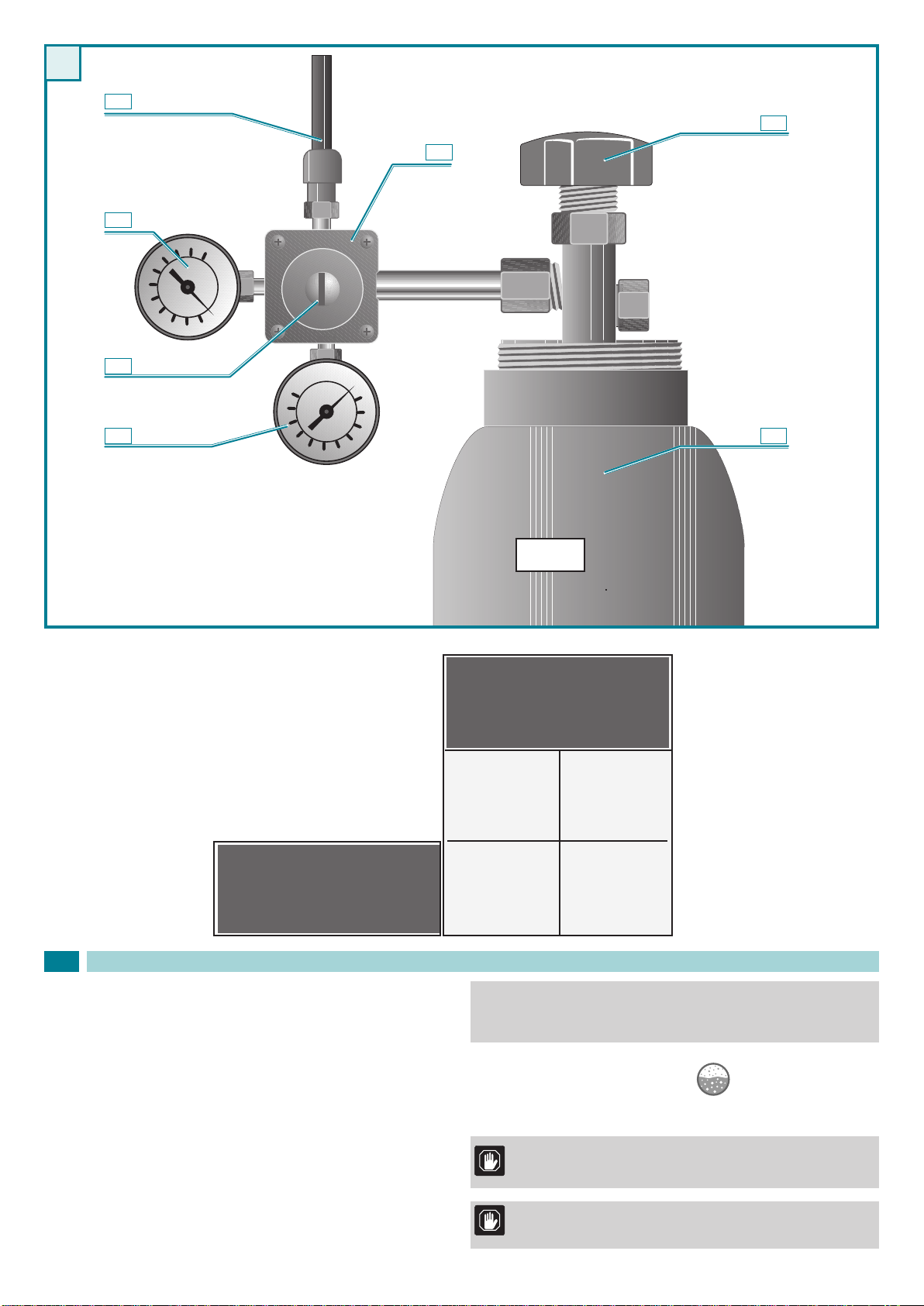

CARBONATING SYSTEM

the carbonated wa-

ter is not very fizzy

or not at all

- the pressure of the gas in the co2 reducer is set

to less than 3 bars

- increaseupto3.5–4bars

- co2 cylinder empty - replace it

- the temperature of the outlet water is high - adjust the position of the thermostat to maximum

- air bubbles inside the carbonator - clean out the carbonator

only gas comes out

of the carbonated

water outlet

- the level probes are dirty - control and replace

- the pump turns continuously - nowaterisenteringorthewaterlterisblocked

- the pump turns continuously, inlet water is pre-

sent

- thepipettingintothecarbonatorisobstructed.disassembleandcle-

an

- the pump is blocked or the pump-motor is not

working

- check it and replace it

- the level controller is faulty - control and replace

- the pump safety device has intervened (no wa-

ter)

-

check that there is pressure in the network

disconnect and reconnect the machine from the electrical network to reset it

continuous dripping

from the outlets

- dirty solenoid valve - disassmeble the solenoid valve and clean it

the still water comes

out carbonated

- there is a shortage of inlet water - disassemble and clean or replace