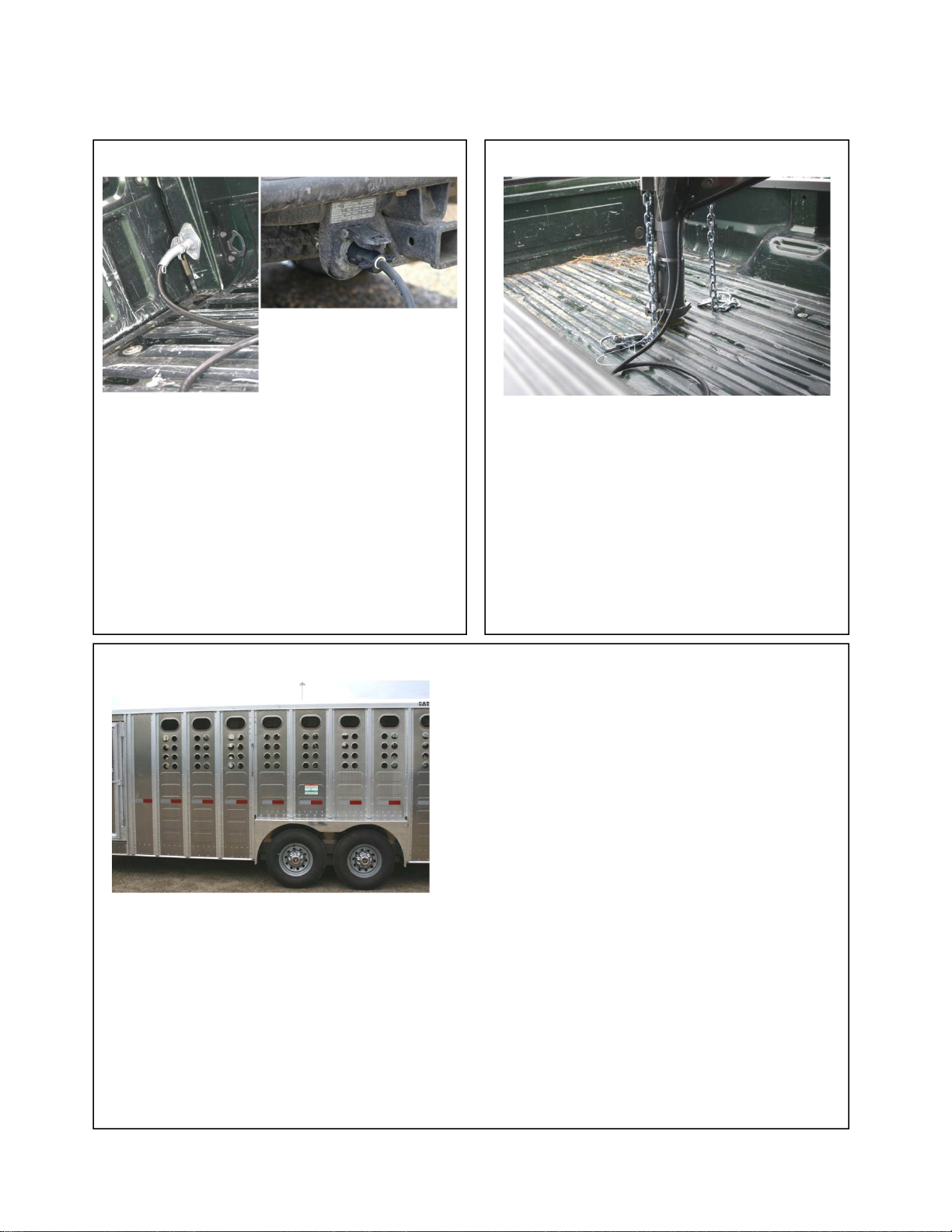

Merritt GOOSENECK LIVESTOCK TRAILER User manual

GOOSENECK LIVESTOCK TRAILER

OWNER’S MANUAL

SEE WARRANTY REGISTRATION FORM ON LAST PAGE

1-800-634-3036 . 9339 BRIGHTON RD. HENDERSON, COLORADO 80640-8229

REV A 6/16/16

79-79-0502

FORWARD

Congratulations and thank you for your purchase of a Merritt Trailers Inc. Gooseneck

Livestock Trailer . Built with pride, American engineering and manufacturing know-

how. It is designed to provide performance for years to come.

This manual is furnished to ensure that the owner\operator is aware of safe operating

procedures. It includes information about the general care and maintenance of your

Gooseneck Livestock Trailer . Also included is an operator’s manual located in a tube

holder on the lower front of the trailer.

Carefully read the following pages. If you have any questions regarding thisGooseneck

Livestock Trailer contact a Merritt dealer.

Merritt dealers have the knowledge and the

facilities to provide you with the best service possible.

We also advise you to strictly follow the recommended maintenance schedule outlined.

This maintenance schedule is designed to ensure that all critical components on this

trailer are thoroughly inspected at various intervals.

All information in this manual is based upon the latest product data and specifications

available at the time of printing. Merritt Trailers Inc. reserves the right to make

product changes and improvements which may affect illustrations or explanations.

This information is also available on our web page. (http://merritt-trailers.com/)

1-1

TABLE OF CONTENTS

WHEEL and TIRES

Wheels..................................................8-1

Torque Requirements............................8-1

Tire safety ............................................8-2

FORWARD

Introduction. .........................................1-1

GENERAL INFORMATION

Normal trailer Operation ......................2-1

Loading and unloading if livestock . . . 2-

1

Modification of Trailer.........................2-1

LOAD LIMITS

LOAD LIMITS.....................................9-1

SAFETY

Over the road safety handling...............3-1

Wheel torque ........................................3-2

SAFETY

Safety..................................................10-1

Safety..................................................10-2

BEFORE TRIP INSPECTION

Safety Chains........................................4-1

Coupler Attachment..............................4-1

Brake and Electrical controls................4-2

Brake Controls......................................4-2

Side Structure. ......................................4-2

Gates.....................................................4-3

Tires......................................................4-3

Wheel & Rims......................................4-3

Door Locks...........................................4-3

ELECTRICAL SYSTEM

Basic Wiring Diagram........................11-1

Breakaway Battery Charger ............... 11-2

12 Volt Sealed Lead-Acid Battery . . . 11-

3

Electrical Connector Wiring Diagram..... 11-3

TROUBLESHOOTING

Electrical Troubleshooting. ................12-1

Electrical Braking Troubleshooting. . 12-2

OPERATION INSTRUCTIONS

Operation of Brakes..............................5-1

Operation of Coupler............................5-1

Operation of Gates................................5-2

CONSUMER INFORMATION

Reporting Safety Defects.................... 13-1

Warranty Certificate. ..........................13-2

Warranty Schedule............................. 13-3

Warranty Certificate. ..........................13-4

GENERAL MAINTENANCE

Fasteners. . . . . . . . . . . . . . . . . . . . . . .

6-1

Floor .....................................................6-1

Gate and Ramp Hinges.........................6-1

Wheel Bearings ....................................6-1

Grease Seals..........................................6-2

General Maintenance............................ 6-2

BRAKES

Brakes...................................................7-1

Brake Adjustment.................................7-2

GENERAL INFORMATION

NORMAL TRAILER OPERATION

This Merritt Gooseneck trailer is designed for

operation within legal highway speed limits on

reasonable road surfaces for the type of service it

was built to perform, and in accordance with the

noted weight restrictions.

Normal use means the loading, unloading and

transportation of uniformly distributed legal loads,

in a manner which does not subject trailer to

stresses or impacts greater than imposed by

reasonable use.

This trailer was built to carry cargo within the two weight ratings on the identification plate

located on the road side of the trailer near the front.

The GAWR (Gross Axle Weight Rating) is the structural capability of the lowest rated

member of the running gear component suspension and spring system, hub, wheels and

drums, rims, bearings, brakes, axle, and tires.

The GVWR (Gross Vehicle Weight Rating) is the structural capability of the trailer when

supported by the kingpin and axles with the load uniformly distributed throughout the cargo.

The maximum load indicated on the identification plate may not be legal o

n the highway you

plan to use. States have differing laws and regulations, affecting vehicle lengths and weights

on the roads that are not a part of the primary interstate.

LOADINGANDTRANSPORTOFLIVESTOCK

The loading of the trailer is important! KEEPTHE CENTER OF GRAVITYAS LOWAS

POSSIBLE. Proper placement of the larger animals should be considered.

Because load types vary, drive with appropriate care and within the limits of the load.

The wellbeing of the Gooseneck Livestock Trailer is dependent on the stock density,

ventilation, skill of driving, and quality of roads. Frequent inspection of livestock and

careful driving cannot be over-emphasized!

MODIFICATION OF TRAILER

Any modifica

tion made to the trailer must comply with DOT and NHTSA regulations and

must not compromise the gross vehicle weight rating (GVWR) of the trailer.

Any operations of the trailer outside the limitations stated in this manual will void any

responsibility of Merritt Trailers Inc. for any of its results

2-1

SAFETY

OVER-THE-ROAD SAFE HANDLING

YOU AND YOURSAFETY

1. You - the operator - have control of the most important factors that affect vehicle stability.

Trailers are important tools in our transportation industry and, like any tool, are safe in the

hands of a properly qualified operator.

2. The fifth wheel coupler should be securely mounted to the tractor frame.

3. The driver should be familiar with the characteristics of the particular trailer and load being

transported.

4. The driver should be familiar with the nature of the roads and traffic encountered during the trip.

5. Stability:

Within the relatively narrow confines of road law, limiting vehicle size and weight, together

with characteristics of available tires, suspensions, and other components, there is little that a

manufacturer can do to affect the inherent stability of a trailer other than keeping the loading

decks as low as feasible, considering the requirements for loading space and adequate tire

clearance. This means that the major factor affecting operational stability are the knowledge

and skill of the driver. The predominant causes of the rollover accidents are:

Excessive speed.

Violent swerving or turning

Application of brakes or tractor power while turning

Entering curves at too high of a speed may be caused by one of the following factors:

a. Traveling at freeway speeds for long periods of time and failing to reduce it before

entering freeway interchanges or other curves requiring a reduced and controlled speed.

b. Lack of familiarity with the vehicle characteristics to recognize its safe speed

with relation to posted speed limits on curves, which are usually determined with

automobile traffic in mind.

c. Failure to reduce speed sufficiently when approaching congested traffic such as

might be found at traffic signals on highways. With the advent of today’s more

powerful and higher torque engines, the original practice of maintaining momentum

to avoid acceleration in traffic is outmoded.

3-1

SAFETY

OVER-THE-ROAD SAFE HANDLING

6.

Tire Characteristics: high pressure truck/trailer tires have different characteristics under high

speed cornering conditions than do passenger car tires. As an extreme example, it is fairly

common knowledge that a skilled race car driver can consistently “drift” his racer around

tight turns where very high lateral ”g” forces are encountered. However, truck/trailer tires

which are designed for carrying high loads over long distances have substantially different

characteristics, and their lateral stability becomes unpredictable when lateral forces approach

0.4g. This means that commercial vehicles must be operated in a conservative manner

when cornering.

Braking and Acceleration: either braking or accelerating while cornering can significantly

7.

reduce the stability of the vehicle and should be avoided. The best driving practice is to

decelerate to safe conservative speed before entering a corner or approaching congested

traffic, and then to apply only moderate power until a straight path has been reestablished.

Like any other vehicles, trailers can tip or slide out of control if turns are negotiated at too

high of a speed or when making violent maneuvers such as abrupt lane changes or other

evasive actions to avoid obstacles.

WHEELTORQUES

Proper torqueing and re-torqueing the wheel nuts are critical to prevent a premature loss of

wheel equipment.

Wheel nuts must be checked and re-torqued after 50 to 100 miles of use. This is

important every time you change a wheel.

3-2

BEFORE TRIP INSPECTIONPROCEDURE

Be careful when making inspections, hookups,

and repairs to avoid personal injury. Make

sure parking brakes are

properly active or that wheel chocks are in place to avoid sudden

or unexpected movement of the trailer which could result in bodilyinjury.

It is the Operator’s responsibility to conduct a safe and accurate pre-trip inspection of the

vehicle including brake condition and proper adjustment and be satisfied that the vehicle is in

safe operating condition. See 49 CFR Parts 383 and 396

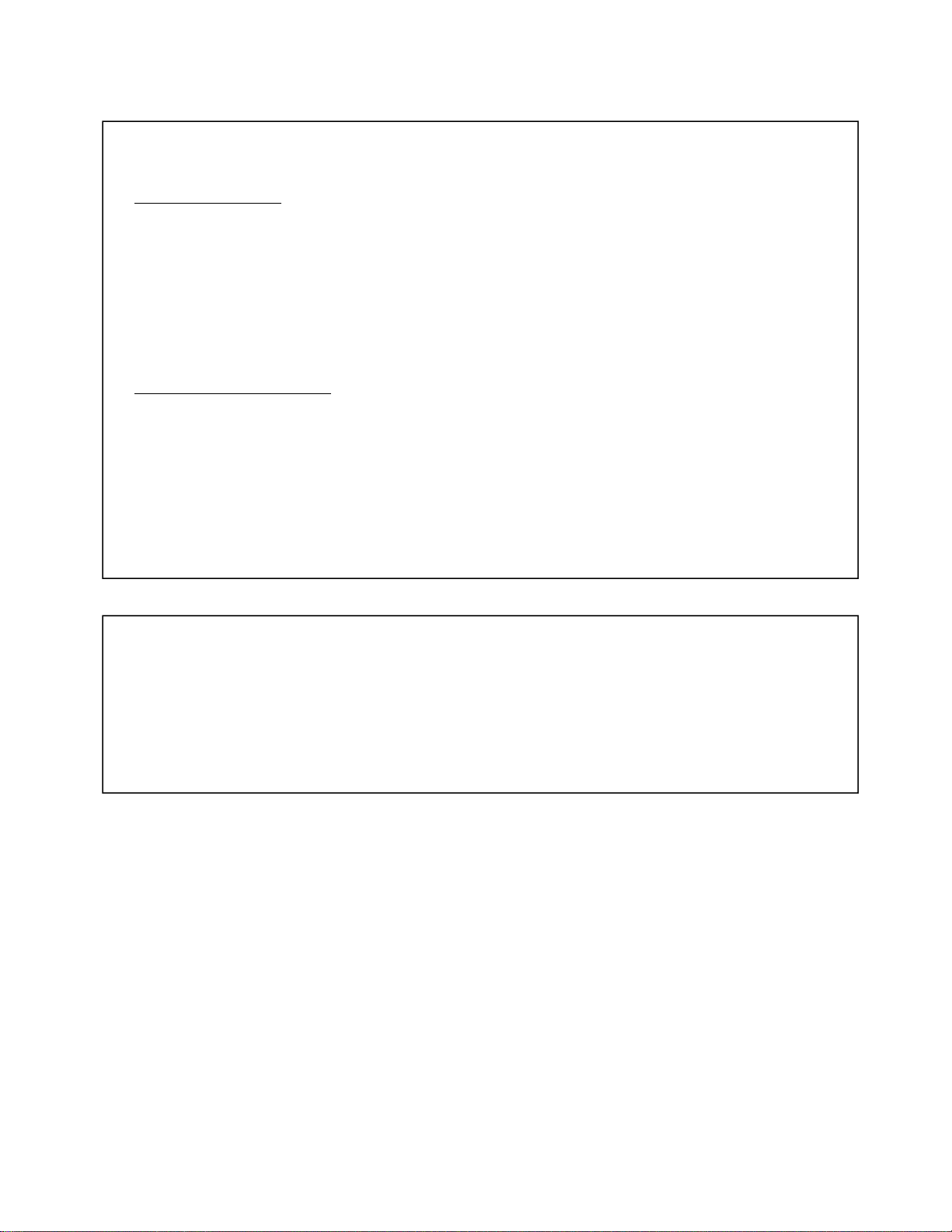

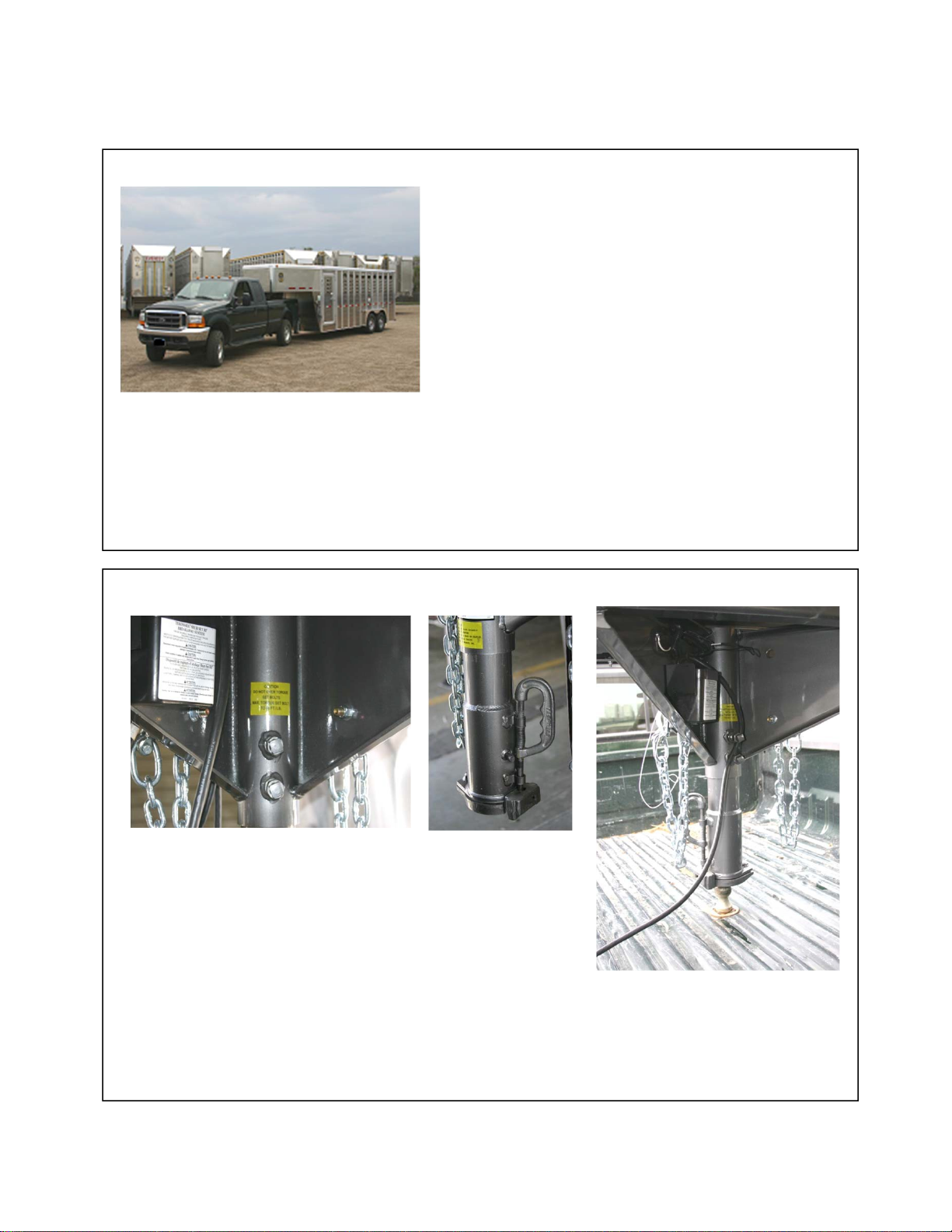

SAFETY CHAINS

COUPLER ATTACHMENT

After hook-up, check for positive engagement of

the hitch ball and coupler. Be certain that lock

handle is completely engaged before towing the

trailer. Also check to insure that coupler

adjustment set screws are torqued to 65-70 ft. lbs

The safety chains should hook

individually behind the coupler to the

attachment points in the tow vehicle (as

shown in the photo). They MUST NOT

be attached to the ball.

4-1

BEFORE TRIP INSPECTIONPROCEDURE

BRAKEAND ELECTRICALCONTROLS

BRAKE CONTROLS

Check brakes for proper operation before

each trip. On trailers with electric brakes,

fasten the breakaway switch actuating cable

securely to the towing vehicle.

Make certain

the breakaway battery is fully charged.

Your breakaway battery kit contains a tow

charger which can keep your battery charged.

The charger is hooked to the clearance light

circuit and will charge while running lights

are being used.

Connect the front receptacle and check for

proper

operation of stop lights, right / left turn

signals and running lights. Repair

malfunctioning lights prior to trip. Check and

clean all lights and reflectors. Proper

operation requires clean and positive contact

between electrical connectors. Be sure the

plug on the light cable and trailer connectors

are free of corrosion. Inspect all wiring to see

it is not frayed.

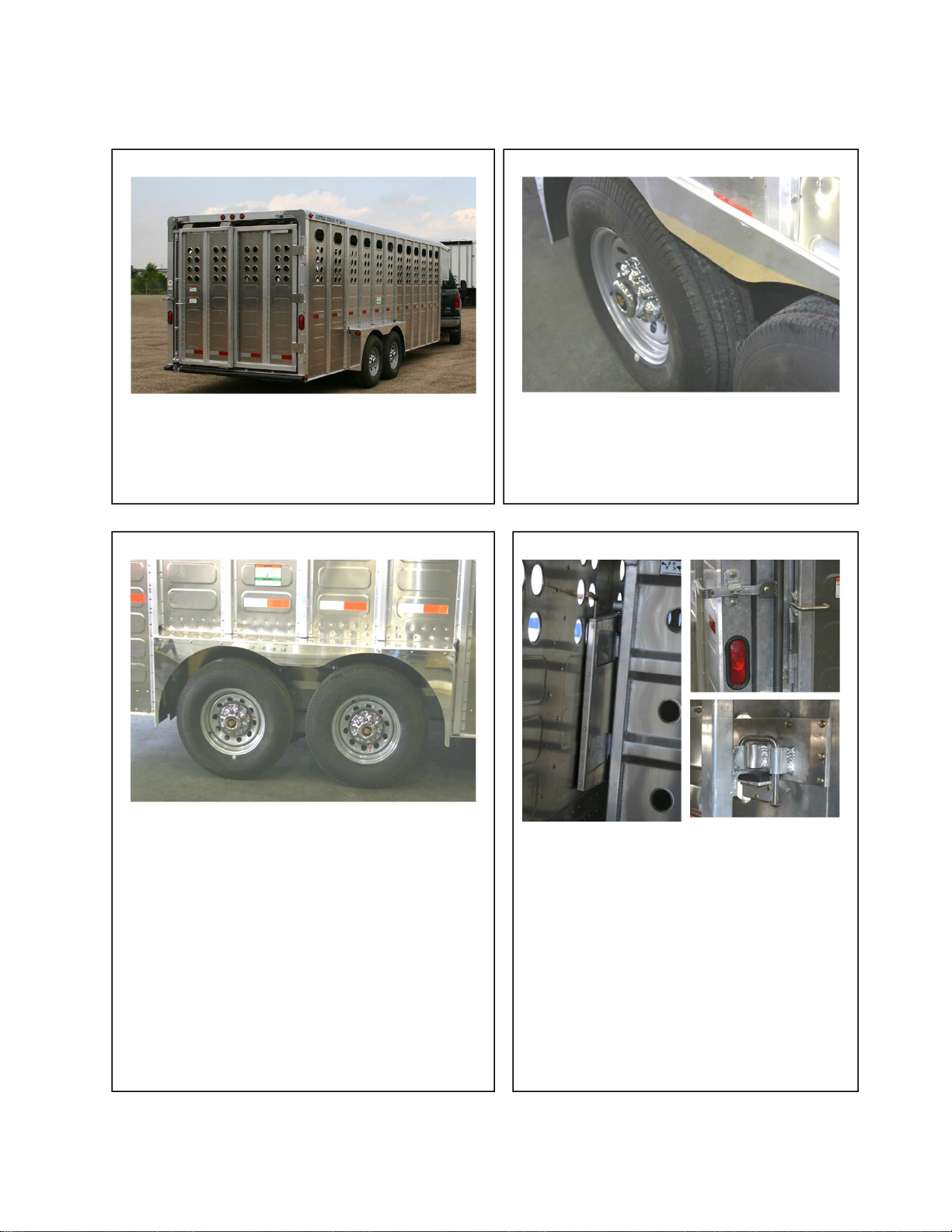

SIDE STRUCTURE

Check the trailer sides for inconspicuous damage to the top and bottom rails as well as the side

structure. Any problems observed in the side structure should be corrected immediately to

prevent the damage from extending further. Unrepaired damage could affect the safe load

carrying capacity of the side structure.

Punched side trailers are built with aluminum side skin. DO NOT use holes to hang heavy

objects on the side. DO NOT use the holes to tie animals. This could damage the side skin.

Failure to follow these procedures may result in unnecessary wear and malfunction. It may also

create difficulties with the mechanical operation of the trailer, and could possibly result in

personal injury and/or property damage.

4-2

BEFORE TRIP INSPECTIONPROCEDURE

GATES

TIRES

Check tires for cuts and abrasions.

Check air pressure before each trip.

Inflate as recommended by tire

manufacture.

Before traveling, be sure that all gates are

locked in either a fully open, or fully closed

position. All roll-

up doors must be closed and

ropes secured.

WHEELS & RIMS

DOOR LOCKS

Check wheel nuts after initial 50 to 100 miles

of service. Refer to the torque requirements

for the correct procedure and specifications if

necessary. Failure to use properly matched

wheels, studs, brakes or cap nuts will result

in equipment damage and could result in

injury or death if wheel comes off.

Insufficient mounting torque can cause wheel

shimmy, resulting in damage to parts and

extreme tire wear. Excessive mounting

torque can cause studs and cap nuts to brake

and discs to crack in stud hole area.

Check all gate locks, access door locks, side

door locks and rear door locks before each

trip to insure that they are in proper working

order. Any door, gate locks or keepers

which show excessive wear should be

replaced immediately. Care should be taken

to keep the area around the do

or frame clear

of any debris or animal waste. A build-

up of

animal waste may result in

more pressure being applied to locks than

they were designed to withstand.

4-3

OPERATING INSTRUCTIONS

OPERATION OF BRAKES

Your trailer brakes are designed to work together with

your towing vehicle brakes to stop the combined load.

When one does the stopping for both, the overload

causes heat build-

up which can result in brake wear, a

direct loss of braking power and increased brake

lining wear.

Jack-knifing can occur if the tow vehicle brakes

are used alone, allowing the trailer to push the

vehicle. This can result in equipment damage and

personal injury.

Complete details for making adjustments on or replacement within your braking system can be

found in the brake manufacturer’s supplement provided with this manual.

Proper synchronization of tow vehicle to trailer braking can only be accomplished by road

testing. Follow the instructions found in the manufacturer’s supplement for correct

synchronization procedures.

OPERATION OF COUPLER

The coupler installed on your trailer is of steel pipe design,

adjustable in height to meet different vehicle hitch heights. The

coupler should be adjusted so that your trailer is level when

towed, not nose up or nose down. To adjust the coupler, back

towing vehicle under the coupler. Level your trailer using the

trailer landing gear, then loosen the two coupler set screws and

lower the inner unit over the tow vehicle hitch ball. Tighten the

coupler set screws to 65-70 foot pounds of torque. The coupler

is now set to the correct height for your vehicle.

Be certain that coupler lock handle is completely engaged

before towing the trailer.

5-1

OPERATING INSTRUCTIONS

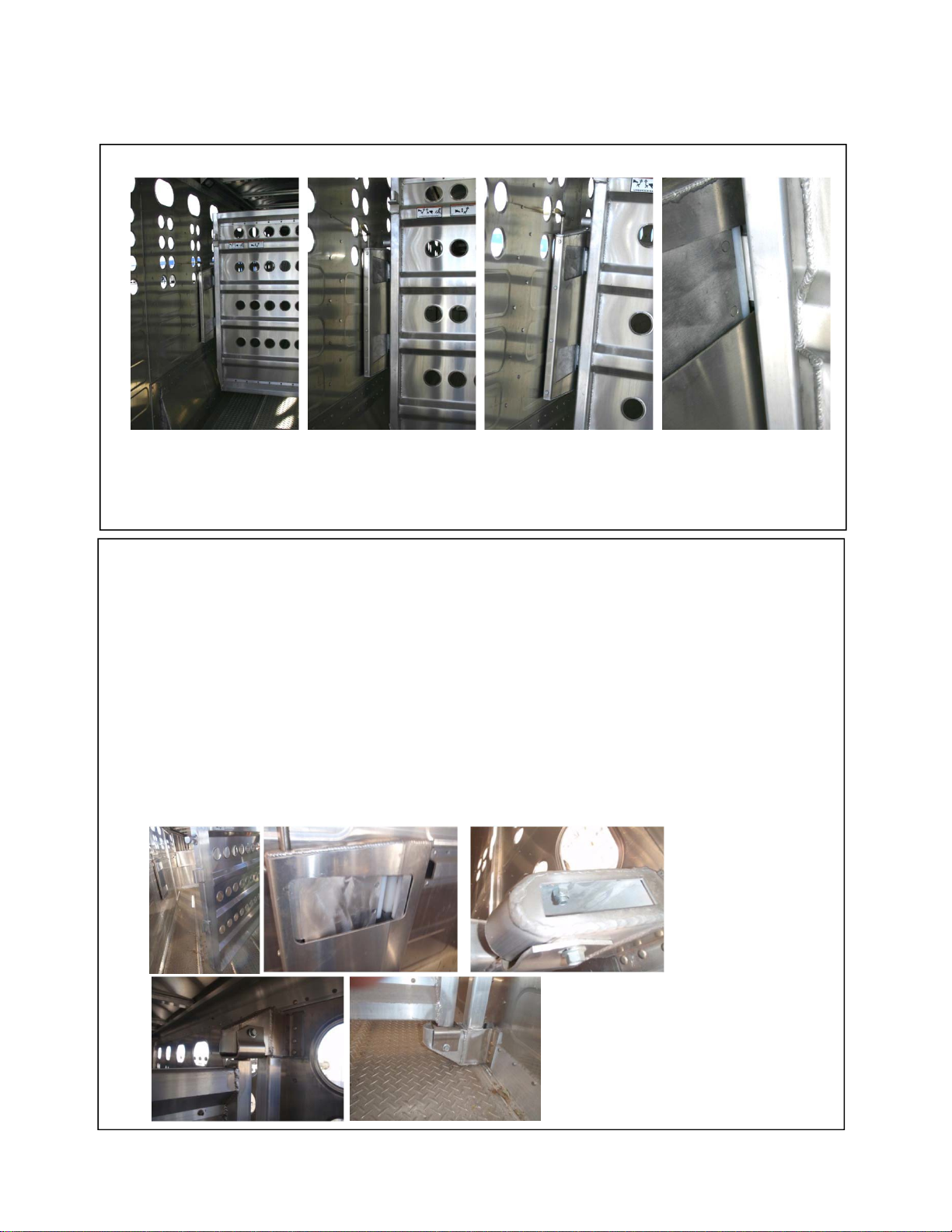

OPERATION OF GATES

Divide gate is provided with a slam lock. Be sure that slam lock is completely engaged before

towing the trailer.

To prevent personal injury, stand clear of swinging gate until slam lock is engaged

ADJUSTMENT OF GATES

Adjustment of gate to slam lock: If your gates need to be adjusted,

1)

Locate the slam lock and gate. Latch on the gate (fig 1) must line up in the center of

catch on the slam lock (fig 2).

Decide if top latch or bottom latch is out of adjustment. Loosen up the bolts on the hinges

(fig 3, 4, 5) and tilt gate to the right to adjust the bottom latch or to the left to adjust the

top. What you are trying to accomplish is to center the latch on the gate (fig 1) to the

center of the catch (fig 2).

Once the gate is back in alignment tighten up the top and bottom bolts (fig 3, 4, 5) and

try the gate. If you need to do some fine tuning on the gate just follow the instructions

2)

3)

FIG 3

FIG 2

FIG 1

FIG 5

FIG 4

5-2

GENERALMAINTENANCE

FASTENERS

FLOOR

Your Merritt Gooseneck trailer is constructed

with aluminum tread plate floors to reduce

slipping. Never use sand or abrasive materials

for animal bedding as this will cause excessive

floor wear. The most important part of floor

maintenance is cleaning.

Floors, deck rails, coupler assemblies,

and tandem sub-

assemblies are attached

to the trailer with zinc plated and

stainless steel fasteners.

Inspect monthly that all zinc plated

fasteners are in place. If any are

missing or loose, they should be

replaced immediately.

WHEEL BEARINGS

GATE AND RAMP HINGES

Wheel bearings and cups should be inspected for

corrosion or wear every 12 months or 12,000

miles. Bearing adjustment and proper lubrication

is essential to the function and reliability of your

trailer axles. Please refer to the Dexter Axle

“Operations Maintenance Service Manual” for

the proper lubricant specifications.

When new bearings are needed, they must

always be replaced in sets of a cone and a

cup.

Gate, door and ramp hinges are provided

with grease fittings. They should be

lubricated on a regular basis in order to

avoid unnecessary wear.

6-1

GENERALMAINTENANCE

GREASE SEALS

GENERAL MAINTENANCE

7,000 lb, 8,000 lb,. Torflex axles are

standard with E_Z lube spindles. This

feature allows the bearings to

periodically lube without removing hubs

from axle. Please refer to the Dexter Axle

“Operation Maintenance Service

Manual” for additional details.

The 7,000 lb, 8,000 lb. Torflex axles and

wheel bearings must be manually

lubricated. The bearings and cups should

be inspected and/or lubricated every 12

months or 12,000 miles. Please refer to

the Dexter Axle “Operation Maintenance

Service Manual” for additional details.

The 10K Torflex axles are equipped with

oil lubricated hubs, periodically check

and refill the hub as necessary with a

high quality hypoid gear oil to the level

indicated on the clear plastic oil cap. The

oiled can be filled from either the oil fill

hole, if present in the hub or through the

rubber plug hole in the cap itself. The

bearing and cups should be inspected

every 12 months or 12,000 Miles

`

6-2

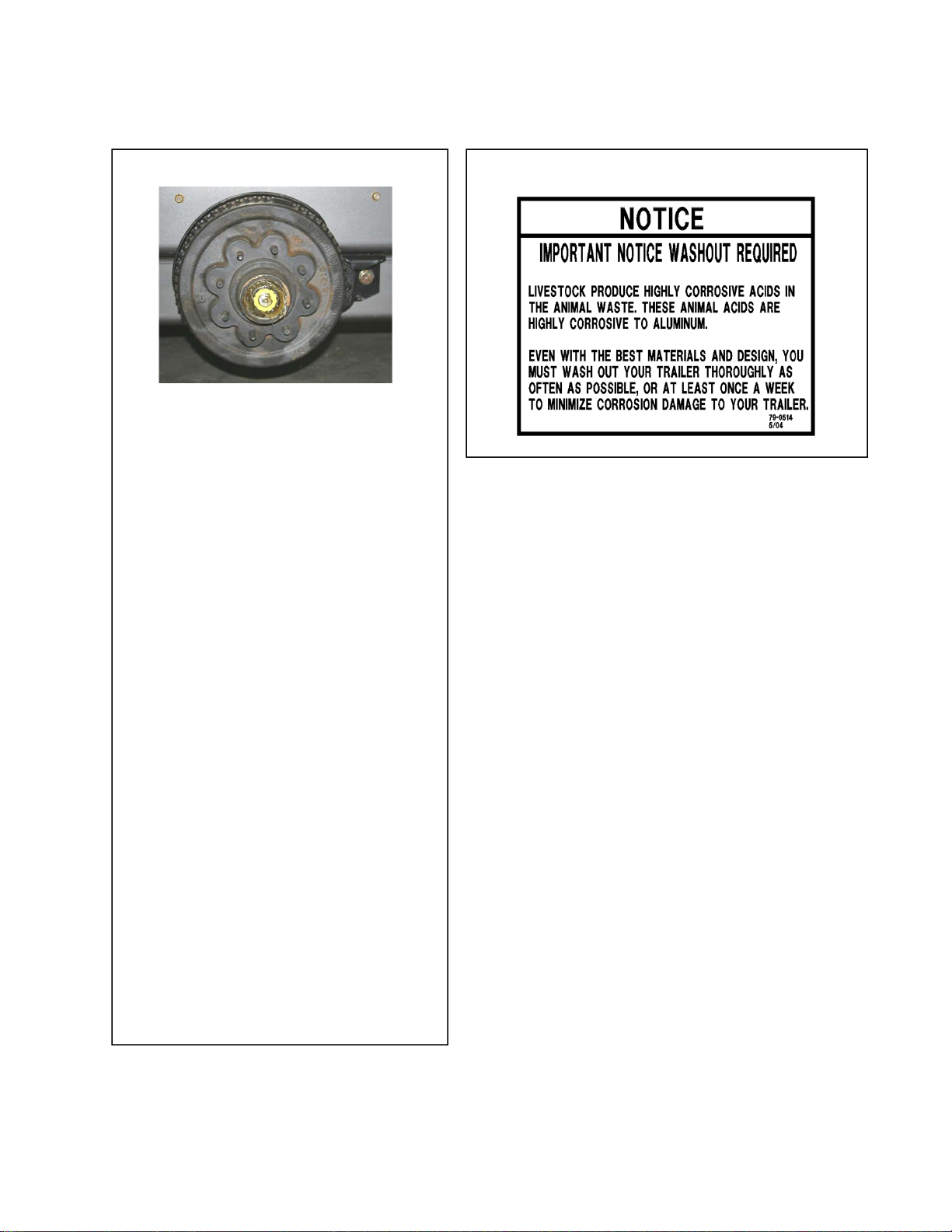

BRAKES

BRAKES

See Notice: Brakes Adjustment (Page 7-2). Adjust your trailer brakes after the first 200 miles and

then after every 3,000 miles or 3 months of use. The brake drum should be inspected every 12

months or 12,000 miles. Inspect the drum surface for excessive wear or heavy scoring. If worn

more than .020”, oversized drums should be turned. The maximum re-bore should not exceed

.090”

On trailers with electric brakes, also inspect the inner surface of the brake drum that contacts the

brake magnet. If the surface is scored or worn unevenly, it should be refaced by removing not

more than .030” of material.

Check the brake magnet for wear and current draw every 6 months or 6,000 miles.

It is important that the wheel bearing bores are not contaminated by metallic chips

resulting from drum turning or re-facing. Make certain that wheel bearing cavities are

clean before reinstalling bearings seals. The presence of contaminants will cause premature

wheel bearing failure.

7-1

BRAKES

BRAKES ADJUSTMENT*

Brakes need to be adjusted (1) after the first 200 miles of

operation when the brake shoes have “seated”, (2) at 3,000

miles intervals, (3) or as use and performance requires. The

brakes should be adjusted in the following manner:

1.

Jack up trailer and secure on adequate jack stands. Check

that the wheel and drum rotate freely.

2.

Remove the adjusting hol

e cover from the adjusting slot on

the bottom of the backing plate

3.

With a screwdriver or standard adjusting tool, rotate the

star wheel of the adjuster assembly to expand the brake

drums. Adjust the brake shoe out until the pressure of the

linings against the drum make the wheel difficult to turn.

4.

Then rotate the star wheel in the opposite direction until

the wheel turns freely with a lining drag.

5.

Replace the adjusting hole cover and lower the wheel to

the ground.

6.

Repeat the above procedure on all brakes.

* This section applicable to trailers equipped with Dexter

Axles. Taken from the Dexter Axle Service Manual.

Adjusting Hole Cover

7-2

NOTICE

GOOSENECK TRAILER BRAKES

•7,000 lb axles may have manually adjusted brakes

•

Manual adjusting brakes require proper maintenance to prevent problemsfrom

developing. `

•

Effective 2018 model year all 7,000, 8,000, 10,000 lb axles have automatic forward

adjusting brakes.

•

The automatic forward adjusting brakes still require periodic inspection and

adjustment asnecessary.

WHEELS ANDTIRES

8-1

WHEELS

Wheels are a critical component of your

running gear system. When replacing the

trailer wheels it is critical to match the

capacity rating and to ensure that they are

equal or greater than the original

equipment supplied by the manufacture.

Do not attempt to repair or modify a

wheel. Even minor modifications can

have great effect. Do not install a tube

to correct a leak through the rim. If the

rim is cracked, the air pressure in the

tube may cause the pieces of the rim to

explode with great force and can cause

serious injury or death.

TORQUE REQUIREMENTS

It is extremely important to apply and

maintain proper wheel mounting torque to

your trailer axle. Torque is a measure of the

amount of tightening applied to a fastener

(nut or bolt) and is expressed as length X

force. A force of 90 pounds applied at the

end of a wrench one foot long will yield 90

foot pounds of torque. Torque wrenches are

the best method to assure that the proper

amount of torque is being applied to a

fastener.

Be sure to use only the fasteners matched to

the cone angle of your wheel (usually 60 or

90 degrees)

The proper procedure for attaching your

TORQUE wheels is as follow:

SEQUENCE 8 BOLT 1. Start all bolts or nuts by hand to prevent

cross threading.

Wheel Nut Torque Guide 2. Tighten bolts or nuts in the sequence

Nut size torque (ft. lbs.) detailed below.

1/2”-20 (Cone) 90-120 3. The tightening of the fasteners should be

9/16”-18 (Cone) 90-120 Steel done in stages. Following the recommended

9/16”-18 (Cone) 120-140 aluminum sequence, first tighten all the fasteners to 20-

5/8”-18 (Cone) (note #1) 190-210 25 ft. lb., and finally to the required torque

5/8”-18 (Flanged nut) 275-325 (One-Piece) based on the size of the wheel nut (see chart).

5/8”-18 (Flanged nut) (note #2) 140-160 (two Piece) 4. Wheel nut/bolts should be torqued before

Note #1 This is when nut is used in conjunction with the first road use and after each wheel

the reinforcing ring. removal. Check and re-torque after the

Note #2 This two piece flange nut is used on the

Alco Aluminum Dual wheel application.

WHEELS ANDTIRES

8-2

Trailers Over 10,000 Pounds GVWR

NOTE: These trailers are not required to have a tire information placard on the vehicle.

Determine the empty weight of your trailer by weighing the trailer using a public scale or other means. This step

does not have to be repeated.

Locate the GVWR (Gross Vehicle Weight Rating) of the trailer on your trailer's federal VIN Tag.

Subtract the empty weight of your trailer from the GVWR stated on the VIN label. That weight is the maximum

available cargo capacity of the trailer and may not be safely exceeded.

TIRE SAFETY

Everything Rides On It

The National Traffic Safety Administration (NHTSA) has published a brochure (DOT HS 809 361) that discusses all

aspects of Tire Safety, as required by CFR 575.6. This brochure is reproduced in part below. It can be obtained and

downloaded from NHTSA, free of charge, from the following web site:

www.nhtsa.dot.gov/cars/rules/TireSafety/ridesonit/tires_index.html

Studies of tire safety show that maintaining proper tire pressure, observing tire and vehicle load limits (not carrying

more weight in your vehicle than your tires or vehicle can safely handle), avoiding road hazards, and inspecting tires

for cuts, slashes, and other irregularities are the most important things you can do to avoid tire failure, such as tread

separation or blowout and flat tires. These actions, along with other care and maintenance activities, can also:

Improve vehicle handling, Help protect you and others from avoidable breakdowns and accidents, Improve fuel

economy, Increase the life of your tires.

This information presents a comprehensive overview of tire safety, including information on the following topics:

Basic tire maintenance, Uniform Tire Quality Grading System, Fundamental characteristics of tires, Tire safety tips.

Use this information to make tire safety a regular part of your vehicle maintenance routine. Recognize that the time

you spend is minimal compared with the inconvenience and safety consequences of a flat tire or other tire failure.

Safety First–Basic Tire Maintenance

Properly maintained tires improve the steering, stopping, traction, and load-carrying capability of your vehicle.

Underinflated tires and overloaded vehicles are a major cause of tire failure. Therefore, as mentioned above, to avoid

flat tires and other types of tire failure, you should maintain proper tire pressure, observe tire and vehicle load limits,

avoid road hazards, and regularly inspect your tires.

Finding Your Vehicle's Recommended Tire Pressure and Load Limits

Tire information and vehicle certification labels contain information on tires and load limits. These labels indicate

the vehicle manufacturer's information including: Recommended tire size, Recommended tire inflation pressure,

Vehicle capacity weight (VCW–the maximum occupant and cargo weight a vehicle is designed to carry), Front and

rear gross axle weight ratings (GAWR– the maximum weight the axle systems are designed to carry).Federal tag is

permanently attached to the vehicle near the front left side.

Understanding Tire Pressure and Load Limits

Tire inflation pressure is the level of air in the tire that provides it with load-carrying capacity and affects the overall

performance of the vehicle. The tire inflation pressure is a number that indicates the amount of air pressure

WHEELS ANDTIRES

8-3

measured in pounds per square inch (psi)–a tire requires to be properly inflated. (You will also find this number on

the vehicle information placard expressed in kilopascals (kPa), which is the metric measure used internationally.)

Manufacturers of passenger vehicles and light trucks determine this number based on the vehicle's design load limit,

that is, the greatest amount of weight a vehicle can safely carry and the vehicle's tire size. The proper tire pressure for

your vehicle is referred to as the "recommended cold inflation pressure." (As you will read below, it is difficult to

obtain the recommended tire pressure if your tires are not cold.)

Because tires are designed to be used on more than one type of vehicle, tire manufacturers list the "maximum

permissible inflation pressure" on the tire sidewall. This number is the greatest amount of air pressure that should

ever be put in the tire under normal driving conditions.

Checking Tire Pressure

It is important to check your vehicle's tire pressure at least once a month for the following reasons:

Most tires may naturally lose air over time.

Tires can lose air suddenly if you drive over a pothole or other object or if you strike the curb when parking.

With radial tires, it is usually not possible to determine under inflation by visual inspection.

For convenience, purchase a tire pressure gauge to keep in your vehicle. Gauges can be purchased at tire dealerships,

auto supply stores, and other retail outlets.

The recommended tire inflation pressure that vehicle manufacturers provide reflects the proper psi when a tire is

cold. The term cold does not relate to the outside temperature. Rather, a cold tire is one that has not been driven on

for at least three hours. When you drive, your tires get warmer, causing the air pressure within them to increase.

Therefore, to get an accurate tire pressure reading, you must measure tire pressure when the tires are cold or

compensate for the extra pressure in warm tires.

Steps for Maintaining Proper Tire Pressure

Step 1: Locate the recommended tire pressure on the vehicle's tire information placard, certification label, or in the

owner's manual.

Step 2: Record the tire pressure of all tires.

Step 3: If the tire pressure is too high in any of the tires, slowly release air by gently pressing on the tire valve stem

with the edge of your tire gauge until you get to the correct pressure.

Step 4: If the tire pressure is too low, note the difference between the measured tire pressure and the correct tire

pressure. These "missing" pounds of pressure are what you will need to add.

Step 5: At a service station, add the missing pounds of air pressure to each tire that is underinflated.

Step 6: Check all the tires to make sure they have the same air pressure (except in cases in which the front and rear

tires are supposed to have different amounts of pressure).

If you have been driving your vehicle and think that a tire is underinflated, fill it to the recommended cold inflation

pressure indicated on your vehicle's tire information placard or certification label. While your tire may still be

slightly underinflated due to the extra pounds of pressure in the warm tire, it is safer to drive with air pressure that is

slightly lower than the vehicle manufacturer's recommended cold inflation pressure than to drive with a significantly

underinflated tire. Since this is a temporary fix, don't forget to recheck and adjust the tire's pressure when you can

obtain a cold reading.

WHEELS ANDTIRES

8-4

Tire Size

To maintain tire safety, purchase new tires that are the same size as the vehicle's original tires or another size

recommended by the manufacturer. Look at the tire information placard, the owner's manual, or the sidewall of the

tire you are replacing to find this information. If you have any doubt about the correct size to choose, consult with

the tire dealer.

Tire Tread

The tire tread provides the gripping action and traction that prevent your vehicle from slipping or sliding, especially

when the road is wet or icy. In general, tires are not safe and should be replaced when the tread is worn down to 1/16

of an inch. Tires have built-in tread wear indicators that let you know when it is time to replace your tires. These

indicators are raised sections spaced intermittently in the bottom of the tread grooves. When they appear "even" with

the outside of the tread, it is time to replace your tires. Another method for checking tread depth is to place a penny

in the tread with Lincoln's head upside down and facing you. If you can see the top of Lincoln's head, you are ready

for new tires.

Wheel Alignment

A wheel alignment adjusts the angles of the wheels so that they are positioned correctly relative to the vehicle's

frame. This adjustment maximizes the life of your tires and prevents your car from veering to the right or left when

driving on a straight, level road. These adjustments require special equipment and should be performed by a qualified

technician.

Tire Repair

The proper repair of a punctured tire requires a plug for the hole and a patch for the area inside the tire that surrounds

the puncture hole. Punctures through the tread can be repaired if they are not too large, but punctures to the sidewall

should not be repaired. Tires must be removed from the rim to be properly inspected before being plugged and

patched.

Tire Fundamentals

Federal law requires tire manufacturers to place standardized information on the sidewall of all tires. This

information identifies and describes the fundamental characteristics of the tire and also provides a tire identification

number for safety standard certification and in case of a recall.

Information on Passenger Vehicle Tires

P

The "P" indicates the tire is for passenger vehicles.

Next number

This three-digit number gives the width in millimeters of the tire from sidewall edge to sidewall edge. In general, the

larger the number, the wider the tire.

Next number

This two-digit number, known as the aspect ratio, gives the tire's ratio of height to width. Numbers of 70 or lower

indicate a short sidewall for improved steering response and better overall handling on dry pavement.

R

The "R" stands for radial. Radial ply construction of tires has been the industry standard for the past 20 years.

WHEELS ANDTIRES

8-5

Next number

This two‐digit number is the wheel or rim diameter in inches. If you change your wheel size, you will have to purchase

new tires to match the new wheel diameter.

Next number

This two‐ or three‐digit number is the tire's load index. It is a measurement of how much weight each tire can

support. You may find this information in your owner's manual. If not, contact a local tire dealer. Note: You may not

find this information on all tires because it is not required by law.

M+S

The "M+S" or "M/S" indicates that the tire has some mud

and snow capability. Most radial tires have these

markings; hence, they have some mud and snow

capability.

Speed Rating

The speed rating denotes the speed at which a tire is

designed to be driven for extended periods of time. The

ratings range from 99 miles per hour (mph) to 186 mph.

These ratings are listed below. Note: You may not find this

information on all tires because it is not required by law.

• For tires with a maximum speed

capability over 149 mph, tire

manufacturers sometimes use the

letters ZR. For those with a maximum

speed capability over 186 mph, tire

manufacturers always use the letters

ZR.

U.S. DOT Tire Identification Number

This begins with the letters "DOT" and

indicates that the tire meets all federal

standards. The next two numbers or letters

are the plant code where it was

manufactured, and the last four numbers

represent the week and year the tire was

built. For example, the numbers 3197 means

the 31st week of 1997. The other numbers are

marketing codes used at the manufacturer's

discretion. This information is used to contact

consumers if a tire defect requires a recall.

Tire Ply Composition and Materials Used

The number of plies indicates the number of layers of rubber-coated fabric in the tire. In general, the greater the number of

plies, the more weight a tire can support. Tire manufacturers also must indicate the materials in the tire, which include steel,

nylon, polyester, and others.

Maximum Load Rating

This number indicates the maximum load in kilograms and pounds that can be carried by the tire.

Letter Rating

Speed Rating

Q

99 mph

R

106 mph

S

112 mph

T

118 mph

U

124 mph

H

130 mph

V

149 mph

W

168* mph

Y

186* mph

Table of contents