Tipping Trailer

2

Contents

1 Introduction ...................................................................................................................................................................................2

1.1 Note well..............................................................................................................................................................................2

2 Operational safety ..........................................................................................................................................................................3

2.1 Safety regulations .................................................................................................................................................................3

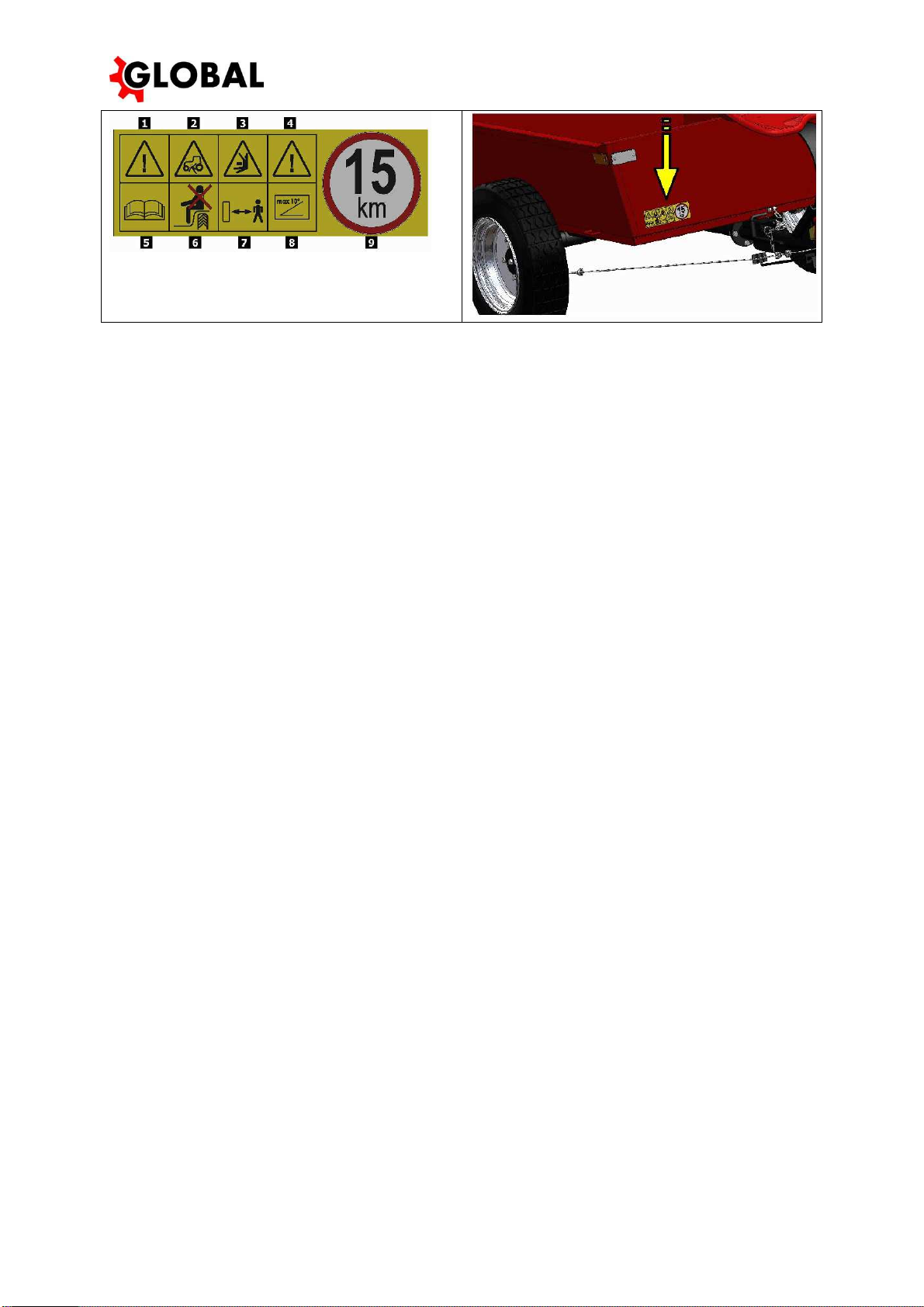

2.2 Safety labels .........................................................................................................................................................................4

3 Basic information............................................................................................................................................................................ 4

3.1 Use of t e device ..................................................................................................................................................................4

3.1.1 Tec nical data .............................................................................................................................................................4

3.2 Description of t e device and its parts.....................................................................................................................................4

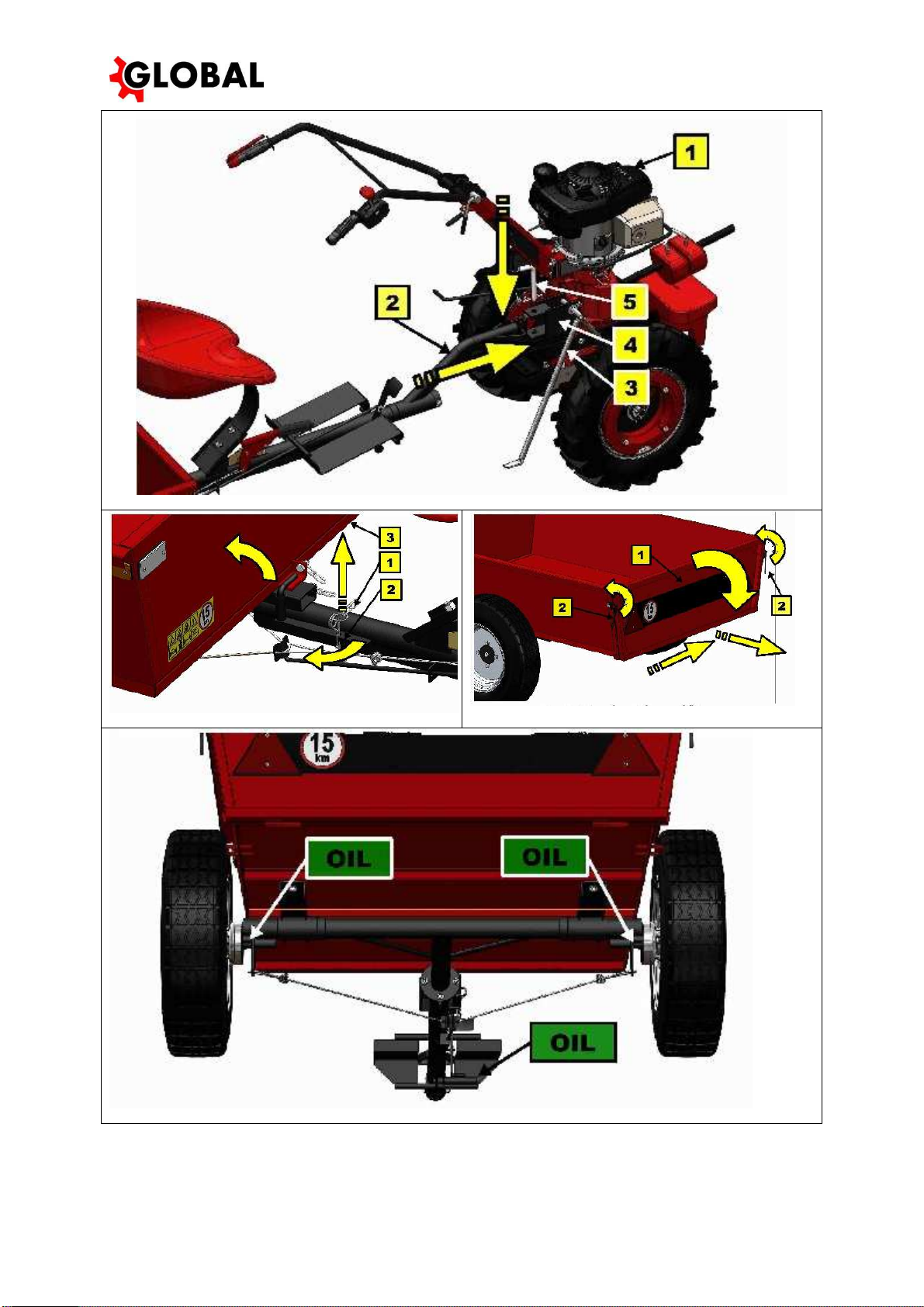

4 Operating instructions .....................................................................................................................................................................4

4.1 Device assembly ...................................................................................................................................................................4

4.1.1 Device assembly procedure...........................................................................................................................................4

4.2 Working wit t e device.........................................................................................................................................................5

4.2.1 Connection to t e small tractor......................................................................................................................................5

4.2.2 Before driving .............................................................................................................................................................5

4.2.3 Driving........................................................................................................................................................................5

4.2.4 Tilting t e body and t e rear end ..................................................................................................................................6

5 Maintenance, care, storing...............................................................................................................................................................6

5.1 Lubrication of t e device ........................................................................................................................................................6

5.1.1 Lubrication points ........................................................................................................................................................6

5.1.2 Brake adjustment.........................................................................................................................................................6

5.1.3 Tyres..........................................................................................................................................................................6

5.2 Storing.................................................................................................................................................................................7

5.2.1 Was ing and cleaning t e device................................................................................................................................... 7

5.3 Disposal of packaging and t e device at t e end of its service life ..............................................................................................7

5.4 How to order spare parts .......................................................................................................................................................7

6 Address of t e Supplier ...................................................................................................................................................................7

7 Attac ed illustrations.......................................................................................................................................................................8

T e manufacturer reserves t e rig t to implement tec nical c anges and innovations not affecting t e operability and

safety of t e device. T ese c anges may not s ow in t ese Operating Instructions. Typograp ical errors reserved.

1 Introduction

Dear Customer/User!

T ank you for your confidence in purc asing our product. You ave become an owner of a device from t e wide range of

mac inery and tools of t e gardening, farming, small scale agricultural and municipal tec nology system supplieded by

KNIGHTS a.s.

Please read t ese Operating Instructions carefully. If you follow t e instructions contained erein, our product will serve

you reliably for many years.

1.1 Note well

T e user must read through t ese Operating Instructions and follow all device operating instructions in order to prevent

any ealt risks or property damage to t e user or ot er persons.

Safety instructions stated in t is manual do not cover all possible conditions and situations w ic may occur in practice.

Safety factors suc as a reasonable approac , care and caution are not included in t is manual but it is assumed t at eac

person using t e device or doing any maintenance work on it is sufficiently endowed wit t ese.

Only mentally and p ysically fit persons may use t is device. S ould t is device be used commercially, t e owner of t e

device is bound to provide t e operators wit work safety training and instruct t em in operation of t e device and keep

records of suc training. The ow er must also impleme t the so-called categorizatio of work accordi g to

respective atio al legislatio .

If any piece of information contained in t e manual is unclear to you, please contact your dealer or directly t e device

supplier.

Operating instructions provided wit t is device form an integral part of it. T ey must be available at all times, stored at an

accessible place w ere t ey cannot get destroyed. In t e case t e device is sold to anot er person, t e operating instructions

must be anded over to t e new owner. T e manufacturer bears no responsibility for t e risks, azards, accidents or injuries

resulting from operation of t e device, if t e above-mentioned conditions ave not been met.

T e manufacturer bears no responsibility for t e damage caused by unaut orized use, inappropriate operation and for any

damage caused by any modification of t e device wit out t e manufacturer’s approval.

During work it is necessary to follow safety regulations to avoid any injury to yourself or ot er persons present nearby and

to avoid any property damage.

T ese instructions are marked in t e manual by t e following warning symbol:

If you see this symbol i the ma ual, carefully read the stateme t followi g after it!

This i ter atio al safety symbol i dicates importa t i structio s co cer i g safety. If you see this symbol, be

aware that there is a risk of i jury to you or other perso s a d carefully read the stateme t followi g after it.

Table 1 : Symbols