Merrylock 2020 User manual

INSTRUCTION BOOK

INSTRUCTION BOOK

INSTRUCTION BOOK

Thank you for your purchase of this Overlock Sewing Machine. This machine, that is intended

for household use will provide you with excellent performance in sewing from light to heavy

material (lawn to denim).

Please refer to this Instruction Book for proper use and optimum service. To get the most out

of your sewing machine, read the entire Instruction Book before attempting to operate the

machine. Then familiarize yourself with the machine by following the Instruction Book page

by page.

To ensure that you are always provided with the most modern sewing capabilities, the

manufacturer reserves the right to change the appearance, design or accessories of this

sewing machine when considered necessary without notification or obligation.

1

PREFACE

When using this machine, basic safety precautions should always be followed including the following.

Read all instructions before using the machine.

* The machine should never be left unattended when plugged in. Always unplug the machine from the

electric outlet immediately after using and before cleaning.

* Always unplug before re-lamping. Replace bulb with the same type rated 15 watts. Be sure to replace the

face plate which covers the light bulb before operating the machine.

* Be sure that the electrical voltage of the electric outlet (wall receptacle) is the same as the rated voltage of

the motor.

* Use this machine only for its intended use as described in this Instruction Book. Use only attachments

recommended by the manufacturer as contained in the Instruction Book.

* To disconnect, turn all controls to the off ("0") position, then remove plug from outlet.

* Disconnect the power line plug from the socket outlet or switch the machine off when making any adjustments

in the needle area, such as threading needle and loopers, changing needle, changing throat plate or changing

presser foot, etc.

* Always unplug the machine from the electrical outlet when removing covers, lubricating, or when making

any other user servicing adjustments mentioned in the Instruction Book.

* Do not attempt to adjust the motor belt. Contact your nearest Service Center should any adjustment be

required.

* Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything on top

of the controller.

* Always use the proper throat plate. The wrong plate can cause the needle to break.

* Do not use bent needles.

* When sewing, keep fingers away from all moving parts. Special care is required around the sewing machine

needle.

* Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

* For double insulated machines, when servicing, use only identical replacement parts. See instructions for

Servicing of Double-Insulated Appliances.

* Never operate the machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into the water. Return the machine to the nearest authorized dealer or

Service Center for examination, repair, electrical, or mechanical adjustment.

* Never operate the machine with any air openings blocked. Keep ventilation openings of the machine and

foot controller free from the accumulation of lint, dust and loose cloth.

* Never drop or insert any object into any opening.

2

DANGER -To reduce the risk of electric shock:

WARNING -To reduce the risk of burns, fire, electric shock or injury to persons:

IMPORTANT SAFETY INSTRUCTIONS

* Do not use outdoors.

* Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

* Do not allow to be used as a toy. Close attention is necessary when the machine is used by or near

children.

* Do not expose the machine or machine plastic case to sunlight directly. Also, do not keep it in a very warm

or damp place.

* Do not touch the machine, foot controller and power line cord with wet hand, wet cloth or with anything wet.

* Do not connect power line cord to one of the many cords connected to one power outlet with adapters.

* Use machine on flat and stable table.

* Be sure to close the looper cover before operating the machine.

* Keep presser foot and needles away from children's reach.

* Be sure the light bulb has cooled off before changing with a new one.

* Do not dismantle or modify the machine yourself.

* Be sure to turn off the power switch and disconnect the power line plug before caring for your machine as

instructed in the Instruction Book.

* SERVICING OF DOUBLE-INSULATED PRODUCTS. In a double-insulated product, two systems of

insulation is provided instead of grounding. No grounding means is provided on a double-insulated product,

nor should a means for grounding be added to the product. Servicing of a double-insulated product requires,

extreme care and knowledge of the system, and should be done only by qualified service personnel,

Replacement parts for a double-insulated product must be identical to those parts in the product. A double-

Insulated product is marked with the word "DOUBLE-INSULATION" or "DOUBLE-INSULATED".

3

1. .........................................................Principal Parts.

2. ...........................................Accessories...................

3. ..................................................Needle Information.

4. .....................................How to Open Looper Cover

5. ......................Principal Parts Behind Looper Cover.

6. .....................................Preparation prior to sewing.

7. ...........Removal and Replacement of Clean Pocket

8. Preparation prior to sewing......................................

1 . How to Remove and Insert Needles........................

2

*Needle position.........................................................

*To remove needle(s).................................................

*To insert needle(s)....................................................

1 . Threading the Machine...........................................

3

*Threading diagram...................................................

*Understanding the color code..................................

*To thread the machine correctly................................

1) Threading the upper looper (Green)...................

2) Threading the lower looper (Red).......................

4) Threading the overedge left needle (Orange).....

21. .........................Handy Reference Chart..............

22. Suggested Tension Setting..................................

4

Page Page

30

31

31

5

7

7

8

8

8

9

10

10

10

10

11

12

12

12

13

13

13

14

14

16

17

19

20

*Setting up the thread guide holder............................

*Anti-spill net..............................................................

*Spool cap..................................................................

9. How to Disengage Movable Upper Knife................

1 . To Convert upper Looper to 2-thread converter.....

0

*To use the ..................................2-thread converter

*To disengage to upper looper...................................

11. Standard overedge and Rolled Hem Stitching........

*To sew standard overedge........................................

*To sew rolled hem.....................................................

14

14

15

15

15

16

23. How to Sew a Rolled hem...................................

1) 3-thread standard rolled hem stitching..............

2) 3-thread upper looper thread wrapped

rolled hem stitching...........................................

3) 2-thread standard rolled hem stitching..............

4) 2-thread lower looper thread wrapped

rolled hem stitching...........................................

24. Stitch Variations and Sewing Techniques...........

*Decorative Flatlocking...........................................

*How to sew an overlock blind hem........................

*How to sew a pin tucks.........................................

*Turning square corners.........................................

*Pin placement.......................................................

*Securing the thread chain.....................................

25. Machine Maintenance.........................................

*Cleaning the machine...........................................

*Oiling the machine................................................

*How to replace the stationary knife.......................

*How to exchange light bulb...................................

26.Optional Accessories............................................

*Snap-on type presser foot.....................................

*Optional presser feet.............................................

1) Elastic foot........................................................

2) Blind hem foot..................................................

3) Shirring foot......................................................

4) Pearl/Sequin foot..............................................

5) Piping/Cording foot...........................................

6) Taping foot.......................................................

27. Troubleshooting Chart.........................................

28. Relationship between Cloth, Thread and Need...

29. Specification........................................................

37

38

38

39

39

41

42

43

43

44

45

45

46

46

46

47

48

49

49

50

50

50

50

50

50

50

51

52

53

1) 2-Thread Wrapped Edge Overlock....................

2) 2-Thread Overedge...........................................

3) 3-Thread Overlock............................................

4) 3-Thread Flatlock...............................................

5) 3-Thread Ultra Stretch Mock Safety Stitch........

6) 4-thread Ultra Stretch Mock Safely Stitch.........

32

33

34

35

36

1 . How to Change Threads / Tie on Method...............

4

1 . How to Adjust the Stitch length...............................5

1 . How to Adjust the Seam width................................6

*Width adjustment by changing needle position........

*Width adjustment with adjustment knob...................

1 . How to Adjust the Presser Foot Pressure...............

7

1 . Differential Feed......................................................8

*Gathered overedge...................................................

22

23

23

23

23

24

25

25

26

27

28

*Stretch overedge......................................................

19 .... Chaining Off and Test Sewing.............................

. Selection stitches....................................................

20

) Threading the overedge right needle (Blue)........3

TABLE OF CONTENTS

16

2

1

3456

7

8

10

9

11

12

13

14

15

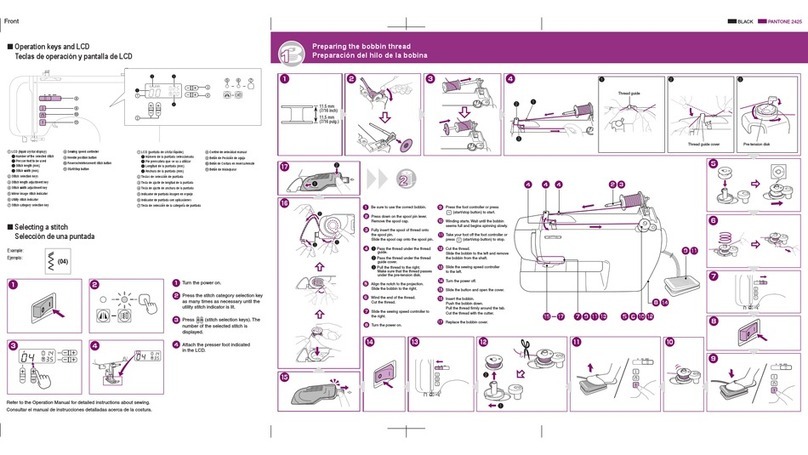

1. Thread guides and holder

2. Handle

3. Left needle thread tension dial (orange)

4. Right needle thread tension dial (blue)

5. Upper looper thread tension dial (green)

6. Lower looper thread tension dial (red)

7. Spool pin

8. Throat plate

9. Cloth plate

10. Looper cover

11. Power & light switch

12. Stitch length dial

13. Hand wheel

14. Spool stand

15. Spool holder

16. Clean pocket

5

1. PRINCIPAL PARTS

17. Presser bar lifter and tension release

18. Differential feed adjusting dial

19. Cutting width dial

20. Foot pressure adjusting dial

20

17

18

19

6

12345

6789

10

11

12

13

Accessories are contained in the accessory case

1. Screw driver (large size)

2. Knife (stationary)

3. Thread Unwinder spool cap

4. Anti-spill net

5. Oiler

6. Allen Screw driver (small)

7. Tweezers

8. Needle set

9. Brush

10. Spool holder

11. Clean pocket

12. Machine cover

This overlock uses a flat shank industrial needle

that eliminates the possibility of inserting the needle

backwards.

Do not attempt to use a standard household sewing

machine needle of any size or type in this overlock.

7

1

1

4

1

1

1

1

1

1

1

1

HAx1 (130/705H)

Overlock needle

4

1.

3 2-thread converter (option) 1

2. ACCESSORIES

3. NEEDLE INFORMATION

ON

OFF

2

1

2

4

3

6

1

5

Caution:

Be sure to turn off power switch.

1 Push the cover to the right as far as it will go.

2 Pull cover down toward you.

8

Caution:

Be sure looper cover is closed when

sewing.

1. Upper looper

2. Moveable Upper knife

3. Presser foot

4. Fixed position lower knife

5. Lower looper

6. Rolled Hem lever

Use only foot controller provided with this machine.

(Type 4C-316B for U.S.A. & CANADA only)

Be sure to make reference to "Warning" on following

Page.

Connect the controller/electric plug to the machine

receptacle.

Plug power line into electric outlet.

Power Switch: Push"l"mark side to turn "ON"

To run the machine and control the speed, press

the controller.

The harder you press, the faster the machine will sew.

To stop the machine from sewing, remove your foot

from the controller.

WARNING:

Push "O" mark side to turn "OFF"

5. PRINCIPAL PARTS BEHIND THE

4. HOW TO OPEN LOOPER COVER

LOOPER COVER

6. PREPARATION PRIOR TO SEWING

1

3

2

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of

electric shock, this plug is intended to fit in a polarized outlet only way. If the plug does

not fit fully in the outlet, reverse the plug. If it still does not fit contact a qualified electrician

to install the proper outlet. Do not modify the plug in any way.

9

Warning:

Insert the clean pocket under the looper cover.

Be sure the left side of clean pocket is mounted near the

cutter where the scraps drop.

* Be sure that the electrical voltage of the electric outlet (wall receptacle) is the same as the rated

voltage of the motor.

* Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything

on top of it when not in use.

* Disconnect the power line plug from the electric outlet when changing needles, presser feet

or when leaving the machine unattended. This eliminates the possibility of starting the machine

by accidentally pressing the controller.

Replacement

To remove, hold the clean pocket as shown and

pull it outward.

Removal

POLARIZED PLUG INFORMATION (FOR U.S.A. & CANADA ONLY)

7. REMOVAL AND REPLACEMENT OF

CLEAN POCKET

Anti-spill net

Spool cap

Thread spool

Press in

10

When using synthetic threads that easily spill off

the cone, slip the anti-spill net furnished with the

machine over the thread from the bottom of the

cone leaving the thread end hanging free at the

top the anti-spill net as shown at right.

Take out the thread guide from the top of

Styrofoam, and insert it as shown on the right

illustration.

This machine is shipped with the thread guide

holder on the top of styrofoam.

Fully extend the thread guide holder.

The two joints on the telescope will click into place

when they are correctly positioned.

Center the thread guides above the spool pins.

Place thread over the cone adapters on the spool

pins.

When using a regular thread spool, fit the spool cap

supplied with the machine onto the thread spool as

shown at right.

Setting Up the Thread Guide Holder

8. PREPARATION FOR THREADING

Anti-spill Net

Spool Cap

2

1

2

1

11

Open looper cover (page 8).

Pull the movable knife holder to the right as far as

it will go.

Turn the holder toward counter clockwise until the

knife clicks into a lock position.

Caution:

Be sure to turn off power switch.

Open looper cover.

Pull the movable knife holder to the right as far as

it will go.

Turn the holder clockwise until the knife clicks into the

working position

Caution:

Always close looper cover before operating

machine.

To place movable knife in working position

To place movable knife in nonworking position

9. HOW TO DISENGAGE MOVABLE

UPPER KNIFE

12

To engage the , insert the sharp part into

the

2-thread converter

eye of upper looper.

When not threading the upper looper, the 2-thread converter

must be engaged into the upper looper eye.

When using the upper looper, the must

be

2-thread converter

disengaged.

Caution:

Be sure to turn off power switch

To disengage the 2-thread converter, raise the handle of

upper looper according to picture .

A raised point located in the trough of 2-thread converter

must be inserted and fixed in the eye of the 2-thread

converter.

1

2

3

1

2

3

3

To Use the 2-thread converter

To Disengage to Upper Looper

10. TO CONVERT UPPER LOOPER TO

2-THREAD CONVERTER

R

N

R

N

13

Set seam width finger knob to N to move seam

width finger to standard overedge sewing position.

Set seam width finger knob to R to retract the seam

width finger and set it for rolled hem.

Note: Be sure to push seam width finger knob as far

as it will go in the direction of setting R.

Note: Be sure to push seam width finger knob as

far as it will go in the direction of setting N.

To Sew Rolled Hem

To Sew Standard Overedge

11. STANDARD OVEREDGE AND ROLLED

HEM STITCHING

Turn the hand wheel toward you until the needles are

at their highest position.

Place a thick piece of fabric [such as felt] under the

presser foot. Lower the needles halfway into the

fabric.

Loosen, but do not remove the needle set screws with

the small allen screwdriver. Hold the needles with

your fingers and raise the needle bar. The needles

will remain in the fabric.

A. Overedge needleleft

B. Overedge needleright

With this machines, two needles can be inserted

to the needle clamp as shown in the drawing but only

one or two needles are to be used for sewing.

The Instruction Book refers to different needle

positions by illustrating the needle clamp at right.

Note: When both the left and right overedge needles

are inserted, the left needle will be slightly

higher than the right.

Caution:

Be sure to disconnect the machine from the

electric outlet before removing needle(s).

Hold the needle with the flat surface to the back.

Insert the needle into the needle socket as far as it

will go.

When inserting a needle, if you first lower it down

into the hole in the throat plate it will line up with the

needle socket. Then direct it upwards

Note: When inserting needles into the A or B sockets

it is necessary to loosen both A & B Allen Screws.

After inserting the needles equally tighten both

Screws.

14

Overedge left needle

Overedge right needle

Left and right

overedge needle

thread

B

To loosen

To tighten

Flat surface to the rear

BA

Right overedge

needle thread

To Insert Needles (s)

12. HOW TO REMOVE AND INSERT

NEEDLES

Needle Position

To Remove Needle (s)

B

A

AB

4312

15

A color coded threading diagram is located inside

the looper cover for quick reference.

Thread the machine in the order 1 to 4 as shown

at right.

Note: Threads go through the take-up lever cover

for Overlock as shown.

1. Upper looper thread............................

2. Lower looper thread............................

3. Left needle thread...............................

4. Right needle thread.............................

Green

Red

Orange

Blue Left needle thread

Right Needle thread

Upper looper thread

Topside

Lower looper thread

Underside

13. THREADING THE MACHINE

Threading Diagram: Overlock and Safety Stitches

Tension Color Code: Overlock and Safety Stitch

To Thread The Machine Correctly

1) Threading the (Green)Upper Looper

16

Caution:

Be sure to turn off power switch.

Thread the top cover

thread guide by pulling

the thread towards the

left until it slips under

guide. Then pull

thread along the right

side of button as

illustrated.

While holding thread with fingers, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3.

Thread the upper looper as indicated 1~9.

Pass thread from back to the front through the

thread guide 1.

Raise Presser foot to release tension discs.

2

4

3

33

2

2

4

7

6

9

8

2

5

3

1

1

2) Threading the (Red)Lower Looper

17

Thread the top cover

thread guide by pulling

the thread towards the

left until it slips under

guide. Then pull thread

along the right side of

button as illustrated.

Thread the lower looper as indicated 1~10.

Thread the looper area of the machine following the

green color coded thread guides (4~9).

Thread the hole in the upper looper from front to

back 9. Note: Make sure thread passes behind lower

looper.

Note: Use tweezers provided in the accessory

case to aid in threading the looper.

Pull about 10cm(4 inches) of thread through the

looper and place to the back of the throat plate.

Pass thread from back to the front through the

thread guide 1.

Raise Presser foot to release Tension discs

10cm

(4")

2

2

9

8

9

5

4

8

6

7

7

9

6

5

8

4

2

3

1

10

1

10cm

(4")

18

Thread the looper eye (A) from front to back.

Pull about 10cm (4 inches) of thread.

Position thread into V cutout (B) on threader.

Firmly hold thread tail with left hand and pull

Threader lever (C) up into place (D).

Turn the hand wheel toward you until the lower

looper extends out 5~10mm from the throat

plate edge.

Thread the looper area of the machine following

the red color coded thread guides 4~10.

Note: Use tweezers provided in the accessory

case to aid in threading the looper.

While holding thread with finger, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3.

Place the thread with the point of the tweezers

slightly from left and to the right of threading guide 4.

Place the thread with the point of the tweezers

slightly from front and to the back of threading guide 5.

4

3

2

10

9

9

D

B

A

10

C

4

5

6

7

8

5

3

4

3

8

6

7

19

Pass thread from back to the front through the

thread guide 1.

While holding thread with finger, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3.

Thread the top cover

thread guide by pulling

the thread towards the

left until it slips under

guide. Then pull thread

along the right side of

button as illustrated.

Thread the right needle as indicated 1~9.

Raise Presser foot to release Tension discs.

4

3

2

3

2

7

5

6

3

2

1

4

3

2

1

3) Threading the (Blue)Overedge Right Needle

(B on needle clamp)

9

8

Table of contents

Other Merrylock Sewing Machine manuals

Popular Sewing Machine manuals by other brands

DURKOPP ADLER

DURKOPP ADLER 745-34 - manual

Brother

Brother S-7200B Specifications

Duerkopp Adler

Duerkopp Adler 745-22 Installation instructions & replacement parts list

Brother

Brother JX2517 Operation manual

Consew

Consew P1255RBL-18 operation instruction

Grace Company

Grace Company G Series instruction manual