JUKI LU-2810 Series User manual

Other JUKI Sewing Machine manuals

JUKI

JUKI HZL - 353Z Series User manual

JUKI

JUKI AP-876/IP-420 User manual

JUKI

JUKI DDL-9000C-S Series User manual

JUKI

JUKI MO-735 User manual

JUKI

JUKI HZL-E70 User manual

JUKI

JUKI LU-2220N-7 User manual

JUKI

JUKI DDL-8700 User manual

JUKI

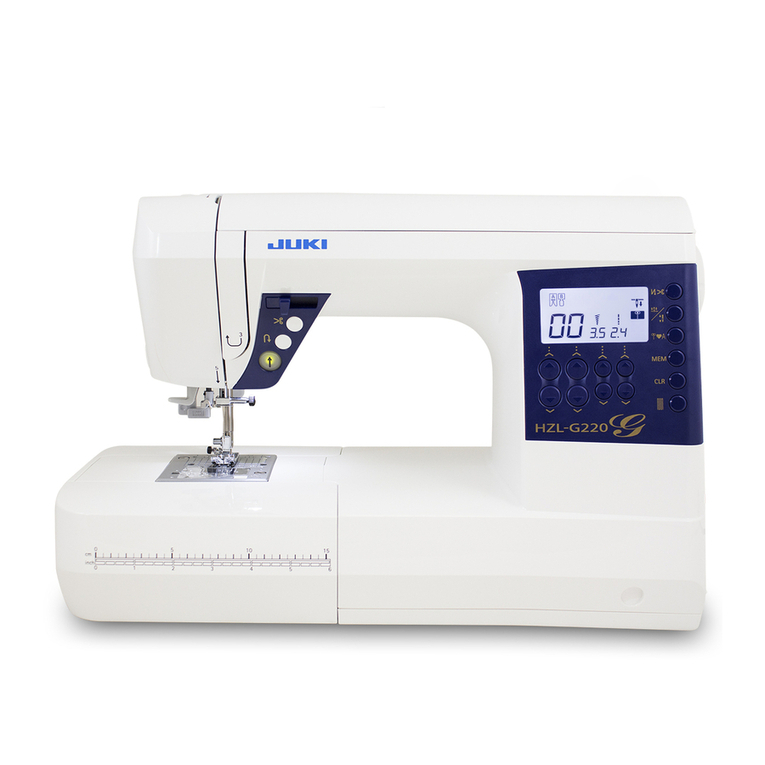

JUKI HZL-G Series User manual

JUKI

JUKI LU-1508N User manual

JUKI

JUKI LU-1520NCS-7 User manual

JUKI

JUKI AMB-289 Quick start guide

JUKI

JUKI DDL-9000B User manual

JUKI

JUKI MO-735N User manual

JUKI

JUKI AB-1351 User manual

JUKI

JUKI LK1903B/BSS302 User manual

JUKI

JUKI DDL-9000B-SH Installation and operation manual

JUKI

JUKI LU2-4652-B1T User manual

JUKI

JUKI CP-180 User manual

JUKI

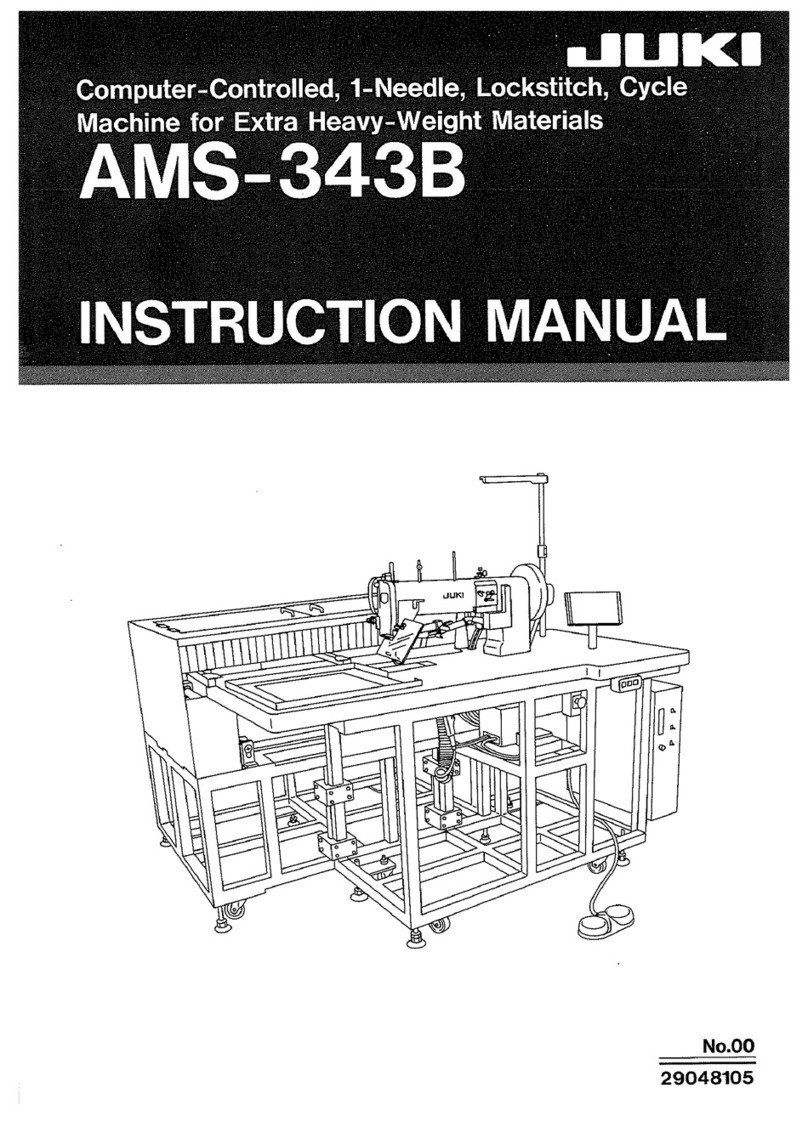

JUKI AMS-343B User manual

JUKI

JUKI IP-110 Type F User manual