Adjustment standard: When the machine is in the parked position (the presser foot is in the

decentralized state), the motor will automatically find the zero position, so that the mechanical lock

between the starting plate and the movement pin left 3mm gap.

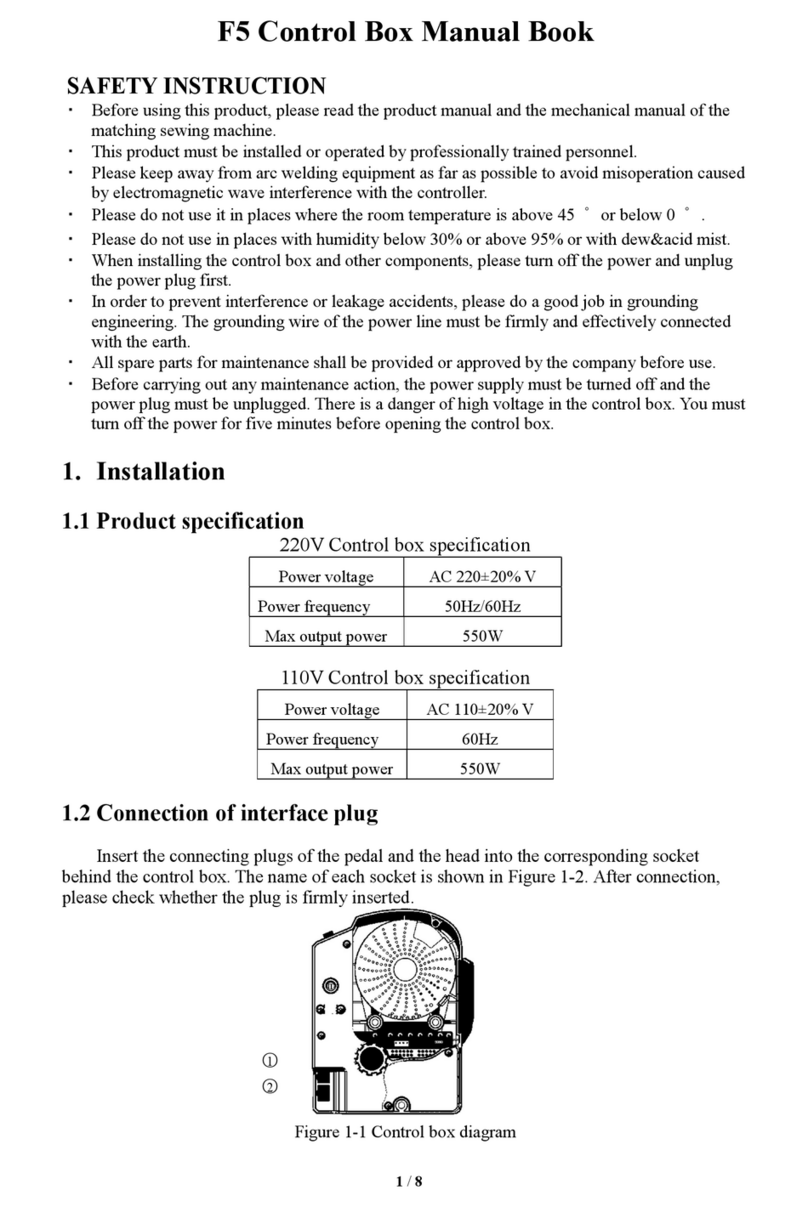

29.0:The sensor chip of automatic foot-lift position adjustment

3mm Gap

Sports pin

Sensor chip

Sensor

The sensor chip is aligned with up-side of the stamp mark of sensor

Stamp mark

Larger

Smaller

Adjustment methods:

1. Loosen the setscrews and adjust the sensor chip up and down relative to the sensor. (Up to adjust sensor

chip, the gap becomes larger after booting to find the zero position, down to adjust the gap smaller.)

2.Re-boot to find zero position, verify the mechanical lock between the starting plate and the

movement pin left 3mm gap.