Merrylock MK 4055 User manual

INSTRUCTION BOOK

INSTRUCTION BOOKINSTRUCTION BOOK

Do not dispose of electrical appliances as unsorted municipal waste. Use

facilities.

Contact your local government for information regarding the collection systems

available.

If electrical appliances are disposed of in landfills or dumps, hazardous

the groundwater and get into the food chain,

damaging your health and well-being.

When replacing old appliances with new one, the retailer is legally obligated to

appliance for disposal at least for free of charge.

separate collection

substances can leak into

take back your old

Thank you for your purchase of this Combination Overlock, Chain Stitch and Cover Stitch

Sewing Machine. This machine, that is intended for household use will provide you with

excellent performance in sewing from light to heavy material (lawn to denim).

Please refer to this Instruction Book for proper use and optimum service. To get the most

out of your sewing machine, read the entire Instruction Book before attempting to operate

the machine. Then familiarize yourself with the machine by following the Instruction Book

page by page.

To ensure that you are always provided with the most modern sewing capabilities, the

manufacturer reserves the right to change the appearance, design or accessories of this

sewing machine when considered necessary without notification or obligation.

1

PREFACE

RECYCLING

2

“IMPORTANT SAFETY INSTRUCTIONS“

“DANGER“___To reduce the risk of electric shock:

“WARNING“___

When using an electrical appliance, basic safety precautions should always be

followed, including the following: Read all instructions before using this overlock

sewing machine.

1. The appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the electric outlet immediately after using and

before cleaning.

1. Do not allow this appliance to be used as a toy. Close attention is necessary

when this appliance is used by or near children and infirm persons.

2. Use this appliance only for its intended use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return the

appliance to the nearest authorized dealer or service center for examination,

repair, electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked. Keep ventilation

openings of the sewing machine and foot control free from the accumulation of

lint, dust, and loose cloth.

5. Keep fingers away from all moving parts. Special care is required around the

sewing machine needle and cutter.

6. Always use the proper stitch plate. The wrong plate can cause the needle to

break.

7. Do not use bent needles.

8. Do not pull or push fabric while stitching. It may deflect the needle causing it to

break.

9. Switch the sewing machine off “ O “ when making any adjustments in the needle

area, such as threading needle area changing needle, threading looper, or

changing presser foot and the like.

10. Always unplug the machine from the electrical outlet when removing covers,

when covers are opened to raise the upper cutter or thread the loopers, when

lubricating or when making any other user servicing adjustments mentioned in

the instruction manual.

11. Never drop or insert any abject into any opening.

12. Do not use outdoors.

13. Do not operate where aerosol (spray) products are being used or where oxygen

is being administered.

14. To disconnect, turn all controls to the off “ O “ position, then remove plug from

outlet.

15. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

16. If the power cord of this appliance is damaged, it must be replaced with a

special cord by your nearest authorized dealer or service center.

To reduce the risk of burns, fire, electric shock, or

injury to persons:

“This overlock sewing machine is intended for household use only.”

you give the machine to a third

may not be able to estimate the

physical, sensory or mental

unless they have been given supervision or instruction

manufactured by Wakaho.

4C-326G/

* Keep the instructions at a suitable place close to the machine and hand it over if

party.

* Use the machine only in dry locations.

* Never leave the machine unattended with children or elderly people due to they

risk.

* Don’t let children play with the machine.

* This appliance is not intended for use by persons (including children) with reduced

capabilities, or lack of experience and knowledge,

concerning use of the

appliance by a person responsible for their safety.

* Children should be supervised to ensure that they do not play with the appliance.

* Always unplug the machine if you leave it unattended, to avoid injury by

expediently switch on the machine.

* Always unplug the machine if you carry out maintenance (oiling, cleaning).

* Don’t use the machine if it’s wet or in humid environment.

* Never pull at the cord, always unplug the machine by gripping the plug.

* Never place anything on the pedal.

* Never use the machine if the air vents are blocked keep the air vents of the

machine and the foot pedal free from dust, fusel and leftovers.

* The machine may only be used with foot pedal Type

4C-316B for USA and Canada, 4C-316C/ 4C-345G for other countries.

* If the supply cord connected with foot pedal is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualified person, in order to avoid a

hazard.

3

“SAVE THESE INSTRUCTIONS“

17. If oil gets in eyes, immediately, rinse the oil out with water. If you swallow oil by

mistake, immediately consult a medical doctor.

20. To reduce risk of injury, switch off before servicing. Close looper cover before

operating.

Lors de l’utilisation de cette machine, les précautions élémentaires de sécurité

doivent être pris es. Lisez attentivement toutes les consignes de sécurité suivantes

avant de l’utiliser :

* Ne laissez pas la machine sans surveillance lorsqu’elle est sous tension.

Débranchez la immédiatement après l’utilisation et avant le nettoyage.

* Débranchez la machine avant de changer l’ampoule. Remplacer l’ampoule par une

autre de 15 Watts et du même type. Assurez vous d’avoir remis le cache après

avoir changé l’ampoule.

* Assurez vous que le voltage du moteur corresponde à celui de l’installation

électrique.

* Cette machine est conçue pour un usage familial tel que décrit dans cette notice

d’utilisation. Utilisez uniquement les accessoires conseillés dans cette notice.

* Pour débrancher la machine positionnez l’interrupteur sur«O»lorsque vous

effectuez des opérations telles que enfilage des aiguilles ou des boucleurs ,

changement de plaque à aiguille ou de pied presseur etc....

* Débranchez la machine lorsque vous retirez les carters , lubrifiez le mécanisme ou

lors de toute opération d’entretien décrite dans cette brochure.

* N’essayez pas de régler vous-même la courroie du moteur. Si un réglage s’avère

nécessaire, contactez votre Service Après Vente .

* Manipulez le rhéostat avec précaution et évitez de le faire tomber. Assurez-vous

que rien n’est posé dessus.

* Utilisez la plaque à aiguille adéquate. Une plaque non conforme pe ut casser

l’aiguille.

* N’utilisez pas d’aiguille tordue.

* Lors de la couture, éloignez vos doigts de toute pièce en mouvement et

particulièrement de l’aiguille.

* Ne tirez et ne poussez pas le tissu lors de la couture, cela pourrait casser l’aiguille.

* Pour l’entretien des machines à double isolation, n’utilisez que des pièces de

rechange identique . Voir les instructions pour le service après-vente des appareils

à double - isolation.

* Ne jamais utiliser la machine si le cordon ou la prise électrique sont endommagés,

si elle est tombée ou abîmée, si elle a été exposée à l’eau. Contactez votre

Service Après Vente pour tout examen , réglage ou réparation.

* N’utilisez pas la machine si les aérations ou le rhéostat sont obstrués par la

poussière, la bourre de fil ou de tissu.

* N’insérez ou ne faîtes pas tomber d’objets dans les ouvertures de la machine.

Pour réduire le risque de blessures, éteindre l'interrupteur avant l'entretien. Fermer

le couvercle boucleur avant exploitation.

*

CONSIGNES DE SECURITE

4

DANGER - Pour reduire le risque de décharges électriques :

AVERTISSEMENT - Pour réduire le risque de brûlures, de feu, de

ou de blessures Aux personnes :décharges électriques

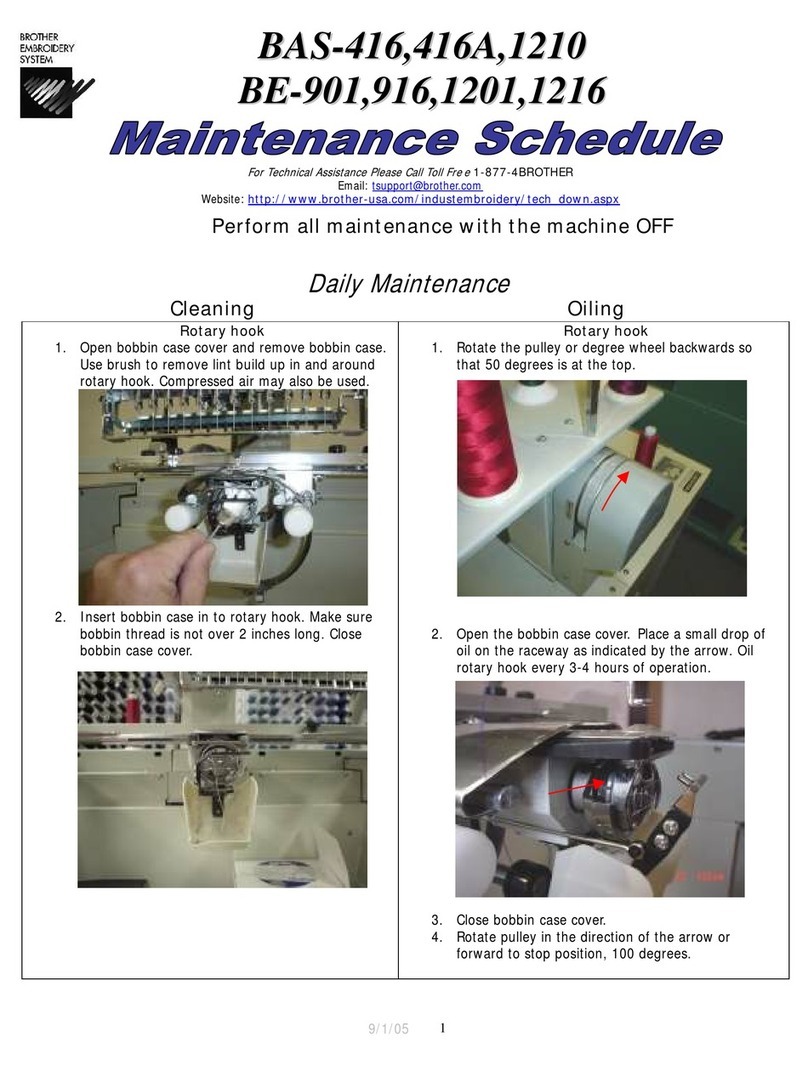

1. PRINCIPAL PARTS

(1) MACHINE OVERVIEW

(2) FREE ARM

(3) MAIN PARTS BEHIND THE LOOPER COVER

2. ACCESSORIES

3. OPTIONAL ACCESSORIES

(1) COVER STITCH PRESSER FOOT

(2) EXTENSION TABLE SET

4. NEEDLE INFORMATION

5. PREPARATION PRIOR TO SEWING

6. TELESCOPIC THREAD STAND

7. PREPARATION FOR THREADING

(1) SETTING UP THE THREAD GUIDE HOLDER

(2) ANTI-SPILL NET

(3) SPOOL CAP

8. REMOVAL AND REPLACEMENT OF CHIP BOX

(1) REPLACEMENT

(2) REMOVAL

9. HOW TO REMOVE AND INSERT NEEDLES

(1) NEEDLE POSITION

(2) TO REMOVE NEEDLE (S)

(3) TO INSERT NEEDLES (S)

10. PRESSER FOOT LIFT

11. CHANGE PRESSER FOOT

12. GENERAL THREADING INFORMATION

(1) TO THREAD CHAIN STITCH/ COVER STITCH

LOOPER THREAD (BROWN)

(2) TO THREAD COVER STITCH RIGHT NEEDLE

(GREEN) (E ON NEEDLE CLAMP)

(3) TO THREAD COVER STITCH MIDDLE /

CHAIN STITCH NEEDLE THREAD (BLUE)

(D ON NEEDLE CLAMP)

(4) TO THREAD COVER STITCH LEFT NEEDLE

THREAD (ORANGE) (C ON NEEDLE CLAMP)

5

13. NEEDLE THREADER

14. HOW TO CHANGE THREADS : TIE ON METHOD

15. STITCH LENGTH ADJUSTMENT

16. SELECTION OF STITCHES

17. STITCH OVERVIEW

18. COVER STITCH SEWING

(1) MACHINE SET UP

(2) SECURING THE COVER STITCH SEAM END

19. PRESSER FOOT PRESSURE ADJUSTMENT

20. DIFFERENTIAL FEED

(1) TO SET THE DIFFERENTIAL FEED ADJUSTING

DIAL FOR GATHERING

(2) TO SET THE DIFFERENTIAL FEED ADJUSTING

DIAL FOR STRETCH

21. HOW TO SEW A COVER STITCH

(1) MACHINE SET UP

(2) ADDITIONAL INFORMATION ABOUT COVER

STITCH

22. SUGGESTED TENSION SETTING

(1) CHAIN STITCH

(2) COVER STITCH, WIDE AND (3) COVER STITCH,

NARROW

(4) COVER STITCH, TRIPLE

23. MACHINE MAINTENANCE

(1) CLEANING

(2) STORAGE

(3) SERVICING

24. TROUBLE SHOOTING

25. SPECIFICATIONS

26. MACHINE DIMENSIONS

6

6

7

8

8

9

9

9

10

10

11

11

11

11

12

12

12

12

13

13

13

14

14

14

15

15

17

18

19

21

22

22

23

23

24

24

24

25

25

25

25

26

27

28

28

28

29

29

29

30

30

30

31

31

TABLE OF CONTENTS

PAGE PAGE

6

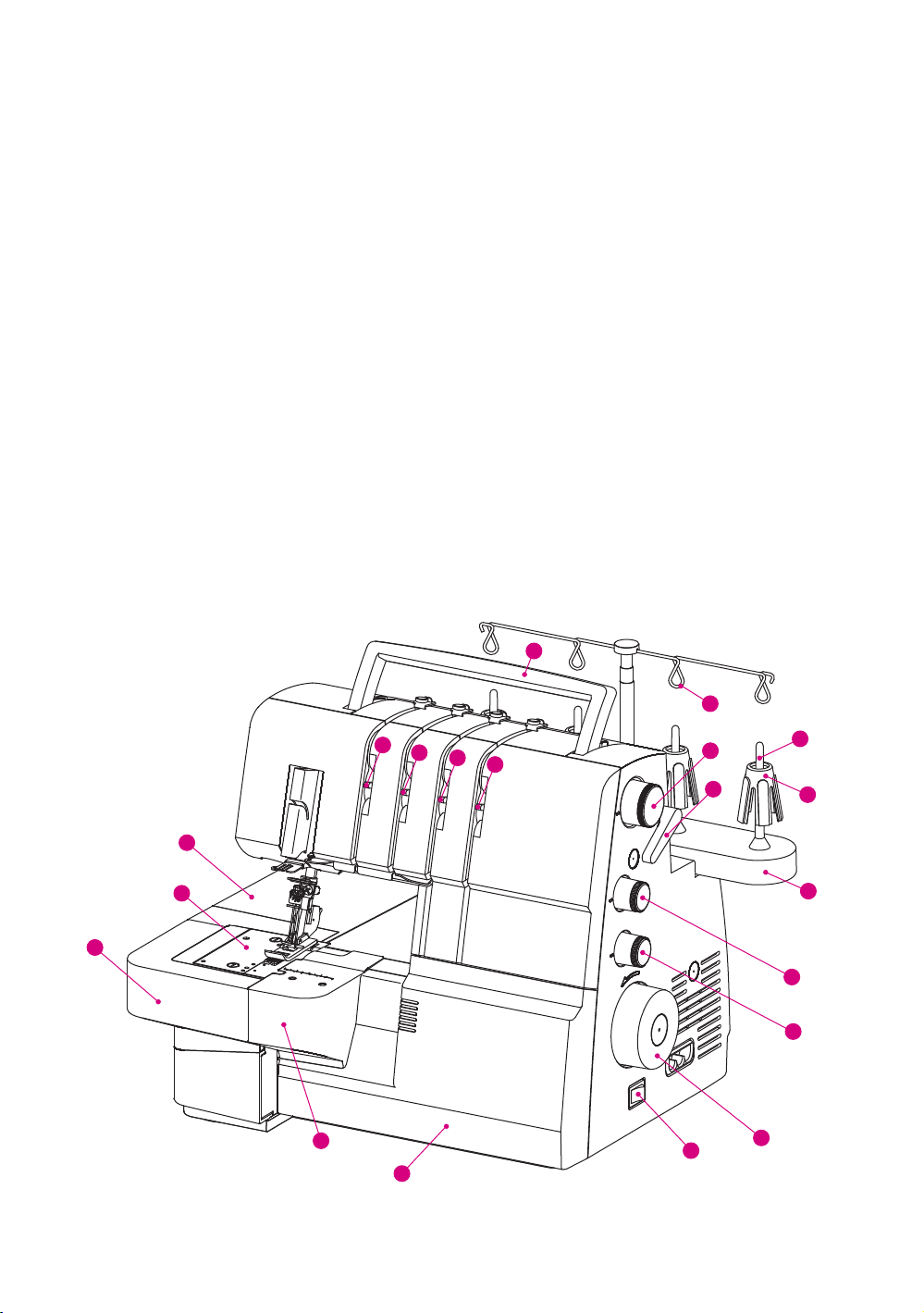

1. PRINCIPAL PARTS

(1) MACHINE OVERVIEW

1. Thread guides and holder

2. Handle

3. Left needle thread tension fine tuning (orange)

4. Right needle thread tension fine tuning (blue)

5. Upper looper thread tension fine tuning (green)

6. Chain stitch looper thread tension fine tuning (brown)

7. Stitch plate

8. Cloth plate

9. Attached extension table

10.

12. Power & light switch

13. Hand wheel

14. Differential feed adjusting dial

15. Stitch length dial

16. Spool stand

17. Spool holder

18. Spool pin

19.

Cutter cover B

11. Looper cover

Presser bar lifter and tension release

20. Auto tension dial

2

1

7

11

12

15

13

16

17

18

6

45

3

14

10

8

9

19

20

7

21. Foot pressure adjusting dial

22. Thread cutter

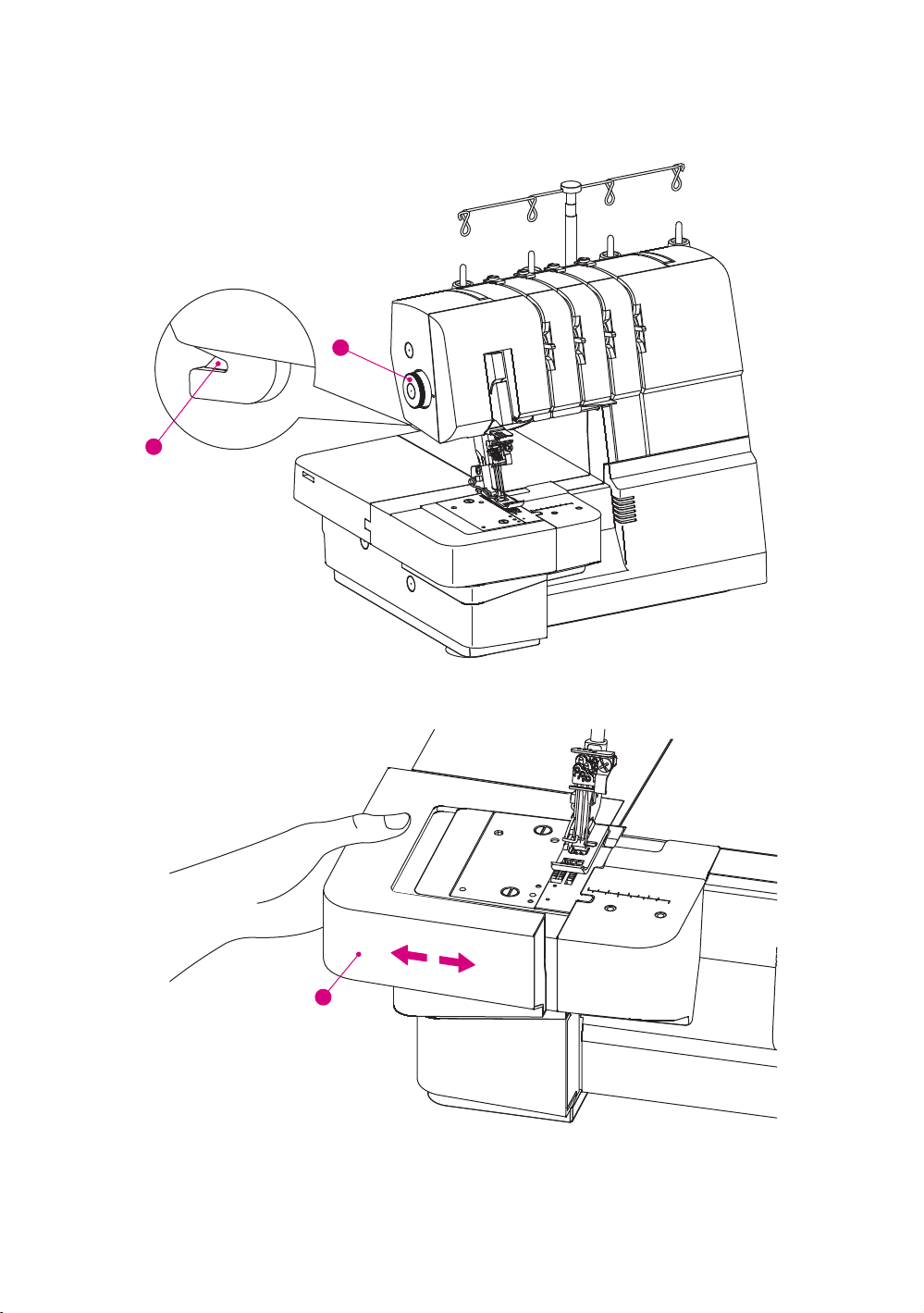

(2) FREE ARM

1. Attached extension table

* The attached extension table can be removed to expose the free arm.

* To remove pull to the left.

* To attach press firmly to the right until it engages.

* The free arm is ideal for sewing tubular items such as ribbing, trousers and sleeve hems.

1

21

22

8

2. ACCESSORIES

Accessories No. 1~10 are contained in the accessory box.

1. Flat blade screw driver

2. Oiler

3. Brush

4. Needle set

5. Anti-spill net (4)

6. Upper cutter

7. Thread unwinding spool cap (4)

8. Needle threader

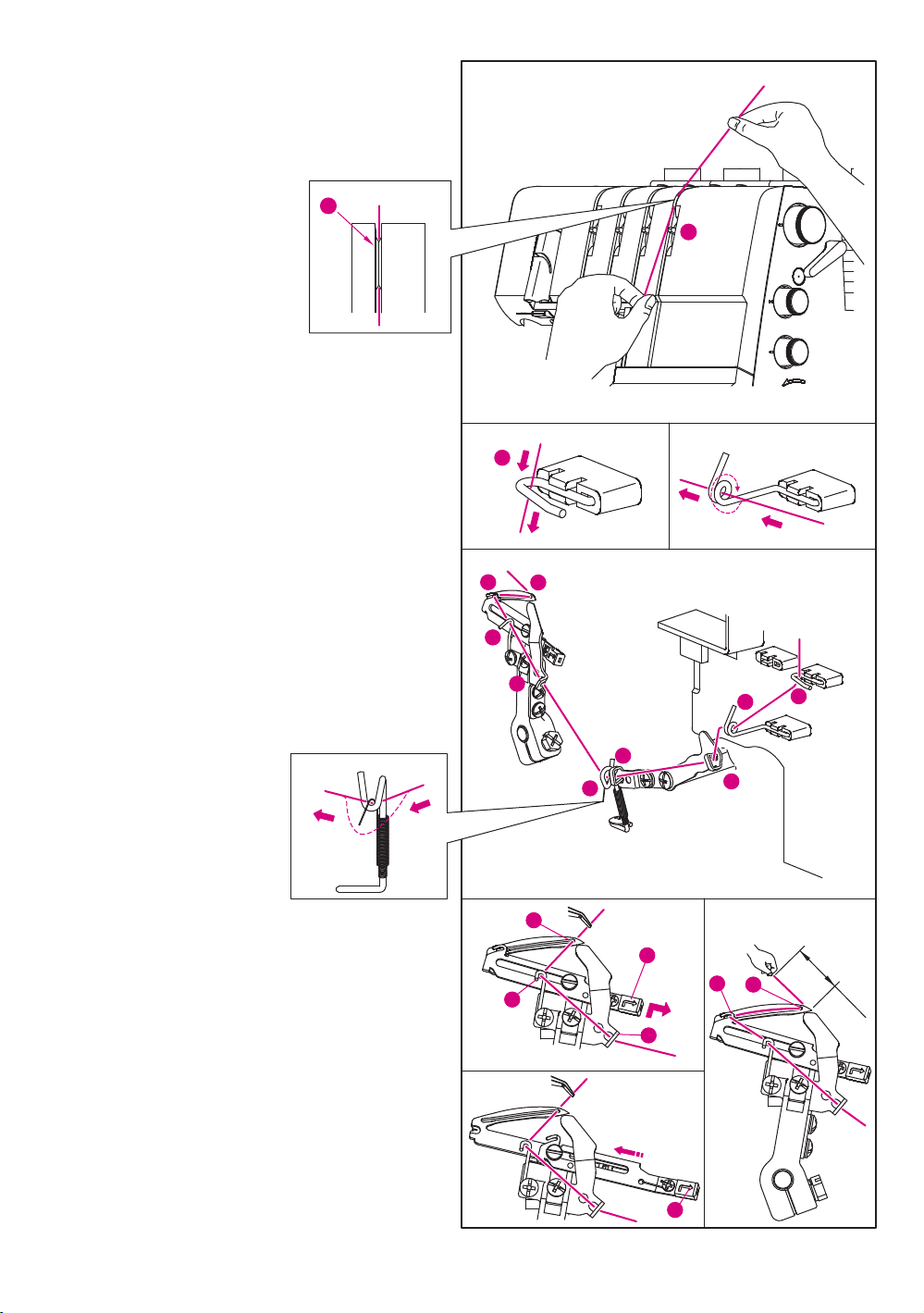

(3) MAIN PARTS BEHIND THE LOOPER COVER

1. Cover stitch looper thread take-up lever (D)

2. Cover stitch looper thread take-up lever (E)

3. Chain looper thread guide set

4. Cover looper protect board

5. Spring

6. Cover looper autothreader

7. Cover looper

9. Screw driver

10. Tweezers

11. Accessory box

12. Spool holder (4)

13. Dust cover

Note : No. 8~10 commonly used accessories can place on looper cover, sewing will be more convenient.

11 13

12

12710

36

5

49

8

4

5

3

2

6

3

1

7

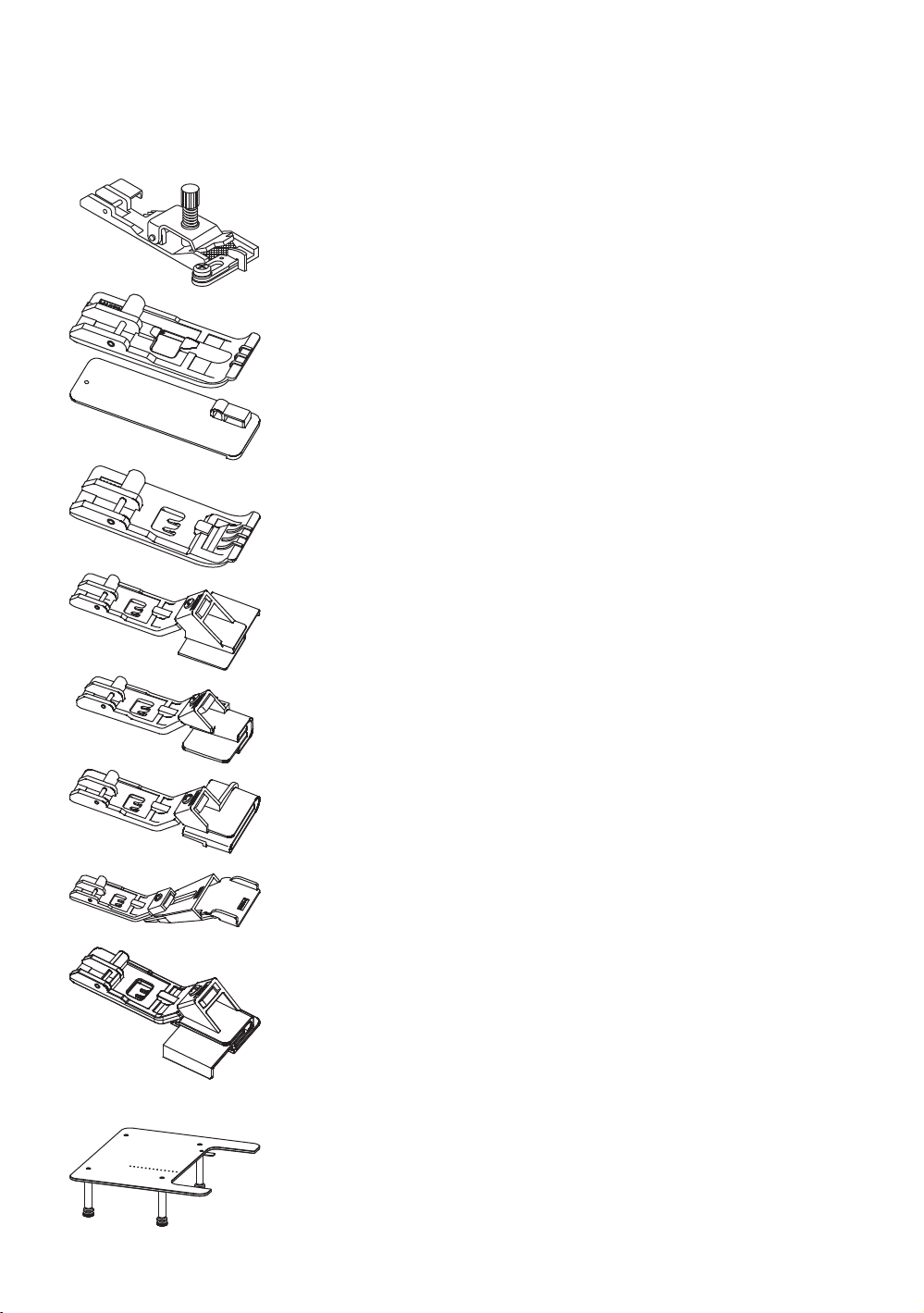

3. OPTIONAL ACCESSORIES

Optional presser feet specially prepared for this machine are available at your dealer. The snap-on type

presser foot used on this machine allows easy removal and replacement.

(2) EXTENSION TABLE SET

Extension Table Set J11862

Including extension table, four legs and push pin. Assemble the extension table

and legs according to the illustrations provided with the table. The push pin is

used in the small holes in the table to hold your fabric in place when sewing

circles.

(1) COVER STITCH PRESSER FOOT

9

Elastic Foot G20804A

The Elastic Foot guides and stretches narrow elastic (6-12mm, 1/4~1/2”) wear

lingerie and other elastic insertion techniques

,

.

Cover Hem Foot H10803

With the Cover Hem Foot, you can see your fabric and marked line under the

foot as you sew.

Flat lace foot H10813

With the Flat Lace Foot, you can easily add lace and trims to the top of the

fabric with a cover stitch to create beautiful decorative edges and effects.

Cording Foot Set H10793

With the Cording Foot with Cording Guide, you can create piping, corded tucks

and decorative trims.

Hemming Foot H10833

With the Hemming Foot makes hems more easily. Just insert the fabric into

fabric guide with the folded side down and slide fabric into guide under foot to

needle.

Bias Tape Folder Foot H10843

With the Bias Tape Folder Foot, create straps and belt loops easily using a

cover stitch. Just put a strip into the foot and the strip is folded automatically

and stitched in place.

Bias Tape Binding Foot

Use t

H10823

he Bias Tape binding Foot to sew bias tape along edge of fabric

.

more

easily

Flat Edge Lace Foot H10853

Use the Flat Edge Foot to hem the fabric edge and attach lace at the same

time.

10

Use only foot controller provided with this machine.

(Type 4C-316B for U.S.A. & CANADA only)

5. PREPARATION PRIOR TO SEWING

* Connect the controller/electric plug to the machine

receptacle.

* Plug power line into electric outlet.

* Power Switch: Push"l"mark side to turn "ON”

Push "O" mark side to turn "OFF”

* To run the machine and control the speed, press

the controller.

* The harder you press, the faster the machine will

sew.

* To stop the machine from sewing, remove your

foot from the controller.

POLARIZED PLUG INFORMATION (FOR U.S.A. & CANADA ONLY)

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this

plug is intended to fit in a polarized outlet only way. If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit contact a qualified electrician to install the proper outlet. Do not modify the plug in any way.

* Be sure that the electrical voltage of the electric outlet (wall receptacle) is the same as the rated voltage of

the motor.

* Handle the foot controller with care and avoid dropping it on the floor. Be sure not to place anything on top

of it when not in use.

* Disconnect the power line plug from the electric outlet when changing needles, presser feet or when

leaving the machine unattended. This eliminates the possibility of starting the machine by accidentally

pressing the controller.

4. NEEDLE INFORMATION

This overlock uses a flat shank industrial needle

that eliminates the possibility of inserting the needle

backwards.

Do not attempt to use a standard household sewing

machine needle of any size or type in this overlock.

Needle ELx705 size 14/90 is finished with the

machine.

Only use Needle ELx705 size 14/90 and 12/80 as

supplied in the accessory case.

ELx705

Overlock needle

11

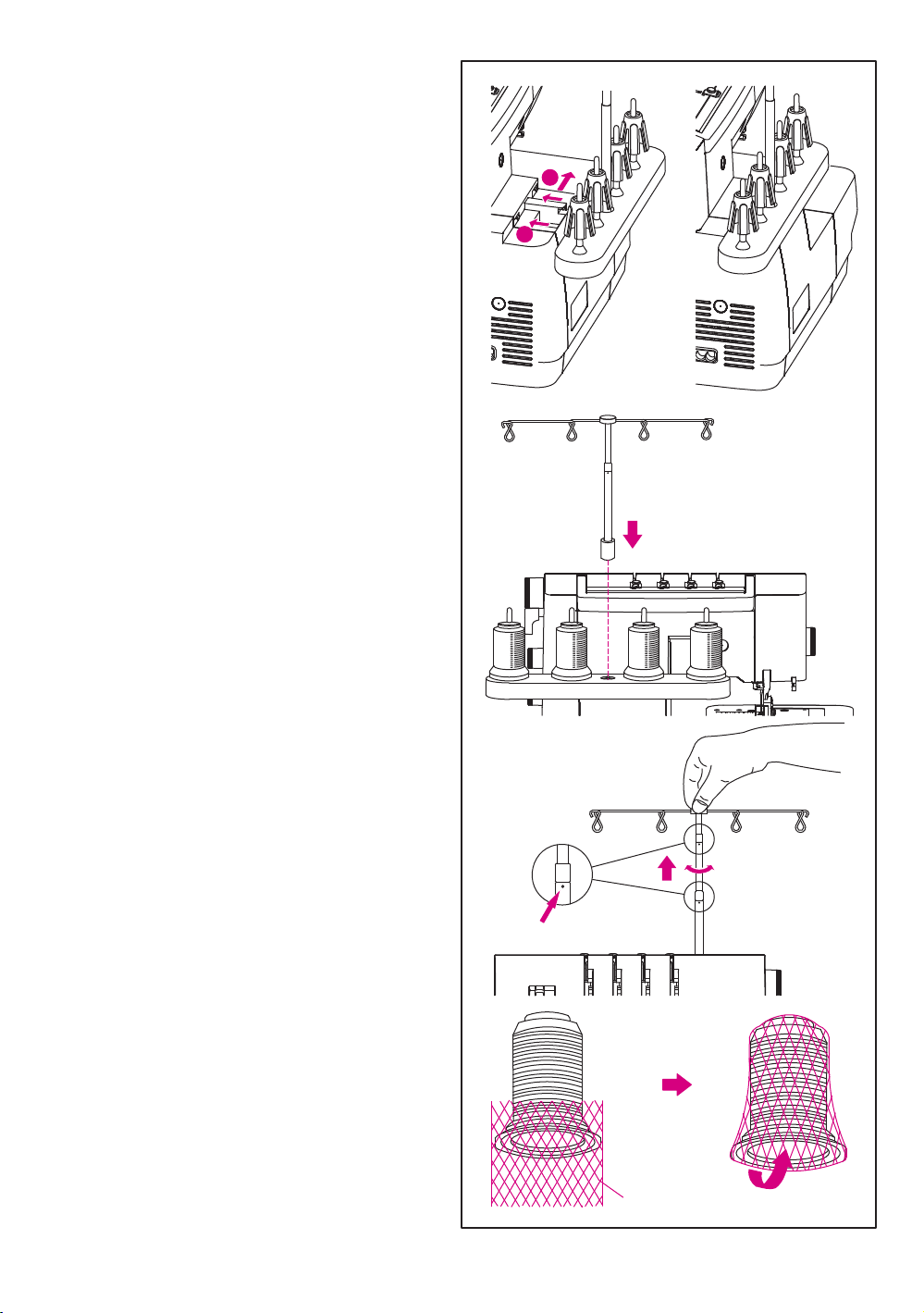

7. PREPARATION FOR THREADING

(1) SETTING UP THE THREAD GUIDE

HOLDER

* This machine is shipped with the thread guide

holder on the top of Styrofoam.

* Fully extend the thread guide holder.

* The two joints on the telescope will click into place

when they are correctly positioned.

* Center the thread guides above the spool pins.

* Place thread over the cone adapters on the spool

pins.

Note : Your new machine is threaded to sew Triple

Cover Stitch. Refer to Page 15 for

instructions on tying on to the threads.

Anti-spill net

(2) ANTI-SPILL NET

*When using synthetic threads that easily spill off

the cone, slip the anti-spill net furnished with the

machine over the thread from the bottom of the

cone leaving the thread end hanging free at the

top the anti-spill net as shown at right.

6. TELESCOPIC THREAD STAND

* Place the thread spools over the cone holders on

the spool pin.

* If the machine is already threaded, straighten the

threads to prevent tangling.

1

2

12

8. HOW TO OPEN AND CLOSE LOOPER

COVER

(1) OPEN LOOPER COVER

* Push the looper cover to the right as far as it will

go.

* Pull looper cover down toward you.

* First pull the looper cover upward and then slide it

to the left until it locks.

Note : The looper cover has a safety switch and the

machine will not sew if the looper cover is

open.

(2) CLOSE LOOPER COVER

(3) SPOOL CAP

Spool cap

Thread spool

Press in

*When using a regular thread spool, fit the spool

cap supplied with the machine onto the thread

spool as shown at right.

Be sure to turn off power switch.

Be sure looper cover is closed when sewing.

1

2

EDC

Cover stitch right needle

Cover stitch middle needle

/ Chain stitch needle

Cover stitch left needle

Be sure to disconnect the machine from the

electric outlet before removing needle(s).

Chain stitch needle thread

Left, middle and right cover

stitch needle thread

Flat surface to the rear

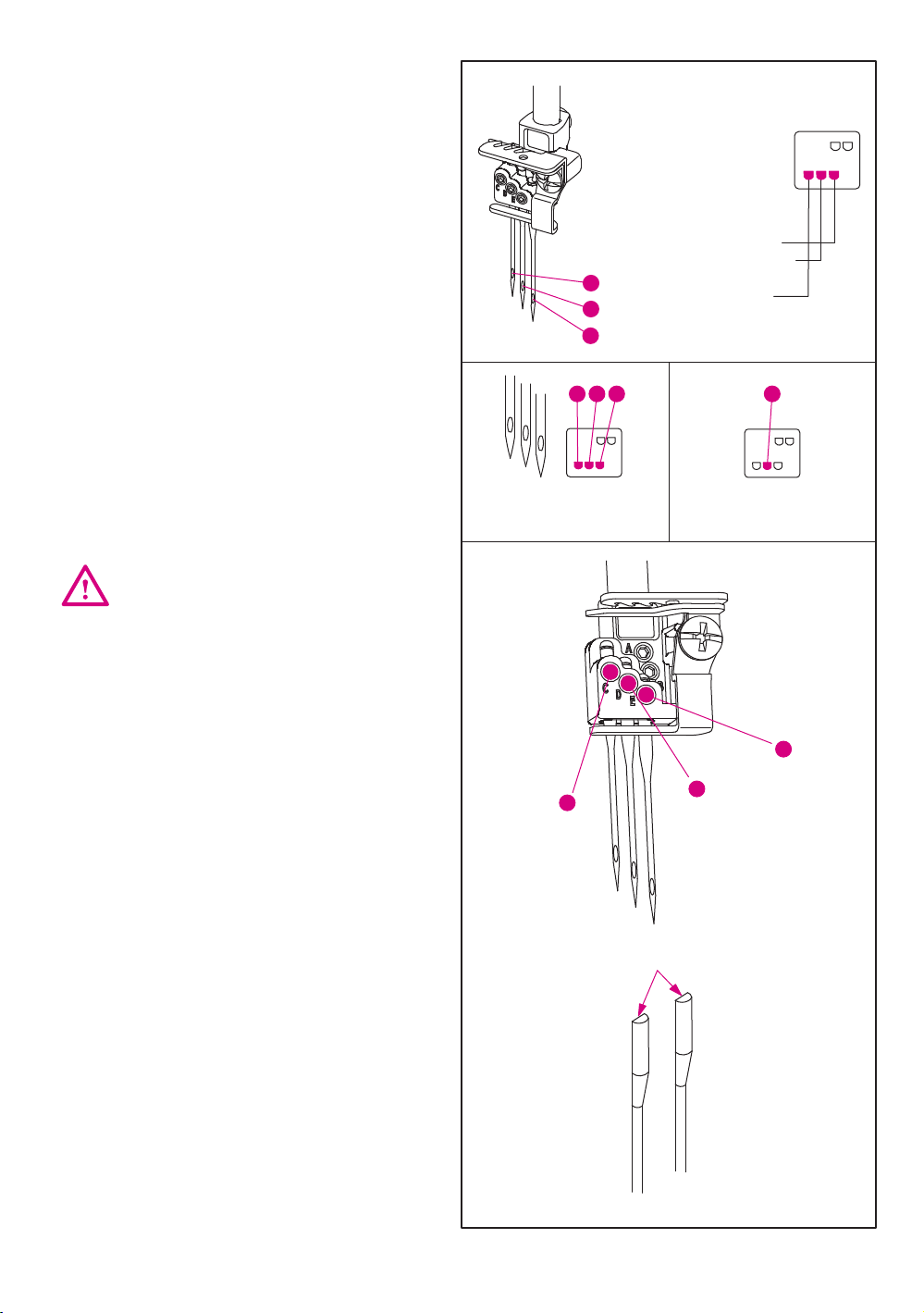

(1) NEEDLE POSITION

* With this machine, five needles can be inserted to

the needle clamp as shown in the drawing but

only one or two or three needles are to be used

for cover stitch sewing.

Note : Do not attempt to use four or five needles.

* The Instruction Book refers to different needle

positions by illustrating the needle clamp at right.

Note : When all cover stitch needles are inserted,

the left needle will be slightly higher than the

others.

1

(2) TO REMOVE NEEDLE (S)

9. HOW TO REMOVE AND INSERT

NEEDLES

* Turn the hand wheel toward you until the needles

are

the

the fabric.

* Loosen, but do not remove the needle clamp

screw with the allen key while you are holding the

needles.

C. Cover stitch left needle

D. Cover stitch middle needle

E. Cover stitch right needle

at their highest position.

* Place a thick piece of fabric [such as felt] under

presser foot. Lower the needles halfway into

Note: After removing the specific needle which is

not currently to be used for sewing, remember to

fasten the set screw in the screw hole of the needle

clamp and to just fasten tight into the hole.

Please do not over-tighten the screw into the hole

or the needle clamp will be damaged.

13

C

E

D

D

C

E

D

To loosen

To tighten

(3) TO INSERT NEEDLES (S)

* Hold the needle with the flat surface to the back.

* Insert the needle into the needle socket as far as

it will go.

* When inserting a needle, if you first lower it down

into the hole in the stitch plate it will line up with

the needle socket. Then direct it upwards.

This machine uses ELx705 needles. Do not use

Standard Household Needles.

14

* Raise the presser foot.

* Turn the hand wheel toward you until the needles

are at the highest position.

* Push the red button on the back of the presser

foot ankle to release the presser foot.

* Raise the presser foot to the extra lift position and

the foot will come off.

* Place the new foot with the pin right underneath

the groove of the ankle while in the extra lift

position.

* Lower the presser foot. Push the red button on the

back of the presser foot ankle and the foot will

snap into place.

11. CHANGE PRESSER FOOT

Turn off the main power switch and unplug

the machine.

10. PRESSER FOOT LIFT

* Raise the presser foot by raising presser foot lift

lever at the right side of the machine.

* Raising up the presser foot lift puts the presser

foot in the extra lift position.

41

32

15

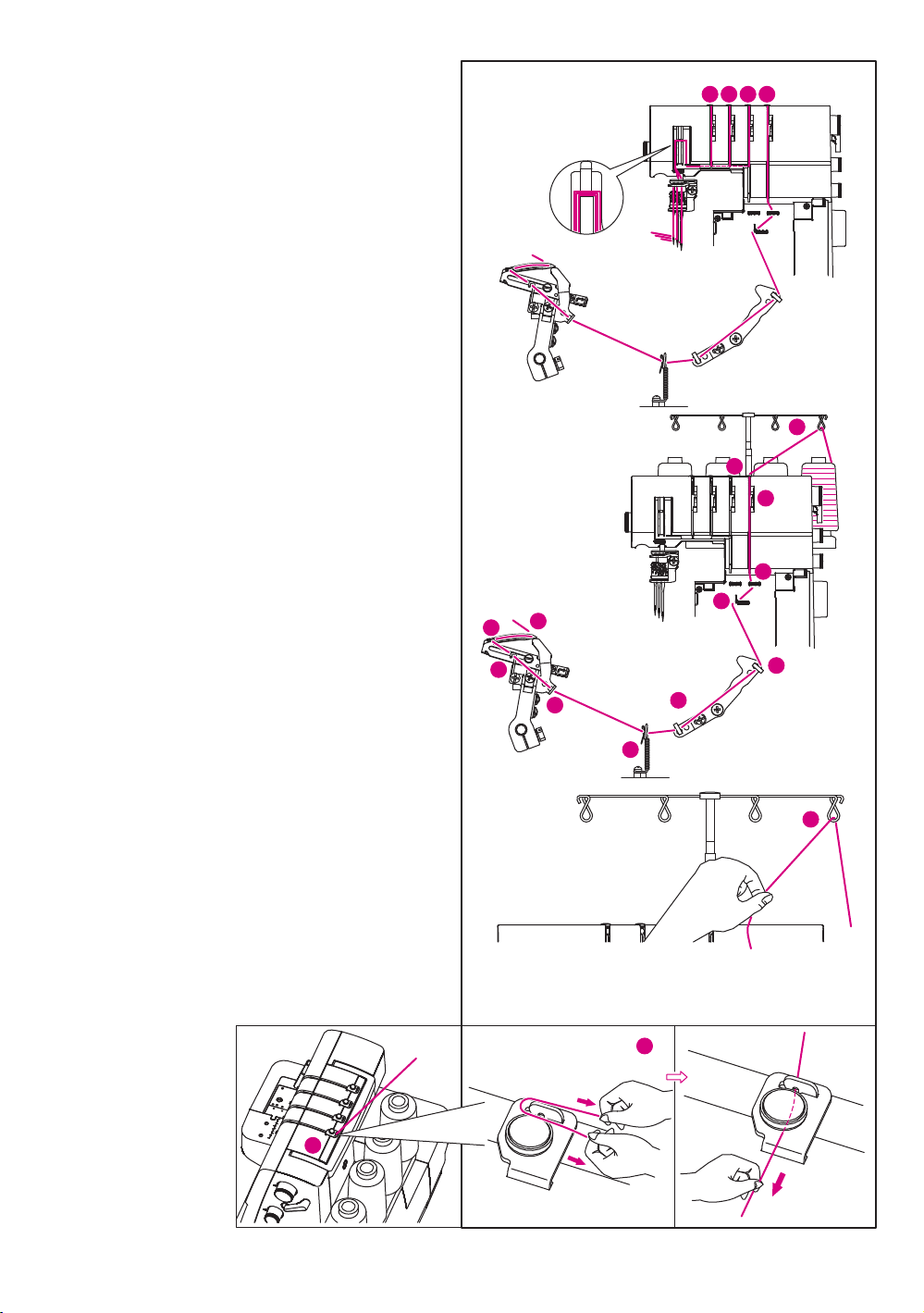

*Thread the machine in the order 1 to 4 as shown

at right.

Note : Threads go through the take-up lever cover

for Chain stitching as shown.

threads to

them through

your new

Tip : Your new machine is threaded to sew a

standard “Triple Cover Stitch”. Tie your own

these threads and carefully pull

the machine, to easily thread

Triple Cover Stitch machine the first

time.

12. GENERAL THREADING INFORMATION

(1) TO THREAD

(BROWN)THREAD

* Thread the chain stitch/cover stitch looper as

indicated 1~12.

* Raise Presser foot to release Tension discs.

* Pass thread from back to the front through the

thread guide 1.

CHAIN STITCH/ COVER

STITCH LOOPER

* Thread the top cover thread guide by pulling the

thread towards the right until it slips under guide.

Then pull thread along the right side of button as

illustrated.

1

2

3

1

4

5

7

8

6

9

10

12

11

2

2

10cm

(4")

* While holding thread with fingers, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3.

16

3

3

* Turn the hand wheel toward you until the cover

stitch looper extends out 10mm from the stitch

plate edge.

* Thread the looper area of the machine following

the brown color-coded thread guides 4~12.

Note : Use the tweezers provided in the accessory

case to aid in threading the looper.

* Place the thread with the point of the tweezers

through threading guide 4~7.

* Thread the Chainstitch

thread guide (8) by holding

the thread in front of the

thread guide pin and pulling

the thread backward and

up, until the thread rests

inside the thread guide loop

and under the spring.

* Position thread through in guide 9. Pull thread in

front the board and through guide 10.

* Thread the looper eye 12 from front to back. Pull

about 10cm (4 inches) of thread through the

looper.

* Press down the threader guide board (A) and pull

to the right side out.

* Release the threader guide board (A) that

automatically spring back and pull thread into

guide 11 and make sure the threader guide board

(A) to the leftmost point.

4

4

5

6

7

8

9

10

12

11

8

10

12

9

11

A

A

12

(2) TO THREAD

(GREEN) (E ON NEEDLE CLAMP)

*

* Pass thread from back to the front through the

thread guide 1.

* Thread the top cover thread guide by pulling the

thread towards the right until it slips under guide.

Then pull thread along the right side of button as

illustrated.

* While holding thread with fingers, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3.

Thread the right needle as indicated 1~10.

* Raise Presser foot to release Tension discs.

COVER STITCH RIGHT

NEEDLE

17

3

4

5

6

7

8

9

10

1

2

1

2

2

3

3

* Continue to thread points 4~9.

* Slip the thread into the rear slot on the thread

guide (5) and into the slot on the take-up lever

cover (6). Then slip the thread into the right slot

on the thread guides (7) and (8).

* Before threading the eye of the needle, make sure

thread is in front of thread guide located on the

bottom of the needle clamp (9).

* Thread the eye of the needle. Use the needle

threader (page 21) to make the threading easier.

* Pull about 10 cm (4") of thread through needle

eye to hang free.

* Place the thread to the back, under the presser

foot.

* Thread the cover stitch middle / chain stitch

needle as indicated 1~10.

* Raise Presser foot to release Tension discs.

* Pass thread from back to the front through the

thread guide 1.

* Thread the top cover thread guide by pulling the

thread towards the right until it slips under guide.

Then pull thread along the right side of button as

illustrated.

(3) TO THREAD

THREAD (BLUE)

(D ON NEEDLE CLAMP)

COVER STITCH MIDDLE /

CHAIN STITCH NEEDLE

18

4

5

6

7

8

9

10

5

3

4

5

6

7

8

9

10

1

2

1

2

2

* While holding thread with fingers, pass it between

the tension discs and pull thread down to make

certain it is properly located in between the

tension discs 3.

* Continue to thread points 4~9.

* Slip the thread into the rear slot on the thread

guide (5) and into the slot on the take-up lever

cover (6). Then slip the thread into the right slot

on the thread guides (7) and (8).

* Before threading the eye of the needle, make sure

thread is in front of thread guide located on the

bottom of the needle clamp (9).

* Thread the eye of the needle. Use the needle

threader (page 21) to make the threading easier.

* Pull about 10 cm (4") of thread through needle

eye to hang free.

* Place the thread to the back, under the presser

foot.

19

3

4

5

6

7

8

9

10

5

3

3

4

5

6

7

8

9

10

1

2

(4) TO THREAD

THREAD (BLUE)

(D ON NEEDLE CLAMP)

* Thread the cover stitch middle / chain stitch

needle as indicated 1~10.

* Raise Presser foot to release Tension discs.

COVER STITCH MIDDLE /

CHAIN STITCH NEEDLE

This manual suits for next models

1

Table of contents

Other Merrylock Sewing Machine manuals