Mestra POLY-PLUS User manual

R-080460

POLY-PLUS

E...........POLIMERIZADORA A PRESIÓN......................3

GB.......PRESSURIZED POLYMERIZER.......................7

F...........POLYMÉRISATEUR À PRESSION................12

P...........POLIMERIZADORA À PRESSÃO ..................16

I.............POLIMERIZZATRICE A PRESSIONE...........20

MESTRA®

TALLERES MESTRAITUA S.L.

Txori-Erri Etorbidea, 60

48150 SONDIKA -BILBAO -ESPAÑA

Tfno. + 34 944530388 -Fax + 34 944711725

Rev. 05/03/12

2

A

F

E

D

B

C

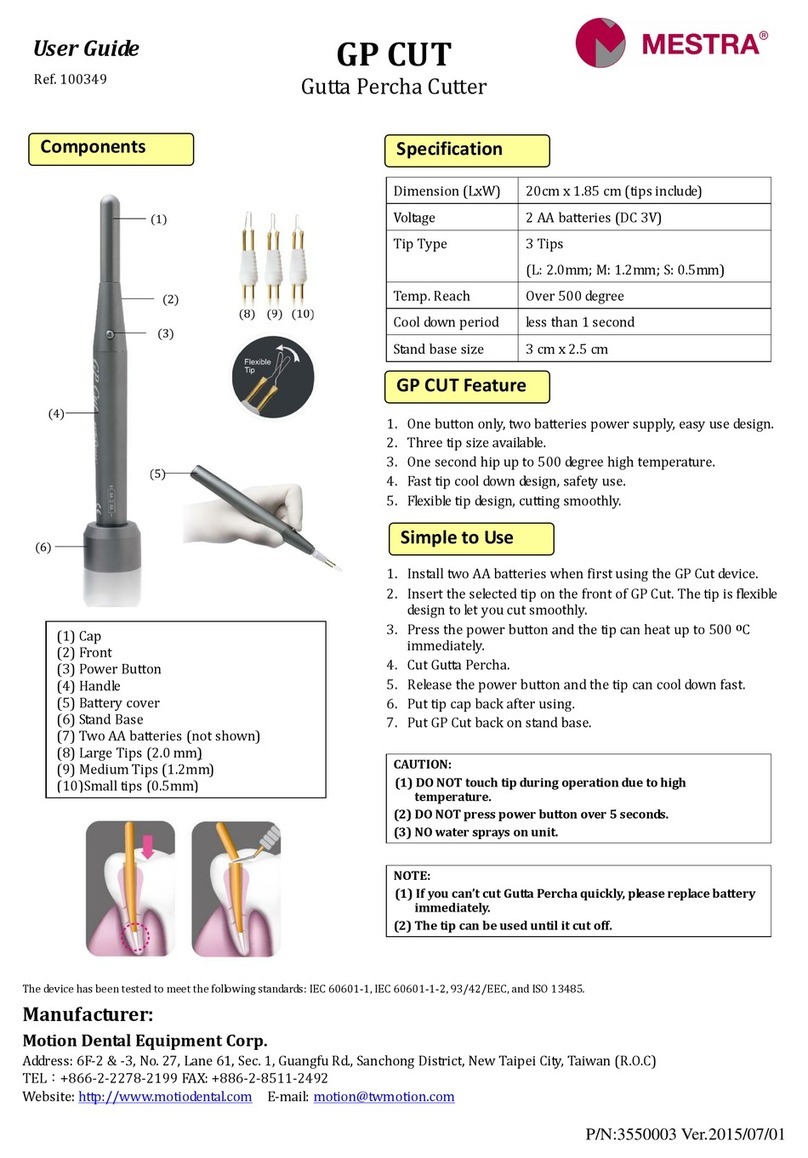

ACorredera de cierre de tapa / Lid Seal Slide (Guide) / Levier de fermeture du couvercle / Corrediça de

fecho da tampa / Chiusura scorrevole coperchio

BManubrio de seguridad / Safety Handle / Virole de sécurité / Maneta de segurança / Impugnatura di

sicurezza

CTeclado control / Control Keyboard / Touches de contrôle / Teclado controlo / Tastiera controllo

DInterruptor general / Main Switch / Interrupteur General / Interruptor geral / Interruttore generale

EManómetro / Pressure Gauge / Manomètre / Manómetro / Manometro

FManorregulador / Manorregulator / Manoréducteur / Regulador de pressão / Regolatore pressione

1.Display de temperatura / Temperature display / Cadran de température / Display de temperatura / Display

temperatura

2.Display de tiempos / Time display / Cadran de temps / Display de tempos / Display tempi tiempos

3.Piloto de control resistencia / Resistance control light / Témoin de contrôle de résistance / Luz ind. de

controlo resistencia / Spia di controllo resistenza

4.Piloto de fin de programa / End of programme light / Témoin de fin de programme / Luz ind. de fin de

programa / Spia di fine programma

5.Tecla de marcha-paro / Start-stop key / Touche Marche-Arrêt / Tecla de func.-parada / Tasto avvio-arresto

6.Piloto de programa en marcha / Programme in operation light / Témoin de fonctionnement du programme /

Luz ind. de programa em funcion / Spia di marcia programma

7.Tecla de modo displays / Display mode key / Touche de contrôle des cadrans / Tecla de modo displays /

Tasto modalità display

8.Tecla de incrementar / Increase key / Touche + / Tecla de incrementar / Tasto incrementare

9.Tecla de decrementar / Decrease key / Touche –/ Tecla de diminuir / Tasto diminuire

10.Tecla de función / Function key / Touche de fonction / Tecla de função / Tasto di funzione

11.Gráfico de programa / Programme graph / Graphique de programme / Gráfico de programa / Grafico

programma

12.Interruptor general / Main switch / Interrupteur general / Interruptor geral / Interruttore gen.

13.Manómetro / Pressure gauge / Manomètre / Manómetro / Manometro

Español

3

E

La R-080460 POLI-PLUS es una práctica

polimerizadora a presión que dispone de un panel de

control para programar una secuencia de temperaturas

y tiempos de polimerización, conforme a una ley

preestablecida por el usuario. De esta forma, cualquier

polimerización consta de los 5 pasos siguientes:

•

Un tiempo durante el que el agua en el interior de

la cuba permanece a temperatura ambiente y

presión atmosférica (tiempo de inicio).

•

Un tiempo durante el que la temperatura del

agua en el interior de la cuba va ascendiendo de

forma lineal, hasta alcanzar una temperatura final

establecida por el usuario (tiempo de 1ª rampa).

Al comienzo de esta fase, el interior de la cuba se

presuriza a un valor definido por el usuario, y que

se mantiene durante todo el programa.

•

Un tiempo durante el que la temperatura del

agua en el interior de la cuba permanece

constante, tomando el valor final adquirido en el

paso anterior (temperatura 1ª meseta).

•

Un tiempo durante el que la temperatura del

agua en el interior de la cuba vuelve a variar

linealmente, hasta alcanzar una temperatura final

establecida por el usuario (tiempo de 2ª rampa).

•

Un tiempo durante el que la temperatura del

agua en el interior de la cuba permanece

constante tomando el valor final adquirido en el

paso anterior (temperatura de 2ª meseta).

Finalizada esta secuencia de pasos, el aparato se

desconecta automáticamente emitiendo una señal

acústica de aviso durante un minuto, y el agua del

interior de la cuba se descarga en una botella de

desagüe, reestableciéndose también la presión

atmosférica. Los tiempos de duración de cada uno de

los pasos puede ser ajustadosentre 0 y 99 horas, 59

minutos. Las temperaturas finales de cada una de las

dos mesetas pueden ser reguladas entre 0 º C y 135

ºC.

Para mostrar al usuario en todo momento la situación y

evolución real del programa, el panel de contro l de la

polimerizadora a presión R-080460 dispone de un

gráfico sinóptico (11). Las lamparitas de LED indican

en todo momento el paso que se está realizando y las

temperaturas alcanzadas. El aparato también dispone

de dos Displays digitales. El superior (1 ) indica la

temperatura instantánea del agua en el interior de la

cuba. El Display inferior (2) indica el tiempo que falta

para que finalice todo el programa.

Ambos displays están dotados de doble función, que

se activa al pulsar la tecla (W/T) (7). Al pul sar dicha

tecla, el display superior (1) muestra la temperatura

que el usuario ha programado como valor final del

paso (temperatura de consigna). Por su parte, el

display inferior muestra el tiempo que falta para que

finalice el paso que se está ejecutando.

INSTALACIÓN

•

Desembale cuidadosamente la polimerizadora a

presión R-080460. Como accesorios encontrará

una botella de desagüe (no representada en la

figura) con su tubo de conexión, y un tubo de

conexión a la red de aire a presión.

También encontrará en el interior de la cuba dos

bandejas. Una de ellas está provista de asa y sirve

para retirar con facilidad los elementos que se

polimerizan. La otra no tiene asa, y sirve como

protección a la resistencia de caldeo. Coloque la

bandeja sin asa en el fondo de la cuba justo por

encima de la resistencia.

•

Elija para el emplazamiento del aparato una base

horizontal, plana y rígida, alejada de fuentes de

calor o vibraciones. Cuide también que en sus

proximidades se encuentre un punto de conexión

a la red de aire a presión. Los laterales del aparato

disponen de ranuras de ventilación. Para

garantizar una adecuada refrigeración, compruebe

que por lo menos queden 15 cm de separación

entre las ranuras y la pared más cercana.

•

Conecte el aparato a una toma de corriente de

230 V, 50/60 Hz provista de tierra.

•

Conecte uno de los extremos del tubo de conexión

neumática en el conector del manorregulador (F).

El otro extremo debe conectarse a la red de aire a

presión.

•

Elija para el emplazamiento de la botella de

desagüe un lugar situado al menos 20 cm por

debajo de la cota inferior de la máquina. El agua

desalojada de la cuba se encuentra a temperatura

de ebullición, por lo que una caída accidental de la

botella podría originar un accidente. Por ello, cuide

que el emplazamiento de la botella de desagüe

asegure una óptima estabilidad y seguridad. Una

vez emplazada la botella, conecte el tubo de

desagüe al racor situado en la parte posterior de la

máquina, y el otro extremo introdúzcalo por el

orificio superior de la botella.

PROGRAMACIÓN

1.Accione el interruptor general (12).

2.Pulse la tecla de función (10). Esta operación

sirve para entrar en el modo de programación.

Observará como el display superior muestra la

leyenda “A0” indicando que se encuentra

activada la programación de este paso. También

en el gráfico sinóptico se encenderá la lamparita

led correspondiente al paso “A0” (tiempo de

inicio).

Español

4

3.Actúe sobre las teclas Incrementar/Decrementar (8

y 9), hasta que en el display inferior (2) aparezca

el valor del tiempo que desea para el primer paso

(tiempo de espera).

4.Vuelva a pulsar la tecla de función (10). Observará

que el display superior muestra la leyenda “A1”,

indicando que se encuentra activada la

programación de ese paso. En el gráfico sinóptico

también se encenderá la lamparita led

correspondiente al paso “A1” (tiempo de 1ª

rampa).

5.Actúe sobre las teclas Incrementar/Decrementar

(8), (9) hasta que en el display inferior (2)

aparezca el valor del tiempo que desea para el

segundo paso.

6.Pulse nuevamente la tecla de función (10). En esta

ocasión verá en el display la leyenda U1,

invitándole a programar la temperatura final de la

primera rampa.

7.Proceda de forma análoga a lo indicado

anteriormente para terminar de programar la

duración y temperatura de los diferentes pasos

que integran el programa.

8.La secuencia ordenada de los pasos que van

apareciendo en el display cuando el aparato se

encuentra en modo de programación, sería:

(A0)-Tiempo de inicio

(A1)-Tiempo de la 1ª rampa

(U1)-Temperatura de la 1ª meseta

(A2)-Tiempo de la 1ª meseta

(A3)-Tiempo de la 2ª rampa

(U2)-Temperatura de la 2ª meseta

(A4)-Tiempo de la 2ª meseta

Para abandonar el modo programación tiene tres

posibilidades: Recorrer todos los menús de

funciones; pulsar en cualquier momento la tecla

(7) (W/T), que actúa a modo de tecla de escape; o

permanecer en posición de visualización sin pulsar

ninguna tecla durante un tiempo superior a los 30

segundos. El programa se almacenará

automáticamente en memoria. Cabe señalar que

cuando se emplea la tecla (W/T) a modo de

escape, el control salta a la situación inicial,

salvando en memoria los parámetros

seleccionados.

9.Si por cualquier motivo desea que el programa

finalice en el paso “A2” (1ª meseta), sin que

ejecute el resto del programa, bastará con que se

sitúe en el paso “A3” y que después pulse la tecla

(9) decrementar hasta que en el display (2)

aparezca la leyenda “

Fin

”.

10.Después de abandonar el modo programar, para

que el aparato ejecute el programa siempre es

preciso que se realice una apertura y un cierre de

la tapa, maniobra necesaria para llenar la cuba

con agua e introducir en ella los elementos a

polimerizar. Para facilitar el manejo y

programación del aparato, el display del control

(2) muestra leyendas de ayuda para el usuario.

El mensaje de abrir tapa se representa mediante

la leyenda “

AbrA

”. El cierre de la tapa con el

mensaje “

Cerr

”. Realizada la maniobra de

apertura y cierre, aparece la leyenda “

StAr

”. A

partir de ese momento, el programa se pondrá

en marcha automáticamente cuando se pulse la

tecla (P/M) (5).

FUNCIONAMIENTO

Para que un programa de polimerización se inicie es

preciso realizar siempre una maniobra de apertura y

cierre de tapa, que permita llenar la cuba de agua e

introducir en ella los elementos que se desea

polimerizar. La secuencia de pasos que permite

ejecutar un ciclo de polimerización es la siguiente:

1.Accione el interruptor general (12). Observará

cómo parte de los elementos del panel de control

del aparato se activan indicando que la

polimerizadora R-080460 se encuentra en

funcionamiento. En esta situación inicial,

observará que el display (2) muestra la leyenda

“

AbrA

”, indicando que la máquina se encuentra

preparada para comenzar un ciclo de

polimerización.

2.Abra la tapa del aparato girando primeramente el

manubrio de seguridad (B) y desplazando luego

la corredera de cierre (A). Comprobará que la

leyenda del display ha cambiando a “

Cerr

”,

indicando de esta manera que el aparato se

encuentra a la espera de que se cierre la tapa

para iniciar el programa

3.Coloque los elementos que desea polimerizar en

la bandeja con asa que encontrará en el interior

de la cuba.

4.Llene la cuba con agua. El nivel final del agua

debe quedar unos 3 cm por debajo del borde

superior de la cuba. Vigile que el nivel del agua

no alcance en ningún caso la cota del racor de

entrada de aire a presión situado en el interior de

la cuba (parte superior). Tampoco son

recomendables niveles de agua por debajo de

los 5 cm de la bandeja de cuba, pues podrían

dejar al descubierto las resistencias de caldeo.

5.Compruebe que la botella de desagüe se

encuentra vacía. Si la botella se encuentra llena,

pueden producirse derrames de agua a

temperatura de ebullición durante la fase de

descarga.

6.Programe la polimerizadora a presión siguiendo

la instrucciones apuntadas en el apartado de

programación.

7.Cierre la tapa del aparato y asegure su fijación

actuando sobre la corredera de cierre y el

manubrio de seguridad. En ocasiones, puede

ocurrir que la junta de goma que corona el borde

Español

5

superior de la cuba del aparato, y que asegura la

correcta estanqueidad de la tapa, se haya salido

de su alojamiento. Vigile este punto con atención,

puesto que una mala colocación de la junta puede

originar fugas de vapor. En el caso de que detecte

una mala colocación de la junta, proceda a

encajarla adecuadamente en la ranura de la cuba.

8.Una vez cerrada la tapa del aparato, el mensaje

del display pasará a ser “

StAr

”, indicando que la

máquina se encuentra en disposición de comenzar

el ciclo de polimerización.

9.Cuando pulse la tecla (P/M) (5) la POLI-PLUS se

pondrá automáticamente en marcha ejecutando el

programa definido. La lamparita (6) se mantendrá

encendida, lo que indica que el programa se

ejecuta sin problemas. Así mismo, en los períodos

en que actúa la resistencia de caldeo, la lamparita

piloto (3) permanecerá encendida. Las lamparitas

del gráfico de programa (11) se irán encendiendo

paulatinamente para indicar el paso de programa

en el que nos encontramos.

Durante el curso normal del programa es posible

detener en cualquier momento el aparato si se

mantiene pulsada la tecla (P/M) (5) durante 5

segundos. Se mostrará en el display la leyenda

“dESC”

pudiéndose entonces abrir el grifo situado

en la parte trasera de la máquina para descargar

el agua de la cuba.

Si lo desea, también en cualquier momento se

puede entrar en modo programación y alterar los

parámetros del programa que se está ejecutando.

Para ello pulse la tecla de programación (10) y

proceda según lo indicado en el apartado de

programación.

Ante un eventual corte del suministro eléctrico, la

POLI-PLUS pasa al estado de paro, mostrando en

el display el mensaje de fallo de red “

FrEd

”,

cuando se reestablezca la corriente.

El manómetro (13) indica en todo momento la

presión en el interior de la cuba. Este valor puede

variarse a voluntad entre los 0 y los 6,5 bares

(presión máxima) actuando sobre el

manorregulador (F). Para ello, tire hacia arriba del

pomo del manorregulador. Girando posteriormente

el pomo en el sentido de las agujas del reloj

conseguirá aumentar la presión. Mediante un giro

en el sentido contrario al de las agujas, se

consigue una disminución de presión. Cuando

finalice con la regulación de la presión, vuelva a

enclavar el pomo del manorregulador presionando

hacia abajo. La máquina sale de fábrica regulada

a una presión de trabajo de 5 bares. A la vista de

los resultados experimentales, TALLERES

MESTRAITÚA, S.L. recomienda emplear siempre

presiones de trabajo máximas comprendidas entre

los 5 ó 5,5 bares.

10.Finalizado el programa de polimerización, la R-

080460 le avisará emitiendo un pitido. También

se encenderá la lamparita (4) del panel de

control. Pulse cualquier tecla para detener el

pitido y cerrar la admisión de aire a presión. La

máquina se encuentra lista para la descarga,

situación que aparece indicada en el display (2)

con la leyenda “dESC”. El tiempo de descarga es

de 3,5 minutos aproximadamente. Es muy

importante que no abra la tapa del aparato hasta

que no haya concluido por completo la descarga.

La salida de vapor de agua podría causarle

quemaduras.

11.Finalizada la descarga (2 minutos

aproximadamente), la leyenda del display (2)

cambia mostrando intermitentemente las

palabras “

Fin

” y “

AbrA

”, indicando de esta

manera que puede proceder a la apertura de la

tapa.

12.En circunstancias especiales, por ejemplo,

cuando la cuba se encuentra llena de agua y a

temperatura muy elevada, puede ocurrir que los

2 minutos que dura la descarga sean

insuficientes para un total vaciado de la cuba.

Por esta razón, antes de abrir la tapa de la POLI-

PLUS debe asegurarse siempre de que la

máquina no sigue descargando agua o vapor, y

que la presión indicada por el manómetro (13) es

0.

13.Cuando el programa finaliza sin ninguna

interrupción del usuario, el display (2) seguirá

mostrando intermitentemente las leyendas “

Fin

”

y “

AbrA

” incluso después de abrir la tapa. Para

reestablecer la situación normal del control,

basta con pulsar la tecla (7) (W/T).

14.Retire los elementos que acaba de polimerizar.

La bandeja suministrada con el aparato dispone

de una práctica asa que le será de utilidad para

sacarla de la cuba. Para realizar la operación,

protéjase con unos guantes y una careta, pues el

interior de la cuba se encuentra a temperatura

elevada.

15.Por último, cierre la tapa de la POLI -PLUS y

desconecte el aparato accionando el interruptor

general (12). Al cabo de un tiempo, cuando la

temperatura de la botella de desagüe haya

descendido, proceda a su vaciado.

Español

6

MANTENIMIENTO Y LIMPIEZA

Para asegurar una óptima fiabilidad y una larga vida

del aparato, le recomendamos:

•

Para evitar que restos de cera obstruyan la salida

de la cuba, limpie periódicamente (aprox. cada 5

usos) el interior de la cuba. Para ello caliente el

agua hasta una temperatura de 120 ºC.

Posteriormente, vacíe la cuba a través de la botella

de desagüe.

•

Desenchufe luego la POLI-PLUS y limpie el interior

de la cuba con un estropajo fino humedecido en

agua jabonosa, cuidando no dañar la resistencia o

la sonda de temperatura. También puede emplear

productos especialmente formulados para la

limpieza de polimerizadoras. Aclare el interior de la

cuba con abundante agua.

•

Periódicamente y en función de la dureza del agua,

limpie los restos de cal que se hayan podido

depositar en la resistencia eléctrica. Para este

cometido puede ayudarse de algún producto

descalcificante.

•

No utilice disolventes o cualquier otro producto

inflamable

•

Periódicamente es recomendable lubricar el eje de

la corredera de cierre de tapa (A), y el eje de giro

del manubrio de seguridad (B). Utilice para ello un

aceite consistente.

•

Después del uso de la polimerizadora elimine la

cera, espuma, restos de resina u otras partículas

que se puedan encontrar en las paredes de la cuba.

•

En caso de introducir en la cuba un nivel excesivo

de agua, es posible que parte de ese agua se

recircule hacia el manorregulador (F),

descargándose por unos orificios situados debajo

del pomo, que actúan como aliviaderos. Esta

situación —aunque en absoluto está

recomendada—se ha previsto en la fase de diseño

del aparato, por lo que no entraña ninguna

peligrosidad.

•

Periódicamente proceda a purgar el agua

acumulada en el filtro del manorregulador. Para ello,

afloje lentamente el tornillo situado en la parte

inferior del filtro hasta que comience a fluir el agua a

través del tornillo. Cuando el agua haya sido

drenada, proceda a reapretar firmemente el tornillo

de purga.

•

En caso de rotura de la sonda de temperatura de la

POLI-PLUS, el display (2) mostrará la leyenda “

rot

”.

Póngase en contacto de inmediato con un

distribuidor autorizado

MESTRA

.

•

Periódicamente conviene sustituir la junta de goma

que corona la cuba del aparato, para conseguir una

buena estanqueidad de la tapa. Emplee para ello

repuestos originales

MESTRA

, puesto que son los

únicos capaces de garantizar unas prestaciones

óptimas del aparato.

PRECAUCIONES

♦

Antes de conectar el aparato asegúrese de que

se trata de una toma de corriente a 230 V, 50/60

Hz dotada de tierra.

♦

Coloque la botella de desagüe en un lugar que

garantice su estabilidad ante vuelcos fortuitos.

Antes de comenzar un nuevo ciclo, asegúrese de

que la botella de desagüe se encuentra vacía. No

conecte el tubo de desagüe a otro recipiente

distinto de la botella suministrada con el aparato.

♦

Antes de poner en funcionamiento el aparato,

asegúrese de que el tapón de la botella de

desagüe está bien roscado, y que la conexión del

tubo con el tapón es firme.

♦

No permita que niños ni personal no cualificado

manipulen el aparato ni la botella de desagüe.

♦

Siempre que introduzca o saque muflas en el

interior de la cuba protéjase adecuadamente.

Utilice guantes y careta de protección.

♦

Abra la tapa del aparato con precaución. La salida

brusca del vapor de agua acumulado en la cuba

podría causarle quemaduras.

♦

Cierre siempre la tapa del aparato con los dos

elementos de seguridad (corredera (A) y

manubrio de seguridad (B)). Durante el

funcionamiento de un programa, no intente abrir

nunca la tapa.

♦

No supere nunca los 6,5 bares de presión. Se

recomiendan presiones máximas de trabajo en

torno a los 5 ó 5,5 bares.

♦

Al finalizar la ejecución de un programa, espere a

que en el display aparezca alternativamente la

leyenda “

Fin

” “

AbrA

”, para proceder a la apertura

de la tapa. Tenga además la precaución de

comprobar que la máquina no sigue descargando

agua o vapor a la botella, y que la presión

indicada por el manómetro (13) es 0.

♦

No abra nunca la tapa durante la fase de

descarga (“

dESC

”) o mientras el apa rato se

encentra ejecutando un programa.

♦

Evite que el nivel de agua en la cuba sea inferior

a los 5 cm desde el fondo de la bandeja, o que se

encuentre por encima de los 3 cm del borde

superior de la cuba.

CARACTERÍSTICAS TÉCNICAS

Alto:320 mm

Ancho:310 mm

Fondo:395 mm

Peso:20 kg

Diámetro de cuba:135 mm

Fondo de cuba:115 mm

Presión máxima:6,5 bares

Temperatura máxima: 135 ºC

Tensión:230 V, 50/60 Hz

Potencia:1000 W

English

7

GB

The R-080460 POLI-PLUS unit is a practical

pressurized polymerizer which incorporates a

control panel in order to programme a sequence of

polymerization temperatures and time, according to

what is preset by the user. Therefore, any

polymerization procedure is made up of the

following 5 steps:

•A period when the water inside the container is

at room temperature and atmospheric pressure

(initial period).

•A period when the water temperature inside the

container is increases linearly, until it reaches a

final temperature set by the user (period of 1st

slope). At the beginning of this phase, the inside

of the container is pressurized at a value set by

the user, which is maintained throughout the

entire programme.

•A period when the water temperature inside the

container remains constant, taking the final

value used in the previous step (temperature

reaches 1st plateau).

•A period when the water temperature inside the

container vanes linearly, until it reaches the final

temperature set by the user (period of 2nd

slope).

•A period when the water temperature inside the

container remains constant taking the final value

acquired in the previous step (temperature

reaches 2nd plateau).

Once this sequence of steps is finished, the unit will

disconnect automatically and let off a warning beep

for one minute, and the water inside the container

is discharged into a drainage bottle, also re-

establishing the atmospheric pressure. The

duration of each step may be set from 0 to 99

hours and 59 minutes. Re final temperatures of

each of the two plateaus may be regulated

between 0 ºC and 135 ºC.

In order to show the user the true status and

evolution of the programme, the control panel on

the R-080460 pressurized polymerizer comes with

a synoptic graph (11). The LED lights indicate at all

times the step being taken and the temperatures

reached. The unit is also equipped with two digital

Displays. The upper one (1) indicating the

instantaneous water temperature inside the

container. The lower Display (2) indicating the time

remaining to the end of the programme.

Both displays have a double function, which is

activated by pressing (W/T) (7). By pressing this

key, the upper display (1) shows the temperature

the user has programmed as the final value o the

step (assigned temperature). The lower display

shows the time left to finish the step being

executed.

PROGRAMMING

Programming a water heating law inside the

container is very simple. In order to do this, we

recommend you carry out the following steps:

1.Activate the main switch (12).

2.Press function key (10). This operation enables

you to enter into the programming mode. You

will notice the upper display reads “A0”

indicating that the programming of this step

has been activated. The LED light on the

synoptic graph will turn on which corresponds

to “A0” (starting time).

3.Press the increase/decrease keys (8), (9), until

the lower display (2) shows the time value you

wish to use for the first step. (Standby time).

4.Press function key (10) again. You will notice

the upper display reads “A1”, indicating that the

programming for this step has been activated.

The LED light on the synoptic graph will turn on

which corresponds to “Al” (period for the 1st

slope).

5.Press the increase/decrease keys (8), (9) until

the lower display (2) shows the time value you

wish to use for the second step.

6.Press function key (10) again. This time you

will read U1 on the display, asking you to

programme the final temperature of the first

slope.

7.Proceed the same above to complete the

programming of the duration and temperature

of the different steps m the programme.

8.The ordered sequence of the steps which will

appear on the display when the unit is in

programme mode, is as follows:

(A0)-Starting time

(A1)-1st slope period

(U1)-Temperature of 71st plateau

(A2)-Time of 1st plateau

(A3)-2nd slope period

(U2)-Temperature of 2nd plateau

(A4)-Time of 2nd plateau

9.You have three ways of leaving the

programming mode: Go through ah of the

function menus; press key (7) (W/T) at any

time, which acts as an escape key; or remain

in visualization position without pressing any of

the keys for a period of more than 30 seconds,

the programme will be automatically stored in

memory. We should point out that when key

(W/T) is used as an escape key, the control

English

8

jumps into start situation, saving the selected

parameters in memory.

10.If for some reason you wish the programme to

finish m step “A2’ (1st plateau), without running

the rest of the programme, just go to step “A3”

and then press key (9) decrease until the

display (2) shows the word ‘Fin”.

11.After leaving the programming mode, in order

for the unit to run the programme you need to

open and close the lid, this is required in order

to fill the container with water and to insert the

elements you wish to polymerize. In order to

facilitate handling and programming the unit,

the control display (2) gives the user

assistance messages. the lid opening message

is represented by the word “AbrA”. Close the

lid with the message on “Cerr”. Once the

opening and closing manoeuvre has been

completed, the word “StAr” will appear. As of

this moment, the programme will start-up

automatically when the (P/M) (5) key is

pressed.

INSTALLING THE UNIT

•Carefully unpack the R-080460 pressurized

polymerizer. The accessories will include a

drainage bottle (which does not appear in the

figure) with its connection pipe, and a

connection pipe for the pressurized air network.

You will also find two trays inside the container.

One of these has a handle and is used to easily

take out the polymerized elements. The other

has no handle, and is used as a protection for

the heating resistance. Place the tray without a

handle on the bottom of the container just above

the resistance.

•Place the unit upon a horizontal, flat and rigid

base, far from heat or vibrating sources. Make

sure that a connection to the pressurized air

network is close by. The sides of the unit are

provided with ventilation grooves. In order to

guarantee appropriate ventilation, make sure

there is at least 15 cm between the grooves and

the nearest wall.

•Connect the device to a 220 V, 50/60 Hz

electricity outlet, provided with an earth

connection.

•Connect one of the pneumatic tube connection

ends to the manoregulator connector (F). The

other end should be connected to the

pressurized air network.

•When locating the drainage bottle be sure to

choose a place at least 20 cm below the lowest

part of the unit. The water discharged from the

container is at boiling temperature, therefore an

if the bottle were to fall it may cause an accident.

Therefore, make sure the drainage bottle is

placed in a location which has optimum stability

and safety. Once the bottle has been placed,

connect the drainage tube to the connector

located on the back of the unit, and insert the

other end through the upper bale of the bottle.

HOW TO PROGRAMME

Let’s suppose we want to programme the

polymerizer in order to carry out the following

steps:

1.Start time-We want the polymerizer to start

operating without a waiting time.

2.Period of the 1st slope-We want the water

inside the container to reach a temperature of

1300 in 1 hour.

3.Period of the 1st plateau-We want the water

inside the container to continue at 130 ºC for 5

minutes.

4.Period of the 2nd slope-Subsequently, the

water temperature inside the container will

descend to 100 ºC in 1 hour.

5.Period of the 2nd plateau-When the 100 ºC are

reached, the water will be kept at this

temperature for 30 minutes. At this time, the

programme will be completed and the

polymerizer will let off a signal and discharge the

water from the container. Light (4) will also turn

on.

The programmng steps are as follows:

1.Press key (10) to enter into programme mode.

“A0” will start blinking.

2.Press the decrease key (8), to place the start

time at zero.

3.Press key (10), to enter into the next step. The

“A1” lamp will start to blink.

4.Press keys (8) and (9) increase/decrease, to

select 1 hour as the 1st slope period.

5.Press key (10) to go onto the next step. “U1” will

start to blink.

6.Press keys (8) and (9) increase/decrease to

select the value of 130 ºC, as the temperature

value during the 1st plateau.

7.Press key (10) to go onto the next step. The

“A2” light will turn on.

8.Press keys (8) and (9) increase/decrease, to

select 5 minutes as the period for the 1st

plateau.

9.Press key (10) to go onto the next step. Light

“A3” will turn on.

10.Press keys (8) and (9) increase/decrease, to

select 1 hour as the period for the 2nd slope.

11.Press key (10) to go onto the next step. The

“U2” light will turn.

12.Press keys (8) and (9) increase/decrease to

select the value of 100 ºC, as the temperature

value during the 2nd plateau.

English

9

13.Press key (10) to go onto the next step. Light

“A4” will turn on.

14.Press keys (8) and (9) increase/decrease, to

select 30 minutes as the period for the 2nd

plateau.

15.Press the function key (10) or (7) (W/T) to

record the programme you’ve just carried out in

the memory.

From now on when you open and close the lid, the

display (2) will show the word “STAr”. Then press

key (5) (P/M), and the R-080460 pressurized

polymerizer will start up automatically running the

programme.

OPERATION

In order for the polymerization programme to

commence it is always necessary to open and

close the lid, enabling you to fill the container with

water and insert the elements you wish to

polymerize. The steps taken in order to execute a

polymerization cycle is as follows:

1.Activate the main switch (12). You will notice

how part of the unit’s control panel elements are

turned on indicating that the R-080460

polymerizer is ¡u operating mode. In this initial

situation, you will notice that the display (2)

shows the word “AbrA”, indicating that the unit is

ready to commence the polymenzation cycle.

2.Open the lid of the unit first of all by turning the

safety handle (B) and then moving the sealing

slide (A). You will notice that the word on the

display has changed to “Cerr”, indicating that the

unit is waiting for the lid to be closed before

commencing the programme.

3.Place the elements you wish to polymerize in

the tray with the handle located inside the

container.

4.Fill the container with water the final level of the

water should come up to 3 cm below the top

edge of the container. Make sure the water level

in no case reaches the pressurized air inlet

connector level which is located inside the

container (upper part). We do not recommend

water levels below 5 cm of the container tray, as

they may leave the heating resistances

uncovered.

5.Check to see if the drainage bottle is empty. If

the bottle is full, water may overflow at boiling

temperature during the discharge phase.

6.Programme the pressurized polymerizer by

following the instructions indicated in the

programming section.

7.Close the lid and make sure it is fastened by

using the sealing slide and safety handle.

Sometimes, the rubber seal placed on the upper

edge of the container, which guarantees the

water tightness of the lid, may be displaced. Pay

special attention to this, because if the seal is

incorrectly placed this may cause steam to leak

out. If you detect the seal is incorrectly placed,

proceed to fit it correctly in the container groove.

8.Once the lid is closed, the display message will

read “StAr”, indicating the unit is ready to

commence the polymerization cycle.

9.When you press the (P/M) (5) key the POLY-

PLUS unit will automatically start-up executing

the programme which has been defined. Light

(6) will stay turned on, which indicated the

programme is being executed without any

problems. Light (3) will also remain turned on

when the heating resistance is implemented.

The programme’s graph lights (11) will gradually

turn an indicating the phase of the programme

you are in.

During the normal running of the programme it is

possible to interrupt the unit by pressing the

(P/M) (5) key for 5 seconds.

The display will show the message “dESC”

meaning you can open the cock to unload the

water from the tank.

You may also, at anytime enter into the

programming mode and alter the parameters of

the programme being executed. In order to do

this press the programming key (10) and

proceed according to the programming section.

During a power supply failure, the POLY-PLUS

goes on to aff status, the display reading “FrEd”,

when the power supply is returned.

The pressure gauge (13) indicates at all times

the pressure inside the container. This value

may be changed at will between 0 and 6.5 bars

(maximum pressure) by using the manoregulator

(F). In order to do this, pull the manoregulator

knob upwards. Then by turning the knob

clockwise you will increase the pressure. The

pressure is reduced by turning the knob anti-

clockwise. Once you have completed the

pressure regulation procedure, lock the

manoregulator knob into position by pressing

downwards. The unit is delivered with a

regulated working pressure of 5 bars. From the

experimental results achieved, TALLERES

MESTRAITUA, S.L. recommends you always

maximum working pressures of between 5 to 5.5

bars.

10.Once the polymerization programme has been

completed, the R-080460 will warn you be

letting off a beep. Light (4) on the control panel

will also turn on. Press any key to stop the

beep and close the air intake. The machine is

ready for download. The display will show the

message "dESC". The discharge time takes

approximately 3.5 minutes. It is of utmost

importance not to open the lid of the unit until

English

10

the discharging procedure has been entirely

completed. As the water steam released may

cause bums.

11.Once the discharge procedure has been

completed (approximately 2 minutes), the

display (2) will intermittently read “Fin” and

“AbrA”, indicating that you may open the lid.

12.In special circumstances, for example, when

the container is full of water and at a very high

temperature, the 2 minute discharge time may

be insufficient to completely empty the

container. Therefore, before opening the lid of

the POLY-PLUS unit always make sure the

machine has stopped discharging water or

steam, and that the pressure on the pressure

gauge (13) is 0.

13.When the programme is completed without any

user interruptions, the display (2) will continue

to intermittently read “Fin” and “AbrA” even

after the lid has been opened. In order to

return to regular control status, just press key

(7) (W/T).

14.Take out the elements you have just

polymerized. the tray supplied with the unit has

a practical handle which is of great use when

taking it out of the container. When carrying

out this operation, wear gloves and a mask,

because the inside of the container is at a high

temperature.

15.Finally, close the lid of the POLY-PLUS unit

and disconnect it by pressing the main switch

(12). After a period of time, when the drainage

bottle temperature has decreased, you may

empty it.

MAINTENANCE AND CLEANING

In order to guarantee the optimum reliability and a

long working life of the unit, we recommend the

following:

•In order to avoid wax obstructions, regularly

clean the interior of the container (approx. after

every 5 uses). In order to do this heat the water

to 120 ºC. Then, empty the container by means

of the drainage bottle.

•Then unplug the POLI-PLUS and clean the

inside of the container with a fine swab dipped in

soapy water, taking care not to damage the

resistance nor the temperature probe. Specially

prepared products may also be used to clean

polymerizers. Rinse the inside of the container

with plenty of water.

•Periodically and depending upon the hardness

of the water, clean the lime remains which may

be deposited on the electric resistance. A

decalcifying product may be used for this work.

•Do not use solvents or any other inflammable

product.

•We recommend lubricating the shaft of the lid

seal slide (A), and the rotation shaft of the safety

handle (B) regularly. Use a thick oil.

•After using the polymerizer get rid of the wax,

foam, resin remains or other particles which may

be found on the container walls

•If too much water is placed in the container, it’s

possible that pan of this water may recirculate

towards the manoregulator (F), being

discharged through some holes located under

the knob, these act as spillways. This situation -

although not at all recommended-has been

foreseen in the unit design phase, it is therefore

not at ah dangerous.

•Regularly purge the water accumulated in the

manoregulator filter. In order to do this, slowly

loosen the screw located on the lower part of the

filter until water commences to flow through the

screw. When the water has been purged,

proceed to firmly re-tighten the purging screw.

•If the temperature probe on the POLY-PLUS

breaks, display (2) will show the word “rot”.

Immediately get in touch with a MESTRA

authorized dealer.

•It is convenient to regularly replace the rubber

seal on the crown of the unit’s container, in order

to achieve a good lid tightness. In order to do

this use MESTRA original spare parts, given that

these are the only ones able to guarantee an

optimum performance of the unit.

PRECAUTIONS

♦Before connecting the unit make sure the

connection plug runs on 220 V, 50/60 Hz

including an earth connection.

♦Place the drainage bottle in a stable location

which prevents it from overturning by mistake.

Before commencing a new cycle, make sure the

drainage bottle is empty. Do not connect the

drainage pipe to another container different

from the bottle supplied with the unit.

♦Before starting up the unit, make sure the

drainage bottle cap it tightly screwed on, and

that the connection between the pipe and the

cap is tight.

♦Do not allow children not unqualified personnel

to handle the unit nor the drainage bottle.

English

11

♦Protect yourself appropriately when placing or

taking out muffles from inside the container.

Always use gloves and a protection mask.

♦Open the lid of the unit carefully. Re sudden

release of steam from the accumulated water in

the container may bum.

♦Always close the lid of the unit with the safety

components (slide (A) and safety handle (B)).

Never open the lid when a programme is

running.

♦Do not exceed 6.5 bars of pressure. The

recommended maximum operating pressures

are approximately 5 or 5.5 bars.

♦When a programme has been completed, wait

until the display alternatively shows the word

“Fin” “AbrA”, in order to open the lid. Also take

care and check that the unit does not continue

to discharge water or steam from the bottle, and

that the pressure indicated on the pressure

gauge (13) is 0.

♦Do not open the lid during the discharge phase

(“dESC”) or while the unit is running a

programme.

♦Make sure the water level of the container is

never less that 5 cm from the bottom of the tray,

or over 3 cm from the upper edge of the

container.

TECHNICAL FEATURES

Height:320 mm

Width:310 mm

Depth:395 mm

Weight:20 kg

Container diameter:135 mm

Depth of container:115 mm

Maximum Pressure:6.5 bars

Maximum temperature:135 ºC

Voltage:220 V, 50/60 Hz

Power:1000 W

Français

12

F

La R-080460 POLI-LUS est un polymérisateur

à pression spécialement pour les travaux de prothèse

dentaire. Il dispose d’un panneau de contrôle pour

programmer une séquence de températures et le

temps de polymérisation parfaitement paramétrable

par l’utilisateur.

Ainsi, quelque soit la polymérisation choisie, la

programmation s’établira selon les 5 étapes

suivantes:

•Un temps pendant lequel l’eau à l’intérieur de la

cuve restera à température ambiante et sous

pression atmosphérique (temps d’attente).

•Un temps pendant lequel la température de l’eau

montera de manière linéaire, jusqu’à atteindre une

température finale établie par l’utilisateur (temps

de la première montée en température). Au début

de cette phase, la cuve est pressurisée à une

valeur définie par l’utilisateur et le restera durant

tout le programme.

•Un temps de maintien en température de l’eau à

l’intérieur de la cuve à la température établie par

l’étape précédente. (température du premier

pallier).

•Un temps pendant lequel la température de l’eau

montera de manière linéaire, jusqu’à atteindre une

température finale établie par l’utilisateur (temps

de la deuxième montée en température).

•Un temps de maintien en température de l’eau à la

température établie par l’étape précédente

(température du deuxième pallier).

Une fois finalisées toutes les étapes de ce

programme, l’appareil se déconnectera

automatiquement en émettant auparavant un signal

acoustique pendant une minute et l’eau de la cuve se

videra dans une bouteille de vidange. La pression

atmosphérique se rétablira également. Les durées de

chacune des étapes sont paramétrables dans un

temps compris entre 0 et 99 heures et 59 minutes. La

température des paliers peuvent être paramétrées

entre 0 ºC et 135 ºC.

Pour indiquer à l’utilisateur la situation et l’évolution

réelle du programme le polymérisateur R-080460

dispose d’un panneau de contrôle et d’un graphique

Synoptique (11). Les témoins lumineux LED

indiquent à tout moment l’étape qui est en train de se

dérouler et la température atteinte. L’appareil dispose

également des cadrans digitaux. Le cadran supérieur

(1) indique la température actuelle de l’eau à

l’intérieur de la cuve. Le cadran inférieur (2) indique

le temps qu’il manque pour la fin du programme.

Chaque cadran est doté d’une double fonction qui

s’active en appuyant sur la touche (W/T) (7). En

actionnant su cette touche le cadran supérieur (1)

indique la température finale du pallier en cours que

l’utilisateur a programmé. Le cadran inférieur (2)

indique le temps qu’il reste pour finir le pallier en

cours.

PROGRAMMATION

La programmation de la chauffe de l’eau à

l’intérieur de la cuve est très simple et rapide. Pour

cela, veuillez suivre les indications suivantes:

1.Actionner l’interrupteur général (12).

2.Appuyer sur la touche de fonction (10). Cette

opération sert à entrer en mode

programmation. Vous constaterez que le

cadran supérieur indiquera la légende “A0”.

Cela voudra dire que l’étape “A0” (temps

d’attente) est activée. Dans le tableau

synoptique le témoin lumineux “A0” s’allumera.

3.Agissez sur les touches + et –(8) et (9) jusqu’à

atteindre dans le cadran inférieur le temps

d’attente souhaité.

4.Appuyer à nouveau la touche de fonction (10).

Vous constaterez que le cadran supérieur

indiquera la légende “A1”. Cela voudra dire que

l’étape “A1” (temps de montée en température

du premier pallier) est activée. Dans le tableau

synoptique le témoin lumineux “A1” s’allumera.

5.Agissez sur les touches + et –(8) et (9) jusqu’à

atteindre dans le cadran inférieur (2) le temps

de montée en température du premier pallier

souhaité.

6.Appuyer à nouveau la touche de fonction (10).

Vous constaterez que le cadran supérieur

indiquera la légende “U1”. Cela voudra dire que

l’étape “U1” (température du premier pallier) est

activée. Dans le tableau synoptique le témoin

lumineux “U1” s’allumera.

7.Agissez sur les touches + et –(8) et (9) jusqu’à

atteindre dans le cadran inférieur (2) la

température du premier pallier souhaitée.

8.Procédez de manière analogue pour finir votre

programmation des temps et des températures.

L’ordre de programmation qui apparaîtront dans

le cadran supérieur est le suivant:

(A0) -Temps d’attente.

(A1) -Temps de montée en température du

premier pallier.

(U1) -Température du premier pallier.

(A2) -Temps de maintien en température du

premier pallier.

(A3) -Temps de montée en température du

deuxième pallier.

(U2) -Température du 2e pallier.

(A4) -Temps de maintien en température du

deuxième pallier.

Français

13

9.Pour abandonner le mode programmation vous

avez 3 possibilités: Parcourir tous les menus de

fonctions; appuyer à n’importe quel moment la

touche (7) (W/T) qui fait fonction de touche de

sortie; ou bien rester en position de visualisation

sans toucher aucune touche pendant un temps

supérieur à 30 secondes. Le programme restera

mémorisé automatiquement. Il est important de

signaler que lorsqu’on utilise la touche (W/T) en

mode de sortie du programme, le contrôle passe

à la situation initiale, mémorisant toutes les

données sélectionnées.

10.Si pour une raison quelconque vous désirez que

le programme s’arrête à l’étape “A2” (premier

pallier) sans que le reste du programme

s’exécute, il vous suffit de vous placer dans

l’étape “A3” et ensuite d’utiliser la touche –(9)

jusqu’à ce qu’apparaisse la légende “Fin” dans le

cadran (2).

11.Après avoir abandonné le mode programmation,

pour faire partir le programme il est nécessaire de

procéder à une ouverture et une fermeture du

couvercle manœuvre nécessaire pour remplir la

cuve d’eau et pour introduire les éléments à

polymériser. Pour faciliter la manipulation et la

programmation de l’appareil, le cadran de

contrôle (2) montre des légendes d’aide pour

l’utilisateur. Le message “ouvrir le couvercle” est

ainsi représenté par la légende “AbrA”. La

fermeture est ordonnée par la légende “Cerr”.

Une fois réalisée l’ouverture puis la fermeture du

couvercle, c’est la légende “StAr” qui apparaîtra.

A partir de ce moment, le programme se mettra

en marche automatiquement quand on appuiera

sur la touche (P/M) (5).

INSTALLATION

•Déballez soigneusement la polymériseuse à

pression MESTRA R-080460. Vous trouverez

comme accessoires un bidon de vidange avec son

tube de connexion ainsi qu’un tube de connexion

au réseau d’air comprimé.

Vous trouverez également à l’intérieur de la cuve

deux plateaux. L’un d’entre eux est pourvu d’une

anse et sert à retirer facilement les éléments à

polymériser. L’autre plateau ‘a pas d’anse. Elle a

fonction de protection de la résistance de chauffe.

Placer ce plateau au fond de la cuve juste au-

dessus de la résistance.

•Choisissez comme emplacement une surface

plane, éloignée de toute source de chaleur ou de

vibrations. Il est recommandé de choisir un endroit

suffisamment ventilé. Veillez à installer la machine

près d’une connexion d’air comprimé. Laissez un

espace latéral d’environ 15 cm pour que les grilles

d’aération puissent remplir leur fonction).

•Connecter l’appareil dans une prise de courant

de 220V, 50/60 Hz pourvue d’une prise de terre.

•Connecter l’une des extrémités du tube de

connexion d’air dans la prise du manorégulateur

(F). L’autre extrémité doit être raccordée à une

prise d’air comprimé.

•Choisissez comme emplacement pour le bidon

de vidange un en droit situé au moins 20 cm en

dessous de la partie la plus basse de la cuve.

L’eau qui sortira de la cuve se trouvera à une

température proche de l’ébullition. Une chute du

bidon de vidange pourrait être à l’origine

d’accidents. Choisissez comme emplacement

du bidon un endroit suffisamment stable et sûr.

Une fois le bidon placé, raccordez le tube de

vidange au raccord situé dans la partie

postérieure de la machine, l’autre extrémité du

tube devra être introduite dans l’orifice supérieur

du bidon.

FONCTIONNEMENT

Pour mettre en marche un programme de

polymérisation il est nécessaire de réaliser

systématiquement une manœuvre d’ouverture et

de fermeture du couvercle. Cela permettra de

remplir la cuve d’eau et d’introduire les éléments à

polymériser. La séquence des étapes qui permet

de réaliser le cycle de polymérisation est la

suivante:

1.Actionnez l’interrupteur général (12). Vous

constaterez qu’une partie des éléments du

panneau de contrôle de l’appareil s’activent

indiquant que la Polymériseuse MESTRA R-

080460 est prête à fonctionner. Dans cette

position initiale le cadran (2) montre la légende

“AbrA” (ouvrir), ce qui signifie que la machine

est prête à commencer un cycle de

polymérisation.

2.Ouvrez le couvercle en tournant dans un

premier temps la manette de sécurité (B) et en

déplaçant la clavette de fermeture (A). Vous

constaterez que la légende du cadran a changé

“Cerr” (fermer), indiquant ainsi que l’appareil se

trouve dans l’attente de fermeture de la cuve

pour commencer le programme.

3.Placer les éléments que vous désirez

polymériser à l’intérieur de la cuve.

4.Remplissez la cuve d’eau. Le niveau final de

l’eau doit être 3 cm en dessous du bord

supérieur de la cuve. Surveillez que le niveau

d’eau n’atteigne en aucun cas le niveau du

raccord d’entrée d’air situé dans la partie

intérieure de la cuve (partie supérieure). Des

niveaux d’eau inférieurs a 5 cm du fond de la

cuve ne sont pas non plus recommandés. Les

résistances de la cuve pourraient se trouver

endommagées.

Français

14

5.Vérifiez que le bidon de vidange est vide. Si le

bidon venait à se trouver plein, il pourrait se

produire des débordements d’eau à une

température élevée durant la phase de vidange.

6.Programmez la polymériseuse en suivant les

instructions.

7.Fermez le couvercle de l’appareil et assurez-vous

sa parfaite étanchéité en actionnant le levier

coulissant de fermeture et la clavette de sécurité.

Dans certains cas, il peut arriver que le joint en

caoutchouc placé sur le bord supérieur de la cuve

et qui assure la parfaite étanchéité de celle-ci, soit

sorti de sa rainure. Surveillez ce point avec

attention. Une mauvaise étanchéité peut

provoquer des projections de vapeur. Dans le cas

d’une telle anomalie, placez correctement le joint

en caoutchouc tout au long de la rainure.

8.Une fois le couvercle fermé, le message du

cadran doit être “StAr”. Ce qui indique que la

machine est prête à initier le cycle de

polymérisation.

9.Lorsque vous appuierez sur la touche (P/M) (5),

la Poli-Plus se mettra automatiquement en

marche commençant le cycle. Le témoin lumineux

(6) restera allumé, ce qui indique un déroulement

correct du programme. Le témoin lumineux (3)

restera allumé dans les périodes ou la résistance

de chauffe marchera. Les témoins lumineux du

graphique (11) s’allumeront au fur et à mesure

que les étapes se dérouleront. Durant le

déroulement du programme il est possible de

l’arrêter à tout moment. Pour cela, il faut maintenir

la touche (P/M) (5) appuyée pendant 5 secondes.

Le contrôle affichera le message "dESC": signifie

que vous pouvez ouvrir le robinet pour décharger

l'eau.

Si vous le désirez également, à n’importe quel

moment vous pouvez entrer en mode

programmation et changer les paramètres du

programme qui est en train de se dérouler. Pour

cela appuyer sur la touche de programmation (10)

et procédez comme indiqué dans le chapitre

programmation. Face à une éventuelle coupure

de courant, la Poli-Plus de chez MESTRA se met

en phase d’arrêt. Le cadran indiquera alors le

message “Fred”, lorsque le courant se rétablira.

Le manomètre (13) indique à tout moment la

pression à l’intérieur de la cuve. Cette valeur peut

varier à volonté entre 0 et 6,5 Bars (pression

maximale) en agissant sur le manorégulateur (F).

Pour cela tirez le bouton supérieur du manomètre

vers le haut. Tournez ensuite le bouton dans le

sens des aiguilles d’une montre pour augmenter

la pression. Pour diminuer la pression, tourner le

bouton en sens inverse. Lorsque vous aurez fini

de régler la pression, rabattez le bouton supérieur

vers le bas. La machine est livrée d’usine à une

pression de 5 Bars. En tenant compte des

résultats expérimentaux, TALLERES

MESTRAITUA S.L. vous recommande d’utiliser

la machine à une pression comprise entre 5 et

5,5 Bars.

10.Au terme du cycle de polymérisation, la Poli-

Plus vous avertira en émettant un signal

acoustique. Le témoin lumineux (4) s’allumera.

Appuyez sur une touche touche pour arrêter le

bip et fermer l'entrée d'air. La machine est prête

pour le téléchargement. l'afficheur indique

"dESC". Commencera alors la phase de

vidange de la cuve (légende “dESC” sur le

cadran (2) ). Le temps de vidange est de 3.5

minutes environ. Il est très important de ne pas

soulever le couvercle jusqu’à ce que cette

opération ne soit pas complètement terminée.

L’émanation de vapeur pourrait provoquer des

brûlures.

11.A la fin de la vidange la légende sur le cadran

(2) marque par intermittence “Fin” et “AbrA” ( fin

et ouvrez). Vous pouvez ouvrir le couvercle.

12.Dans des circonstances spéciales, par

exemple lorsque la cuve se trouve pleine d’eau

à une température très élevée, il peut arriver

que 2 minutes ne soient pas suffisantes pour

vider complètement la cuve. Pour cette raison,

avant de procéder à l’ouverture du couvercle,

vous devez vous assurer que la machine a fini

de réaliser la vidange et que le manomètre

marque la pression 0 (13).

13.Lorsque le programme est terminé sans aucune

interruption de la part de l’utilisateur le cadran

(2) continuera à marquer par intermittence les

légendes “Fin” et “AbrA” même après

l’ouverture du couvercle. Pour rétablir la

situation normale du contrôle, il suffit d’appuyer

sur le bouton (7) (W/T).

14.Retirer les éléments que vous venez de

polymériser. Le plateau fourni avec la machine

est pourvu d’une anse pratique pour sortir les

travaux de la cuve. Pour réaliser cette opération

protégez-vous avec des gants et un masque.

L’intérieur de la cuve est à une température

élevée.

Français

15

15.Vous pouvez refermer le couvercle de la Poli-Plus

et déconnecter l’appareil en actionnant

l’interrupteur général (12). Au bout d’un moment,

lorsque la température de l’eau vidangée sera

descendue videz le bidon de vidange.

MAINTENANCE ET ENTRETIEN

Pour une fiabilité optimale de la machine et pour une

plus grande longévité veuillez tenir compte des

recommandations suivantes:

•Nettoyer périodiquement (environ toutes les 5

utilisations) l’intérieur de la cuve. Pour cela,

chauffer l’eau à 120 ºC. Videz ensuite la cuve

dans le bidon de vidange. Débranchez ensuite la

Poli-Plus et nettoyer l’intérieur de la cuve avec un

chiffon doux humide à l’eau savonneuse, attention

de ne pas endommager la résistance ou le

thermo-sonde. Vous pouvez également employer

des produits spécialement conçus pour le

nettoyage de la Poli-Plus. Rincer à l’eau.

•Périodiquement et en fonction du niveau calcaire

de l’eau nettoyez les restes de calcaire qui

pourraient se déposer sur la résistance. Aidez-

vous d’un produit anticalcaire.

•N’utilisez pas de dissolvants ou de produits

inflammables.

•Périodiquement veillez à lubrifier la glissière de

fermeture du couvercle (A), ainsi que l’axe de

fermeture du levier de sécurité (B). Utilisez une

huile consistante.

•Après l’utilisation de la polymériseuse, éliminer les

cires, la mousse et autres particules qui pourraient

se déposer dans les parois de la cuve.

•Dans le cas ou l’on ait introduit un niveau d’eau

trop important il est possible qu’une partie de cette

eau se retrouve dans le manorégulateur qui

l’évacuera par des orifices situés sous le bouton

supérieur qui agissent comme des échappatoires.

Cette situation, bien que proscrite a été prévue

pour ne pas endommager la machine.

•Veillez àpurger de temps en temps l’eau

accumulée dans le filtre du manorégulateur. Pour

ce faire, dévissez lentement la vis située dans la

partie inférieure du filtre jusqu’à ce que l’eau

commence à s’évacuer. Une fois que l’eau sera

évacuée resserrer fermement la vis de purge.

•Dans le cas de rupture de la thermo sonde, le

cadran (2) affichera la légende “rot”. Mettez-vous

en contact avec un distributeur agréé MESTRA.

Il est également conseillé de changer périodiquement

le joint en caoutchouc du couvercle pour conserver

une étanchéité parfaite de couvercle. Utiliser

uniquement les éléments d’origine MESTRA.

PRECAUTIONS

♦Avant de connecter la machine, assurez-vous

que la prise électrique est de 230V, 50/60Hz

reliée à la terre.

♦Ne pas autoriser la manipulation de cet appareil

aux enfants ni même au personnel non qualifié.

♦

Choisissez un emplacement stable plat rigide et à

niveau, éloigné de toute source de chaleur ou de

vibrations. Eliminez toute possibilité de

renversement de la machine. Veiller à laisser un

espace de plus de 15cm entre le mur ou autre

objet et les grilles d’aération de la machine.

♦Protégez-vous lors de la manipulation de la

machine: utilisez gants et masque.

♦Levez le couvercle avec précaution. La

projection soudaine de vapeur peut provoquer

des brûlures.

♦Placez le bidon de vidange dans un endroit

garantissant une parfaite stabilité. Avant de

recommencer un programme assurez-vous que

le bidon est vide. Ne branchez pas le tube de

vidange à un récipient autre que celui qui vous

est fourni.

♦Avant de mettre en marche l’appareil, assurez-

vous que le bouchon du bidon est bien vissé et

que la connexion du tube de vidange est bonne.

♦Fermez systématiquement le couvercle de la

machine avec les deux éléments de sécurité.

Pendant le fonctionnement de la machine

n’essayez pas de soulever le couvercle.

♦Ne dépassez jamais une pression de 6,5 bars.

La pression recommandée se situe entre 5 et

5,5 Bars.

♦A la fin du programme attendez que le cadran

indique alternativement les légendes «Fin » et

“AbrA“, avant de procéder à l’ouverture du

couvercle. Vérifier également que la machine

ne soit pas en train de vidanger et que la

pression soit égale à 0.

♦Ne soulevez jamais le couvercle pendant la

vidange de la machine.

♦Evitez que le niveau d’eau dans la cuve ne soit

inférieur à 5 cm à partir du bas de la cuve et se

situe à moins de 3 cm par rapport au bord

supérieur de la cuve.

CARACTERISTIQUES TECHNIQUES

Hauteur 320 mm

Largeur 310 mm

Profondeur 395 mm

Poids 20 kg

Diametre de la cuve 135 mm

Pression maximale 6,5 Bars

Temperature maximale de travail 135 ºC

Tension 230V, 50/60 Hz

Puissance 1000 W

Português

16

P

A R-080460 POLI-PLUS é uma prática

polimerizadora, dotada de um painel de controlo

para programar uma sequência de temperaturas e

de tempos de polimerização, conforme a uma

norma preestabelecida pelo usuário. A

polimerizadora tem os 5 passos seguintes:

•Um tempo durante o qual a água no interior da

cuba fica à temperatura ambiente e à pressão

atmosférica (tempo de inicio).

•Um tempo durante o qual a temperatura da

água no interior da cuba vai subindo de forma

linhal, até alcançar uma temperatura final

estabelecida pelo usuário (tempo de 1ª subida).

No princípio desta fase, o interior da cuba

pressuriza-se a um valor definido pelo usuário,

que se mantém durante todo o programa.

•Um tempo durante o qual a temperatura da

água no interior da cuba permanece constante,

tomando o valor final adquirido no passo

anterior (temperatura 1ª etapa).

•Um tempo durante o qual a temperatura da

água no interior da cuba volta a variar

linearmente, até alcançar uma temperatura final

estabelecida pelo usuário (tempo de 2ª subida).

•Um tempo durante o qual a temperatura da

água no interior da cuba permanece constante

tomando o valor final adquirido no passo

anterior (temperatura de 2ª etapa).

Quando finaliza esta sequência, o aparelho

desliga-se automaticamente emitindo um sinal

acústico de aviso durante um minuto e a água do

interior da cuba despeja-se numa garrafa de

despejo, restabelecendo-se também a pressão

atmosférica. Os tempos de duração de cada um

dos passos podem ser ajustados entre 0 e 99

horas, 59 minutos. As temperaturas finais de cada

uma das duas subidas podem ser reguladas entre

0 º C e 135 ºC.

Para mostrar ao usuário em todo momento a

situação e a evolução real do programa, o painel

de controlo da polimerizadora à pressão R-080460

dispõe de um gráfico sinóptico (11). As lâmpadas

indicam em qualquer momento o passo que se

está a realizar e as temperaturas alcançadas. O

aparelho também está dotado de dois displays

digitais. O superior (1) indica a temperatura

instantânea da água no interior da cuba e o display

inferior (2) indica o tempo que falta para terminar o

programa.

Ambos os displays têm uma dupla função, que se

activa quando se carrega na tecla (W/T) (7).

Quando se carrega nessa tecla, o display superior

(1) indica a temperatura que o usuário programou

como valor final do passo (temperatura de referência)

e o display inferior indica o tempo que falta para

terminar o passo que se está a executar.

PROGRAMAÇ ÃO

Programar uma lei de aquecimento da água no

interior da cuba é muito simples. Para isso,

recomendamos proceder da seguinte maneira:

1.Acenda o interruptor geral (12).

2.Carregue na tecla de função (10). Esta operação

serve para entrar no modo de programação. O

display superior mostra a legenda “A0” indicando

que está activada a programação desse passo.

No gráfico sinóptico acende-se a lâmpada

correspondente ao passo “A0” (tempo de inicio).

3.Carregue nas teclas Incrementar/Diminuir (8 e

9), até no display inferior (2) aparecer o valor do

tempo que deseja para o primeiro passo (tempo

de espera).

4.Volte a carregar na tecla de função (10). O

display superior mostra a legenda “A1”,

indicando que a programação desse passo está

activada. No gráfico sinóptico também se acende

a lâmpada correspondente ao passo “A1” (tempo

de 1ª subida).

5.Carregue nas teclas Incrementar/Diminuir (8), (9)

até no display inferior (2) aparecer o valor do

tempo que deseja para o segundo passo.

6.Carregue novamente na tecla de função (10). O

display mostra a legenda U1, para solicitar que

programe a temperatura final da primeira subida.

7.Proceda da mesma forma que a indicada

anteriormente para terminar de programar a

duração e a temperatura dos diferentes passos

do programa.

8.A sequência ordenada dos passos que vão

aparecendo no display quando o aparelho está

em modo de programação, seria:

(A0)-Tempo de inicio

(A1)-Tempo da 1ª subida

(U1)-Temperatura da 1ª subida

(A2)-Tempo da 1ª subida

(A3)-Tempo da 2ª subida

(U2)-Temperatura da 2ª subida

(A4)-Tempo da 2ª subida

9.Para abandonar o modo programação existem

três possibilidades: Recorrer todos os menus de

função; carregar em qualquer momento na tecla

(7) (W/T), que actua como tecla de escape; ou

permanecer em posição de visualização sem

carregar em nenhuma tecla durante um tempo

superior a 30 segundos. O programa guarda-se

automaticamente na memória. É preciso

Português

17

sublinhar que quando se utiliza a tecla (W/T)

como escape, o controlo salta para a situação

inicial, salvando na memoria os parâmetros

seleccionados.

10.Se desejar que o programa se termine no

passo “A2” (1ª subida), sem executar o resto

do programa, situe-se no passo “A3” e

carregue na tecla (9) diminuir, até no display

(2) aparecer a legenda “Fin”.

11.Depois de abandonar o modo programar, para

o aparelho executar o programa, sempre é

preciso abrir e fechar a tampa. Esta manobra é

necessária para encher a cuba de água e

introduzir nela os elementos a polimerizar.

Para facilitar o manejo e a programação do

aparelho, o display do controlo (2) mostra

mensagens de ajuda para o usuário. A

mensagem abrir a tampa representa-se

mediante a legenda “AbrA”. O fecho da tampa

com a mensagem “Cerr”. Depois de realizar a

manobra de abertura e fecho, aparece a

legenda “StAr”. A partir desse momento, o

programa põe-se em funcionamento

automaticamente quando se carregar na tecla

(P/M) (5).

INSTALAÇÃO

•Desempacote cuidadosamente a polimerizadora

à pressão R-080460. Encontrará os acessórios

seguintes: uma garrafa de despejo (não

representada na figura) com o tubo de ligação e

um tubo de conexão à rede de ar à pressão.

Também encontrará no interior da cuba duas

bandejas. Das quais uma com asa, que serve

para tirar com facilidade os elementos

polimerizados. A outra não tem asa e serve de

protecção da resistência de aquecimento.

Coloque a bandeja sem asa no fundo da cuba

justo por cima da resistência.

•Coloque o aparelho sobre uma base horizontal,

plana e rígida, afastada das fontes de calor ou

de vibrações. Coloque perto de um ponto de

conexão à rede de ar à pressão. Os laterais do

aparelho levam umas ranhuras de ventilação.

Para garantir uma adequada refrigeração, deve

deixar pelo menos 15 cm de separação entre as

ranhuras e a parede mais próxima.

•Ligue o aparelho a uma tomada de corrente de

230 V, 50/60 Hz com tomada de terra.

•Ligue um dos extremos do tubo de conexão

pneumática no conector do regulador de

pressão (F). O outro extremo será ligado à rede

de ar à pressão.

•Coloque a garrafa de despejo pelo menos a 20

cm por baixo da cota inferior da máquina. A

água despejada da cuba está à temperatura de

ebulição e uma queda acidental da garrafa pode

provocar um acidente. A garrafa de despejo deve

de estar colocada de maneira a assegurar uma

óptima estabilidade e segurança. Quando a

garrafa estiver colocada, ligue o tubo de despejo à

junção situada na parte traseira da máquina e

introduza o outro extremo pelo orifício superior da

garrafa.

FUNCIONAMENTO

Para um programa de polimerização começar, é

preciso sempre abrir e fechar a tampa, para poder

encher a cuba de água e introduzir os elementos que

se deseja polimerizar. A sequência de passos que

permite executar um ciclo de polimerização é a

seguinte:

1.Acenda o interruptor geral (12). A parte dos

elementos do painel de controlo do aparelho

activam-se, indicando que a polimerizadora R-

080460 está em funcionamento. Nesta situação

inicial, observará que o display (2) mostra a

mensagem “AbrA”, indicando que a máquina

está preparada para começar um ciclo de

polimerização.

2.Abra a tampa do aparelho girando primeiro a

maneta de segurança (B) e deslocando depois a

corrediça de fecho (A). A legenda do display

muda para “Cerr”, indicando que o aparelho está

à espera que se feche a tampa para começar o

programa

3.Coloque os elementos que deseja polimerizar na

bandeja com asa que encontrará no interior da

cuba.

4.Encha a cuba de água. O nível final da água

deve ficar uns 3 cm por baixo do borde superior

da cuba. Vigile que o nível da água não alcance

nunca a cota da junção de entrada de ar à

pressão situada no interior da cuba (parte

superior). Também não são recomendáveis

níveis de água por baixo dos 5 cm da bandeja da

cuba, já que podem deixar descobertas as

resistências de aquecimento.

5.Verifique se a garrafa de despejo está vazia. Se

a garrafa estiver cheia, a água à temperatura de

ebulição pode-se entornar durante a fase de

descarga.

6.Programe a polimerizadora à pressão seguindo a

instruções dadas no parágrafo sobre a

programação.

7.Feche a tampa do aparelho e assegure a fixação

com a corrediça de fecho e a maneta de

segurança. Algumas vezes, a junta de borracha

do borde superior da cuba do aparelho que

assegura a correcta hermeticidade da tampa,

pode sair do encaixe. Vigile este ponto com

atenção, já que uma má colocação da junta pode

provocar fugas de vapor. Se observar que a

Português

18

junta está mal colocada, encaixe-a bem na

ranhura da cuba.

8.Depois de fechar a tampa do aparelho, a

mensagem do display será “StAr”, indicando

que a máquina está preparada para começar o

ciclo de polimerização.

9.Quando carregar na tecla (P/M) (5) a POLI-

PLUS põe-se automaticamente em

funcionamento e executa o programa definido.

A lâmpada (6) fica acesa para indicar que o

programa se está a executar sem problemas.

Por outra parte, quando a resistência de

aquecimento actua, a lâmpada de sinalização

(3) fica acesa. As lâmpadas indicadoras do

gráfico de programa (11) vão-se acendendo

pouco a pouco para indicar em que passo do

programa nos encontramos.

Durante o curso normal do programa pode-se

parar em qualquer momento o aparelho

mantendo carregada a tecla (P/M) (5) durante

5 segundos. O controlo mostra no display a

mensagem “dESC”. Abrir a torneira na parte

traseira da máquina para drenar a água.

Pode também em qualquer momento entrar

em modo programação e alterar os parâmetros

do programa que se está a executar,

carregando na tecla de programação (10);

depois, proceda como se indica no parágrafo

de programação. Em caso de corte da

corrente, a POLI-PLUS passa para o estado

de parada, mostrando no display a mensagem

de falho de rede “FrEd”, quando voltar a

corrente.

O manómetro (13) indica em qualquer

momento a pressão no interior da cuba. Este

valor pode ser variado à vontade, entre 0 e 6,5

bares (pressão máxima) mediante o regulador

de pressão (F). Para isso, puxa para cima o

pomo do regulador de pressão. Girando depois

o pomo no sentido das agulhas do relógio,