5

1 Declaration of Conformity

2 Specified Conditions of Use

3 General Safety Instructions

4 Special Safety Instructions

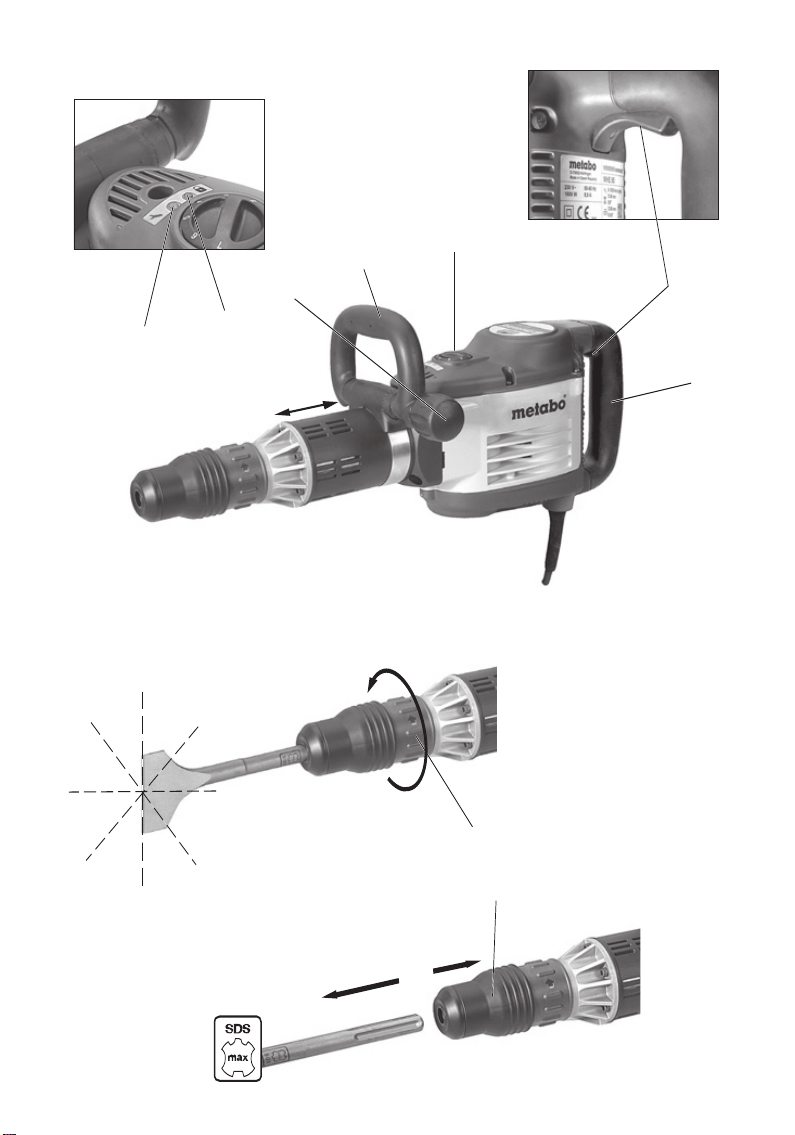

5Overview

6 Special Product Features

7 Initial Operation

7.1 Assembly of the additional handle

8Use

8.1 Positioning, removing tool

8.2 Setting chisel position

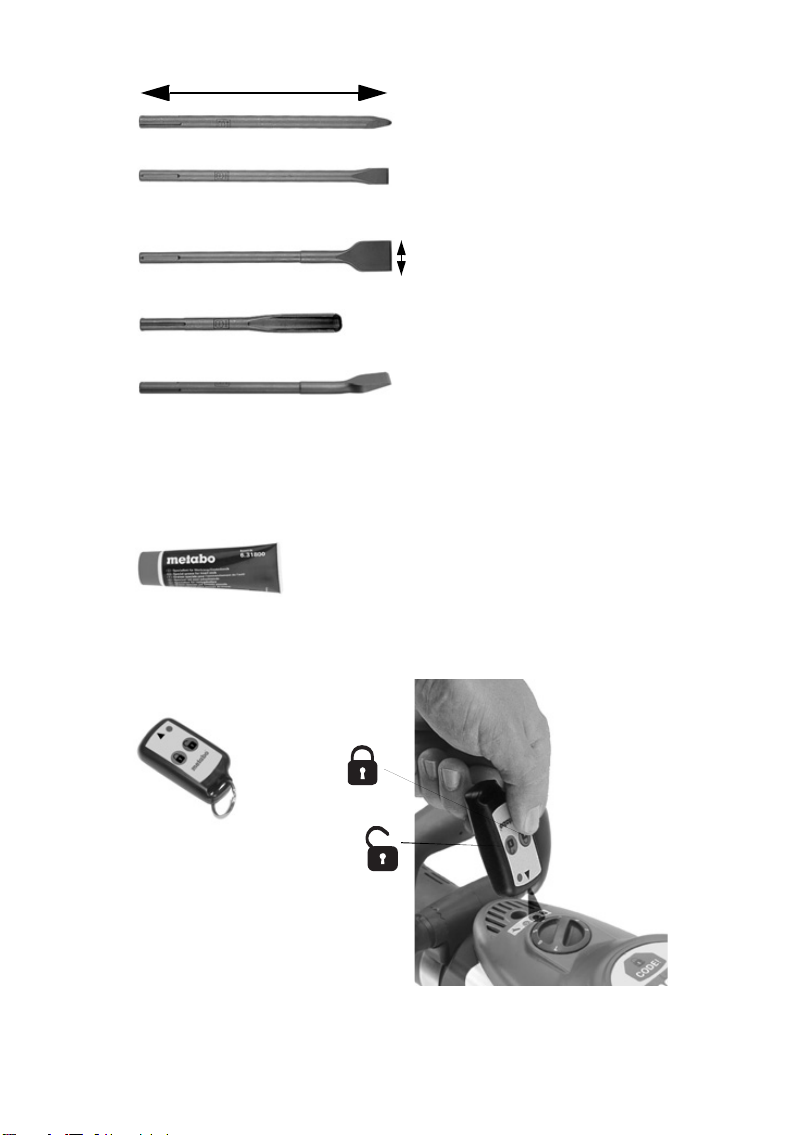

8.3 Setting impact force

8.4 Switching on and off

9 Tips and Tricks

10 Servicing

11 Troubleshooting

12 Accessories

13 Repairs

14 Environmental Protection

15 Technical Specifications

We, being solely responsible, hereby declare that

this product conforms to the standards and direc-

tives specified on page 2.

The chisel hammer, with suitable accessories, is

suitable for heavy demolition work, chiselling and

embossing in concrete, brick, stone and similar

materials.

The user bears sole responsibility for damage

caused by improper use.

Generally accepted accident prevention regula-

tions and the enclosed safety information must be

observed.

Before using this power tool, carefully read

through and familiarise yourself with all the

enclosed safety information (red booklet) and the

instructions. Keep all enclosed documentation for

future reference, and pass on your power tool only

together with this documentation.

For your own protection and for the

protection of your power tool pay

attention to all parts of the text that

are marked with this symbol!

Pull the plug out of the plug socket before any

adjustments or servicing are performed.

Avoid inadvertent starts: always switch the tool off

when the plug is removed from the mains socket or

if there has been a power cut.

Use the additional handles supplied with the

tool.

Loss of control can lead to injuries.

Always hold the machine with both hands at the

intended handles, take a secure stance and

concentrate on the work.

Always wear protective goggles, gloves, and

sturdy shoes when working with this tool.

Wear ear protectors.

Exposure to noise can

cause loss of hearing.

Ensure that the spot where you wish to work is free

of

power cables, gas lines or water pipes

(e.g.

using a metal detector).

Hold the power tool only at insulated housing

parts if there is any danger of making contact

with concealed electric cables or the supply

cable.

Contact with live wires energises the metal

parts of the housing and can cause electric shock

to the operator.

Work only with a correctly positioned tool. Pull on

the tool to check that it is correctly seated. (The

tool must move a few centimetres in axial direc-

tion.)

In cold weather, or if the tool has not been used for

a long time, run the tool for a few minutes without

load before using.

Operating Instructions

Dear Customer,

Thank you for the trust you have placed in us by buying a Metabo power tool. Each Metabo power tool

is carefully tested and subject to strict quality controls by Metabo’s quality assurance. Nevertheless, the

service life of a power tool depends to a great extent on you. Please observe the information contained

in these instructions and the enclosed documentation. The more carefully you treat your Metabo power

tool, the longer it will provide dependable service.

Contents

1 Conformity Declaration

2 Specified Use

3 General Safety Instructions

4 Special Safety Instructions

Wear ear protectors.

Exposure to noise can

cause loss of hearing.

Ensure that the spot where you wish to work is free

of

power cables, gas lines or water pipes

(e.g.

using a metal detector).

Hold the power tool only at insulated housing

parts if there is any danger of making contact

with concealed electric cables or the supply

cable.

Contact with live wires energises the metal

parts of the housing and can cause electric shock

to the operator.

Work only with a correctly positioned tool. Pull on

the tool to check that it is correctly seated. (The

tool must move a few centimetres in axial direc-

tion.)

In cold weather, or if the tool has not been used for

a long time, run the tool for a few minutes without

load before using.

01_ENG_MHE95_Asien_0506 05.05.2006 11:25 Uhr Seite 5