Metaflex Medicare EI1 2.0 User manual

Metaflex Doors Europe BV

Ambachtsstraat 11

NL

- 7122 MP Aalten

T +31 88 14 14

900

info@metaflexdoors.com

www.metaflexdoors.com

Installation manual

Metaflex Medicare EI1 2.0

202571

Page 2 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

Table of Content

1. Foreword ............................................................................................................................................................ - 3 -

2. Specifications...................................................................................................................................................... - 3 -

3. Safety guidelines ................................................................................................................................................ - 4 -

4. Transport and storage........................................................................................................................................ - 4 -

5. Fastening materials............................................................................................................................................ - 4 -

6. Tools required..................................................................................................................................................... - 5 -

7. Necessary PPE .................................................................................................................................................... - 5 -

8. Installation steps ................................................................................................................................................ - 6 -

8.1 Dimension check ................................................................................................................................................ - 6 -

8.2 Frame assembly.................................................................................................................................................. - 7 -

8.3 Rail system installation..................................................................................................................................... - 11 -

8.4 Door Leaf Assembly .......................................................................................................................................... - 13 -

8.5 Opener (optional) ............................................................................................................................................. - 17 -

8.6 Adjusting door leaf and drive belt .................................................................................................................... - 18 -

8.7 Guiding rollers assembly .................................................................................................................................. - 20 -

8.8 Canopy.............................................................................................................................................................. - 23 -

9. Operations & Maintenance.............................................................................................................................. - 26 -

Page 3 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

1. Foreword

This manual describes the assembly of a Metaflex Medicare EI1 sliding door. The information in this manual is important

for the good and safe functioning of the door system. Read this user manual thoroughly from cover to cover. Metaflex

Doors Europe (MDE) urges that all new users (operators, installers, maintenance staff and where applicable cleaning

staff) should receive training, for which this user manual may serve as a basis.

MDE advises that the original copy, including its attachments, should be stored in a safe, central place. Another copy of

this manual should be stored close to the apparatus in the workspace.

The assembly instructions are intended for technical personnel.

The maintenance instructions assume that the maintenance staff have been authorized by Metaflex Doors Europe.

This warning sign indicates points which require special attention during installation.

2. Specifications

Product description

Serial number: Indicated on the component ID label

Variants: Metaflex EI1 frame

Areas of application

Healthcare facilities, hospitals, pharmaceutical.

Dimensions

Variable clear opening width x clear opening height, up to a maximum of 2000 x 2700 mm.

Lifespan

10 years when maintained according to Metaflex Doors Europe's maintenance guidelines.

Weight

The weight of a Medicare EI1 2.0 door system depends on the clear width and height. The maximum weight of the door

leaf is 320 kilograms.

Assembly options

Panel wall (through the wall), provided they are suitable for carrying the weight of the door.

Page 4 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

3. Safety guidelines

General guidelines

1. Always wear dry work clothes and safety shoes.

2. Work may only be carried out if the local legal regulations are observed.

3. Always switch the circuit breaker/power supply off and place warning signs when carrying out work

so that the door cannot be operated.

4. Before starting, check that the on/off switch is switched to the 'OFF' position. Only insert the plug

once assembly has been completed.

5. Ensure that fingers do not become trapped, especially:

•During installation/adjustment of the guide rollers.

•When installing/adjusting the toothed belt of the motor/return pulley.

•Between the end stop and the door.

•Between the rollers and the rail.

•Between the frame and flush handle on the inner side of the door leaf.

6. Use only original components and accessories.

7. Do not alter the way in which the door is constructed or controlled. If done so, the manufacturer warranty will be

void. All claims on the warranty due to the failure at the consumer unit will be rejected.

Incorrect setting of the opening direction has a consequence on the safety systems. The changing of parameters

concerning DIN direction and automation type can lead to improper functioning of the automation and/or the door and

may cause damage.

Safety in special situations

Take extra safety precautions in all settings, for example in surroundings where people are unaware of the risks of

becoming trapped. In order to prevent this, the following facilities are available:

•Radar and/or a light curtain detecting the opening.

•Light curtain sensor detecting the door when operating.

•Screening off of the area in which the door operates.

4. Transport and storage

Transport

Metaflex Doors takes care when packing the products. The door (system) and/or automation are shipped in crates or

on pallets. During transport, no other goods may be stacked on the Metaflex packaging. Be careful not to shake the

packaging.

Storage

The door (systems) and/or automation should be stored in their original packaging in a dry and frost-free environment

until installation.

5. Fastening materials

202569 Assembly kit frame EI1 2.0

200234 Assembly kit MF5 rail

VMF10063 Guiding roller set medical grounding

200235 Assembly kit MF5 hook lock

Page 5 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

6. Tools required

7. Necessary PPE

Ensure to proceed with installation wearing specialized safety clothing/equipment.

Ø 5.3

Ø 7.8 TX-40

3/8”, 13mm

PH2

S13 / S17

Safety goggles

Helmet

Hearing protection

Safety shoes

Gloves

Page 6 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

8. Installation steps

Follow the described sequence and, if in doubt, contact Metaflex Doors Europe to clarify. DO NOT

IMPROVISE as the doors have to be assembled according to certified guidelines.

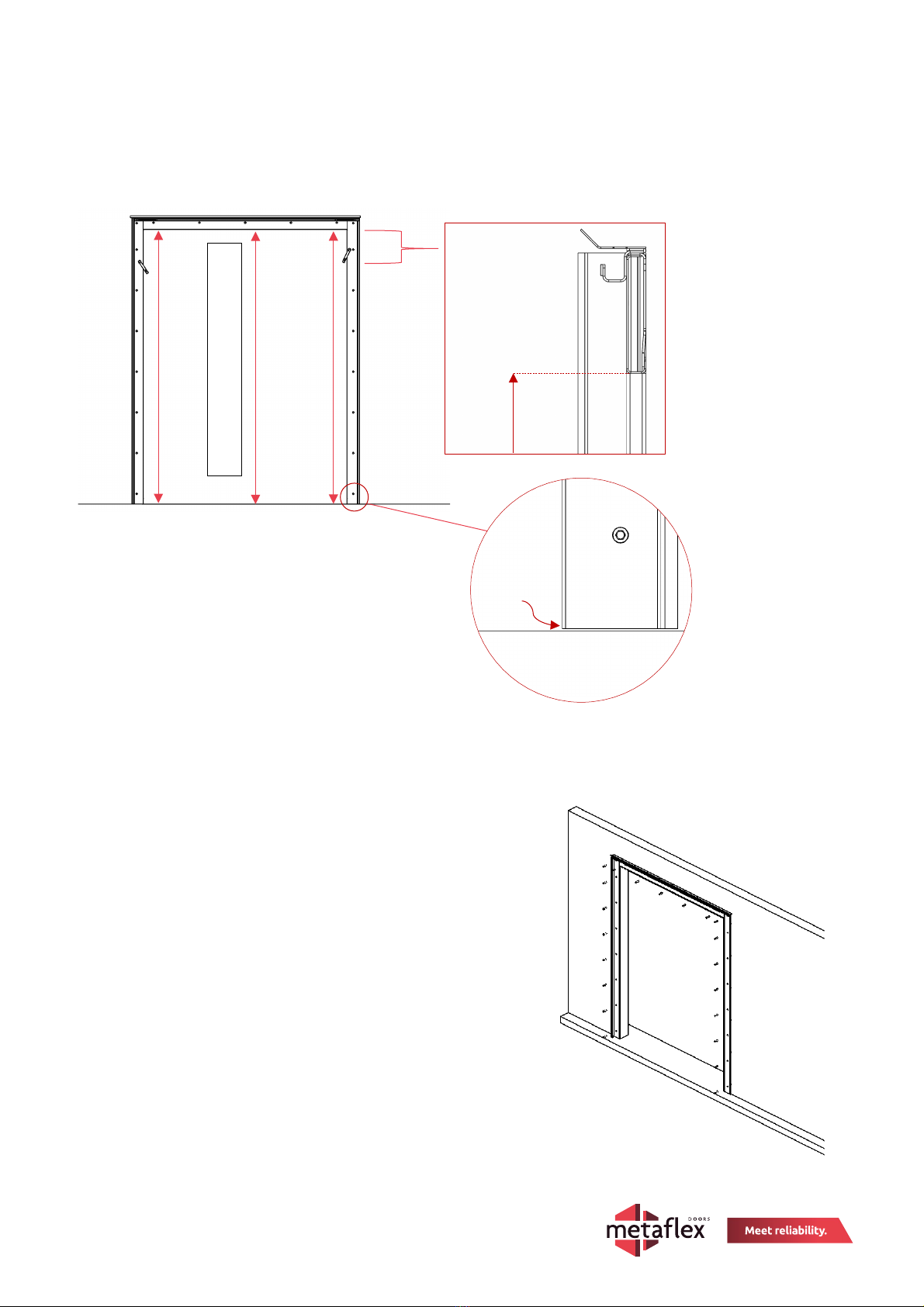

8.1 Dimension check

Check the dimensions and proceed.

Check the width (B), the height (H) and the wall thickness (D) of the door opening with floor plan.

Clear opening data available on customer drawing.

B = Clear opening width

H = Clear opening height

D = Wall thickness

Check if the finished floor and walls are level and straight. Maximum tolerances ±2 mm.

H

B

D

Page 7 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

8.2 Frame assembly

Step 1: Align the 3 frame components (left, right and top) and connect to eachother using the click-in construction as

shown below.

Step 2: Once the frame components are connected, align the frame around the wall opening and temporary fixate the

frame with te help of bar clamps. Make sure that the bar clamps have soft clamping surfaces that prevent damaging the

door frame and/or the finished wall. Use a spirit level to check all frame components are installed correctly.

Page 8 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

Step 3: Measure the distance from the finished floor level to the inside frame heightat the 3 points (see image below).

This distance must be “Clear Opening Height”. Make sure all three positions are within tolerance by adjusting the frame

along the wall. In the ideal situation, the wall frame should be 4 mm free from the finished floor level.

Step 4: Pre-drill the holes before installing the screws with drill Ø 5.3 mm.

Fix the frame to the wall using screws (6,5 x 50 mm self-tapping screw). Make sure the base of the frame is free from

the finished floor level.

Tool: 3/8” Hexagon socket

►In case of medical grounding: Slide the plastic covers over the

mounting screws. After securing the frame, measure whether the

frame is grounded.

Clear Opening Height

Side-view

Frame

Floor

4 mm gap

Page 9 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

Step 5: Using the silicone sealant from assembly kit 202569, surrounding (path along yellow highlight) the

frame, seal both inside and outside to make it airtight and smoke resistance.

Page 10 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

Step 6: Attach the Promaseal on the frame. Cut the Promaseal strips tothe according sizes. Attach the Promaseal on the

frame. Cut the Promaseal strips to the according sizes. The strips have a maximum length of 2150 mm. Therefore, devide

one 60 mm strip in length over the two lateral frame parts. Start fixating the lateral strips from the top, so that the seam

between the strips is not at visual height.

•The vertical strips (60mm wide) should be taped approximately 40mm from the inside of the frame edge.

•Horizontal strip (40mm wide) should be level with the top labyrinth as shown in the following figure.

60mm Promaseal

40mm Promaseal

60mm Promaseal

Page 11 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

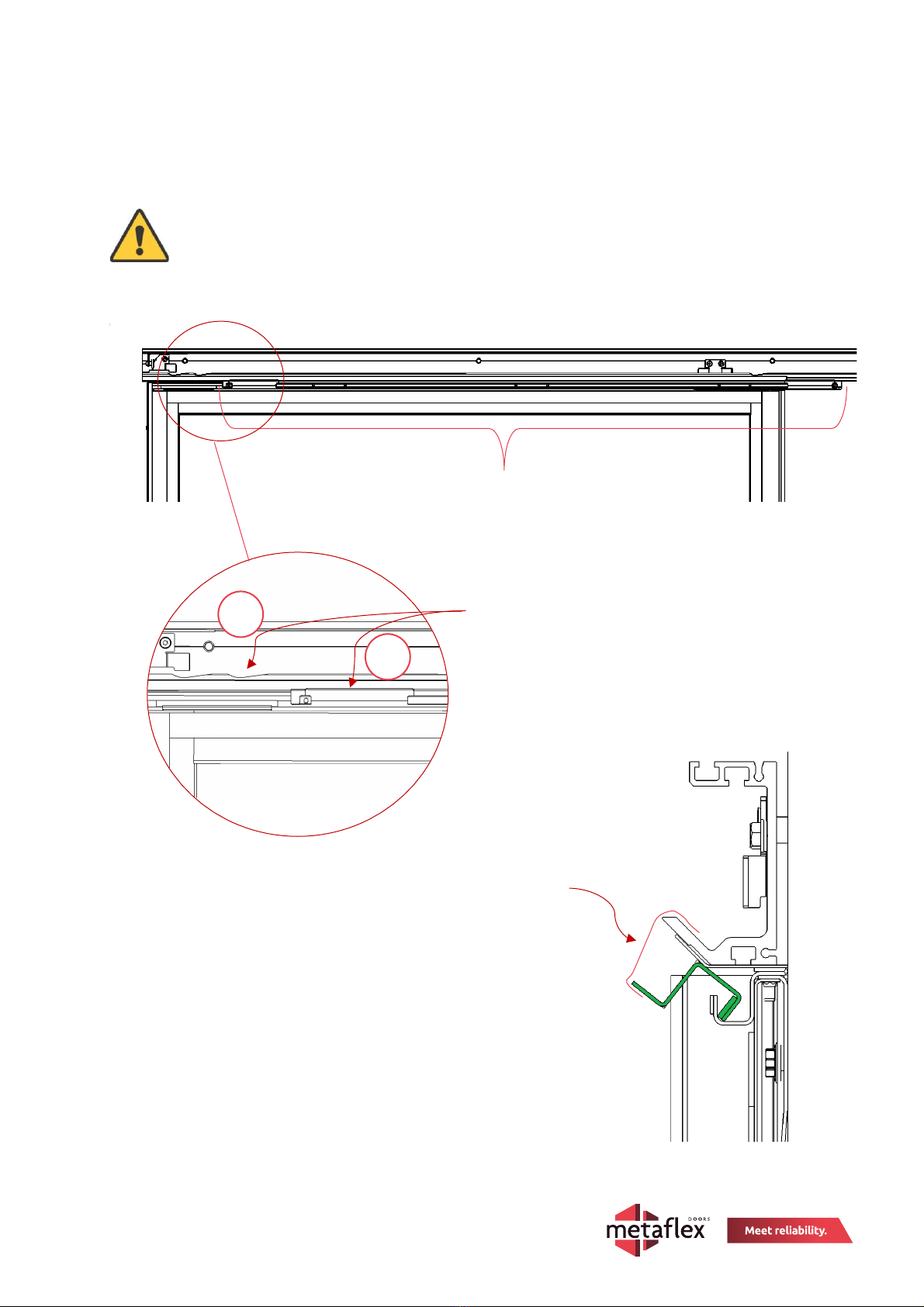

8.3 Rail system installation

ATTENTION: PLEASE USE CAUTION WHEN INSTALLING. FALL HAZARD!

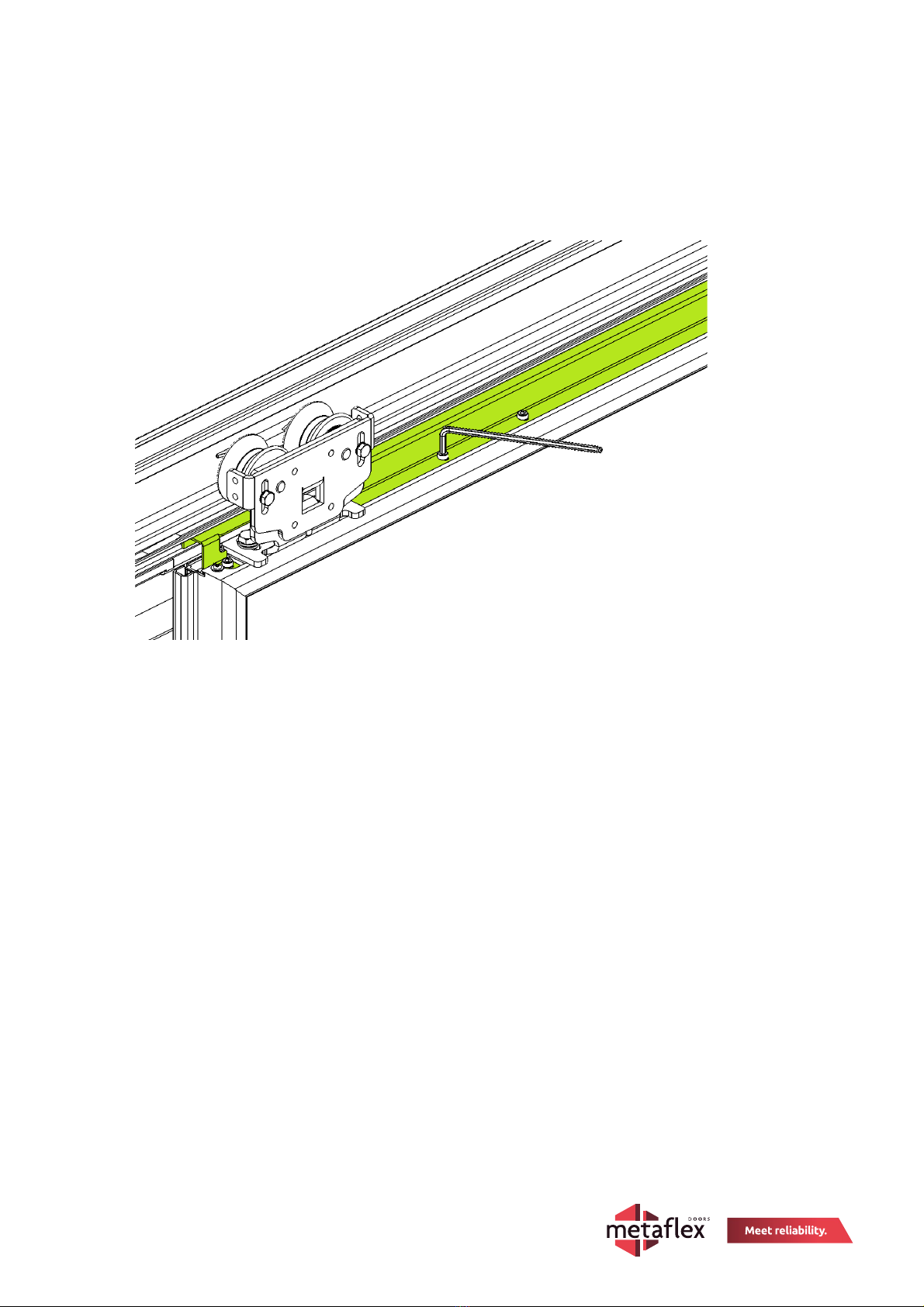

Step 1: Ensure that the fire-resistant strip is mounted behind the rail, should be already attached to

create an offset of 6 mm between wall and rail. Rest the rail on top of the wall frame (rail support profile), and align it

with the rail support profile on the opener side.

Step 2: Use the holes in the rail as a reference for

drill point coordinates.

Before marking any hole points, use a spirit level

to check if the rail is horizontally levelled.

1. Secure the rail to the first hole at opening

side using bolts from assembly kit 200234.

Use plastic bushes over the mounting

screws if the door system must be set up

grounded medicaly.

2. Keep the rail level and secure the end of

the rail.

3. Mount the remaining bolts to secure the

rail.

Tool: 13mm Hexagon socket wrench

►In case of medical grounding: Use plastic

covers over the mounting screws if the door

system must be set up grounded medicaly.

fire-resistant strip

1

2

3

Page 12 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

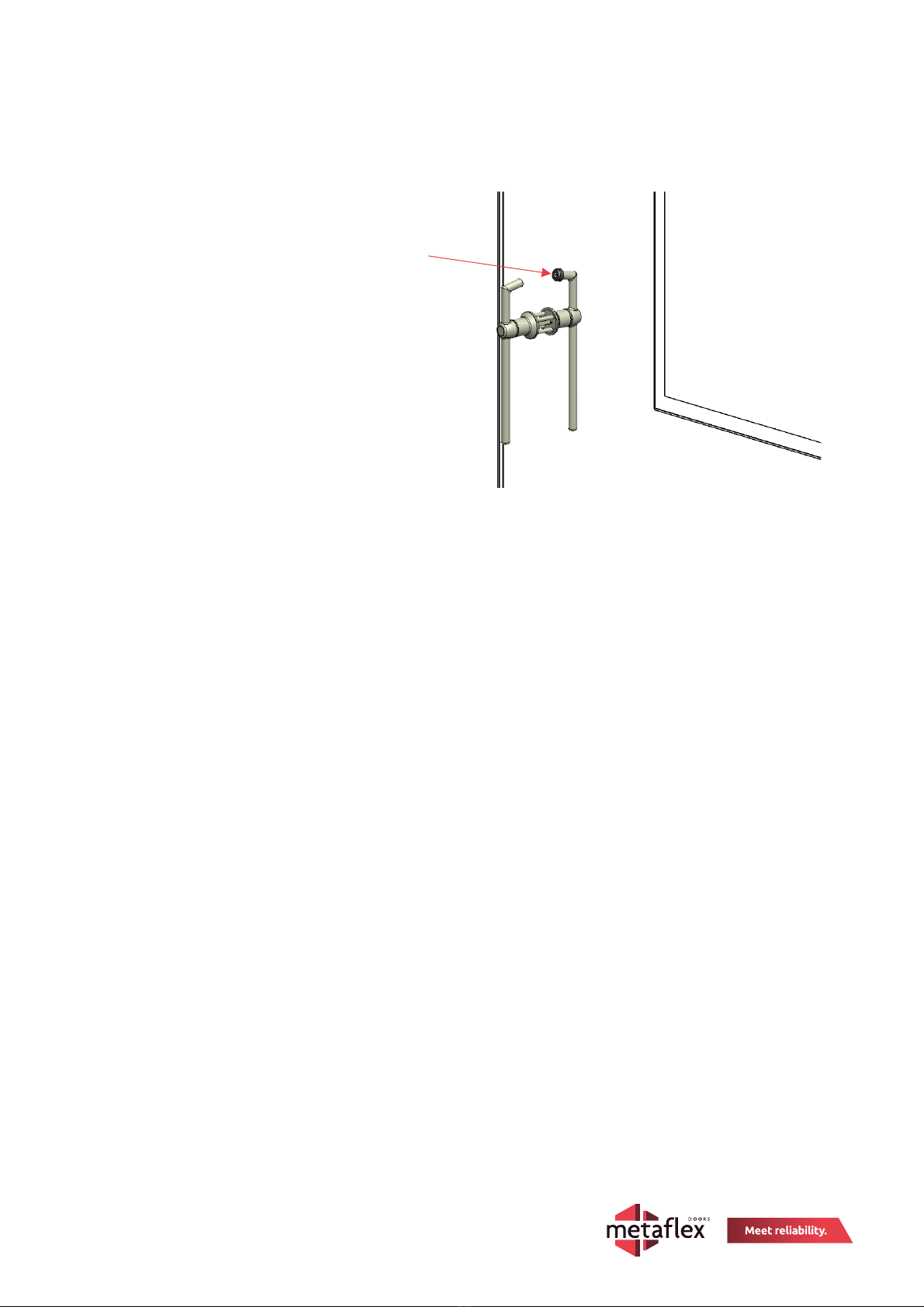

Step 3: Unthighten the two bolts of the endstop at the opening side and slide

the endstop near the clear opening. Correctly install both fire hooks to the wall

through the rail using the self-tapping screws. All the required fastening

material are in assembly kit number 200235.

Tool: 13mm wrench, TX-40

►In case of medical grounding: Use plastic covers over the mounting screws

if the door system must be set up grounded medicaly.

Step 4: Slide the end stop back in the previous position and thigten the bolts. Maintain a distance of 15 mm from the

rail end and lock it in position using hex nuts. The stopper can also be manually adjusted by rotating the stopper knob.

Tool: 13mm wrench

15 mm

Page 13 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

8.4 Door Leaf Assembly

ATTENTION: PLEASE HANDLE WITH CARE

Step 1: Prior installing the door leaf, first place the “door leaf top labyrinth” inside the wall frame labyrinth.

Keep the labyrinth in an upwards placed position with the help of tape.

Position the cutouts of the labyrinths away from the rail indentations.

Typ hier uw vergelijking.

Use tape on several

positions to hold the

labyrint temporary in

an upwards position

Door leaf labyrinth

1. Cutouts of the labyrinths away from the

2. rail indentations

1

2

Page 14 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

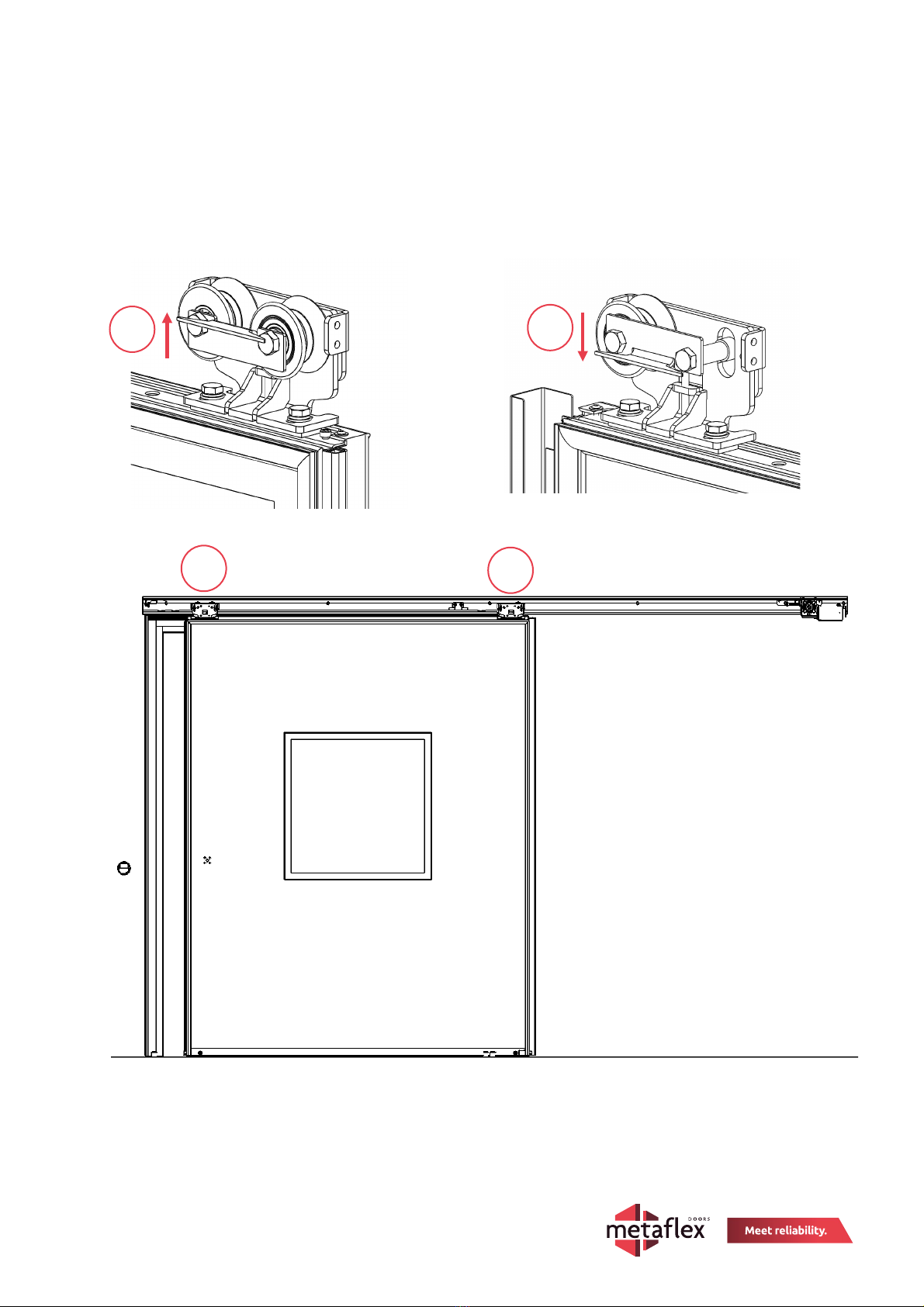

Step 2: Mount the track trolleys on top of the door leaf with M10 x 25 stainless steel bolts already mounted in the door.

Ensure that the hooks [1] on the track trolleys are placed on the correct side. At the opening side, the hook should be

placed upwards. On the closing side the hook should be placed downwards.

Lock it just, but not all the way, for later adjustment

Tool: 17mm wrench

1

2

1

2

Page 15 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

Step 3: Stand the door upright in front of the frame. Make sure that the track trolleys are aligned with the cutouts in

the labyrinth. Lift the door into the rail making sure the wheels positioned onto the rail.

Alignment of the

labyrinth cutout and

track trolley

Wheel position after

lifting the wheels onto

the rail.

Page 16 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

Step 4: Remove the tape thats keeping the labryint it in its upward position and install the labyrint on the door leaf with

the help of stainless steel M6 x 16 Hexagon socket head screws.

Tool: 5mm Allen key

Page 17 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

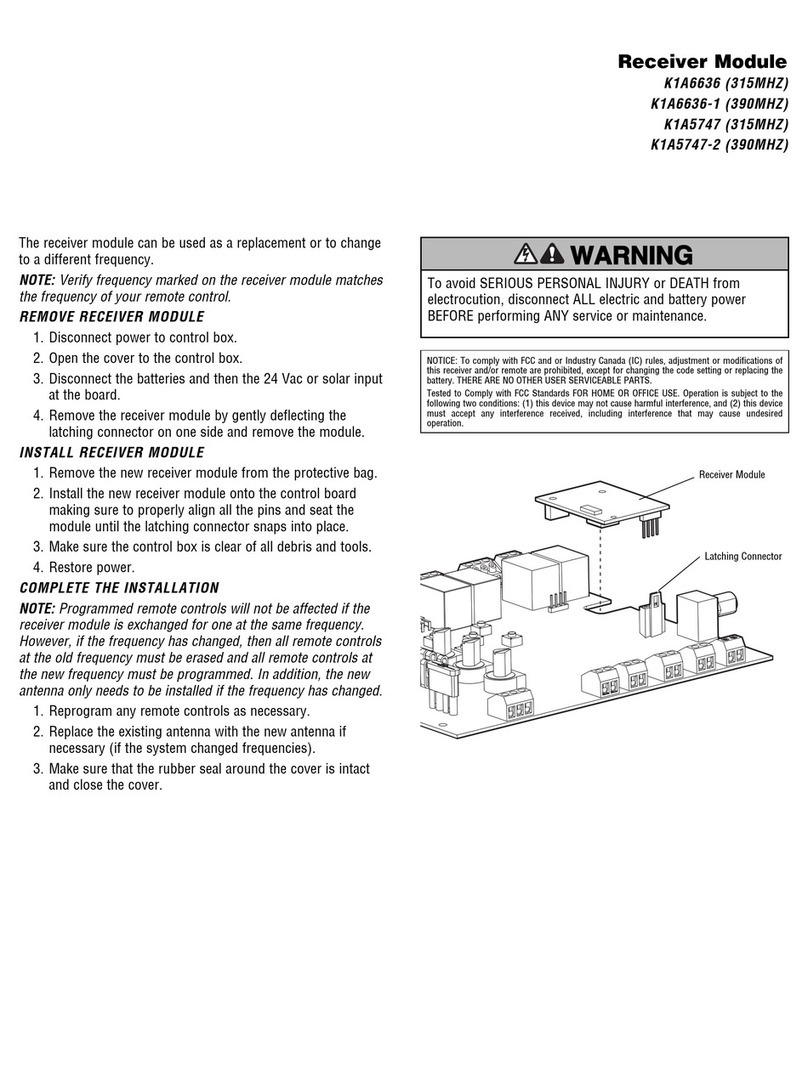

8.5 Opener (optional)

Step 1: Install the openers on the door body using the instruction manual included.

The black cap used in the opener is placed on

the inside wall opening to damper if any

contact with door frame.

Page 18 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

Adjusting depth: Make sure that the door is in

the open position. The distance between the

wall surrounding seal and the Promaseal (red)

strip on the frame should be 3 to 4 mm.

Tool: 17mm wrench (Torque: 40 Nm)

NOTE: When in Closed position make sure the EPDM is pressed against the Promaseal strip and the floor to create

air tight passage

8.6 Adjusting door leaf and drive belt

Adjust both the track trolleys so that no fouling occurs during operation and the door is fully sealed when in closed

position.

Adjusting height: Make sure that the door is in the open position

and the trolleys are out of rail indents. The bottom floor seal should

be at a distance of ±4 mm from the finished floor. Before adjusting

the height with the M6 bolt, untighten the M8 bolts located on the

opposite side [1]. Tighten the M8 bolts after adjusingt the height.

Tool: 5mm Allen key, 13mm wrench

Note: The right wheel is missing, this is only a

representation for clear understanding of the

sequence.

It is also possible that a trolley is supplied

with two wheels, use the same procedure

mentioned above for adjustment.

1

2

Page 19 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

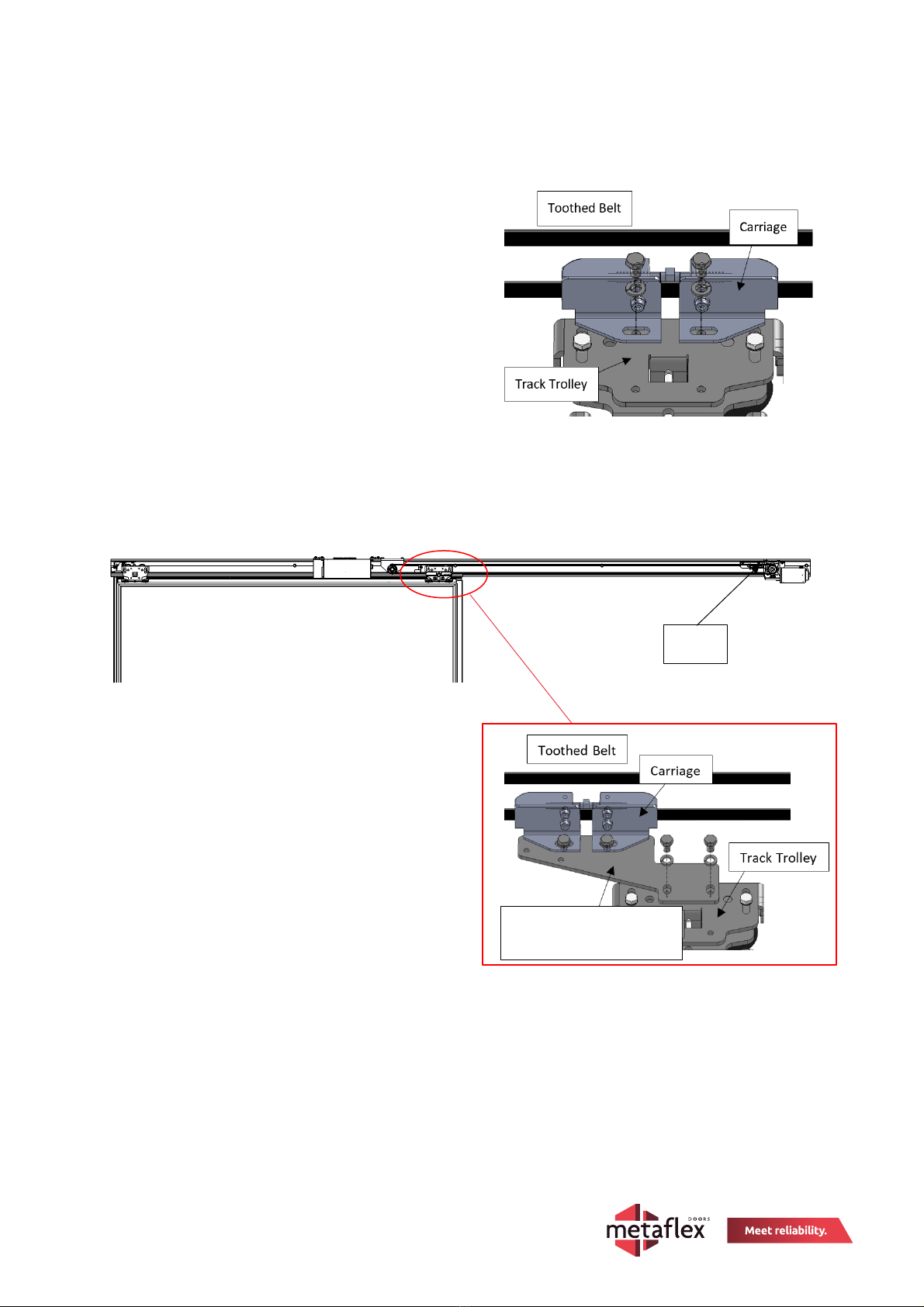

8.6.1 Carriage

Mount the carriage to the track trolley (M8x10).

Tool: 13mm wrench (Torque: 25,5Nm)

Alternatively if the motor is positioned above the rail – Mount the Drive Support bracket including the Carriage to the

Track Trolley.

Tool: 13mm wrench (Torque: 20Nm)

Motor

Driver Support bracket (if

motor placed on top of rail)

Page 20 of 27

Doc QA No 10.20.3

3 Rev. 03 | 08.03.2023

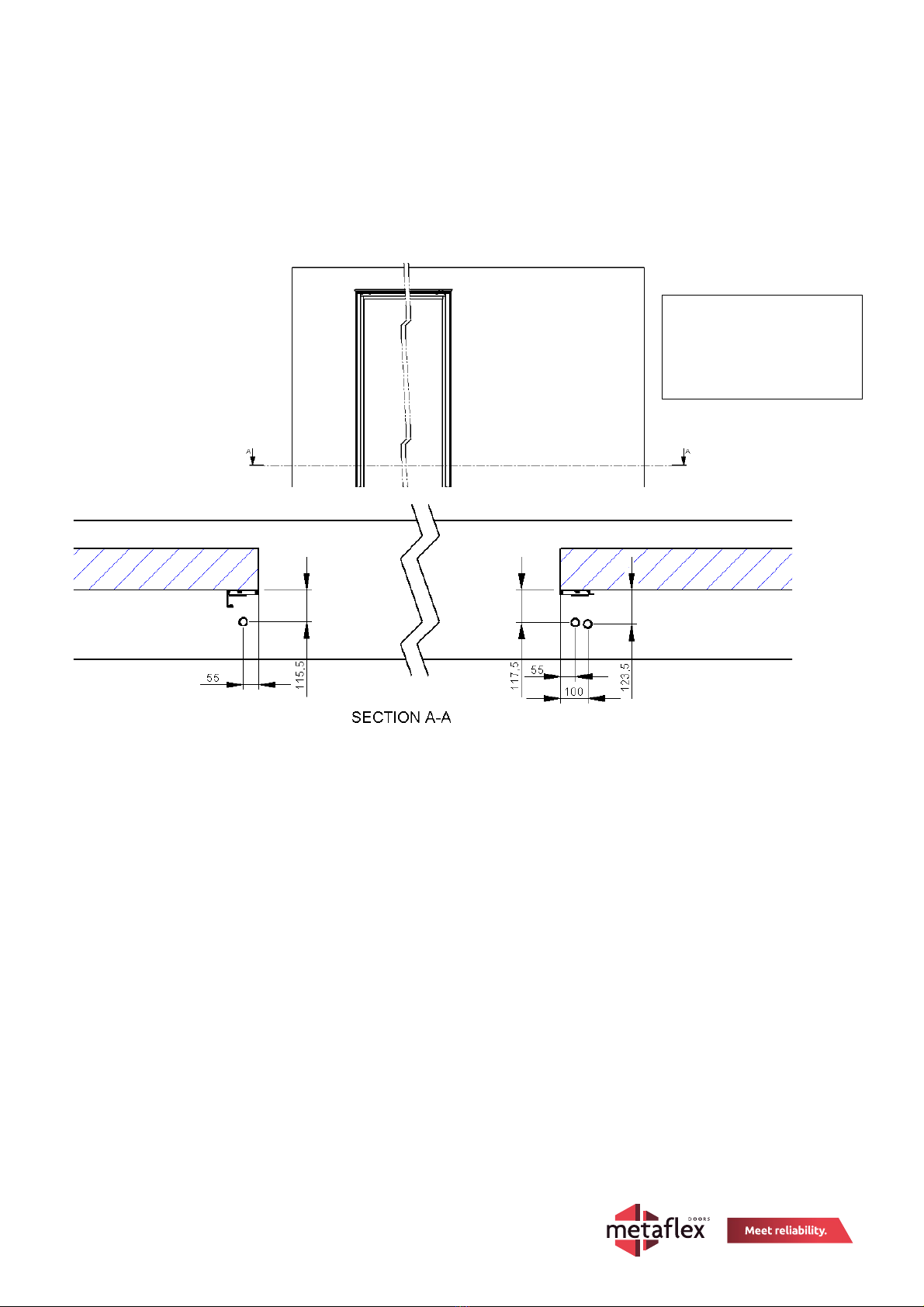

8.7 Guiding rollers assembly

Step 1: Open the door and mark the drill points on the floor. Then drill 3 holes of ø 10 mm each on the marked points.

►The positioning of the guiding rollers as shown below is indicational. Place the guiding rollers on sight to get a

proper sealing.

Guiding rollers – X With metal stud inside

Guiding rollers – Y

Without metal stud inside

X

X

Y

The below drill positions are

for Right opening doors.

For Left opening mirror the

direction.

This manual suits for next models

1

Table of contents

Other Metaflex Door Opening System manuals

Popular Door Opening System manuals by other brands

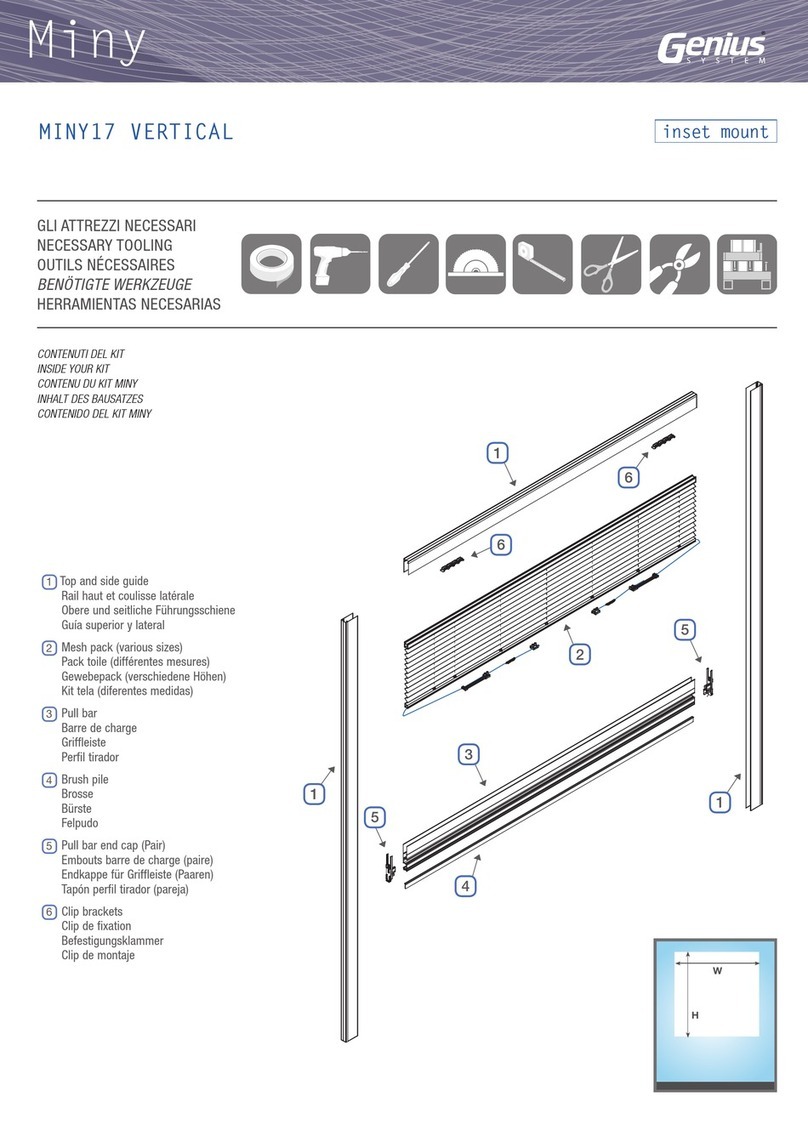

Genius

Genius MINY17 Assembling instructions

Tormax Automatic

Tormax Automatic Win Drive 2201 Instructions for use

Dahua

Dahua Unit VTO6221E-P user manual

B&D

B&D Smart Pro Quick operation guide

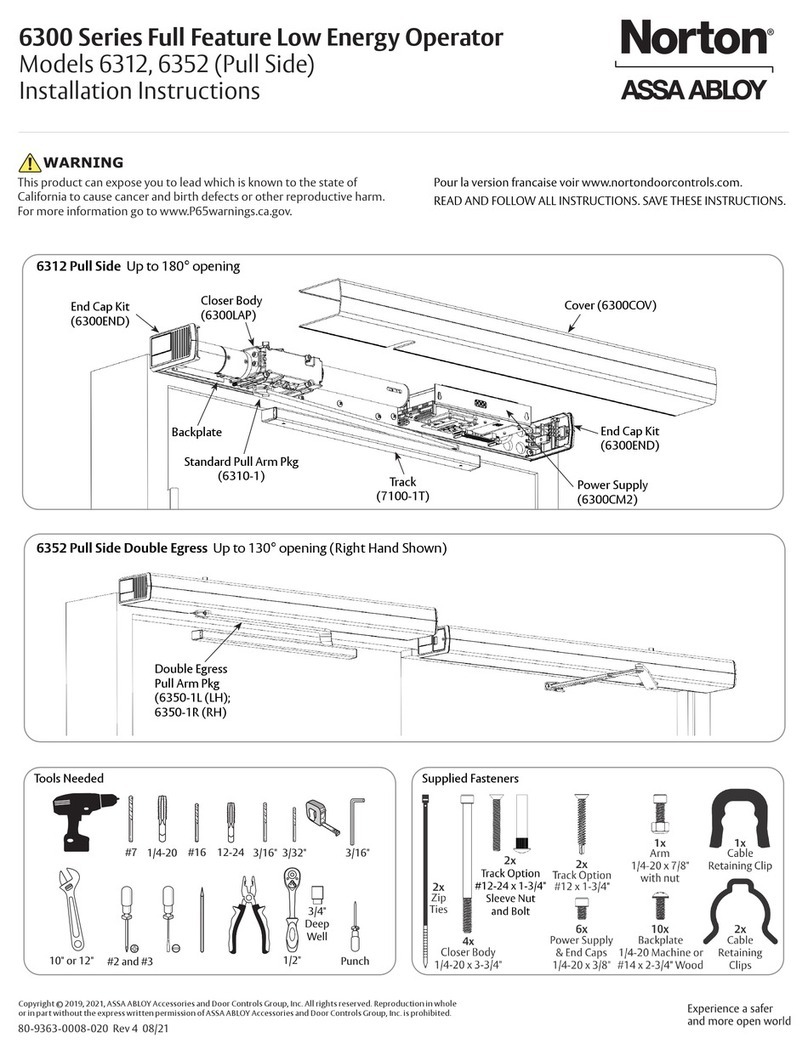

Assa Abloy

Assa Abloy Norton 6300 Series installation instructions

Assa Abloy

Assa Abloy SW200 Installation and service manual

EINHELL

EINHELL FH 70 operating instructions

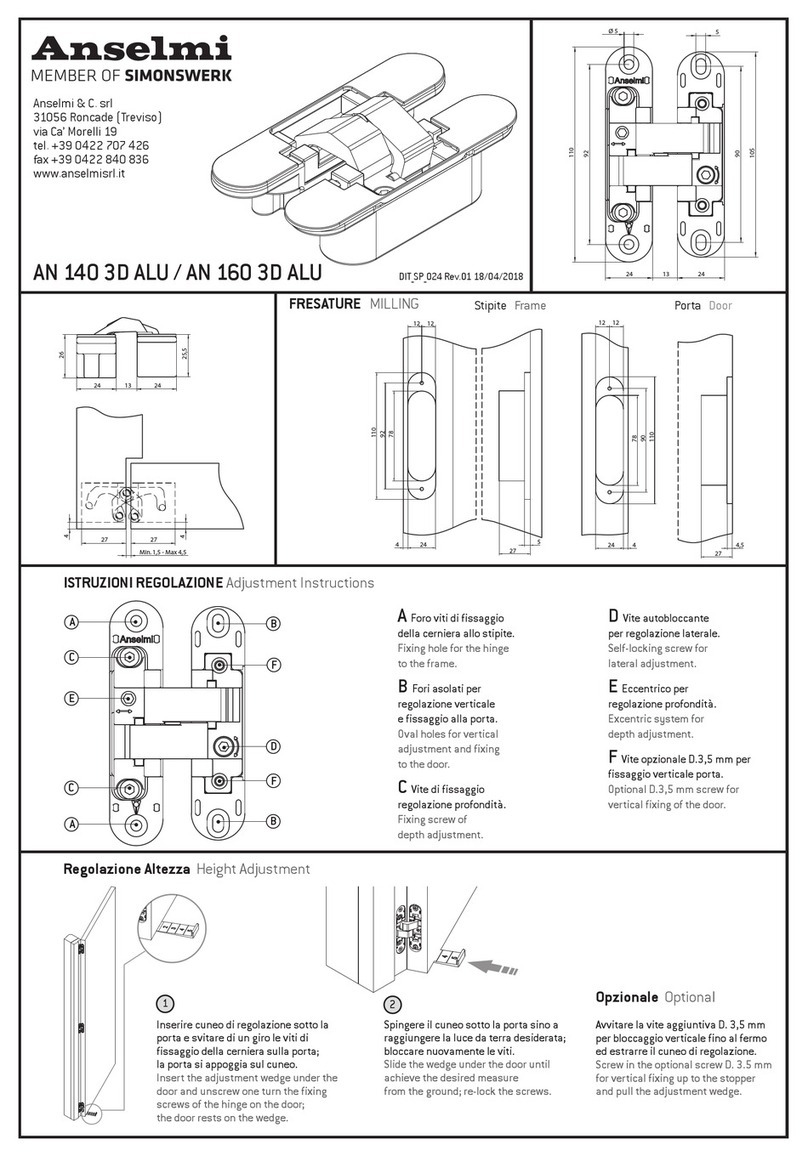

SIMONSWERK

SIMONSWERK Anselmi AN 140 3D ALU installation instructions

Prismatibro

Prismatibro Prisma Button 800 installation manual

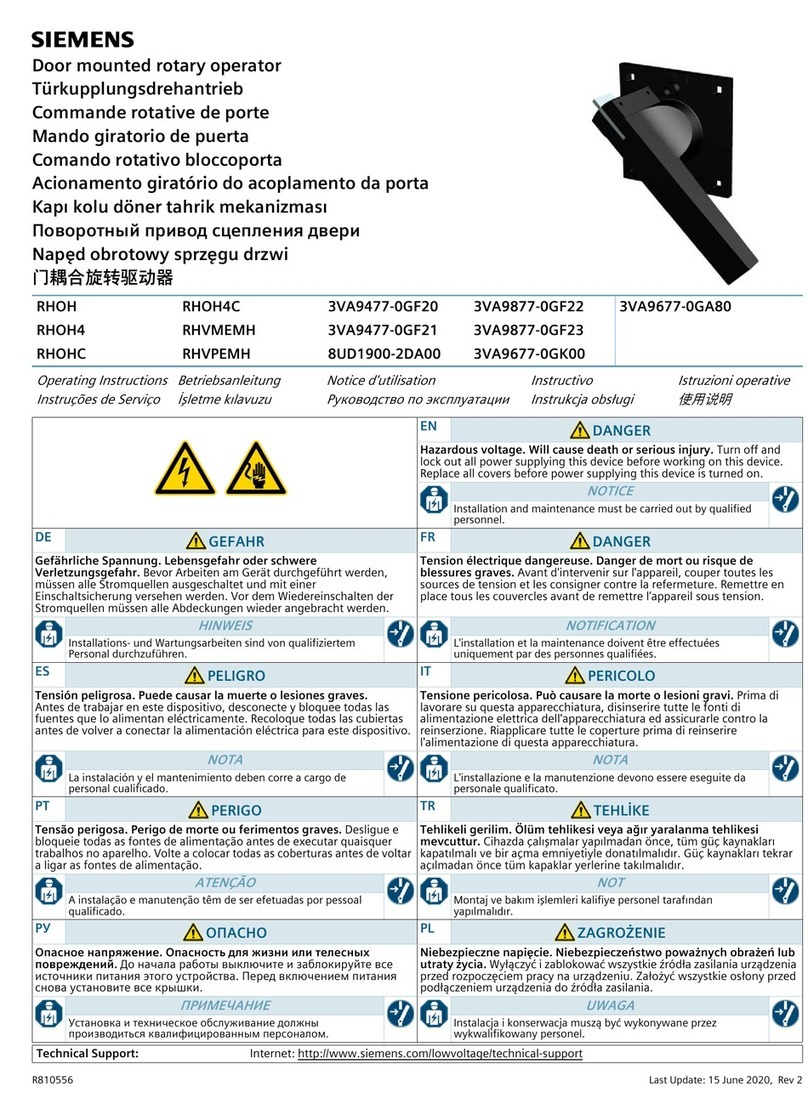

Siemens

Siemens RHOH quick start guide

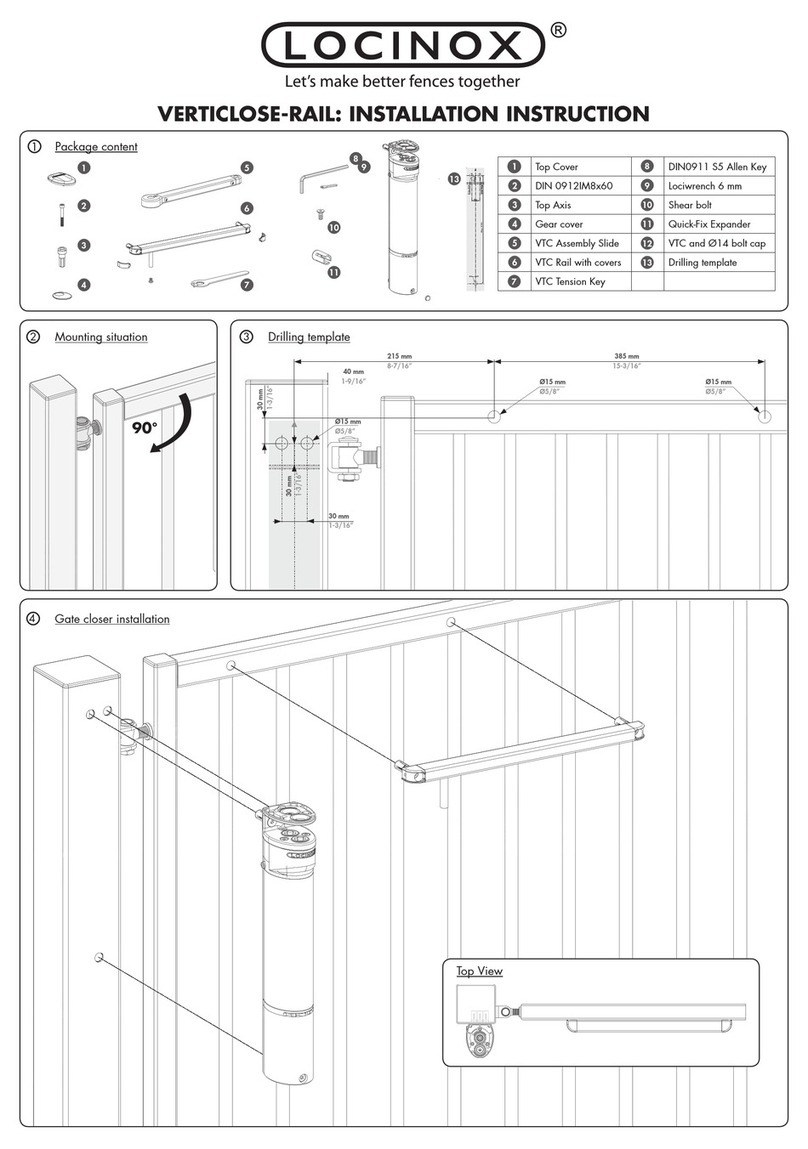

Locinox

Locinox VERTICLOSE-RAIL Installation instructions manual

Iseo

Iseo ACE IS9100 Mounting instructions