Metal Samples Company CorrTran MV MS2900L User manual

MS2900L Transmitter

Operator’s

Manual

Metal Samples Company

ADivision of Alabama Specialty Products, Inc.

152 Metal Samples Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515

CorrTran MV Corrosion Monitor

1

Contents

1 SAFETY INSTRUCTIONS / DISCLAIMER ................................................................... 2

1.1 Designated use .................................................................................................... 2

1.2 Installation, commissioning, and operation .......................................................... 2

1.3 Operational safety ................................................................................................ 2

1.4 Maintenance safety ............................................................................................... 2

1.5 Notes on safety conventions and symbols ........................................................... 3

1.6 Disclaimer ............................................................................................................. 3

2 IDENTIFICATION........................................................................................................... 3

2.1 Device designation ............................................................................................... 3

2.2 Contents of delivery .............................................................................................. 5

2.3 Incoming acceptance, transport, storage ............................................................. 5

2.4 Certicates and approvals .................................................................................... 5

2.5 Registered trademarks ......................................................................................... 5

2.6 Patents ................................................................................................................. 5

3 INSTALLATION AND MOUNTING ............................................................................... 6

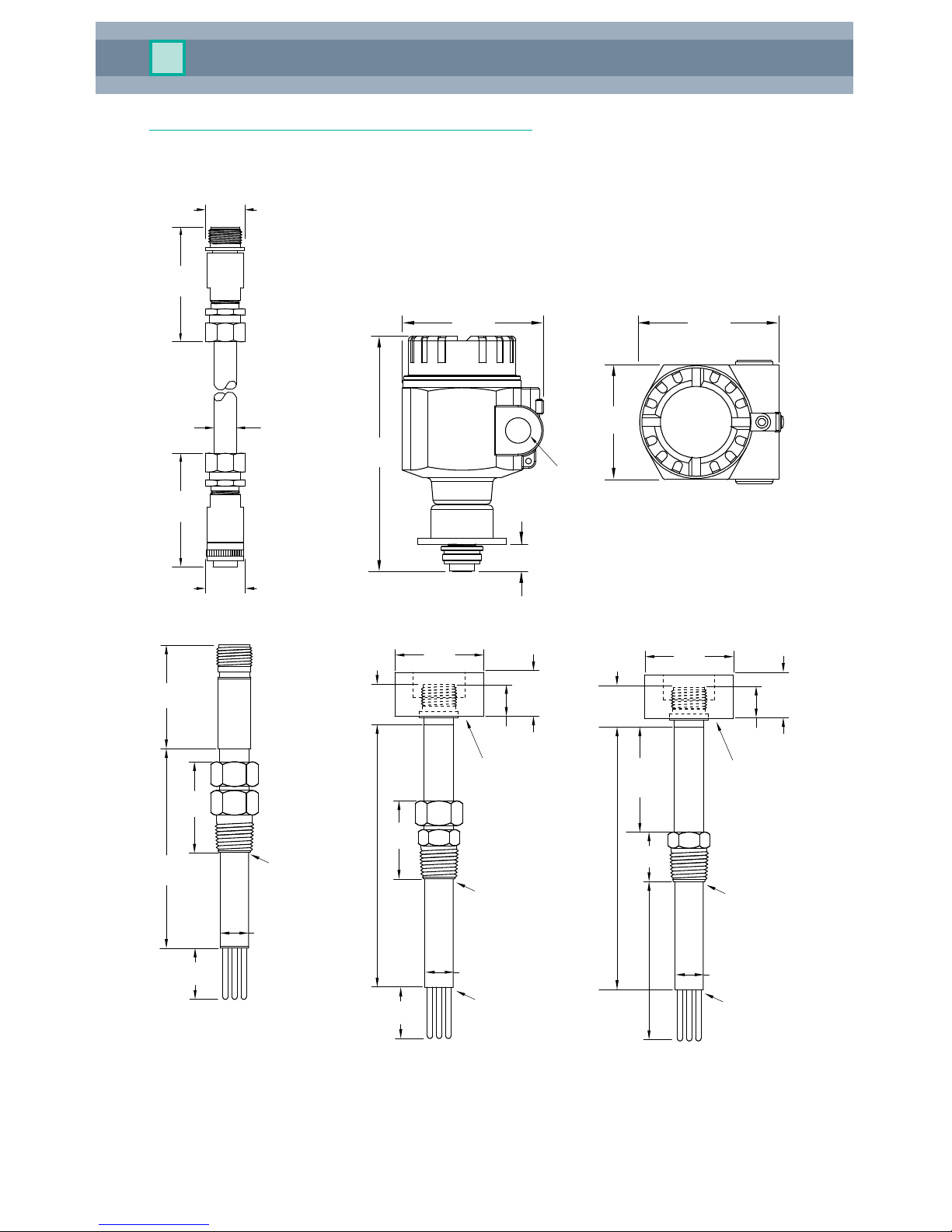

3.1 Dimensions............................................................................................................ 6

3.2 Probe specications ............................................................................................. 9

3.3 Mounting safety procedures and hints ............................................................... 15

3.4 Installation instructions ....................................................................................... 19

4 WIRING ....................................................................................................................... 24

4.1 Quick wiring guide .............................................................................................. 24

4.2 HART introduction .............................................................................................. 25

4.3 Wiring with HART ............................................................................................... 25

4.4 Post-installation check ........................................................................................ 26

5 CONFIGURATION AND COMMISSIONING .............................................................. 27

5.1 PACTware introduction ....................................................................................... 27

5.2 Establishing communication with PACTware ..................................................... 27

5.3 CorrTran MV online variables and parameters ................................................... 31

5.4 CorrTran MV test probe: CMP-TESTER ............................................................. 40

6 REPLACEMENT PARTS AND ACCESSORIES ........................................................ 41

6.1 CorrTran MV parts .............................................................................................. 41

6.2 HART accessories .............................................................................................. 44

6.3 Surge protection and IS barriers ........................................................................ 44

6.4 Additional accessories ........................................................................................ 45

7 SYSTEM SPECS ......................................................................................................... 45

8 TROUBLESHOOTING ................................................................................................ 49

9 MEASURING PRINCIPLE ........................................................................................... 51

10 APPENDIX A................................................................................................................ 53

11 APPENDIX B: CorrTran EC Startup........................................................................... 56

11.1 CorrTran MV/EC Evaluation Tool ........................................................................ 56

11.2 Hints on Extending Battery Life ........................................................................... 59

12 Notes ........................................................................................................................... 60

CorrTran MV Corrosion Monitor

2

1 SAFETY INSTRUCTIONS / DISCLAIMER

1.1 Designated use

The CorrTran MV is a compact, 4-20 mA corrosion transmitter used to detect general

corrosion, localized corrosion, and conductance in a wide range of industries. The

transmitter measures the corrosion rate and pitting factor, giving the readout in mil/year or

a 0-1 pitting factor, respectively. It also provides a conductance measurement. The readings

are taken in real time and are updated every 21 minutes.

1.2 Installation, commissioning, and operation

CorrTran MV is designed to operate safely in accordance with relevant technical and

safety standards. If installed incorrectly or used for applications for which it is not intended,

application-related dangers may arise. For this reason, the instrument must be installed,

connected, operated, and maintained according to the instructions in this manual by

appropriately trained personnel. This manual must be read, understood, and the instructions

must be followed. Modications and repairs to the device are permissible only when they

are expressly approved in this manual.

1.3 Operational safety

Measurement systems used in a hazardous (classied) area must comply with all existing

national standards. CorrTran MV can be supplied with the certicates listed in Table 1. All

technical personnel must be sufficiently trained. All measurement and safety regulations

that apply to the measuring points must be observed.

CorrTran MV CMC M - _ _ _ _ _ _ _ _ _ - _ _ - _ _ _ _ _ - _ _ - _ _ _

Code Certicate Protection

GP N/A General Purpose

D2 cCSAus NI: Cl. I, II, III; Div. 2: Groups A…G

IS cCSAus IS: Cl. I, II, III; Div. 1, 2; Groups A…G

II 1G EEx ia IIC T4

EX cCSAus EX: Cl. I; Div. 1,2; Groups A…D

Table 1. Certicates for Application in Hazardous Areas

General-purpose versions of CorrTran MV shall only be used to detect corrosion in tanks

and pipes that are non-hazardous (non-explosive). Failure to comply with this specication

will create a potentially hazardous situation.

1.4 Maintenance safety

The transmitter must be mounted with the safety warning label visible at all times to any

employee or other person called upon to replace the electrodes or otherwise service the

transmitter. The label is on every safety bracket with adjustable probes. Please see section

6.4 for ordering instructions.

DO NOT REMOVE THIS DEVICE UNLESS PIPE OR VESSEL

HAS FIRST BEEN DEPRESSURIZED AND PURGED OF

ANY HAZARDOUS SUBSTANCES. DEATH OR INJURY MAY

RESULT IF SAFETY PROCEDURES ARE NOT OBSERVED.

CorrTran MV Corrosion Monitor

3

1.5 Notes on safety conventions and symbols

The following conventions are used to highlight safety-relevant or alternate operating

procedures in this manual and are shown in the margin where appropriate.

Safety conventions

Symbol Meaning

Warning

A warning highlights actions or procedures which, if not performed

correctly, will lead to personal injury, a safety hazard, or destruction of

the instrument.

Attention

A caution highlights actions or procedures that, if not performed

correctly, may lead to personal injury or incorrect functioning of the

instrument.

Note

A note highlights actions or procedures that, if not performed correctly,

may indirectly affect operation or may lead to an instrument response

which is not planned.

A terminal symbol indicates that a protective grounding (earth)

terminal must be connected to earth ground prior to making any other

connection to the equipment.

1.6 Disclaimer

Metal Samples has no power, nor does it undertake to police or enforce, compliance with

the contents of this manual or observance of the safety precautions set forth herein. Metal

Samples does not certify, test, or inspect the installations of CorrTran MV for safety or other

purposes. Metal Samples disclaims liability for any personal injury, property, or other

damages of any nature whatsoever, whether special, indirect, consequential, or

compensatory, directly or indirectly resulting from the publication, use of, or reliance upon

this manual. Metal Samples makes no guaranty or warranty, express or implied, as to the

accuracy or completeness of any information published in this manual, and disclaims and

makes no warranty that the information in this manual will fulfill any particular purposes or

needs. Metal Samples' only warranty is set forth in the written Limited Warranty specifically

provided by Metal Samples in connection with the purchase of the CorrTran MV.

2 IDENTIFICATION

2.1 Device designation

2.1.1 Nameplates

black

Twinsburg

CONFIDENTIAL acc. to ISO 16016 Only valid as long as released in EDM or with a valid production documentation!

PRINT PLATE for

CorrTran DIV (I.S.)

respons.

approved

norm

US.JMB

date: 2005-Nov-04

sheet 1 of 2

110-2417A

plate number print laser sticker

scale: 1:1

Dieses Dokument enthält sicherheitsrelevante Angaben. Es darf nicht ohne Absprache mit dem Normenfachmann geändert werden!

This document contains safety-relevant information. It must not be altered without the authorization of the norm expert!

US.AAS

US.CPR

110-2417 / A

Input = 9 - 30 Vdc Output = 4 - 20mA HART

a

Cl. I, Div. 1, Gr. A,B,C,D; T4

Cl. II, Div. 1, Gr. E,F,G; Cl. III

WARNING - SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY

INTRINSICALLY SAFE WHEN

INSTALLED PER DRAWING 116-0275

-40°C<T <70°C

CSA Type 4X IP67

Exia

II 1G EEx ia IIC T4

LCIE 05ATEX6097X

Twinsburg, OH USA (330) 425-3555

2005-Nov-04

110-2417 / A

SCALE = 2X

Input = 9 - 30 Vdc Output = 4 - 20mA HART

a

Cl. I, Div. 1, Gr. A,B,C,D; T4

Cl. II, Div. 1, Gr. E,F,G; Cl. III

WARNING - SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY

INTRINSICALLY SAFE WHEN

INSTALLED PER DRAWING 116-0275

-40°C<T <70°C

CSA Type 4X IP67

Exia

II 1G EEx ia IIC T4

LCIE 05ATEX6097X

110-2417A 110-2417A->Released EDM checkout 2009-JAN-20

black

Twinsburg

CONFIDENTIAL acc. to ISO 16016 Only valid as long as released in EDM or with a valid production documentation!

PRINT PLATE for

CorrTran MODEL

respons.

approved

norm

US.JMB

date: 2007-Sep-28

sheet 1 of 2

110-2388D

plate number print laser sticker

scale: 1:1

Dieses Dokument enthält sicherheitsrelevante Angaben. Es darf nicht ohne Absprache mit dem Normenfachmann geändert werden!

This document contains safety-relevant information. It must not be altered without the authorization of the norm expert!

US.RHW

110-2388 U D

SCALE = 2X

Made in U.S.A.

Serial No.

Twinsburg, OH USA / www.pepperl-fuc hs.com

Part No.

Patents: 7,239,156 7,245,132

7,265,559 7,282,928

2007-Sep-28

110-2388 U D

Made in U.S.A.

Serial No.

Part No.

Patents: 7,239,156 7,245,132

7,265,559 7,282,928

110-2388D 110-2388D->Released EDM checkout 2009-JAN-20

CorrTran MV Corrosion Monitor

4

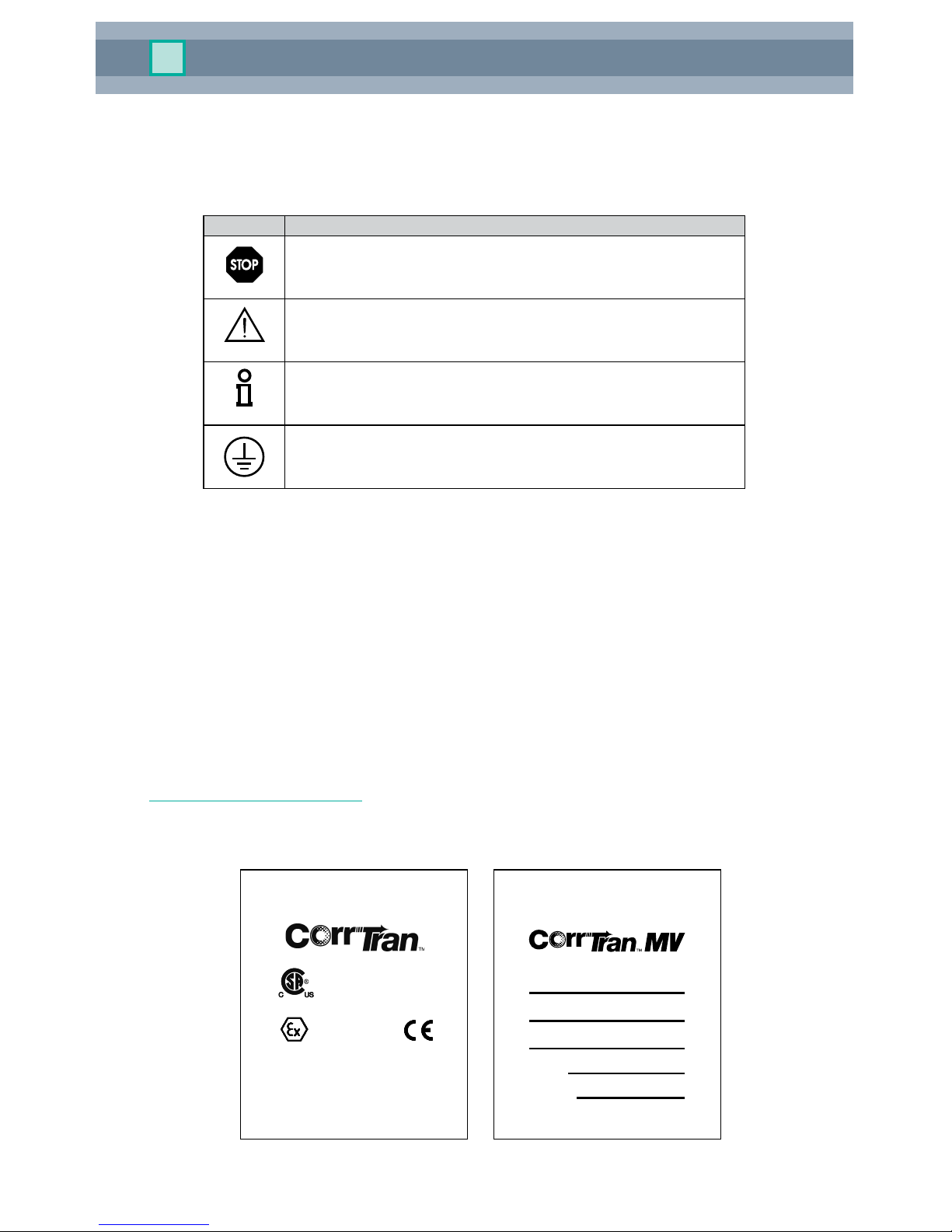

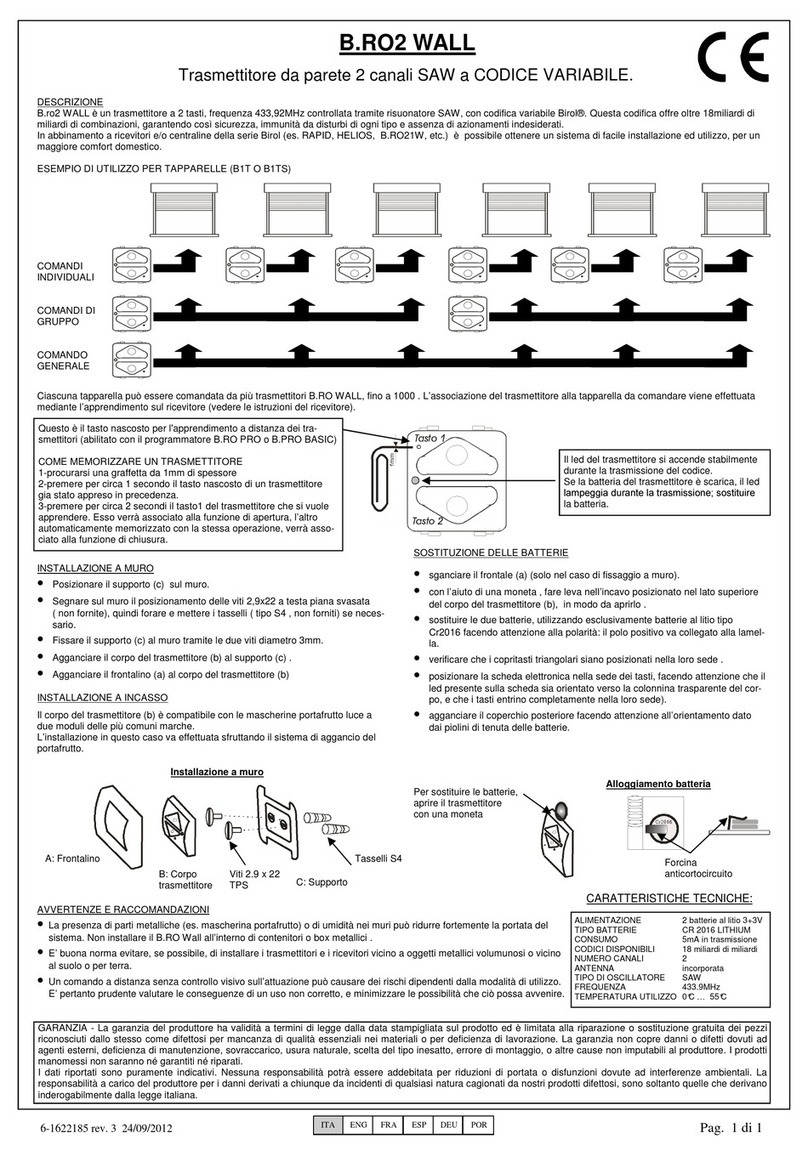

2.1.2 Key to model number

*Probe Mounting Guide and Electrode Material Guide can be found in the Appendix.

C M C M - - - A 2 I H - -

Insertion Length (fixed probes only)

in inches, 5" … 28", in 0.2" increments

050 5.0"

052 5.2"

…

278 27.8"

280 28.0"

in mm, 130mm … 710mm, in 5mm increments

130 130mm

135 135mm

…

705 705mm

710 710mm

Certificates

D2 cCSAus, NI, Cl. I,II,III; Div. 2, Group A-D

Ex cCSAus, EX, Cl. 1; Div. 1,2; Group A-D

GP gneral purpose

IS cCSAus, IS, Cl. I, II, III; Div. 1, 2; Group A-D

II 1G EEx ia IIC T4

Transmitter Mounting

1 direct mount

2 remote mount with 1.8m (6') cable

3 remote mount with 3.6m (12') cable

4 special mount

5 remote mount with 1.8m (6') cable with retrievable probe adapter

6 remote mount with 3.6m (12') cable with retrievable probe adapter

Electrical Output

IH 4-20 mA, HART

Housing

A2 aluminum housing, Nema 4x, 3/4" NPT

Electrode Material

0A… see electrode material guide

Probe Length

050* 5", 3/4" NPT

080 8", 3/4" NPT

110*

11", 3/4" NPT

120 12", 3/4" NPT or Flange

180 18", 3/4" NPT or Flange

240 24", 1" NPT, 3/4" NPT, or Flange

300 30", 1" NPT, 3/4" NPT, or Flange

127* 127 mm, 3/4" NPT

204 204 mm, 3/4" NPT

280* 280 mm, 3/4" NPT

305 305 mm, 3/4" NPT or Flange

457 457 mm, 3/4" NPT or Flange

610 610 mm, 1" NPT, 3/4" NPT, or Flange

762 762 mm, 1" NPT, 3/4" NPT, or Flange

ADP Retrievable Probe Electrical Adaptor

*epoxy probe only

Probe Mounting

See probe mounting guide

Measurement Unit, Probe Material

CB inches, 1.4435, 316L

CC inches, hastelloy C

CF inches, epoxy glass

DB mm, 1.4435, 316L

DC mm, hastelloy C

DF mm, epoxy glass

HF

HF applications, no glass seal

CS Special, consult factory

Process Connection

A31 1", flange ANSI B 16.5, 150 lbs

A32 1", flange ANSI B 16.5, 300 lbs

A61 2", flange ANSI B 16.5, 150 lbs

A62 2", flange ANSI B 16.5, 300 lbs

F61 DN40 PN6 Form B Flange

F65 DN40 PN40 Form B Flange

N21 3/4" NPT, ANSI B 1.20.1, 1.4435/316L

N2P

3/4" NPT, ANSI B 1.20.1, adj. thread, nylon

N31 1" NPT

U31 UNS 1-14, 1" left handed thread

XXX Special Version

*Consult factory for other available options

Corrosion Type

M Multivariable

CorrTran MV Corrosion Monitor

5

2.2 Contents of delivery

It is essential to follow the instructions concerning the unpacking, transport,

and storage of this instrument given in section 2.3, “Incoming acceptance,

transport, storage.”

The contents of delivery consist of:

• Assembledinstrument

• Stainlesssteelprobe

• 3-electrodeelements(ngertypesattachedlooselyinbox)

• Cable(remotemountversiononly)

• Accessories(ifanyareordered)

• Instructionmanual(thisdocument)

2.3 Incoming acceptance, transport, storage

2.3.1 Incoming acceptance

Check the packing and contents for any signs of damage. Check the shipment to ensure

that all parts have been included and to verify that the shipment matches your order.

All probes are shipped with the insulating gaskets installed. Upon removing the

protective cap, ensure that the O-rings are not loose. The O-rings are made of

Viton®(standard) or Kalrez (on request). If they are not installed, the probe will

not operate properly. Please refer to Figure 17 on page 20.

2.3.2 Transport

Protect the transmitter electrodes from damage. Do not attempt to carry the transmitter by

its electrodes.

2.3.3 Storage

Always pack the instrument for storage or transport to protect it against impact. The original

packing material provides the optimum protection for the device. The permissible storage

temperature is -40 °F to +176 °F (-40 °C to +80 °C).

2.4 Certicates and approvals

The CorrTran MV is designed to meet relevant safety requirements. It has been fully tested

to ensure that it is in safe operating condition. The instrument complies with the applicable

regulations in accordance with known standards.

2.5 Registered trademarks

HART®

Registered trademark of HART Communication Foundation, Austin, USA

Viton®

Registered trademark of the company E.I. Du Pont de Nemours & Co., Wilmington, USA

Teon®

Registered trademark of the company E.I. Du Pont de Nemours & Co., Wilmington, USA

2.6 Patents

This instrument is protected by one or more patents registered in the US Patent Office.

Warning

Attention

CorrTran MV Corrosion Monitor

6

3 INSTALLATION AND MOUNTING

3.1 Dimensions

1.8 or 3.6 m

(6 or 12 feet)

2.8 mm

(1.1")

76 mm

(3.0")

76 mm

(3.0")

ø 18 mm

(0.7")

29 mm

(1.15")

Extended cable

for remote mounting

length

3/4 NPT

96 mm

(3.8")

96 mm

(3.8")

160 mm

(6.3")

80 mm

(3.2")

19 mm

(0.75")

Transmitter

housing

(side view)

Transmitter

housing

(top view)

51 mm

(2.00")

190 mm

(7.50")

Ø 19 mm

(0.75")

70 mm

(2.78")

32 mm

(1.25")

¾ NPT

nylon

compression

thread

Adjustable epoxy glass

probe and electrode

32 mm

(1.25")

20 mm

(0.78")

51 mm

(2.00")

29 mm

(1.16")

Ø 19 mm

(0.75")

Ø 60 mm

(2.36")

26 mm

(1.02")

¾ NPT

compression

thread

Adjustable stainless steel

probe and electrode

3 electrode

end cap

Thread for direct

mount only

Length 204 mm, 305 mm, 458 mm,

611 mm, 763 mm (8", 12", 18", 24", 30")

29 mm

(1.16")

Ø 60 mm

(2.36")

26 mm

(1.02")

20 mm

(0.78")

30.5 mm

(1.20")

Ø 19 mm

(0.75")

min.

25.4 mm

(1.00")

¾ NPT

thread

Fixed stainless steel

probe and electrode

Thread for direct

mount only

Insertion length

3 electrode

end cap

Length 204 mm, 305 mm, 458 mm,

611 mm, 763 mm (8", 12", 18", 24", 30")

CorrTran MV Corrosion Monitor

7

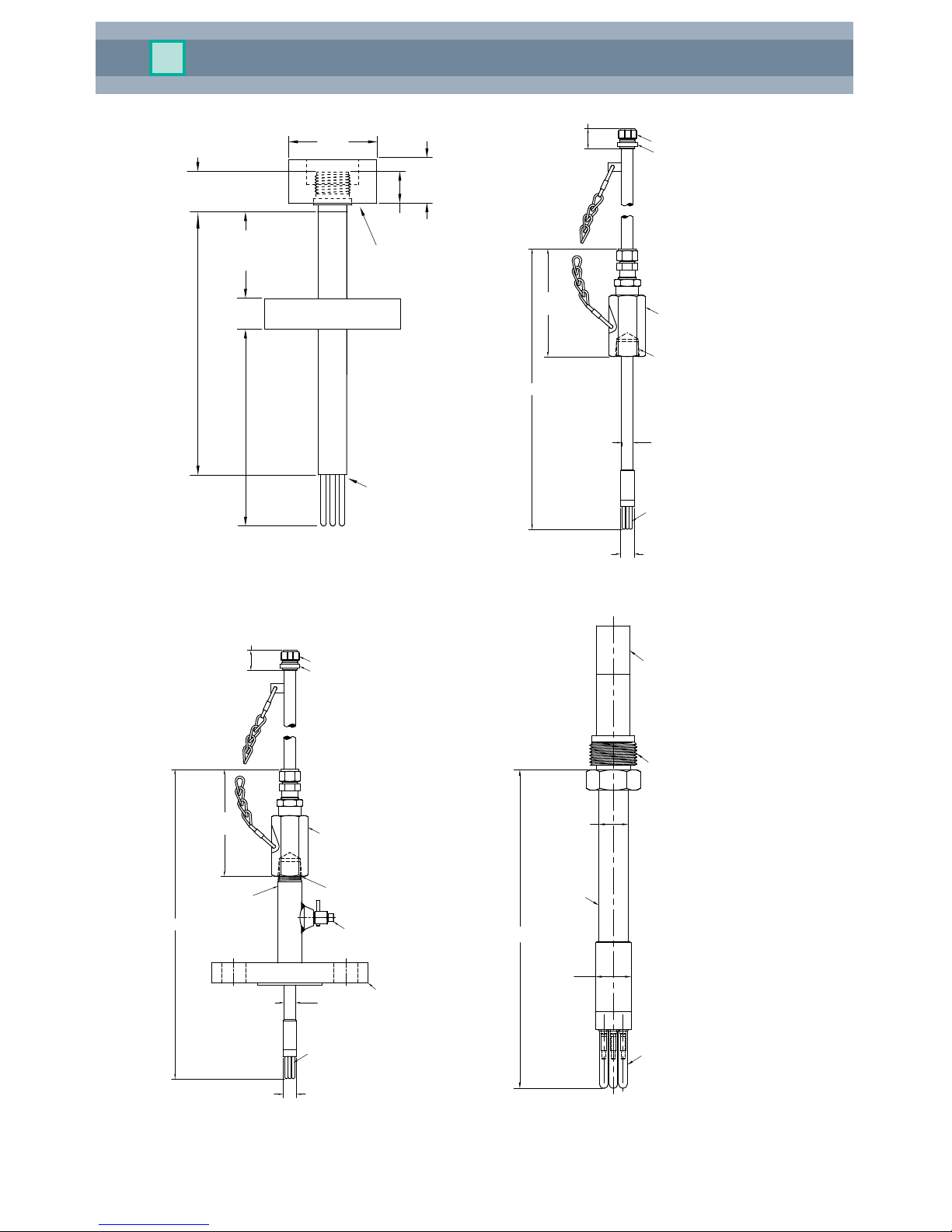

29 mm

(1.16")

Ø 60 mm

(2.36")

26 mm

(1.02")

20 mm

(0.78")

min.

50.8 mm

(2.00")

Thickness

ANSI B 16.5

standard

Stainless steel probe

with fixed flange

3 electrode

end cap

Thread for direct

mount only

Insertion length

Length 305 mm, 458 mm, 611 mm,

763 mm (12", 18", 24", 30")

(5.9")

I.L.

Six pin connector cap

Six pin circular connector

Ø5/8

Packing gland assembly

3x electrodes

(ordered separately)

Ø3/4

(1.6")

1" FNPT

Retractable probe & electrode,

remote mount

(5.9")

I.L.

Six pin connector cap

Six pin circular connector

Ø5/8

Packing gland assembly

(1.6")

Flange

1" NPT nipple

Bleed valve

Welded

3x electrodes

(ordered separately)

Ø3/4

Retractable flange & electrode,

remote mount

1-14 UNS-2A (L.H.)

Six pin circular connector

Ø5/8

Ø3/4

Insertion rod

3x electrodes

* specify alloy at

time of order

I.L.

Retrievable probe & electrode,

remote mount

CorrTran MV Corrosion Monitor

8

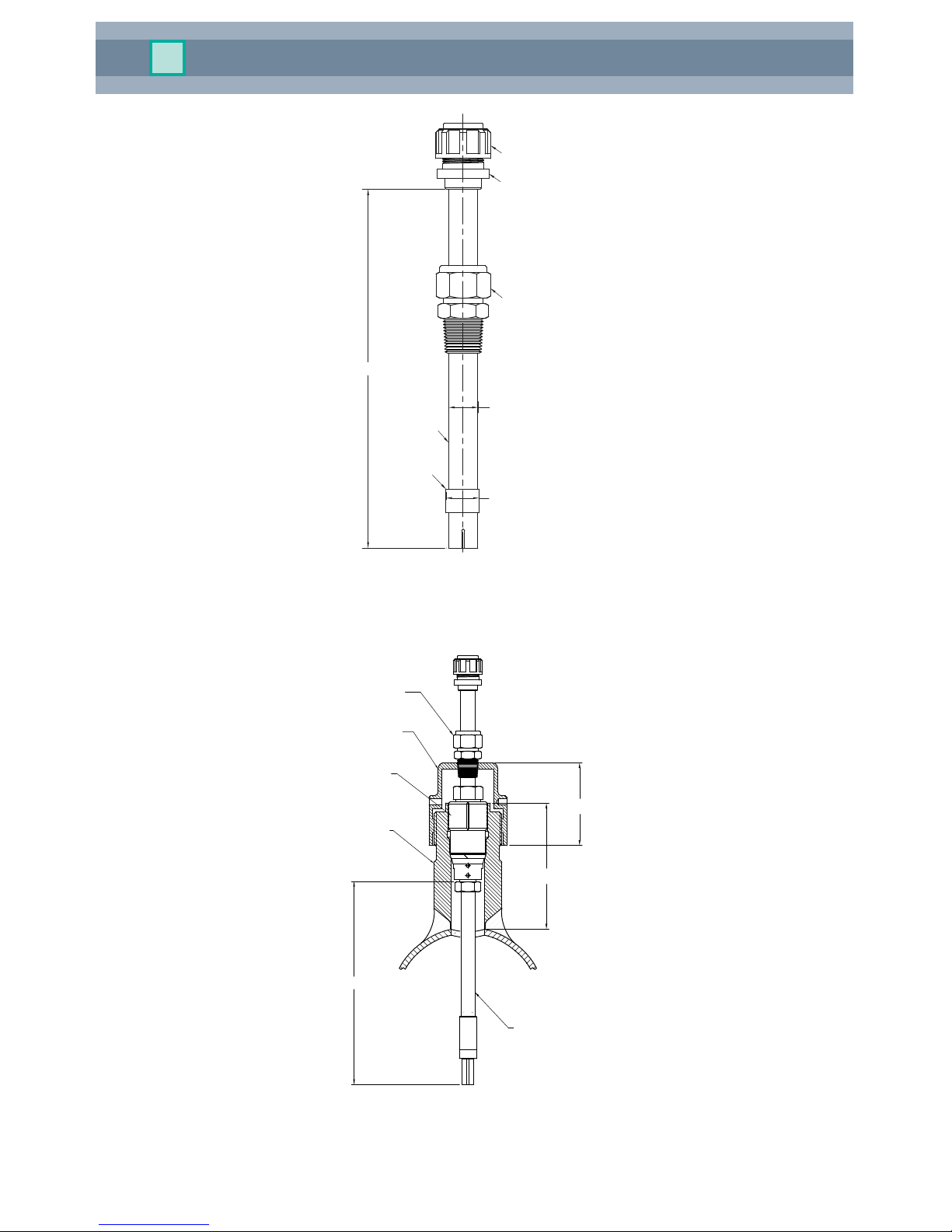

Six pin connector cap

Six pin receptacle assembly

1/2" NPT ø5/8" fitting

Ø5/8

Ø.7

Insertion rod

Blow out

preventer

(optional)

8"

Retrievable probe adapter,

remote mount

(3.88)

(5 1/4)

Hollow plug

assembly

Heavy protective cover

with 1/2" NPT

HP flareweld

access fitting

LPR probe

I.L.

Adj. probe exten. adapter

Retrievable probe complete

assembly, remote mount

CorrTran MV Corrosion Monitor

9

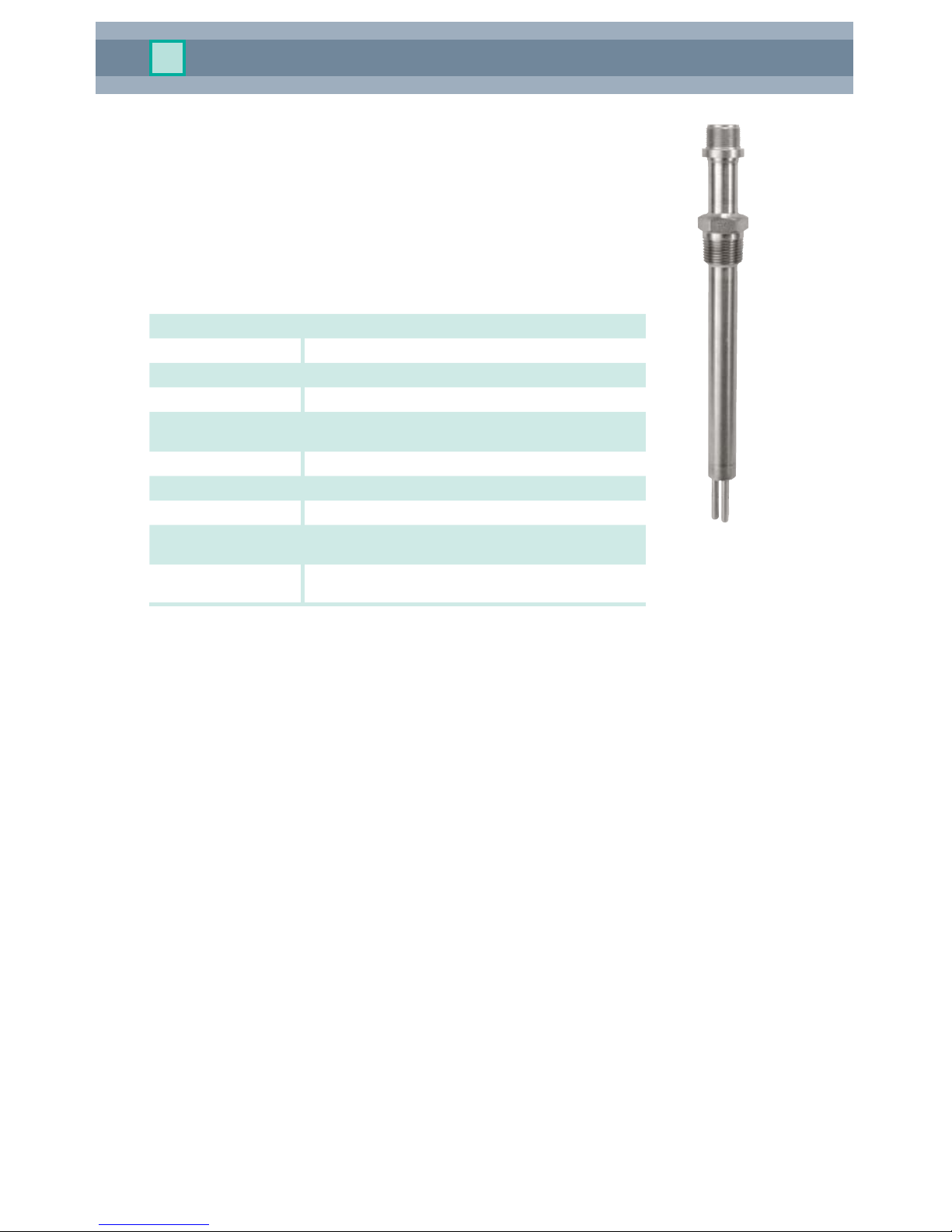

Figure 1. CMP Epoxy

Adjustable Probe

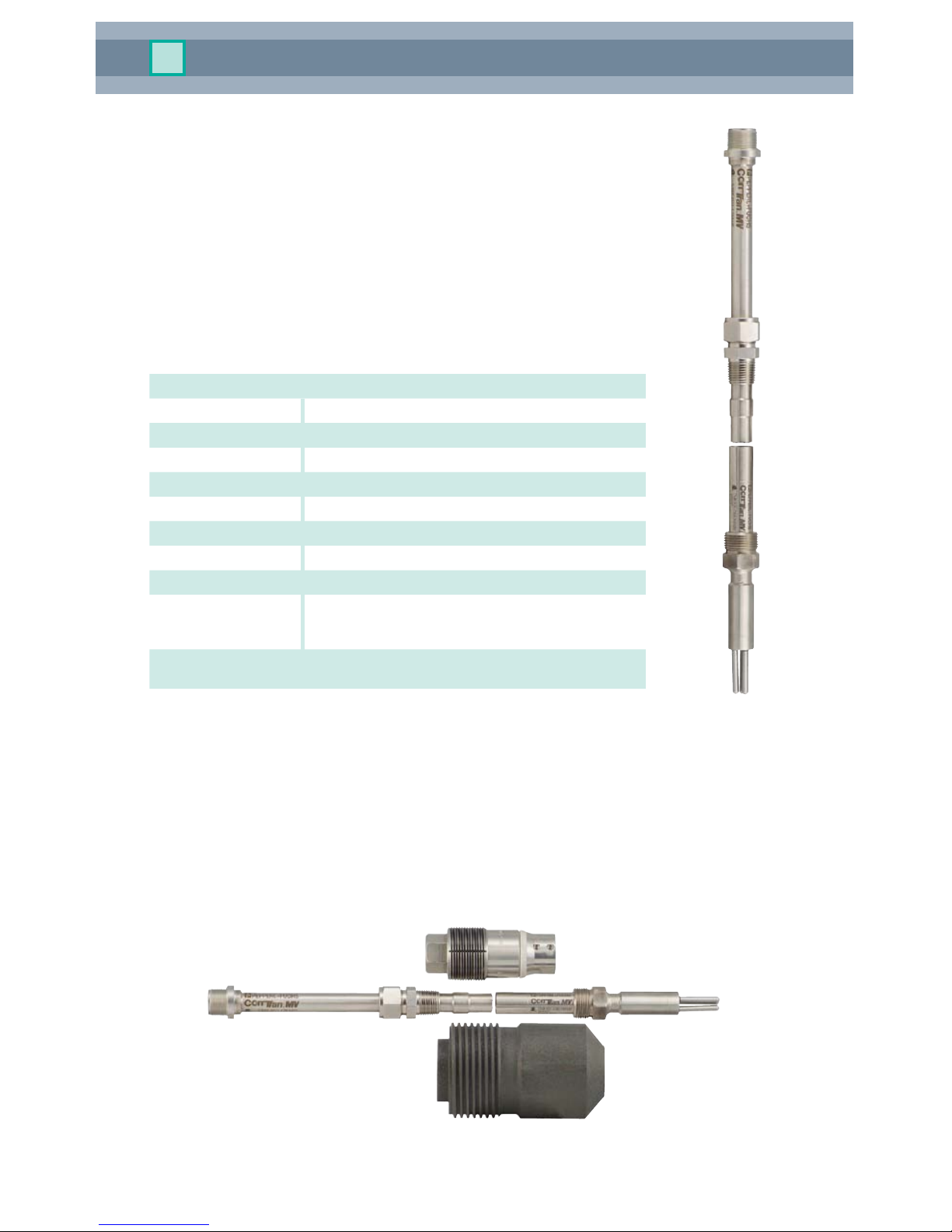

Figure 2. CMP

Adjustable Probe

3.2 Probe specications

CMP epoxy adjustable probe

The CMP epoxy adjustable probe (Figure 1) consists of a glass

epoxy probe with a ¾” NPT nylon compression tting for insertion

into the system. The studs for mounting the electrodes and the six-pin

connector are held in place by the epoxy ll material. This probe is

available in 127 mm and 280 mm (5” and 11”) lengths only. This probe

is only available with the remote mounting option.

Electrodes shown in the picture are ordered separately.

Specications

Probe Body Glass epoxy

Endcap Seal Epoxy

Fill Material Epoxy

Process Temperature -50…65 °C (-58…149 °F)

Pressure Rating 7 bar (100 psi)

Mounting 3/4” NPT nylon tting

Standard Lengths 127, 280 mm (5, 11”)

Custom Lengths N/A

Insertion Length Adjustable, Max = probe length - 89 mm (3.5”) + EL

*EL = 32 mm (1.25”) for nger and 0 mm (0”) for ush electrodes

CMP adjustable probe

The CMP adjustable probe (Figure 2) is an adjustable probe commonly

used in many eld applications. The assembly consists of a ¾” NPT

compression tting, an insertion rod with a hermetically sealed three-

electrode end cap, and a six-pin connector welded in place. The

insertion length is adjustable using the compression tting. This probe

is only available with both the remote and direct mounting options.

Electrodes shown in the picture are ordered separately.

Specications

Probe Body 1.4435, 316L SS; Hastelloy C

Endcap Seal Glass

Fill Material Epoxy

Process Temperature Direct mount: -50…121 °C (-58…250 °F)

Remote mount: -50…260 °C (-58…500 °F)

Pressure Rating 102 bar (1500 psi)

Mounting 3/4” NPT tting

Standard Lengths 204, 305, 457, 610 mm (8, 12, 18, 24”)

Custom Lengths Lengths available in increments of 10 mm (0.5”).

Min: 170 mm (7”), Max: 762 mm (30”)

Insertion Length Adjustable, Max = probe length - 51mm (2.0”) + EL

*EL = 32 mm (1.25”) for nger and 0 mm (0”) for ush electrodes

CorrTran MV Corrosion Monitor

10

Figure 3. CMP

Fixed Probe

CMP xed probe

The CMP xed probe (Figure 3) is a xed-length probe. The probe

assembly consists of a ¾” NPT pipe plug that is welded in place, an

insertion rod with a three-electrode end cap, a hermetically sealed

connector, and a six-pin connector welded in place. The insertion

length (I. L.) is calculated to the end of the electrode and must be

specied by the customer. This probe is only available with both the

remote and direct mounting options.

Electrodes shown in the picture are ordered separately.

Specications

Probe Body 1.4435, 316L SS; Hastelloy C

Endcap Seal Glass

Fill Material Epoxy

Process Temperature Direct mount: -50…121 °C (-58…250 °F)

Remote mount: -50…260 °C (-58…500 °F)

Pressure Rating 206 bar (3000 psi)

Mounting 3/4” NPT tting

Standard Lengths 204, 305, 457, 610 mm (8, 12, 18, 24”)

Custom Lengths Lengths available in increments of 10 mm (0.5”).

Min: 170 mm (7”), Max: 762 mm (30”)

Insertion Length Fixed, Max = probe length - 38 mm (2.5”) + EL,

Length specied in 5 mm (0.2”) increments.

*EL = 32 mm (1.25”) for nger and 0 mm (0”) for ush electrodes

CorrTran MV Corrosion Monitor

11

CMP xed ange probe

The CMP xed ange probe (Figure 4) is a xed-length probe. The

probe assembly consists of a specied ange that is welded in place,

an insertion rod with a three-electrode end cap, a hermetically sealed

connector, and a six-pin connector welded in place. The insertion

length (I. L.) is calculated to the end of the electrode and must be

specied by the customer. This probe is only available with both the

remote and direct mounting options.

Electrodes shown in the picture are ordered separately.

Specications

Probe Body 1.4435, 316L SS; Hastelloy C

Endcap Seal Glass

Fill Material Epoxy

Process Temperature Direct mount: -50…121 °C (-58…250 °F)

Remote mount: -50…260 °C (-58…500 °F)

Pressure Rating 206 bar (3000 psi)

Mounting Flange connection

Standard Lengths 305, 457, 610 mm (12, 18, 24”)

Custom Lengths Lengths available in increments of 10 mm (0.5”).

Min: 170 mm (7”), Max: 762 mm (30”)

Insertion Length Fixed, Max = probe length - ange thickness - 50.4

mm (2.0”) + EL, Length specied in 5 mm (0.2”)

increments.

*EL = 32 mm (1.25”) for nger and 0 mm (0”) for ush electrodes

Figure 4. CMP

Fixed Flange Probe

CorrTran MV Corrosion Monitor

12

Figure 5. CMP

Retractable Probe

CMP retractable probe

The CMP retractable probe (Figure 5) is an adjustable-length

probe. A specially designed packing gland is used with the probe

for insertion into or retraction from a pressurized system without a

process shutdown. The packing gland is designed to mount easily

on a 1” piping system with a ball valve, but it can be modied for

your specic mounting requirements. The probe assembly consists

of a packing gland, an insertion rod with a hermetically sealed

three-electrode end cap, and a six-pin connector welded in place.

A safety chain is also provided to prevent blowout. The insertion

length (I. L.) is calculated to the end of the electrode and can be

specied by the customer. This probe is only available with the

remote mounting option.

Electrodes shown in the picture are ordered separately.

Specications

Probe Body 1.4435, 316L SS; Hastelloy C

Endcap Seal Glass

Fill Material Epoxy

Process Temperature Remote mount: -50…260 °C (-58…500 °F)

Pressure Rating 102 bar (1500 psi)

Mounting 3/4” NPT tting

Standard Lengths 610, 762, 914, 1066 mm (24, 30, 36, 42”)

Custom Lengths Lengths available in increments of 10 mm (0.5”).

Min: 170 mm (7”), Max: 762 mm (30”)

Insertion Length

Adjustable, Max = probe length - 165 mm (6.5”) + EL

*EL = 32 mm (1.25”) for nger and 0 mm (0”) for ush electrodes

CorrTran MV Corrosion Monitor

13

Figure 6. CMP

Retractable Probe

CMP retractable ange probe

The CMP retractable ange probe (Figure 6) is an adjustable-

length probe. A specially designed packing gland is used with

the probe for insertion into or retraction from a pressurized

system without a process shutdown. The packing gland

is welded to a 1” pipe nipple with bleed valve attached to

a specied ange, and is designed to mount easily on a

matching ange valve. The probe assembly consists of a

packing gland, 1” pipe nipple with bleed valve welded to

specied ange, an insertion rod with a hermetically sealed

three-electrode end cap, and a six-pin connector welded in

place. A safety chain is also provided to prevent blowout. The

insertion length (I. L.) is calculated to the end of the electrode

and can be specied by the customer. This probe is only

available with the remote mounting option.

Electrodes shown in the picture are ordered separately.

Specications

Probe Body 1.4435, 316L SS; Hastelloy C

Endcap Seal Glass

Fill Material Epoxy

Process Temperature Remote mount: -50…260 °C (-58…500 °F)

Pressure Rating 102 bar (1500 psi)

Mounting Flange connection

Standard Lengths 610, 762, 914, 1066 mm (24, 30, 36, 42”)

Custom Lengths Lengths available in increments of 10 mm (0.5”).

Min: 170 mm (7”), Max: 762 mm (30”)

Insertion Length Adjustable, Max = probe length - ange thickness -

255 mm (10”) + EL

*EL = 32 mm (1.25”) for nger and 0 mm (0”) for ush

CorrTran MV Corrosion Monitor

14

Figure 7. CMP

Retrievable Probe

and Probe Adapter

CMP retrievable probe

The CMP retrievable probe (Figure 7) is a xed-length probe. It is

designed to be used with HPTM and MHTM high-pressure access

systems. The probe assembly consists of an insertion rod with a

hermetically sealed three-electrode end cap, a hollow plug nut, and a

standard six-pin connector, which are all welded in place. The hollow plug

nut on the probe screws into the hollow plug of the access system. This

allows the probe to be installed in the process, using a retrieval tool and

service valve, without process shutdown. The insertion length (I. L.) is

calculated using one of the formulas bellow and must be specied by the

customer. This probe is only available with the remote mounting option.

Electrodes shown in the picture are ordered separately.

Specications

Probe Body 1.4435, 316L SS; Hastelloy C

Endcap Seal Glass

Fill Material Epoxy

Process Temperature Direct mount: -50…121 °C (-58…250 °F)

Remote mount: -50…260 °C (-58…500 °F)

Pressure Rating 245 bar (3600 psi)

Mounting UNS 1-14, 1” left-handed thread

Standard Lengths Length dependent on insertion length

Insertion Length

Finger Electrodes

Top-of-the-line: I.L. = PD + WT + 44.5 mm (1.75”)

Middle-of-the-line: I.L. = PD + WT + 22.25 mm (.875”)

Bottom-of-the-line: I.L. = PD + WT

Insertion Length

Flush Electrodes

I.L. = PD + WT + 44.5 mm (1.75”)

*EL = 32 mm (1.25”) for nger and 0 mm (0”) for ush

*PD = Penetration depth, for ush mount PD = 0

*WT = Wall thickness

Hollow plug and access tting are ordered separately.

CorrTran MV Corrosion Monitor

15

3.3 Mounting safety procedures and hints

The CorrTran MV must be installed in locations that are most susceptible to corrosion.

In most cases, the highest levels of corrosion tend to occur where water is trapped or

stagnant.

The electrodes selected must reect the same metal properties as the piping or other

components susceptible to corrosion. For example, in applications where the pipe is made

of stainless steel and the water pump’s impeller is made of carbon steel, the impeller will

corrode faster than the pipe. In this case, it is advisable to select electrodes that are made

of the same material as the pump’s impeller.

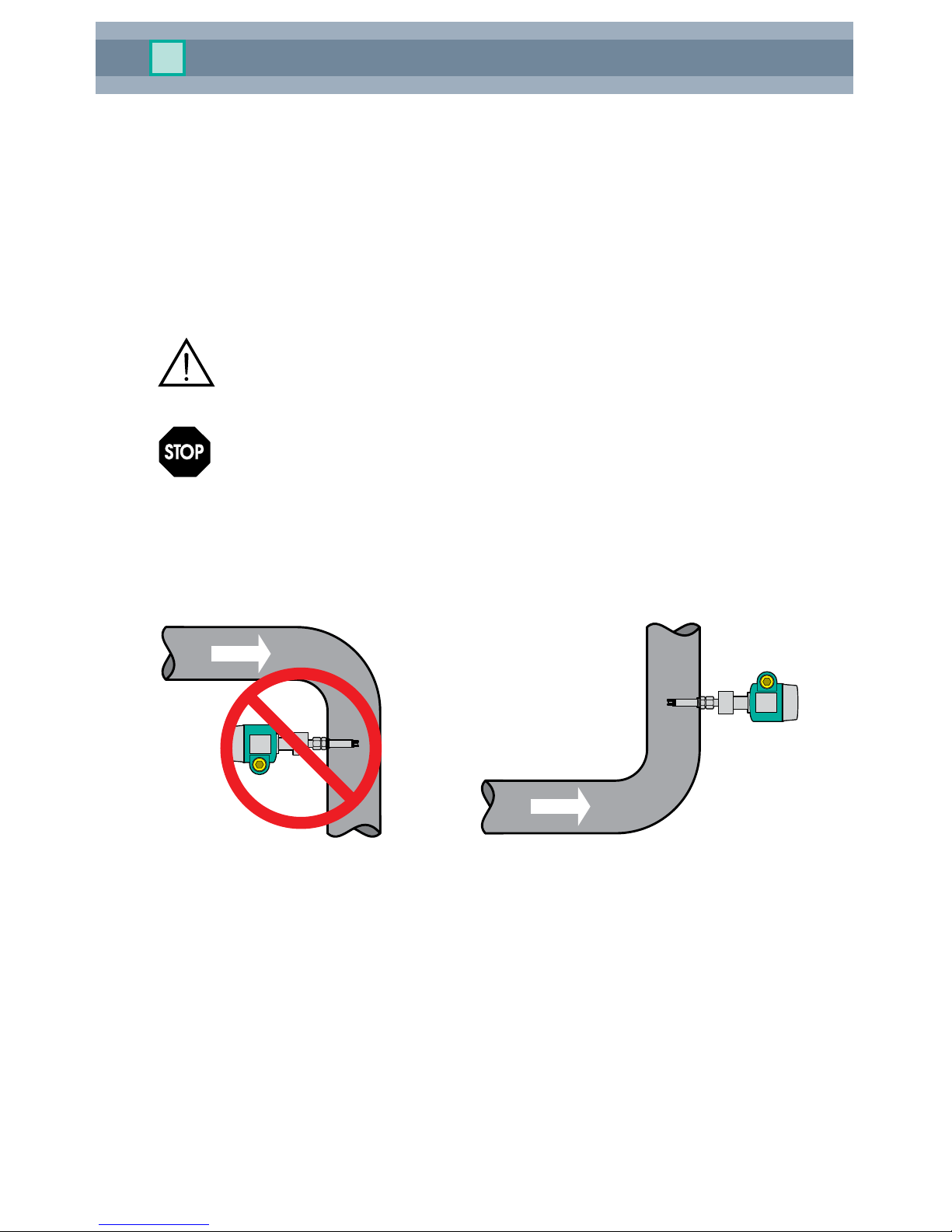

3.3.1 Mounting requirements / scenarios

The transmitter should not be mounted in a pipe drop since the corrosive liquid

may not be in full contact with the electrodes as shown in Figure 8.

CorrTran MV should be mounted in the riser of a pipe near an elbow where the

velocity is the highest. In general, CorrTran MV should be mounted in pipes

or tanks at locations of highest liquid velocity and constant immersion, shown

in Figure 9. For velocities greater than 20 fps, the protruding nger electrodes

must be protected. As noted above, high uid velocities can also cause unwanted

turbulence in the pipe due to the extension of the probe. Using an adjustable CorrTran MV

probe with electrodes mounted ush to the wall of the pipe will eliminate this problem.

Warning

Attention

OK!

Figure 8. CMC Transmitter Installation Figure 9. CMC Transmitter Installation

CorrTran MV Corrosion Monitor

16

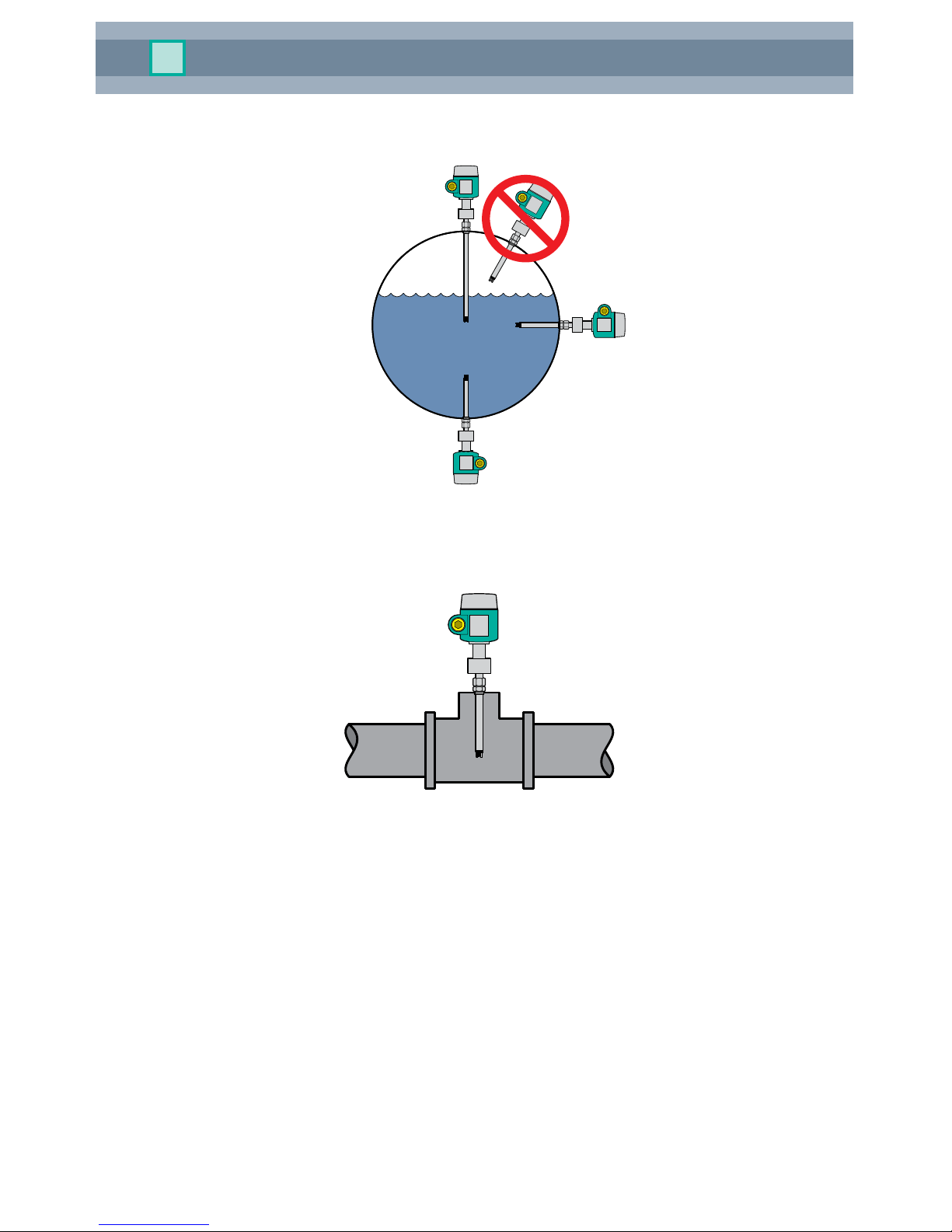

CorrTran MV can be located at any point on the pipeline but should always be immersed in

the corrosive material as shown in Figure 10.

Figure 10. Correct CorrTran MV Pipeline Position

A tee in the condensate return line (Figure 11) is a good location to mount CorrTran MV.

Figure 11. CorrTran MV Located in Tee

CorrTran MV Corrosion Monitor

17

CorrTran MV should be located downstream of a control valve for best performance and

can also be located in the deadleg portion of a by-pass. Note that the transmitter located

in the by-pass leg should be mounted in front of the valve for best performance. As shown

in Figure 12. This guarantees that the electrodes will always be immersed in the corrosive

material.

Figure 12. CorrTran MV Located in Bypass Loop

Installing separate CorrTran MV units with different electrode materials on the

suction side of the pump will ensure monitoring of the pump impeller and the pipe

as shown in Figure 13.

There should be a minimum separation distance of 50 cm (19.7”) between probes.

Figure 13. CorrTran MV Mounted With Different Electrodes

Note

CorrTran MV Corrosion Monitor

18

In addition to pipes, a condensate ash tank, shown in Figure 14, is also a good application.

Figure 14. CorrTran MV Installed in a Condensate Flash Tank

The CorrTran MV transmitter is shown in the blow down of a Y-strainer in Figure 15, and the

discharge side of the basket strainer is shown in Figure 16.

Figure 15. CorrTran MV Mounted in

Y-Strainer

Figure 16. CorrTran MV Mounted in

Basket Strainer

It is essential that isolators are installed between the transmitter and the control

system if the I/O card is not fully isolated from the ground. See section 4.3 for

more information on the proper installation wiring.

Note

CorrTran MV Corrosion Monitor

19

3.4 Installation instructions

3.4.1 General

A trained specialist must perform the necessary installation and commissioning

of CorrTran MV. Recognized rules of the technology and setup requirements

must be maintained both during and after installation. Safety requirements

must be observed during all installation steps.

If the pipe or vessel into which the CorrTran MV is to be inserted is under

pressure and/or contains any hazardous substance, such as steam, caustic

solutions, acids, toxins or other substances specied by OSHA as physical or

health hazards, the pipe or vessel must rst be depressurized, any hazardous

substance purged therefrom, and appropriate lockout/tagout procedures

observed in accordance with Section 1910.147 of the OSHA Regulations,

before CorrTran MV can be installed. Failure to follow these procedures may

result in serious injury or death.

CorrTran MV consists of three basic components:

Transmitter: A transmitter housing contains the electronics and provides the 4-20 mA with

HART output signal.

Probe: There are two basic options, direct mount and remote mount. The remote mount

probe is supplied with a 6’ or 12’ cable.

Electrodes: Either nger electrodes or electrodes ush to the probe end are used. Correctly

chosen electrodes will corrode in the same manner as the metal being investigated. For

accurate measurements, the electrodes must reect the same metal properties as the

metal being investigated.

3.4.2 Electrode installation

The electrodes are shipped loose and must be installed hand-tight. Ensure that the Viton

(standard) or Kalrez (on request) gaskets are in place prior to installing the electrodes. See

Figure 17 for the electrode installation drawing.

Metal Samples recommends changing the electrodes when they are at 50% of

their useful life:

• Finger:0.4mmmaterialloss.Thismeansthatwithanaveragegeneralcorrosion

rate of 16 mpy (0.4 mmpy) you would have to replace once a year.

• Flush:3.175mmmaterialloss.Thismeansthatwithanaveragegeneral

corrosion rate of 127 mpy (3.175 mmpy) you would have to replace once a year.

Figure 17. Electrodes and Viton Gaskets

Warning

Electrodes Viton Gaskets

Note

Table of contents

Popular Transmitter manuals by other brands

JAROLIFT

JAROLIFT TDRC01W Original assembly and operating instructions

Allmatic

Allmatic B.RO2 WALL quick start guide

Becker

Becker Centronic SunWindControl SWC441-II Assembly and operating instructions

Sennheiser

Sennheiser SK 250 Instrucciones para el uso

Phonic Ear

Phonic Ear 340T user guide

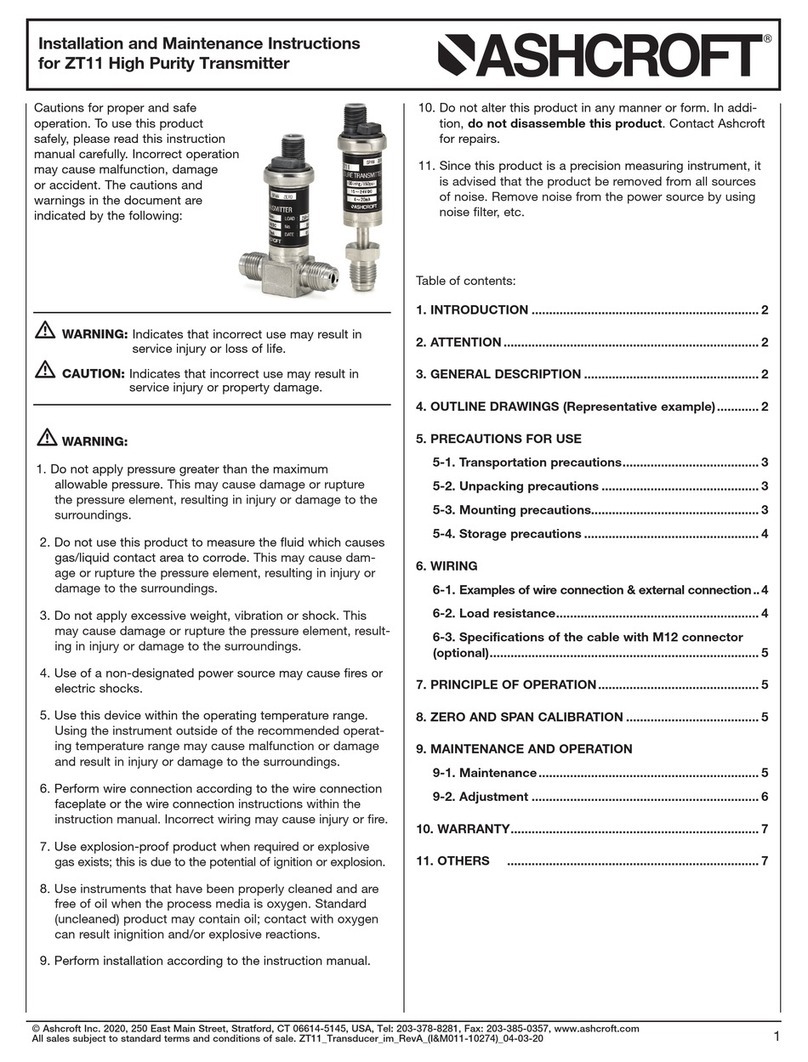

Ashcroft

Ashcroft ZT11 Installation and maintenance instructions