Metal Samples MS2500E User manual

MS2500E Transmitter

Operator’s Manual

Metal Samples Company

A Division of Alabama Specialty Products, Inc.

152 Metal Samples Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515

E-mail: [email protected] Internet: www.metalsamples.com

.

Table of Contents

I. General Description ........................................................................................................ 1

A. Introduction .............................................................................................................. 1

B. General Description.................................................................................................. 1

C. Principles of Operation............................................................................................. 2

D. Technical Specifications........................................................................................... 3

II. InstallationandOperation.................................................................................................. 4

A. ReceivingtheMS2500ETransmitter ........................................................................... 4

B. Installation .................................................................................................................. 4

1. MechanicalMounting............................................................................................ 4

Figure1. PreferredInstallation ........................................................................... 5

2.ElectricalConnection .............................................................................................. 5

C. SafeAreaWiring ........................................................................................................ 6

D. HazardousAreaWiring............................................................................................... 6

1. ProbeSelectionTerminals ..................................................................................... 7

2. Calibration............................................................................................................ 7

Figure2. CalibrationConnections ...................................................................... 8

Figure 3. Switch Locations................................................................................ 9

3. Operation ............................................................................................................. 9

Figure4.Output LinearRelationship .................................................................. 10

4. DeterminingCorrosionRate .................................................................................. 10

E. SelectingtheProbe ..................................................................................................... 10

1. ProbeReplacementCalculation............................................................................. 10

F. Maintenance ............................................................................................................... 11

G. ReturningtheInstrumentforRepair ............................................................................. 12

III. MaintenanceandRepairInstructions.................................................................................. 13

IV. WarrantyInformation ........................................................................................................ 15

.

1

I. General Description

A. Introduction

The development of the MS2500E Transmitter provides the corrosion engineer with a simple,

lowcost, computer-compatible corrosion monitoring instrument. Designed to be incorporated into

a 20 mAcurrent loop, the MS2500E Transmitter uses the principle of electrical resistance to deter-

mine the corrosion rate of a metal specimen immersed in a process stream. The electrical resis-

tance of a metal specimen is a physical property dependent on the specimen’s physical dimensions

(length and cross section) and on the metal’s inherent resistivity. If all other factors remain con-

stant, any decrease in the cross section of a metal specimen will increase its resistance.

The MS2500E Transmitter is used in process systems for which appropriately designed electrical

resistance probes are available. Such systems include, but are not limited to nonaqueous, noncon-

ductive process streams, process streams where erosion-corrosion occurs and process streams

having either a predominant liquid or vapor phase. Examples of industries where such process

streams are found include chemical plants, refineries, gas plants, oil and gas production systems,

paper mills, power plants and tank farms.

B. General Description

The MS2500E Transmitter provides a two-wire interface between a single electrical resistance

probe and a customer-supplied process computer, recorder, or control system, or between a probe

and the MS2510 Receiver (ordered separately). The MS2510 Receiver and the MS2500E Trans-

mitter function together as a stand-alone, single-station monitoring system.

The current loop connecting the Transmitter and the data receiving station may be up to 11 miles in

length for circuits that do not include safety barriers and up to 1 mile for intrinsically safe circuits

(circuits that do include safety barriers or their equivalent). A customer-supplied DC power source

energizes the monitoring system. Probe signals representing metal loss are processed by the Trans-

mitter and are relayed to the data receiving station as a 4-20mA signal.

Unlike similar devices available from other manufacturers, the MS2500E Transmitter does not

require factory modification to accommodate different probe types.Asimple field calibration pro-

cedure permits the MS2500E to be used with any electrical resistance probe. The MS2500E will

accommodateall MetalSamples electricalresistance probesand mostof theelectricalresistance probes

ofothermanufacturers.

The MS2500E Transmitter is available in one enclosure style. This style is mounted on any flat

surface up to 5 feet from the probe and is connected to the probe via a special cable, model

Cb-8140 (included).

2

C. Principles of Operation

Electrical resistance probes contain a continuous sensing device that is divided into “elements”

connected in series. These elements include a measuring element and a reference element. The

measuring element is exposed to the corroding environment. The resulting loss of metal de-

creases the measuring element’s thickness and causes an increase in this element’s resistance.

The reference element is protected from the corroding environment and retains its original

thickness and resistance. The MS2500E Transmitter is powered by a customer-supplied 10-35V

DC power source. As the probe’s measuring element corrodes, the Transmitter sends to the data

receiving station a proportional 4-20mA signal that represents the element’s metal loss.

The measurement technique employed by the Transmitter eliminates electrical resistance

changes due to temperature fluctuations by measuring the ratio of the exposed measuring

element’s resistance to that of the protected reference element’s resistance exposed. This ratio

then regulates Transmitter output current (4-20mA) such that it represents the metal lost by the

exposed element. For example, a Transmitter output current of 4mA indicates 0 (zero) corro-

sion. An output current measurement of 20mA indicates the end of probe life.

The Transmitter’s 4-20 mA current range is “divided” into 1,000 probe reading units. A single

unit represents 0.001 of probe life. Probe life is equivalent to the amount of metal that the

measuring element can lose during the useful life of the probe. Initial probe measurements

taken when the probe is first installed will be at approximately 0 to 100 units. The maximum

probe measurement (20 mA) is equivalent to 1000 units.

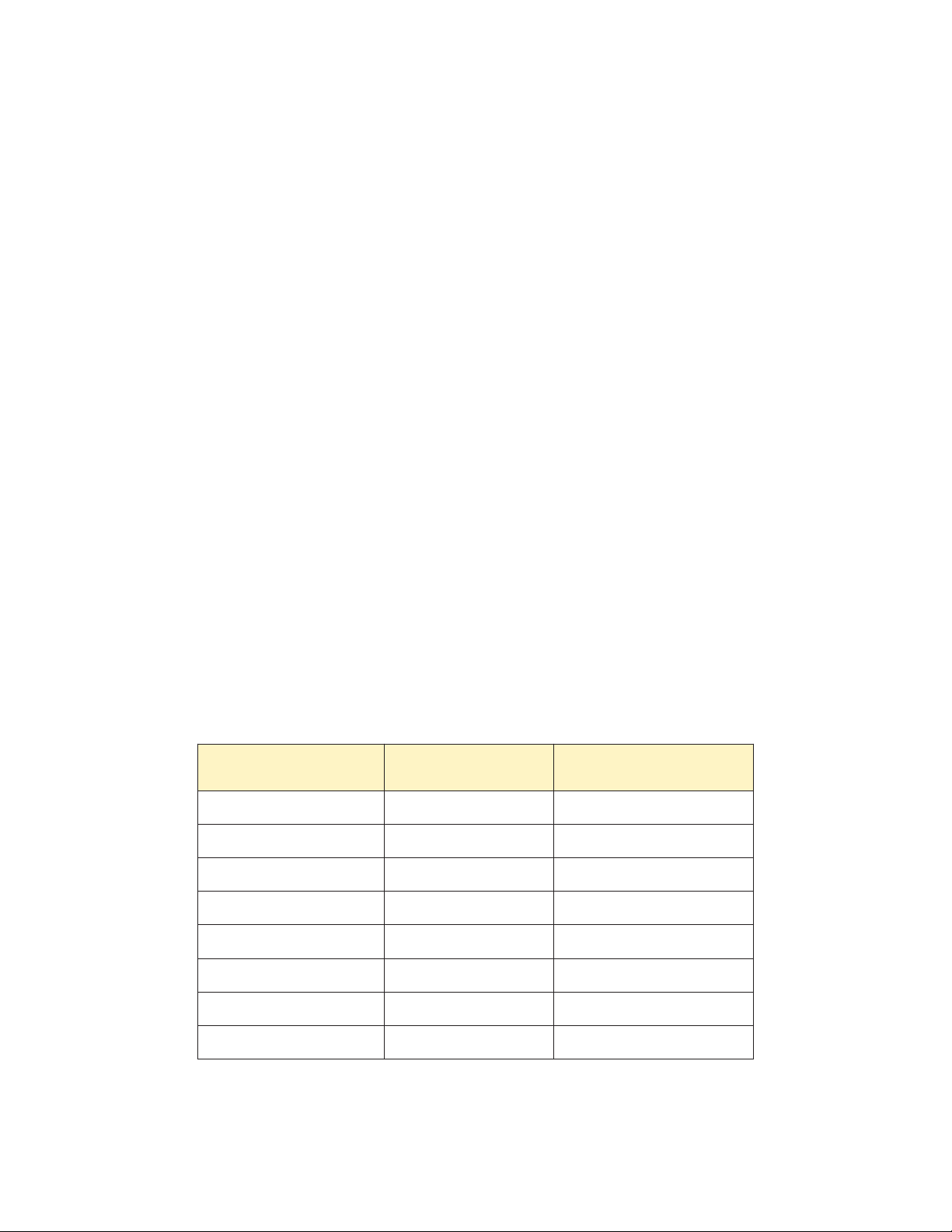

Expectedprobelife forelements presentlyavailable fromMetal Samplesarelistedinthe tablebelow.

epyTtnemelE ssenkcihT

)sllim(

efiLevitceffE

)sllim(

pooLralubuT42

84

pooLeriW0401

0802

lacirdnilyC015

0201

csiDhsulF55.2

015

3

D. Technical Specifications

Model

MS2500E- Loop-PoweredERTransmitter (Ordering # IN2500)

Physical Data

InstrumentWeight: 5.02 lb. (2.28 Kg)

TotalWeightw/Accessories: 7.08 lb. (3.21 Kg)

InstrumentDimensions: 5.81"Hx 4.5"Wx 4.81"D (14.76cm x 11.43cmx 12.22cm)

CaseSpecifications: ExplosionProof (FM, CSA, CENELEC, UL)

Class I, Groups B, C, D, Class II, Groups E, F, G, Class III,

CENELEC: EexdIIC

NEMA 4X, 7BCD, 9EFG

MountingSpecifications: 0.728"Hx 1.756"W (1.85cm x4.46cm)Bolt Pattern with 1/4-

20TappedMounting Holes, or May Be Mounted on a 1/2" to

2"(1.27cm to 5.08cm)Pipe Using SuppliedHardware

OperatingTemperature: 0° to 140°F (-18° to 60°C)

StorageTemperature: -40° to 176°F (-40° to 80°C)

PerformanceData

MeasurementType: ERmeasurementusing anystandard ERprobe type(Wire

Loop,TubeLoop,Cylindrical, Flush,Strip,etc.)

Range: 0-100%of probe life

Resolution: 0.4%of FullScale

CycleTime: 1Minute

Electrical Data

PowerRequirements: 10 to 35 VDC

MaximumProbeCableDistance: 5 ft (1.52 m)

OutputSpecifications: 4-20mACurrent Loop Output

IntrinsicSafety: Certifiedto CAN/CSA

STD E9-0-95 & E79-11-95

ClassI,Division 1,

Groups C and D, T4

Special Features

• Switchselectable probetype (wireloop,tube loop,cylindrical, etc.)

• Loop powered

Accessory Items

5'Probe Cable (attached), MeterProver,Mounting Hardware,Operation Manual

4

II. Installation and Operation

A. Receiving the MS2500E Transmitter

Check the MS2500E Transmitter for damage when it is first received. Obvious damage to the

shipping carton should be brought to the attention of the responsible carrier’s agent.

When the MS2500E is unpacked, verify that the shipping carton contains the following items:

1. MS2500E Transmitter

2. 5' Cb-8140 Probe Cable (attached to housing)

3. Meter Prover

4. MS2500E Transmitter Operator’s Manual

B. Installation

Installation of the MS2500E Transmitter involves the following three procedures:

1. Mechanical Mounting

2. Electrical Connection

3. Calibration

Caution: If the transmitter is to be installed in a safe area, complete the three installation proce-

dures in the order listed above. However, if the transmitter is to be installed in a hazardous area,

complete the calibration procedure first; then follow with the mechanical mounting procedure

and the electrical wiring procedure.

1. Mechanical Mounting

The MS2500E must be mounted on a flat surface connected to earth ground. Locate it within 5

feet of the installed probe and connect the transmitter to the probe via Cb-8140 connection

cable. The transmitter will not function properly if cable other than Cb-8140 is used or of

extension cable is added.

Note: If the transmitter is to be located in a nonhazardous area, allow sufficient vertical clear-

ance for the removal of the enclosure top so that wiring and calibration procedures can be

completed. See Drawing 1 for MS2500E dimensions.

5

Figure 1. Preferred Installation

2. Electrical Connection

The current loop cable used to connect the MS2500E Transmitter with its power supply must be

a twisted pair, shielded, industrial gauge cable. The current loop cable enters the MS2500E via

the Transmitter’s 1/2-inch NPT access hole and is connected to the two loop connection termi-

nals located within the Transmitter enclosure. Polarity is critical when attaching the cable to the

MS2500E loop connection terminals. The loop connection terminals are easily accessed by

unscrewing the top of the Transmitter’s enclosure.

Caution: Do not connect cable shielding to the Transmitter. The shield must remain floating at

the Transmitter.

The maximum permissible length of the current loop cable that connects the Transmitter and its

power supply is determined by the power supply voltage, the electrical resistance of the current

loop cable and the load of the receiver/CPU. If the Transmitter is to be installed in a safe area,

refer to the paragraph Safe Area Wiring for details; if the Transmitter is to be installed in a

hazardous area, refer to Hazardous Area Wiring instructions.

6

C. Safe Area Wiring

For basic safe area wiring information, refer to the circuit diagram shown in Drawing 2. Use

the following equation to determine maximum permissible cable length:

Where:

D = Max. cable length in feet.

VS= Power supply voltage.

R = Cable resistance in ohms per 1000 feet.

Example:

VS= 24 Volts

R = 16.1 (22 AWG cable)

D. Hazardous Area Wiring

Whenever an electrically driven sensor or measuring device is used in a potentially explosive

environment the measuring system must be installed in such a way that electrical energy is

either effectively isolated from the explosive environment (via explosive-proof containers,

cable conduits, etc.) or the amount of electrical energy produced in the hazardous area must be

limited to an intrinsically safe level.

Limiting electrical energy is the most practical method of protecting the MS2500E measuring

system when the Transmitter is installed in a hazardous area. In the MS2500E system, electri-

cal energy limits are maintained by the use of a repeater safety barrier (or its equivalent)

installed in the 4-20 mA current loop per standard practice. The safety barrier must be located

in the safe area near the boundary between the safe and hazardous areas. The safety barrier will

Vs- 10

(4 x 10-5) (R)

D =

D =

24 - 10

(4 x 10-5) (16.1)

D = = 21,739 feet

7

repeat the signal current generated by the Transmitter and will relay the signal to the data receiv-

ing station.

Caution: When a safety barrier is used with the MS2500E system, the current loop cable must

be connected to the barrier’s hazardous area terminals. All other connections must be made to

the barrier’s safe area terminals.

The type of repeater safety barrier employed in the MS2500E system depends on the specific

classificationofthehazardousenvironment inquestion.MetalSamples willprovide,uponrequest,

assistanceandtechnicaladvice inthe selectionof arepeater safetybarrier orits equivalent.

Formostinstallations, MetalSamplesrecommends theintrinsically safeMTL2441 RepeaterPower

Supply.

The maximum length of the current loop cable that connects the MS2500E Transmitter to the

repeater safety barrier is as follows:

Example:

17.5 Volts

22 AWG Cable = 5,434 feet maximum

16 AWG Cable = 21,788 feet maximum

1. Probe Selection Terminals

Housed within the MS2500E enclosure are probe selection terminals which correspond to

specific element types and which are used in the calibration procedure outlined below. The

probeselectionterminalspermittheTransmittertobe usedwith allMetal SamplesER probesand with

electricalresistanceprobes availablefrom othermajor manufacturers,regardlessofprobeelement type

orelementthickness.

2. Calibration

For routine calibration checks, a meter prover is provided. These units are factory calibrated

before shipment and being solid potted exhibit no drift with time unless mechanically damaged.

The meter prover is stamped with a three-digit number that represents percent of full scale (to

one decimal place). Instruments should be checked against the meter every six months by dis-

connecting the instrument probe cable from the probe and plugging the meter prover into the

probe cable connector. The instrument should be allowed to perform measurements on the

8

prover for 12 minutes. The value of the meter prover should be reproduced by the instrument

±0.5%. The relationship between the recorded loop current and the meter prover value is:

x = Loop current (Milliamps)

P = Prover value

Should the instrument be outside the calibration limits, the following recalibration should be

carried out before rechecking with the meter prover

Refer to the figure below while completing the following calibration procedure for the MS2500E

Transmitter.

MS2500

Figure 2. Calibration Connections

1. Unscrew the instrument cover.

2. Connect the 4-20mA current loop as in the figure.

3. Set the selector switches to "4mA" (see table below). Adjust the calibration potentiometer

R22 until the ammeter reads 4.00mA.

4. Set the selector switches to "20mA" (see table below). Adjust the calibration potentiometer

R20 until the ammeter reads 20.00mA.

5. Replace instrument cover.

6. The MS2500E is now calibrated.

x (1000)

P = x - 4

16

9

3. Operation

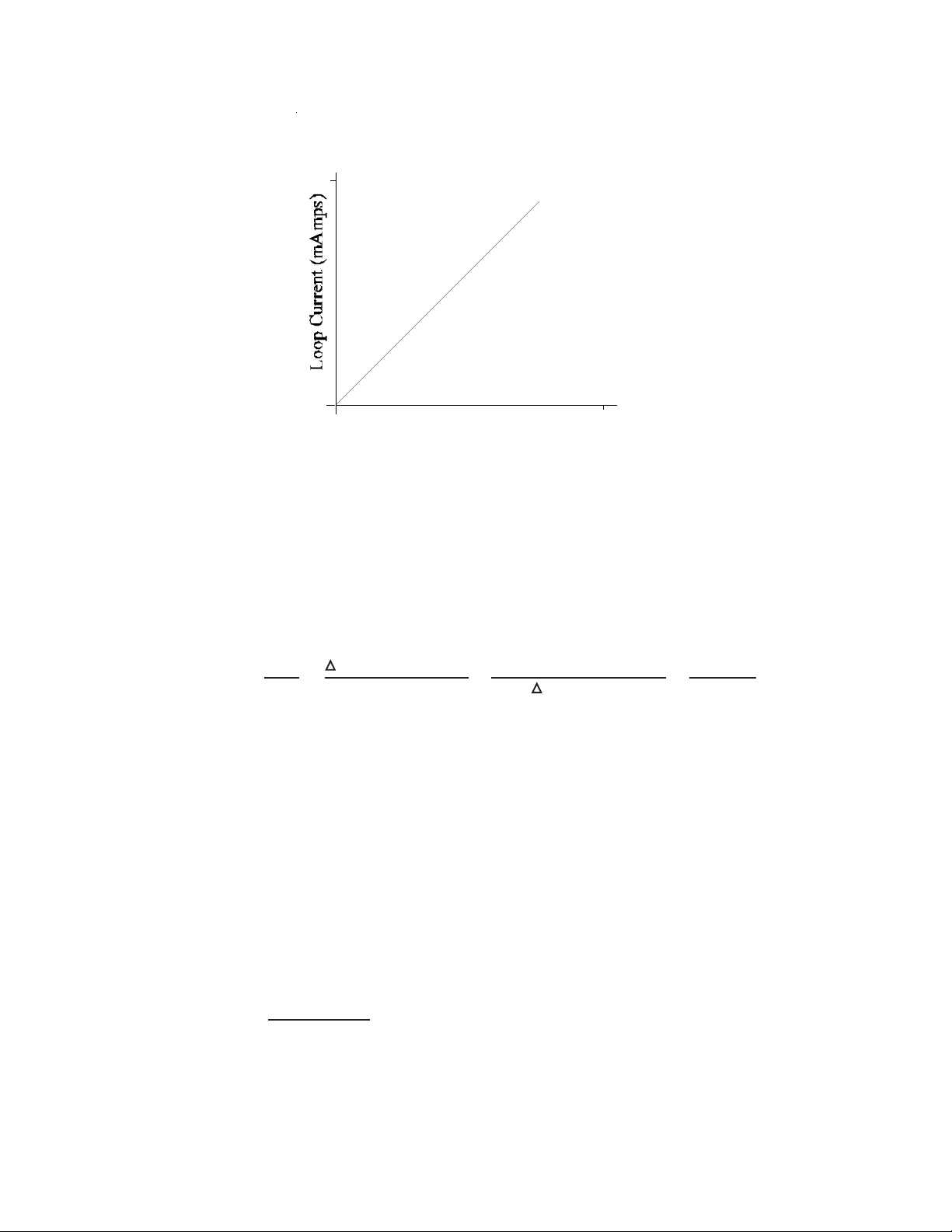

As shown in Figure 4, the transmitter output is linear. Initial Transmitter current output begins at

4mA and increases to a maximum of 20mA. The maximum output of 20mA indicates that the

measuring element has been completely corroded and that the probe must be replaced.

Figure3. Switch Locations andOrientation

21

TUBE

WIRE

SPEC

TEST

R22 R20

FA

+-

4-20mA Loop

Connection

Calibration

Potentiometers

Digital

Circuit Board

Probe Selection

Switch

Switches are UP

Switch is DOWN

*20mAsetting isillustratedin Figure3below.

10

01000

4

20

Probe Start Probe Finish

Probe Units

Figure 4. Output Linearity Relationship

4. Determining the Corrosion Rate

Use the following formula to determine the corrosion rate occurring at the installed probe:

E. Selecting the Probe

To avoid premature probe failure, match the expected probe operating lifetime to the process

system’s expected corrosion rate. This will permit probe replacement during scheduled shut-

downs.

1. Probe Replacement Calculation

A probe replacement calculation is as follows:

T = L x 365

(R)

Corrosion Rate =xx

(mils)

(year) 16 (mA)

Probe Reading (mA) Effective Probe Life (mils)

Time (days) 365 (days)

(year)

11

Where:

L = Effective life in mils.

R = Expected corrosion rate in mils per year.

T = Replacement period in days.

Since the initial estimation of expected corrosion rate prior to monitoring may be in error,

definitely replace probe if transmitter output reaches 20 mA.

F. Maintenance

Once installed, the MS2500E does not require maintenance. However, if malfunctions occur

which cannot be attributed to the data receiving station, power supply, or safety barrier, proceed

as follows:

1. Ensure that the probe is operational and is not completely corroded.

2. Examine all electrical connections for proper electrical connections, signs of corrosion and to

ensure that the connections are environmentally protected.

3. Recalibrate the MS2500E Transmitter following the calibration procedure.

4. ContactMetalSamplesfortechnicalassistanceiftheTransmittercontinuestomalfunctionfollowing

recalibrationoriftheTransmitterisobviously damaged.If advisedto returnthe MS2500Efor repair,

followtheInstructionsforReturningtheInstrumentforRepair.

12

G. Returning the Instrument for Repair

Complete the following procedures to ensure the fastest possible repair and return cycle:

1. If possible, pack the instrument in the original shipping carton. If the original carton is not

available, pack the instrument in a rigid cardboard or wooden carton. Surround the instrument

with a minimum of three inches of resilient packing material such as foam rubber or shredded

newspaper.

2. Ship the instrument prepaid via Air Freight or Air Express to:

MetalSamples

152 Metal Samples Road

Munford, AL 36268

3. Contact Metal Samples by telephone (256) 358-4202orbyfax (256) 358-4515 and inform your

salesrepresentativeof:

a. the name of the airline carrying the instrument

b. the flight number

c. the estimated time of arrival

d. the waybill number and delivery instructions

4. When the instrument is packed, include a copy of the form on the next page, filled in as

required, to expedite the repairs.

13

III. Maintenance and Repair Instructions

Thisformmay bephotocopied forusewhen returninginstruments toMetalSamplesforrepair.

Pleasefillinallknowninformation. Encloseacopyofthefilledinformwiththeinstrument.

1. CHECK ONE:

Repair this instrument under warranty.

Repair this instrument regardless of problem or cost of repair.

Inspect the instrument and advise the customer of the approximate cost of

repairs if the instrument is not covered under warranty. (Note - this

proceduremaydelaythereturn ofthe instrumentto you.)

2. INSTRUMENTIDENTIFICATION:

Instrument Model Number:

Serial Number:

Date of Purchase:

Company’s Purchase Order Number for Original Sale:

3. RETURN THE INSTRUMENT TO:

Company Name:

14

Address:

Telephone Number:

4. INVOICE INSTRUCTIONS:

5. DESCRIPTION OF TROUBLE:

(A clear description of the problem may shorten the repair time.)

6. URGENCYOF REPAIR:

Shipping Address:

MetalSamples

152 Metal Samples Road

Munford, AL 36268

15

IV. Warranty Information

MetalSamples warrants that any part ofthe MS2500E and accessories which provesto be defective

inmaterialor workmanshipwithinone yearofthedateof originalshipmentto Purchaserwillberepaired

orreplaced, at Metal Samples option, free of charge.Thiswarranty does not cover (1) probe assem-

blies,(2) itemsexpendable innature, or (3)items subjectto damagefromnormal wear, misuse or

abuse,orfailure tofollow useand careinstructions.

Alldamaged itemsare to beshipped atPurchaser’s expenseto andfromMetal Sampleswhich shall

havethe rightto finaldetermination astothe existenceand causeof adefect.

Theforegoingshall constitutethe soleand exclusiveremedy ofanypurchaserofMetal Samplesprod-

uctsfor breach of warranty and ISEXCLUSIVEAND IN LIEU OFALLOTHERWARRANTIES,

EXPRESSED,IMPLIED OR STATUTORY,INCLUDING THEIMPLIEDWARRANTIES OR

MERCHANTABILITYAND FITNESS. INNO EVENTSHALLMETALSAMPLESBE LIABLE

FOR SPECIALOR CONSEQUENTIALDAMAGES, OR FORANY DELAYINTHE PERFOR-

MANCE OF THISWARRANTYDUETO CAUSES BEYOND ITS CONTROL.

Orders or request for additional information should be addressed to:

MetalSamples

P.O. Box 8

Munford, AL 36268

Telephone: (256) 358-4202

Fax: (256) 358-4515

The technical information and suggestions contained herein are believed to be reliable, but they

are not to be construed as warranties since conditions of use are beyond our control.

Shipping Address

MetalSamples

152 Metal Samples Road

Munford, AL 36268

Telephone: (256) 358-4202

Fax: (256) 358-4515

Table of contents

Other Metal Samples Transmitter manuals

Metal Samples

Metal Samples MS2901E User manual

Metal Samples

Metal Samples MS2600E User manual

Metal Samples

Metal Samples MS2500L User manual

Metal Samples

Metal Samples CORR Velox MS2800E User manual

Metal Samples

Metal Samples CORR VELOX MS2801E User manual

Metal Samples

Metal Samples MS2701E User manual

Metal Samples

Metal Samples MS2700E User manual

Metal Samples

Metal Samples MS2601E User manual