Metal Samples MS2600E User manual

MS2600E

High Resolution ER 4-20mA Transmitter

Operator’s

Manual

Metal Samples Company

ADivision of Alabama Specialty Products, Inc.

152 Metal Samples Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515

.

Table of

Contents

I.Introduction..............................................................................................................................................1

A.GeneralDescription...................................................................................................................1

B.PrinciplesofOperation..............................................................................................................1

C.TechnicalSpecifications.............................................................................................................3

II.InstallationandOperation.......................................................................................................................4

A.ReceivingtheMS2600ETransmitter.........................................................................................4

B.Installation.................................................................................................................................4

1.PhysicalMountingandProbeConnection...................................................................4

a.Direct‐ProbeMounting

......................................................................................4

b.RemoteMounting..............................................................................................5

2.CurrentLoopConnection.............................................................................................5

a.MakingConnections........................................................................................5

b.Grounding.........................................................................................................6

c.WiringforaSafeAreaInstallation....................................................................7

d.WiringforaHazardousAreaInstallation..........................................................7

3.SetupandOperation.......................................................................................................9

a.ProbeSelectionSwitches................................................................................9

b.TestingtheCurrentLoop..............................................................................10

i.Calibration...............................................................................................10

ii.Testingloopoutputzero(4mA)andspan(20mA).................................10

iii.TestingtheMS2600EwiththeMeterProver..........................................10

c.InterpretingData............................................................................................11

i.MetalLoss................................................................................................11

ii.CalculatingCorrosionRate.......................................................................11

d.Commissioning..............................................................................................13

C.Maintenance............................................................................................................................13

D.Troubleshooting.......................................................................................................................14

III.ServiceandWarrantyInformation.......................................................................................................15

A.Warranty...................................................................................................................................15

B.ObtainingServiceandReturningtheInstrumentforRepair....................................................15

C.InstrumentRepairForm...........................................................................................................16

AppendixA‐Drawings...............................................................................................................................17

ControlDrawing(HazardousAreaWiringDiagram).....................................................................18

SafeAreaWiringDiagram.............................................................................................................19

AppendixB–RevisionHistory...................................................................................................................20

.

1

I.Introduction

A.GeneralDescription

TheMS2600Eisahigh‐resolutionmeterdesignedtotransmitcorrosion(metalloss)datafroman

ElectricalResistance(ER)probetoaplantcontrolsystemorotherrecordingdevice.TheMS2600E

utilizestraditional4‐20mAcurrentloopcommunicationandisloop‐powered,soitrequiresonlyatwo‐

wireinterface.Thisresultsinasimpleandlow‐costinstallation.Theuseofthe4‐20mAprotocolalso

allowstheMS2600Etobeplacedgreatdistancesfromthecontrolsystemorrecorderwhile

maintaininggoodnoiserejection.Practicalcurrentloopdistancescanbemanythousandsoffeet(see

pages6and7forexactspecifications.)

TheMS2600EiscompatiblewithalltypesofMetalSamplesERprobes,aswellasanystandardER

probefromothermanufacturers.Unlikecompetitors’products,theMS2600ETransmitterdoesnot

requirefactorymodificationtoaccommodatedifferentprobetypes.Theprobetypecanbeeasily

changedatanytimeusingtheon‐boardprobeselectionswitches(seepage9.)

TheMS2600Eisavailableasdirect‐mount(standard)orremote‐mount.Inthedirect‐mountversion

theMS2600EismounteddirectlytotheERprobe.Thisoptionoffersthesimplestinstallationand

minimizesnoiseproblems.Theremote‐mountoptionallowstheMS2600Etobemounted

independentlyfrom(butincloseproximityto)theERprobe.Itisthenconnectedtotheprobeviaa

shortprobecable.(Seepage5formountingdiagramsandspecifications.)

B.PrinciplesofOperation

TheMS2600EoperatesontheElectricalResistance(ER)techniqueandisusedinconjunctionwithan

ERprobe.TheERprobeutilizesaresistivesensingelementmanufacturedfromthematerialof

interest(oracloseapproximation)whichisexposedtoacorrodingenvironment.Thisiscalledthe

ExposedorCorrodingElement.TheresistanceoftheExposedElementisdirectlyrelatedtoits

thickness,soastheelementcorrodestheresultinglossofmetalcausesaproportionalincreaseinthe

element’sresistance.TheprobealsocontainsaninternalReferenceElementwhichisusedto

compensatefortheinfluencesoftemperatureontheExposedElement.

TheMS2600EisdesignedtoworkwithanystandardERprobe,butitisrecommendedthatCylindrical

andLargeFlushtypeprobesbeusedtoensureoptimumperformance.Theirphysicaldesignplaces

theReferenceElementincloserproximitytotheExposedElementcomparedtootherprobetypes,

providingmoreeffectivetemperaturecompensationandthusreducingtheeffectsofthermalnoise.

Becausetheyaredesignedtocorrode,ERprobesaresacrificialinnature.EachERprobewillhavea

finitelifethatisbasedontheelementthickness.ERprobesareavailableinanumberofgeometries

andthicknessesdesignedtosuitawidevarietyofapplications.Table1liststhecommonERelement

optionsavailablefromMetalSamplesandtheeffectivelifeofeach.

2

ElementTypeCompatibilityThicknessProbeLife

(Span)

TubularLoopCompatible

42

84

WireLoopCompatible

4010

8020

Flush(Small)Compatible

4 2

8 4

20 10

CylindricalPreferred

10 5

20 10

50 25

Flush(Large)Preferred

52.5

10 5

20 10

40 20

Table1.StandardERProbeElements

TheMS2600EmeasuresanERprobeutilizingahigh‐resolution,16‐bitmeasurement.Thisallowsthe

MS2600Etodetectmuchsmalleramountsofmetalloss,thusrespondingfastertocorrosionevents

andupsets(comparedtotraditionalERmeters.)At16‐bitresolutiontheMS2600Ecanmeasure

metallossamountsassmallas0.0015%oftheprobelife.

MetallossreadingstakenbytheMS2600Eareconvertedtoalinearized4‐20mAcurrentloop

output.The4‐20mAsignalcanbefedintoaplantcontrolsystemorotherdevicesandscaled

accordinglytoreflectmetalloss.Thencorrosionratescanbecalculatedbasedonthemetalloss

dataovertime.Thisiscoveredinmoredetailonpages11and12.MoreinformationonERprobes,

theirtheory,selection,andusecanbefoundonourwebsiteat http://www.alspi.com/erintro.htm.

3

C.TechnicalSpecifications

ModelMS2600E‐HighResolutionER4‐20mATransmitter

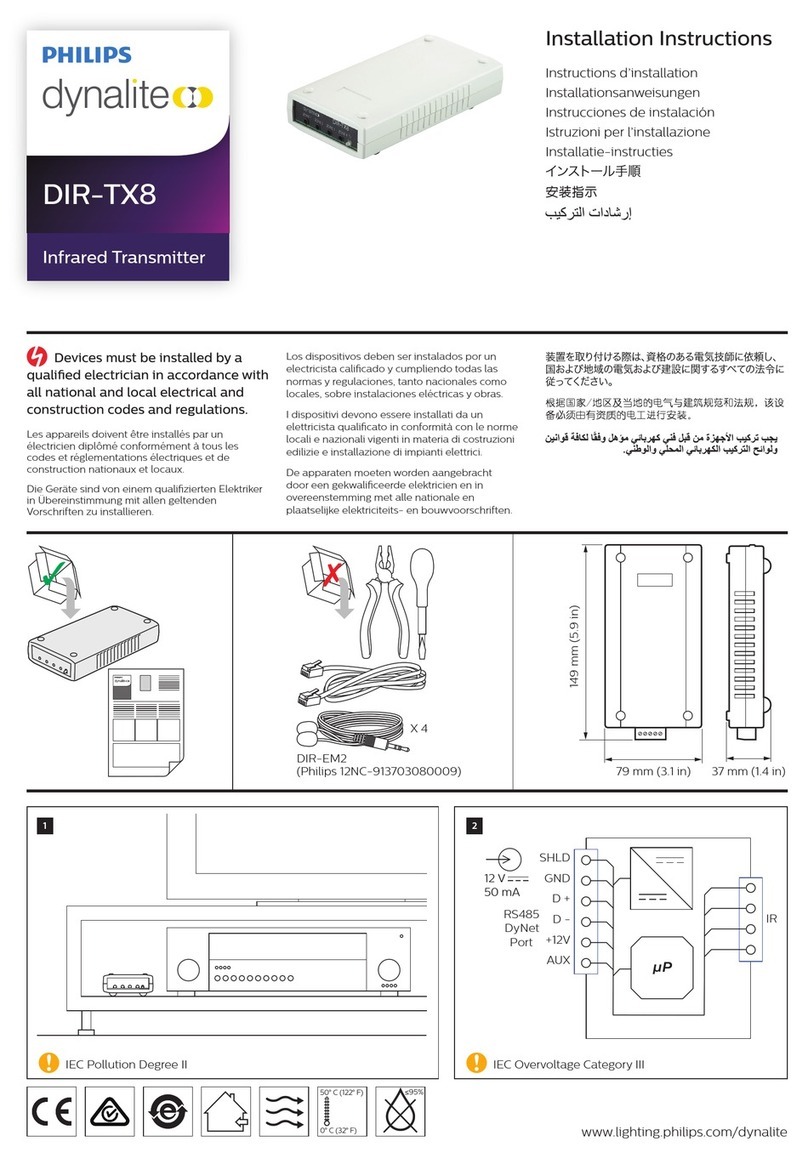

PhysicalData

InstrumentWeight: 3.70lb.(1.68Kg)

TotalWeightw/Accessories:5.76lb.(2.61Kg)

InstrumentDimensions:6.0"Hx4.0"Dia

(15.25cmHx10.16cmDia)

OperatingTemperature:

StorageTemperature:

32°to158°F(0°to70°C)

-40°to176°F(‐40°to80°C)

EnclosureMaterial:316StainlessSteel

MountingSpecifications:Directprobemount(standard)

Maybepolemountedusingoptionalhardware

(Uptoa2.5”(6.35cm)Dia.pole)

PerformanceData

MeasurementType: ERmeasurementusinganystandardERprobetype

(WireLoop,TubeLoop,Cylindrical,Flush,Strip,etc.)

Range:0‐100%ofprobelife

Resolution:0.0015%ofProbeLife(16‐bit)

CycleTime:1Minute

ElectricalData

PowerRequirements:10to28VDC

MaximumProbeCableDistance:30ft(9.1m)

OutputSpecifications:4‐20mACurrentLoopOutput

HazardousLocationCertifications–IntrinsicSafety

USA/CanadaConformstoANSI/ULStd.60079‐0,60079‐11,61010‐1

CAN/CSAStd.E66079‐0,E60079‐11&CAN/CSAC22.2No.61010‐1

ClassI,Zone0,AExiaIICT4Ga

Zone20,AExiaIIICT130°CDa

‐20°C≤Ta≤+70°C

EuropeandWorldwideII1GExiaIICT4Ga

(ATEXandIECEx)II1DExiaIIIT130°CDa

‐20°C≤Ta≤+70°C

ATEXCertificateNo:ITS14ATEX27981X

IECExCertificateNo:IECExITS14.0010X

X.Probedielectricrating<500Vr.m.s.Donotexceed.

IncludedAccessories

33’(10meters)CurrentLoopWiringHarness(providedtofacilitatewiringtoanearbyjunctionbox,can

becuttolengthifrequired),MeterProver,OperationsManual

OptionalAccessories

ProbeExtensionCable,RemoteMountingHardware

4.0”Dia

(10.16cm)

6.0”H

(15.25cm)

Figure1.MS2600EDimensions

4

II.InstallationandOperation

A.ReceivingtheMS2600ETransmitter

ChecktheMS2600ETransmitterforanyshippingdamagewhenitisfirstreceived.WhentheMS2600E

isunpacked,verifythatthefollowingitemsareincluded:

MS2600ETransmitter

CurrentLoopWiringHarness

MeterProver

User’sManual

ProbeCable(optional,forremote‐mountonly)

MountingHardware(optional,forremote‐mountonly)

Intheeventofshippingdamage,quantityshortage,ormissingitems,itisrecommendedthatthe

eventisdocumentedimmediatelyandthatdigitalphotographsaretaken.Anyshortagesormissing

itemsshouldbereportedtoMetalSamplesimmediately.Intheeventofshippingdamage,aclaim

shouldbeopenedwiththeresponsiblecarrier.

B.Installation

CAUTION:Usingthisproductinanywayotherthanthatspecifiedwithinthismanualmayimpairthe

intrinsicsafetyprotection.

InstallationoftheMS2600ETransmitterinvolvesthefollowingsteps:

1. PhysicalMounting

2. ElectricalConnection

3. SetupandProgramming

1.PhysicalMountingandProbeConnection

WhenselectingalocationtomounttheMS2600Eitisimportanttoconsiderthesurrounding

environment.Toensureproperoperation:

DonotmounttheMS2600Einalocationthatexceedsitsoperatingtemperature.

AvoidmountingtheMS2600Enearsourcesofstrongelectricalnoise.

Ensurethatthereissufficientclearanceforinstallationandtoopenthetransmittercover

afterwards.

a.Direct‐ProbeMounting

TheMS2600Eisdesignedfordirect‐probemountingwhicheliminatestheneedforadditional

hardwareandtransmitter‐to‐probecabling.Thisgreatlysimplifiesinstallation,reducescosts,and

minimizeselectricalnoisethatcanbecoupledontoprobecablingfromnearbyelectricalequipment.

BeforemountingtheMS2600E,firstensurethattheprobeisinstalledproperlyandsecurely.During

installationitisimportantthatyoudonotapplyexcessiveforceontheprobeorseals,asdoingso

couldbreakthesealandresultinsystemleakage.

5

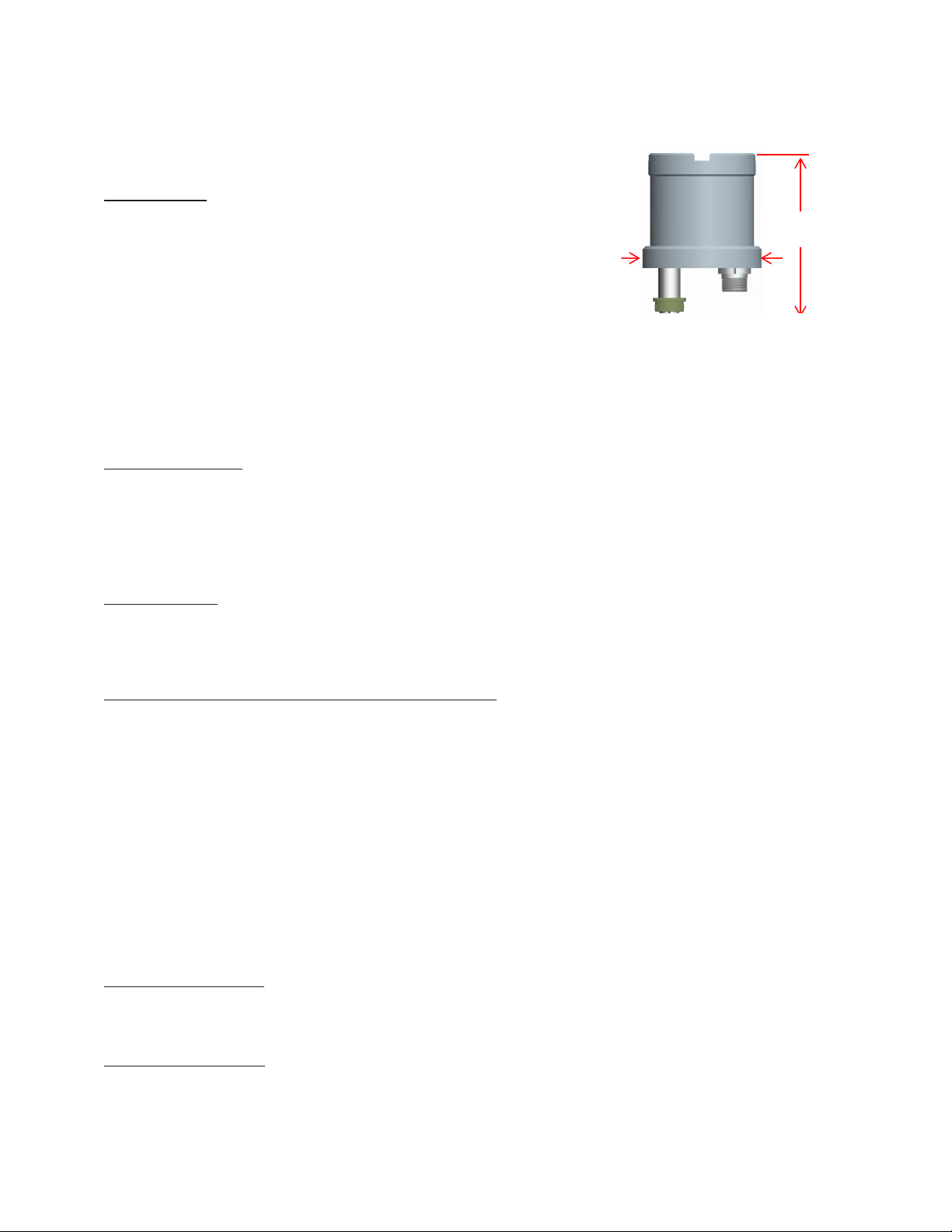

TomounttheMS2600E:

1. Alignthekeywaysofthetransmitterandprobeconnectors.

2. Insertthetransmitterconnectorplugfullyintotheprobeconnectorreceptacle.

3. Securethetransmittertothetopoftheprobebytighteningthecouplingnut.

NOTE:Hand‐tightissufficient.Donotover‐tightenthecouplingnut.

NOTE:Neverforcetheconnectorstomate.Ifthereisresistance,stopandcheckforbentpinson

theprobeandforforeignmaterialinthefemalesocketsofthetransmitterconnector.Gently

straightenanybentpinsandclearanyforeignmaterialthatmaybefound.

Figure2.MS2600EDirectMountInstallation

b.RemoteMounting

Whenitisnotpracticaltodirect‐probemounttheMS2600E,theunitcanberemotemountedinstead.

InthiscasetheinstrumentismountedtoaseparatemountingpoleusingtheoptionalRemote

MountingHardwareKit.TheMS2600EisthenconnectedtotheERprobeviatheoptionalprobe

extensioncable.Whenpossible,theMS2600Eshouldbemountedwithin10’(3m)oftheprobeto

keeptheprobecablingshortandminimizesignaldegradation.

2.CurrentLoopConnection

a.MakingConnections

TheMS2600Ecurrentloopconnectionismadeviatheexternal6‐pincircularconnectorasshown

below.Thishermeticallysealedconnectorpreventsmoistureingress,andeliminatestheneedfor

internalwiringbyanoperatorwhichreducestheriskofdamagetothecircuit.

AlignKey

Insert

Connector Tighten

CouplingNut

12 3

6

Figure3.MS2600ECurrentLoopConnector

Tofacilitatewiring,athirty‐threefoot(10meter)CurrentLoopWiringHarnessisprovided.Thiswiring

harnessconnectsdirectlytothe6‐pinconnector,andextendstoanearbyjunctionbox(notincluded)

tomakethenecessarywiringconnectionstothecurrentloopwiringfromthecontrol(DCS/SCADA)

system.Thewiringharnesscanbecuttolengthifrequired.

Figure4.MS2600EWiringHarness

NOTE:DonotconnectcableshieldingtotheTransmitter.Theshieldmustremainfloatingatthe

Transmitter.

ThemaximumpermissiblelengthofthecurrentloopwiringbetweentheMS2600ETransmitterand

thecontrolsystemisdeterminedbythecontrolsystemsupplyvoltage,theelectricalresistanceofthe

currentloopcableandtheloadofthecontrolsysteminput.IftheTransmitteristobeinstalledina

safearea,refertosectionc.WiringforaSafeAreaInstallationfordetails.IftheTransmitteristobe

installedinahazardousarea,refertosectiond.WiringforaHazardousAreaInstallation.

b.Grounding

TheMS2600Eenclosureisgroundedinternallythroughthewiringharness,butanadditional,external

groundingterminalisprovidedaswell.Theenclosureshouldbegroundedproperlyusingtheexternal

groundingterminaltoensuresafeoperation.

CurrentLoopConnector

JunctionBox

(NotIncluded)

MS2600E

Wiring Harness

7

c.WiringforaSafeAreaInstallation

CAUTION:Whenusedinnon‐hazardousareas,equipmentmustbesuppliedwithapre‐approvedpower

supplyunitorapprovedequipmentwiththefollowingmaximuminputparameters.

Ui=28V,Ii=93mAandPi=0.65W

Thepre‐approvedequipmentmustbecertifiedtotheelectricalsafetystandardsforequipmentin

ordinarylocation.ForExampleEN/IEC/CSAUL61010‐1,EN/IEC/CSAUL60950‐1etc…,

Forbasicsafeareawiringinformationrefertothecircuitdiagramshownonpage19.Usethefollowing

equationtodeterminemaximumpermissiblecablelength:

10

4∗10

Where:

D=Max.cablelengthinfeet.

VS=Powersupplyvoltage.

R=Cableresistanceinohmsper1000feet.

Example:

VS=24Volts

R=16.1(22AWGcable)

24 10

4∗10

16.1 21,739

d.WiringforaHazardousAreaInstallation

CAUTION:Thissectionprovidesgeneralguidelinesforhazardousareawiring.However,regardlessof

anythingstatedhere,theMS2600Emustbeinstalledinfullcompliancewiththecontroldrawing

locatedonpage18andallofthelocalarearequirements.

CAUTION:WhenusedinHazardousareas,equipmentmustbesuppliedwithapre‐approvedpower

supplyunitorapprovedequipmentviaacertifiedintrinsicallysafebarrieroragalvanicallyisolated

barrier)withthefollowingmaximuminputparameters.

Ui=28V,Ii=93mAandPi=0.65W

Wheneveranelectricallydrivensensorormeasuringdeviceisusedinapotentiallyexplosive

environmentthemeasuringsystemmustbeinstalledinsuchawaythatelectricalenergyiseither

effectivelyisolatedfromtheexplosiveenvironment(viaexplosive‐proofcontainers,cableconduits,

etc.)ortheamountofelectricalenergyproducedinthehazardousareamustbelimitedtoan

intrinsicallysafelevel.

LimitingelectricalenergyisthemostpracticalmethodofprotectingtheMS2600Emeasuringsystem

whentheTransmitterisinstalledinahazardousarea.IntheMS2600Esystem,electricalenergylimits

aremaintainedbytheuseofarepeatersafetybarrier(oritsequivalent)installedinthe4‐20mA

currentloopperstandardpractice.Thesafetybarriermustbelocatedinthesafeareanearthe

8

boundarybetweenthesafeandhazardousareas.Thesafetybarrierwillrepeatthesignalcurrent

generatedbytheTransmitterandwillrelaythesignaltothedatareceivingstation.

Caution:WhenasafetybarrierisusedwiththeMS2600Esystem,thecurrentloopcablemustbe

connectedtothebarrier’shazardousareaterminals.Allotherconnectionsmustbemadetothe

barrier’ssafeareaterminals.

ThetypeofrepeatersafetybarrieremployedintheMS2600Esystemdependsonthespecific

classificationofthehazardousenvironmentinquestion.MetalSampleswillprovide,uponrequest,

assistanceandtechnicaladviceintheselectionofarepeatersafetybarrieroritsequivalent.

Formostinstallations,MetalSamplesrecommendstheintrinsicallysafeMTL5441RepeaterPower

Supply.

ThemaximumlengthofthecurrentloopcablethatconnectstheMS2600ETransmittertothe

repeatersafetybarrierisasfollows:

Example:

17.5Volts

22AWGCable=5,434feetmaximum

16AWGCable=21,788feetmaximum

CAUTION:Forhazardousareainstallations,themaximuminductanceandcapacitanceoftheloop

wiringbetweenthesafetybarrierandthetransmittercannotexceedtheentityparametersofthe

selectedbarrier.

9

3.SetupandOperation

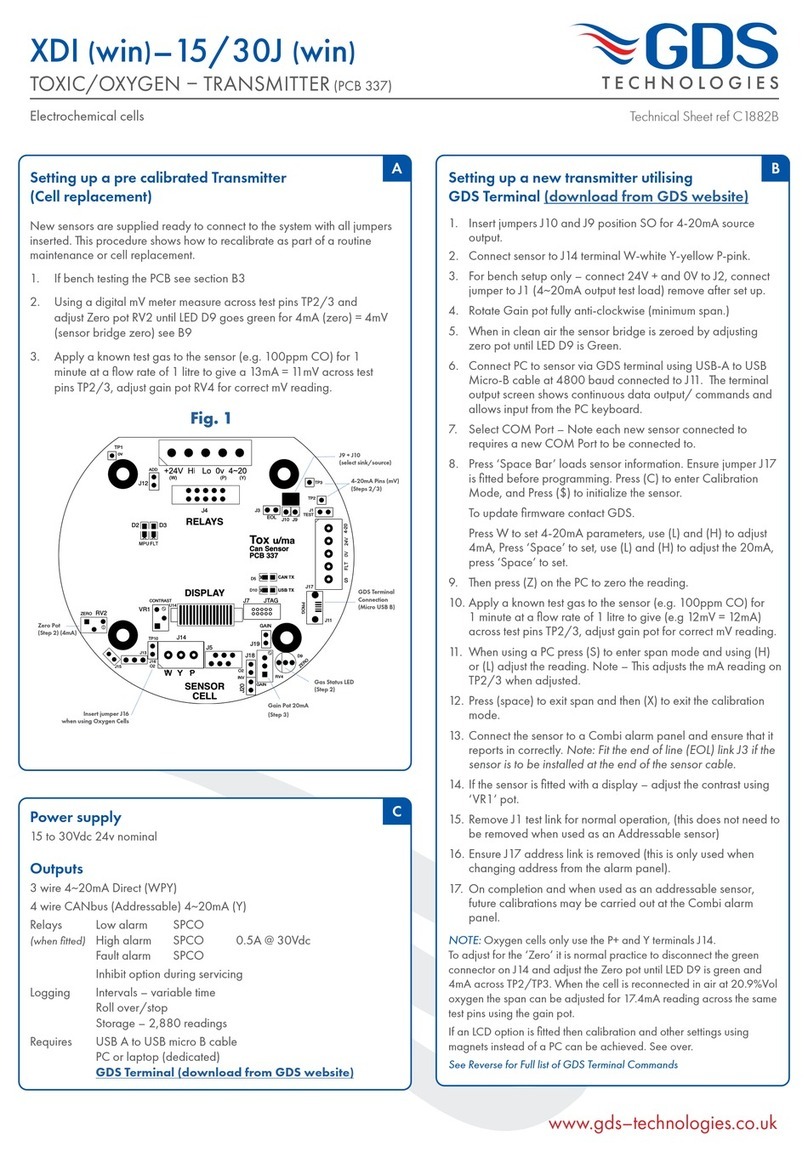

a.ProbeSelectionSwitches

HousedwithintheMS2600Eenclosureareprobeselectionswitcheswhichallowtheinstrumenttobe

setforanystandardERprobetype.Theyalsoallowtheinstrumenttobeplacedintoseveraltest

modeswhichoutputfixedvalues,allowingverificationofthecurrentloopconnectionandDCS

program.

Figure5.ConnectorandSwitchDetails

Setting

Switch

1

Switch

2

Switch

3

Switch

4

Operating

Positions

Wire Loop Off (↓)On (↑) On (↑) Off (↓)

Tube Loop/Flush On (↑) Off (↓)On (↑) Off (↓)

Cylindrical*Off (↓)Off (↓)On (↑) Off (↓)

Test

Positions

4mA Output On (↑) On (↑) Off (↓)Off (↓)

20mA Output Off (↓)On (↑) Off (↓)Off (↓)

4-20mA Sweep On (↑) Off (↓)Off (↓)Off (↓)

Table2.ProbeSwitchSettings

*Cylindricalprobesettingisillustrated.

ProbeSelectionSwitch

(Seedetailbelow)

4‐20mACurrent

L

oop

Co

nn

ec

t

o

r

ProbeCableConnector

10

b.TestingtheCurrentLoop

i.Calibration

TheMS2600Eisfullycalibratedwhenshippedfromthefactory.Thecalibrationsettingsarefixedto

avoidaccidentalchangewhichcouldresultinerroneousdata.Nofieldcalibrationisrequired.

However,itisimportanttotesttheMS2600Euponinstallation,andduringperiodicmaintenance

inspections,toensuretheunitisoperatingproperly.

ii.Testingloopoutputzero(4mA)andspan(20mA)

TheMS2600EProbeSelectionSwitches(page9)offerthreetestsettingsthatallowtheunittobe

placedintovariousdiagnosticmodesasfollows:

1) 4mAOutput–Forcesaconstant4mAoutputonthecurrentloop.

2) 20mAOutput–Forcesaconstant20mAoutputonthecurrentloop.

3) 4‐20mASweep–Causestheoutputtocontinuallycyclefrom4mAupto20mA.

Thesetestmodescanbeusefulwhentroubleshootingproblemswiththecurrentloopwiringand

DCS/SCADAsystem.

iii.TestingtheMS2600EwiththeMeterProver

AMeterProverisprovidedtoallowroutinechecksoftheMS2600E.TheMeterProversimulatesa

WireLooptypeprobeatafixedvalue.TotesttheMS2600EwiththeMeterProver:

1) Disconnectpower.

2) DisconnecttheMS2600Efromtheprobe(oriftheMS2600Eisremote‐mounted,disconnect

theprobeextensioncablefromtheprobe.)

3) ConnecttheMeterProvertotheMS2600Eprobeconnectorstem(ortotheprobeextension

cableiftheMS2600Eisremote‐mounted.)

4) LoosentheMS2600EEnclosureLockScrew.

5) UnthreadandremovetheMS2600Ecover.

6) ChangetheProbeSelectionSwitchestotheWireLoopposition(seepage9.)

7) Reconnectpowerandallowtheinstrumenttomeasureforseveralminutestostabilize.

8) Afterseveralminutesobservethetransmitteroutput.Theoutputshouldcloselymatchthe

valueprintedontheMeterProverlabel.

IfthetransmitteroutputmatchestheMeterProvervalue,youmayreturntheProbeSelection

SwitchestotheirprevioussettingandreconnecttheMS2600Etotheprobe.Ifthetransmitteroutput

showsasignificantdifferencecomparedtotheMeterProvervalue,furthertroubleshootingmaybe

required.Refertopage14fortroubleshootingorcontactthefactoryforfurtherassistance.

BesuretoreinstalltheenclosurecoverandtightentheLockScrewwhenputtingtheMS2600Eback

intoservice.

11

c.InterpretingData

i.MetalLoss

TheMS2600EmeasurestheMetalLossofanERprobeandconvertsthatvaluetoalinearized4‐20mA

currentloopoutput.The4‐20mAoutputisdirectlyproportionaltothecumulativeMetalLossofthe

ERprobeatanygiventime.Theoverallspanofthe4‐20mAoutputisproportionaltothelifeofthe

probeinuse,soforDCS/SCADAprogrammingthe4‐20mAsignalcanbescaledasfollows:

4mA=0mils(0%MetalLoss)

20mA=ProbeLifeinmils(100%MetalLoss)

TheProbeLifecanbefoundinTable1andisalsolistedontheMetalSamplesprobetag(asthe

“Multiplier”.)

Figure6.MetalSamplesProbeTag

Figure7illustratestherelationshipbetweenLoopCurrentandMetalLoss.Inthisexampleaprobe

witha10‐millifeisassumed.However,theXaxiscouldbechangedtorepresentanyProbeLife.

Figure7.OutputRelationship

Asseenhere,thetransmitteroutputbeginsat4mAforanewprobe(zeroMetalLoss)andincreasesas

theprobeelementcorrodes,eventuallyreachingamaximumof20mAwhentheprobesensing

elementhasbeencompletelyconsumedbycorrosion(inthiscase,10milsofMetalLoss.)Atthistime

theprobehasreacheditsend‐of‐lifeandmustbereplaced.

ii.CalculatingCorrosionRate

Asexplainedpreviously,ERprobesandinstrumentsreportMetalLoss.However,thevaluethatisof

12

ultimateinterestisCorrosionRate.TheCorrosionRateisessentiallyMetalLossovertime,sothe

CorrosionRatecanbecalculatedusingthefollowingformula:

CorrosionRatempy ∆LoopCurrentmA

16 365

∆Timedays ProbeLifemils

where:

LoopCurrent(mA)isthedifferencebetweentworeadings

Time(days)isthetimedifferencebetweenthosetworeadings

Itisacommonpracticetoprogramthisformulaintothecontrol(DCS/SCADA)systemandhaveit

calculateCorrosionRateonacontinualbasisfromtheMetalLossdata.Thechallengeindoingthisis

selectinganappropriatetimeinterval.Usinganintervalthatistooshortmaygiveerraticresults,

whileselectinganintervalthatistoolongmaygiveresultsthatareinsensitivetosystemupsets.The

idealtimeperioddependsonmanyfactors,andwillvaryfromsystemtosystem.Itmaytakesome

trialanderrortosettleonthebesttimeperiodforyourinstallation.

InsomecasesitmaybenecessarytoreviewtherawMetalLossdataandmanuallyapplythe

CorrosionRateformulatoperiodsofinterest.Forexample,lookatthegraphbelowandseehow

muchthecalculatedCorrosionRatecanvarydependingonthetimeperiodused.

Figure8.CorrosionRatescalculatedfromMetalLossdata

Whileeachoftheresultsisvalidfortheselectedtimeperiod,theoneofmostinterestisthevalueof

11.81mpywhichrepresentssometypeofsystemupset.WhentheCorrosionRateiscalculated

automaticallyonapre‐selectedtimeperiod,thereisnoguaranteethattheselectedtimeperiodwill

alwayscoincidewithsystemupsetssuchasthis.Thatiswhymanualreviewandinterpretationof

MetalLossdataisalsohelpful.

13

d.Commissioning

OncetheMS2600Ehasbeeninstalled,tested,andproperlyconfiguredfortheprobeinuse,itcanthenbe

closedandputintoservice.First,performonelastvisualinspectiontoensurethatallelectrical

connectionsaresecure,andthattheenclosureo‐ringisinplaceandisingoodcondition.Thenthreadthe

enclosurelidontothebasefully.Oncethelidhasbeenthreadedintoplace,tightentheLockScrewto

preventunauthorizedtampering.

Figure9.EnclosureLockScrew

CAUTION:TheLockScrewontheinstrumentbasemustbetightenedsecurelytopreventunauthorized

personnelfromopeningtheMS2600E,andensurethattheintrinsicsafetyisnotviolated.Onlyqualified

personnelshouldbeallowedtoinstall,operate,andmaintenancetheMS2600E.

C.Maintenance

Onceinstalled,theMS2600Erequireslittlemaintenance.However,itisimportanttoverifythefollowingitems

periodicallytoensurecontinuedsafeoperation.

CAUTION:BeforeperforminganytestsormaintenanceontheMS2600E,ensurethatallhazardousarea

requirementsaremet.

InspectionItemFrequency

Inspecttheenclosureo‐ringforanysignsofdamage.Replaceasnecessary.Annually

Inspecttheprobeconnectoro‐ringforanysignsofdamage.Replaceasnecessary.Annually

Inspecttheexternalelectricalconnectionsforsignsofcorrosion,mechanicaldamage,or

foreignmatterthatcouldcausedamageorcauseanelectricalshort.Cleanasnecessary.

Annually

EnsurethatthelockingscrewisinplaceandissecureAnnually

TheMS2600Eenclosureismadeofcorrosion‐resistant316stainlesssteel.However,it

shouldstillbecheckedperiodicallyforanysignsofcorrosion.

Annually

Checkforanysignsofmoistureingresswithintheenclosure.Annually

ContactMetalSamplesforreplacementpartsorifinstrumentrepairisnecessary.

14

D.Troubleshooting

IftheMS2600Edoesnotseemtoperformasexpected,checkthefollowingitems:

CAUTION:BeforeperforminganytestsormaintenanceontheMS2600E,ensurethatallhazardousarea

requirementsaremet.

1. Ensurethattheprobeisoperationalandisnotcompletelycorroded.Thiscanbedoneintwoways.

a. TesttheprobewithaportableERmeterifavailable.

b. Testtheprobewithaportableresistanceorcontinuitymeterasfollows:

i. Connectonetestleadtopin‘A’oftheprobes6‐pinconnector.

ii. Measurecontinuitytoeachoftheotherpins.Thereshouldbecontinuity(low

resistance)toeachpin.

NOTE:Continuityoneachpindoesnotensurethattheprobeisgood.However,ifyou

findanopencircuitonanypinsthenitisalmostcertainthattheprobeisbadandshould

bereplaced.

2. EnsurethattheProbeSelectionSwitchesaresetcorrectlyfortheprobebeingused.Confirmthe

probetype,andrefertoTable2onpage9toverifytheappropriateswitchsettings.

3. Performavisualinspectionofthecircuitboardstolookforanysignsofmechanicalorelectrical

damage.

4. Ensurethatallelectricalcablesandwiringareingoodcondition.

5. Ensurethatallelectricalcontactsaresecureandfreeofcorrosion.

6. Ensurethatthereisadequatesupplyvoltageatthe4‐20mACurrentLoopConnector.

7. Verifythatthesupplyvoltagepolarityiscorrect.

8. Ifthereisinsufficientsupplyvoltageonthe4‐20mACurrentLoopConnector,checkthesafety

barrier(ifapplicable)forablownfuseoranyotherfailure.

9. TesttheMS2600EusingthesuppliedMeterProver(seepage10.)

10. TesttheMS2600Ewithalocalmulti‐meterorloopcalibrator.

Thesebasicchecksshouldindicatethesourceofanyproblem(probe,powersupply,wiring,etc…)Ifitis

determinedthattheMS2600Eismalfunctioning,orifyouneedfurtherassistanceintroubleshooting,

contactMetalSamplesTechnicalSupport.

CAUTION:IftheMS2600Eshowsanysignsofdamageremoveitfromserviceimmediatelyandconsultthe

factory.

15

III.ServiceandWarrantyInformation

A.Warranty

MetalSampleswarrantsthatanypartoftheMS2600Eandaccessorieswhichprovestobedefectivein

materialorworkmanshipwithinoneyearofthedateoforiginalshipmenttoPurchaserwillberepairedor

replaced,atMetalSamplesoption,freeofcharge.Thiswarrantydoesnotcover(1)probeassemblies,(2)

itemsexpendableinnature,or(3)itemssubjecttodamagefromnormalwear,misuseorabuse,orfailure

tofollowuseandcareinstructions.

AlldamageditemsaretobeshippedatPurchaser’sexpensetoandfromMetalSampleswhichshallhave

therighttofinaldeterminationastotheexistenceandcauseofadefect.

TheforegoingshallconstitutethesoleandexclusiveremedyofanypurchaserofMetalSamplesproducts

forbreachofwarrantyandISEXCLUSIVEANDINLIEUOFALLOTHERWARRANTIES,EXPRESSED,IMPLIED

ORSTATUTORY,INCLUDINGTHEIMPLIEDWARRANTIESORMERCHANTABILITYANDFITNESS.INNOEVENT

SHALLMETALSAMPLESBELIABLEFORSPECIALORCONSEQUENTIALDAMAGES,ORFORANYDELAYIN

THEPERFORMANCEOFTHISWARRANTYDUETOCAUSESBEYONDITSCONTROL.

Thetechnicalinformationandsuggestionscontainedhereinarebelievedtobereliable,buttheyarenotto

beconstruedaswarrantiessinceconditionsofusearebeyondourcontrol.

B.ObtainingServiceandReturningtheInstrumentforRepair

Ifyouexperienceproblemswithyourinstrumentpleasecontactthefactoryat256‐358‐4202andaskfor

customersupportforinstrumentation.Ourcustomersupportdepartmentwillassistyouin

troubleshootingyourinstrument.

Mostissuescanberesolvedoverthephone,butinsomecasesitmaybenecessarytoreturnyour

instrumentforfurtherevaluationandrepair.Inthiscase,pleaseobtainaReturnMaterialsAuthorization

(RMA)numberfromthesalespersonorsupporttechnician.ThisRMAnumberwillensurethatyour

instrumentisroutedtothecorrectdepartmentwhenitisreceivedatthefactory.

AfterreceiptofanRMAnumberyoumaypackyourinstrumentforreturn.Besuretopackyour

instrumentinasturdyboxandtopaditsufficientlytoavoiddamageduringtransit.Alsobesureto

completethe“InstrumentRepairForm”onthenextpageandincludeacopywithyourrepair.Thiswill

ensurethattherepairdepartmenthassufficientinformationregardingtheproblemsyouareexperiencing

withyourinstrument,aswellasthebilling,contact,andreturnshippingdetailsfortherepair.

OnceyouhaveobtainedanRMAnumber,completedthe“InstrumentRepairForm”,andpackedyour

instrumentsecurely,pleaseshipitprepaidtothefollowingaddress:

MetalSamples

152MetalSamplesRoad

Munford,AL36268

ATTN:RMA#_____

NOTE:BesuretolistyourRMAnumberintheattentionline(shownasblanksintheexampleabove.)

16

C.InstrumentRepairForm

ThisformmaybephotocopiedforusewhenreturninganinstrumenttoMetalSamplesforrepair.

Pleasefillinallknowninformationandencloseacopyofthecompletedformwiththeinstrument.

GeneralInformation

Model

Number

Serial

Number

RMA

Number

Dateo

f

Purchase*

*Ifknown.

ContactInformationforRepair

Contact

Name

Company

Phone

Number

E‐mail

Address

ReturnShippingInformation

Recipient

Name*

Company*

Return

Address

*Ifdifferentthanabove.

ReasonforReturn.(Provideasmuchdetailaspossible.Attachadditionalpagesifrequired.)

InvoiceInstructions(Fornon‐warrantyrepairs)

Invoicemefortherepair

(RequiresanopenaccountwithMetalsamples.)

Reference

PO#

Contactmeforcreditcardinformation

(Forsecuritypurposes,donotlistcreditcardinformationonthisform..)

Table of contents

Other Metal Samples Transmitter manuals

Metal Samples

Metal Samples MS2700E User manual

Metal Samples

Metal Samples CORR Velox MS2800E User manual

Metal Samples

Metal Samples MS2601E User manual

Metal Samples

Metal Samples CORR VELOX MS2801E User manual

Metal Samples

Metal Samples MS2701E User manual

Metal Samples

Metal Samples MS2901E User manual

Metal Samples

Metal Samples MS2500E User manual

Metal Samples

Metal Samples MS2500L User manual