Metallkraft RBM 305 User manual

Operating Instructions

Plate rolling machine

RBM 305

RBM 305

RBM 305

2 RBM 305 | Version 2.02

Imprint

Product identification

Plate rolling machine Item number

RBM 305 3780112

Manufacturer

türmer Maschinen GmbH

Dr.-Robert-Pfleger- tr. 26

D-96103 Hallstadt/Bamberg

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Indications regarding the operating instructions

Original instructions

Edition: 29.08.2018

Version: 2.02

Language: English

Author: FL

Indications regarding the copyright

Copyright © 2018 türmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the sole

property of the company türmer.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

ubject to technical modifications and error.

Content

1 Introduction ............................................................. 3

1.1 Copyright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................................... 3

2.1 ymbol explanation ............................................ 3

2.2 Requirements to staff.......................................... 4

2.3 Personal protective equipment ........................... 4

2.4 General safety regulations.................................. 5

2.5 afety labels on the Plate rolling machine.......... 5

3 Intended use............................................................ 5

3.1 Unintended use................................................... 6

3.2 Residual risks ..................................................... 6

4 Technical Data.........................................................

5 Transport, packaging, storage...............................

5.1 Transport ............................................................ 6

5.2 Packaging........................................................... 6

5.3 torage ............................................................... 6

Description of the Device ....................................... 7

6.1 cope of delivery ................................................ 7

7 Assembly ................................................................. 7

7.1 etting up the machine ....................................... 7

7.2 Hazardous Areas................................................ 8

7.3 Lubricate bearings .............................................. 8

8 Operation ................................................................. 8

8.1 Work flow............................................................ 9

8.2 etting the sheet thickness................................. 9

8.3 Adjusting the guide pulley................................. 10

8.4 bending process ............................................... 10

8.5 Bending wires ................................................... 12

9 Care, maintenance and repair.............................. 12

9.1 Cleaning and Maintenance............................... 13

9.2 Repair ............................................................... 13

9.3 Lubrication schedule......................................... 13

9.4 Troubleshooting................................................ 13

10 Disposal, recycling of used devices ................. 14

10.1 Decommissioning ........................................... 14

10.2 Disposal of lubricants...................................... 14

11 Spare parts .......................................................... 14

11.1 Ordering spare parts....................................... 14

12 Spare parts drawing............................................ 15

13 Declaration........................................................... 1

14 Notes .................................................................... 17

Introduction

RBM 305 | Version 2.02 3

1 Introduction

You have made a good choice by purchasing the

METALLKRAFT Plate rolling Machine

Read the operating manual thoroughly before com-

missioning the machine.

It gives you information about the proper commissioning,

intended use and safe and efficient operation and main-

tenance of your Plate rolling Machine.

The operating manual is part of the Plate rolling Machine

package. Always keep this operating manual in the loca-

tion where your Plate rolling Machine is being operated.

All local accident prevention regulations and general

safety instructions for the operating range of your Plate

rolling Machine must also be complied with.

1.1 Copyright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the

Plate rolling Machine. Any application beyond those de-

scribed is not permitted without the written approval of

türmer GmbH. For the protection of our products, we

shall register trademark, patent and design rights, as this

is possible in individual cases. We strongly oppose any

infringement of our intellectual property

1.2 Customer service

Please contact your dealer if you have questions con-

cerning your Plate rolling Machine or if you need techni-

cal advice. They will help you with specialist information

and expert advice.

Germany:

türmer Maschinen GmbH

Dr.-Robert-Pfleger- tr. 26

D-96103 Hallstadt

Repair service:

Fax: 0049 (0) 951 96555-111

Email: [email protected]

Spare part orders:

Fax: 0049 (0) 951 96555-119

Email: [email protected]

We are always interested in valuable experience and

knowledge gained from using the application-which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards and

rules, the state-of-the-art technology and our long-term

knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- unauthorised modifications

- technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the expla-

nations and presentations described here in case of spe-

cial models, when using additional ordering options or

due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-

tions of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This section provides an overview of all important safety

packages for the protection of operating personnel as

well as for safe and fault-free operation. Other task-

based safety notes are included in the paragraphs of the

individual phases of life.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

WARNING!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to death or severe injury if not avoided.

4 RBM 305 | Version 2.02

Safety

Tips and recommendations

It is necessary to observe the safety notes written in

these operating instructions in order to reduce the risk of

personal injuries and damages to property.

2.2 Requirements to staff

Qualifications

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-

formed beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company expres-

sively commissioned the operator.

Electrically qualified person

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a posi-

tion to carry out work on the electrical systems and to in-

dependently recognize and avoid possible dangers.

Qualified personnel

Due to their professional training, knowledge and experi-

ence as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.3 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while

working. The staff member has to wear personal protec-

tive equipment while performing different tasks on and

with the machine which are indicated in the individual

paragraphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

CAUTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to material or environmental damage if not

avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate

the risks while using the machine and expose

themselves and others to the danger of severe or

lethal injuries.

- Have all works only performed by qualified persons.

- Keep insufficiently qualified persons out of the work-

ing area.

Eye Protection

The Eye protection protect the eyes from flying parts

and liquid splashes.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Intended use

RBM 305 | Version 2.02 5

2.4 General safety regulations

Please note the following:

- Use the guards and secure them securely. Never work

without protections and get them working.

- Always keep the machine and its working environment

clean. Ensure adequate lighting.

- The bending machine may not be modified in its design

and may not be used for purposes other than those fo-

reseen by the manufacturer.

- Never work under the influence of concentration-distur-

bing illnesses, fatigue, drugs, alcohol or medicines.

- Keep children and persons not familiar with the Plate

rolling machine away from their work environment.

- Do not pull on the mains lead to pull the plug out of the

socket. Protect the cable from heat, oil and sharp

edges.

- Eliminate disturbances that affect safety immediately.

- Protect the round bending machine from moisture.

- Make sure that no parts are damaged before using the

plate rolling machine. Damaged parts must be replaced

immediately to avoid danger sources.

- Do not overload the bending machine! You work better

and safer in the specified performance range. Use the

right tool! Make sure the tools are not dull or damaged.

- Only use original spare parts and accessories to avoid

possible risks and risks of accidents.

2.5 Safety labels on the Plate rolling machine

The plate rolling machine has various warning labels and

safety markings that must be observed and followed.

The safety markings attached to the plate rolling ma-

chine must not be removed. Damaged or missing safety

markings can lead to malfunctions, personal injury and

material damage. They are to be replaced immediately.

If the safety markings are not immediately recognizable

and comprehensible, the round bending machine should

be taken out of operation until new safety markings have

been made.

Fig. 1: afety labels

3 Intended use

The round bending machine RBM 305 is used exclusi-

vely for the production of round shaped parts such as pi-

pes, cones, cylinders, wires etc. with a maximum width

of 305 mm.

The material must consist of sheets of steel and other

metallic materials, as well as materials which are

suitable for processing because of their plastic deforma-

bility. Editing brittle and brittle materials is prohibited.

The material to be bent must not exceed the maximum

sheet thickness specified for the machine. The work-

pieces must be in the form of sheet metal or flat profiles

so that they can be safely captured and transported by

the rollers. The machine may only be operated by a

single person who has been instructed in the use and

maintenance of the machine.

Safety boots

afety boots protect the feet from being crushed, fall-

ing parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

123

4

5

6 RBM 305 | Version 2.02

Technical Data

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or

otherwise is considered misuse.

3.1 Unintended use

By observing the intended use, no reasonably fore-

seeable misuse is possible, which could lead to dange-

rous situations with personal injury.

3.2 Residual risks

Even if all safety instructions are observed, and the ma-

chine is put to its intended use, there are still residual

risks, which are listed below:

- There is a risk of injury to the upper limbs (e.g., hands,

fingers).

- Danger from falling workpieces

- Danger from the ingress of clothing and objects.

- During set-up and set-up work, it may be necessary to

dismantle on-site protective equipment. This creates

various residual risks and potential dangers that every

operator must be aware of.

4 Technical Data

* Bending power ratings refer to 235JR with a tensile strength of 400

N / mm2

* heet bending capacity in VA = factor 0.75; Conical bending with half

of the max. heet thickness possible

Fig. 2: Diagram for yield points

5 Transport, packaging, storage

5.1 Transport

Check the Plate rolling Machine on delivery for any visi-

ble transportation damage. If you notice any damage to

the device please report this immediately to the carrier or

dealer.

5.2 Packaging

All used packaging materials and packaging aids are re-

cyclable and should be taken to a materials recycling de-

pot to be disposed of.

The delivery packaging is made of cardboard, so please

dispose carefully by having it chopped up and given to

the recycling collection

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (P ). Deliver these substances to a

collection point for recyclable materials or to the waste

disposal company which looks after your region.

5.3 Storage

tore the Plate rolling Machine thoroughly cleaned in a

dry, clean and frost-free environment. It must not be shut

down with chemicals in a room. If the machine is stored

for a long time, all bare metal parts must be greased

against rusting.

WARNING!

Dangers in case of unintended use!

Misuse of the bending machine can lead to dange-

rous situations.

- Only operate the bender in the power range speci-

fied in the technical data.

- Never bypass or override the safety devices.

- Only operate the round bending machine in a tech-

nically perfect condition.

Type RBM 305

Max. working width 305 mm

Roller Ø 25 mm

Longitudinal grooves in

diameter

4/6/8 mm

Dimensions L x B x H 580 x 210 x 255 mm

Weight 14 kg

Max. sheet thickness 0,8 mm

Bending Ø min. 40 mm

WARNING!

Danger to life!

The packaging elements may pose potential hazards

(e.g., plastic bags):

- Packaging material for children and persons

who are unaware of their actions or keep ani-

mals inaccessible.

Description of the Device

RBM 305 | Version 2.02 7

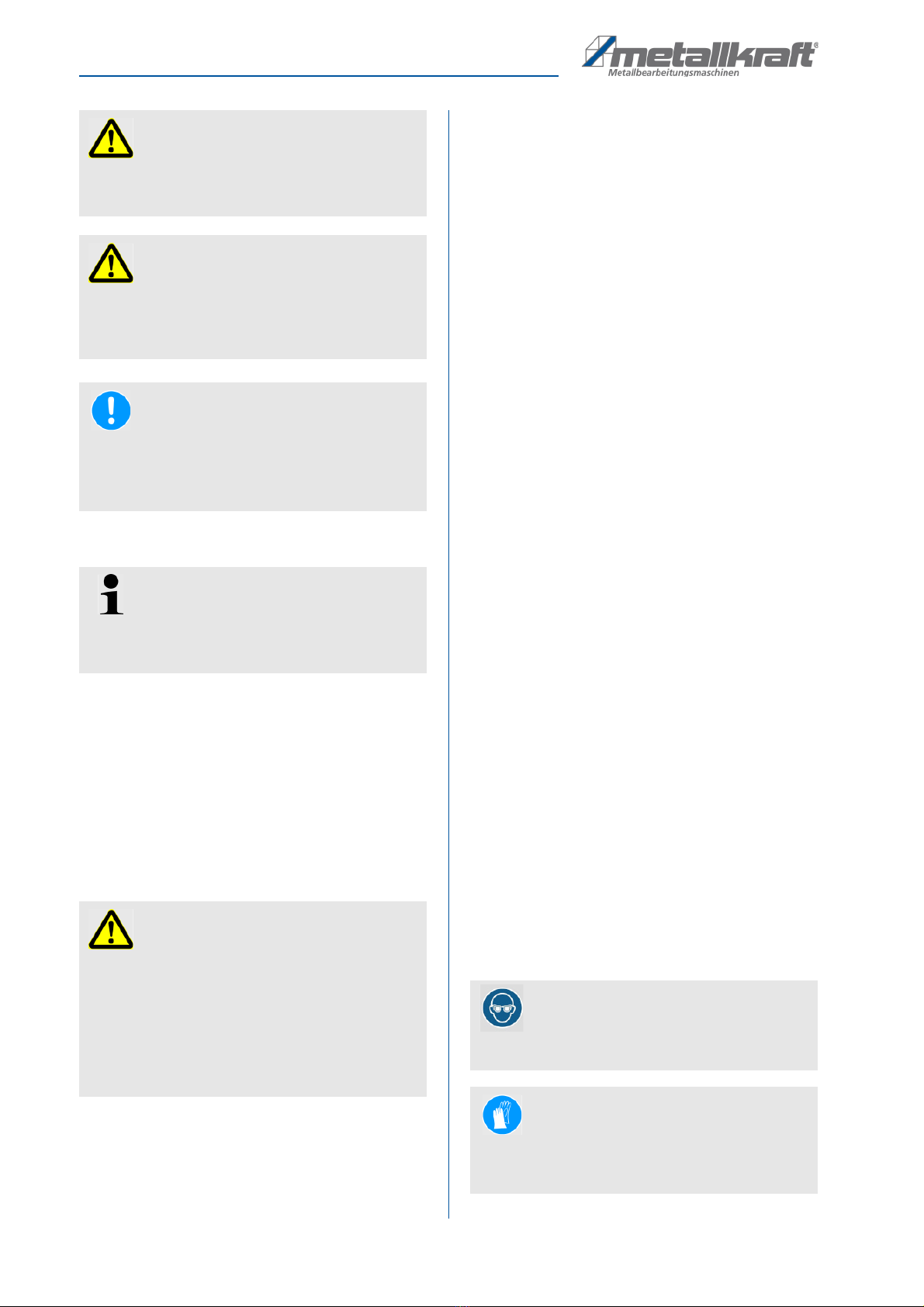

6 Description of the Device

Illustrations in this operating manual serve the gene-

ral understanding and may deviate from the actual

design.

Fig. 3: Description of the RBM 305

1 Adjusting wheel guide roller (plate thickness)

2 Guide roller

3 Guide roller

4 Adjusting wheel guide roller (radius)

5 Winch

6 Machine frame

6.1 Scope of delivery

The scope of delivery of the machine includes:

- Asymmetrical 3-roller system with swing-out top

roller

- Rolls of steel

- Conical-bender

- operating manual

Optional accessories:

- ubstructure Item number: 3780113

7 Assembly

7.1 Setting up the machine

To achieve good functionality and long life of the plate

rolling machine, the site should meet the following crite-

ria:

- The substrate must be level, firm and vibration-

free.

- The installation or work area must be dry and well

ventilated.

- Do not operate machines that cause dust and

chips near by.

- There must be sufficient space for the operating

personnel, for material transport as well as for ad-

justment and maintenance work.

- The site must have good lighting.

Space Requirement

The measure of the space requirement on the right side

of the machine should be slightly larger than a roll length

and allow easy material removal.

The amount of space required in front of and behind the

machine should be calculated so that the operator can

easily feed the material and remove it from the machine.

tep 1: Place the machine on a level and stable surface,

such as a workbench.

tep 2: The round bending machine is to be mounted on

the base and aligned horizontally with a spirit

level. Pay attention to the space required.

tep 3: Place the round bending machine on the base

and mark the 4 specified holes.

tep 4: Take the bender from the pad and pierce the

markers. The holes should be 6.5mm.

tep 5: Attach the Bending Machine to the base and use

four screws (M6) that are about 20mm longer

than the thickness of their backing. Use 8 was-

hers and 4 nuts.

Wearing safety gloves!

Wear safety shoes!

Wear protective clothing!

2

3

5

4

1

ATTENTION!

Crushing!

The Plate rolling Machine can tilt when setting up

and cause injury.

NOTE!

- The plate rolling machine is already pre-assembled

on delivery.

8 RBM 305 | Version 2.02

Operation

7.2 Hazardous Areas

The round bending machine is provided with the neces-

sary protective equipment to prevent injuries that may be

caused by the gears. Another area of danger that must

be carefully observed during the machining process is

the range of rotation of the rollers.

Fig. 4: Danger area at the round bending machine

7.3 Lubricate bearings

Before using the machine for the first time, check and lu-

bricate the bearings, see chapter "Cleaning and main-

tenance".

8 Operation

NOTE!

After setting up, remove the protective agent from the

bare metal parts, which have been applied to protect

against rusting.

- Use usual solvents.

- No water, no nitrolic solvents or similar use!

NOTE!

The moving parts must be free from dirt and dust.

be free.

- If necessary, lubricate the moving parts as listed in

the Care and Maintenance section.

WARNING!

Danger due to insufficient qualification of per-

sons!

Insufficiently qualified persons can not assess the

risks involved in handling the bending machine and

expose themselves and others to the risk of serious

injury.

- All work should only be carried out by qualified per-

sons.

- Keep inadequately qualified persons out of the work

area.

WARNING!

Risk of Crushing!

The upper limbs must be kept away from the

machine during insertion and during machining of the

workpiece.

DANGER!

- Never perform any work on the bending machine

under the influence of alcohol, drugs or medication

and / or in case of fatigue or concentration-impai-

ring illnesses.

- The bender may only be operated by a trained per-

son.

DANGER!

Before using the round bending machine for the first

time, it is essential to lubricate the chains and bea-

rings!

We assume no liability for damages due to improper

commissioning.

DANGER!

When operating the rollers: Do not drive the rol-

lers against the lower stop!

DANGER!

- The operator should have a basic knowledge of this

type of machine.

- Operators should not wear wide garments, neck-

laces, rings, etc. to prevent them from being pulled

into the running machine.

Operation

RBM 305 | Version 2.02 9

The machine is designed for steel processing and not for

processing flammable or harmful substances. The custo-

mer is responsible for the choice of the material to be

processed.

It must also be ensured that the safety of nearby opera-

ting personnel is ensured.

The material should meet the following requirements:

- Dry and clean, free of oil.

- The diameter must correspond to the specificati-

ons.

- The material should have a degree of hardness th-

roughout.

- Buying high quality material is advisable

- The surface of the areas to be bent should be

smooth.

A complete bend with one pass is not possible. To get

the desired radius, several passes are required. Tighter

bends and full radii always require several passes.

In order to be able to remove a bent workpiece from the

machine, the locking handle of the upper roller must be

released and the upper roller must be removed from the

guide.

Fig. 5: Locking uper roll

8.1 Work flow

tep 1: Before starting the machine, check the locking of

the top roller.

tep 2: Check the parallelism of the rollers with a gauge

and a spirit level.

Fig. 6: Check parallelism of rollers

tep 3: Clean the rollers and the workpiece.

tep 4: Perform Bending.

tep 5: Loosen the lock of the upper roller, fold out the

upper roller and remove the workpiece.

tep 6: Fold in the top roller and lock.

8.2 Setting the sheet thickness

The sheet thickness is set via the two rotary handles (1).

By unscrewing the gap between roller 1 and 2 roll increa-

ses, by screwing it decreases this. It is advantageous to

insert the sheet only to then adjust the distance between

the two rollers so that they rest against the sheet.

NOTE!

- The safety devices as well as the protective covers

must be functional.

NOTE!

It is important to thoroughly clean the rollers to avoid

possible slippage of the profile due to grease resi-

dues on the rollers.

Wearing safety gloves!

Wear safety shoes!

Wear protective clothing!

DANGER!

The unfolded top roller must not be overloaded by

the workpiece.

Locking

10 RBM 305 | Version 2.02

Operation

Fig. 7: etting the sheet thickness

8.3 Adjusting the guide pulley

The guide roller (3) is adjusted by means of the two

rotary handles (2; Fig. 8). In order to achieve a greater

radius of curvature of the sheet, the rotary handles must

be unscrewed, screwed in for a smaller radius of curva-

ture. To create straight tubes, the idler must be set paral-

lel to the other rollers. For conical tubes, the idler must

be set at an angle. For this purpose, one of the rotary

handles (2) must be screwed in correspondingly deeper

than the other.

Fig. 8: Adjusting the guide pulley

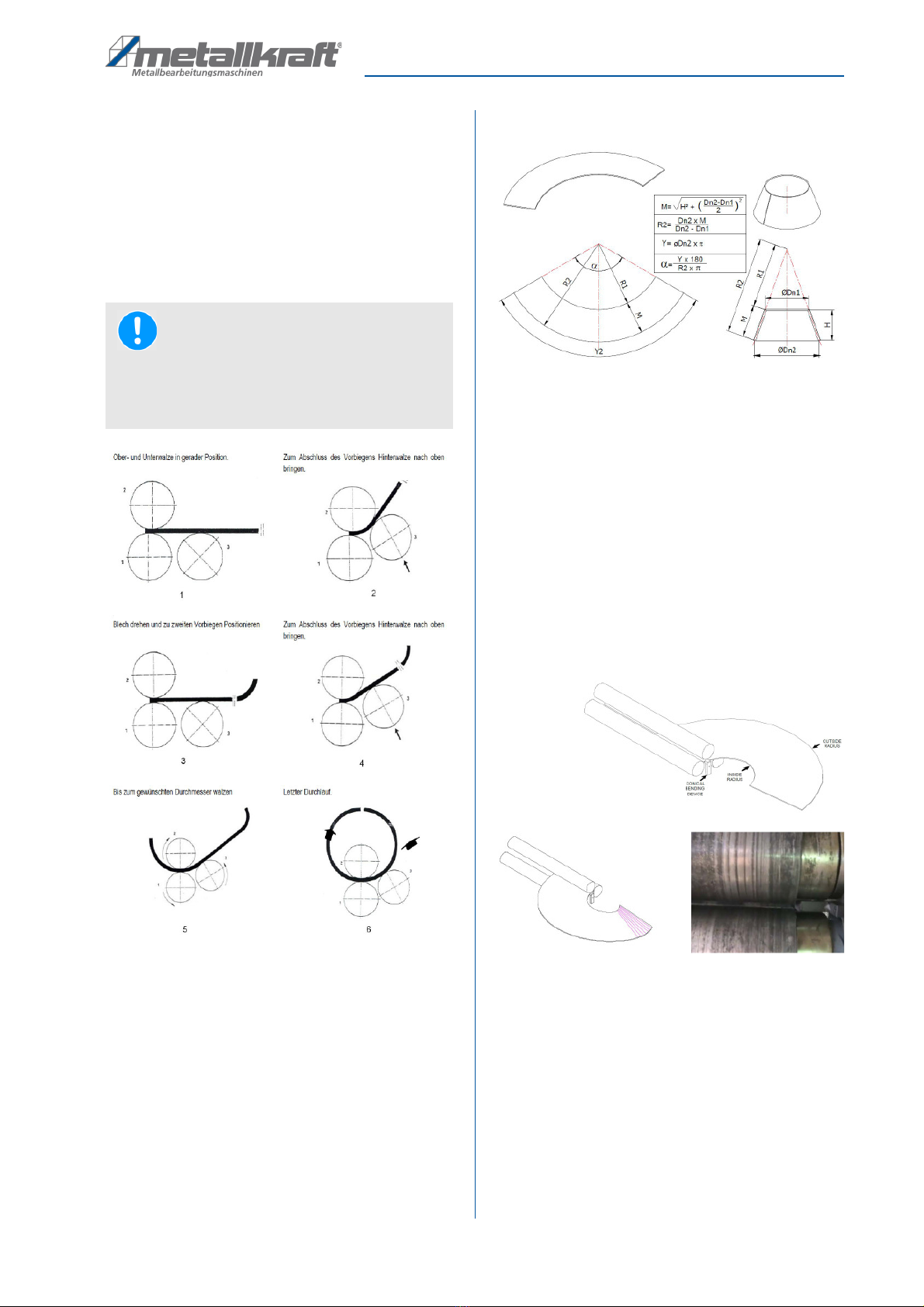

8.4 bending process

Bending may only be performed by qualified personnel

experienced in these machines. All steps of bending,

pre-bending and conical bending must be carried out ex-

tremely carefully. It should be noted that a small radius is

made by repeating the bending process several times;

Once too much bent, this step can not be undone.

Before editing

- Remove dirt and oil from the material.

- The material ends must be free of chips and burnt

residues.

- Burned material is harder at the points of separa-

tion than in the remaining area.

- The material has to be level.

- It is recommended to make a stencil made of card-

board or cardboard for the desired radius

Always work the workpiece in the center of the rollers

Fig. 9: Position workpiece in the middle of the rollers

Calculation of the workpiece length

Fig. 10: Calculation of the workpiece length

Bending chart

Fig. 11: Bending chart

WARNING!

It is not allowed to use profiles exceeding the specifi-

cation strength. Do not work on more than one piece

at a time. Use the machine only for the intended pur-

pose.

Operation

RBM 305 | Version 2.02 11

pre-bending

Pre-bending is the operation whereby the ends of the

material are bent to the same radius as the final radius.

As a result, the best results are achieved at full radii (eg

making tubes) or for operations where no flat ends are

desired.

Bending

Fig. 12: Bending process

Conically bending

Conical bending is more difficult than normal bending.

The machine performance is reduced by 30% to 50%,

the conical bending capacity decreases by about 25%.

The material thickness must be reduced accordingly.

Calculation of the workpiece dimensions

Fig. 13: Calculation of the workpiece dimensions

Bending process

tep 1: Before conical bending, the sheet must be pre-

bent at the ends with parallel rolls.

tep 2: Then the machine has to be prepared for conical

bending:

tep 3: Adjust the guide roller in its angular position by

turning the handwheel so that the smaller dia-

meter of the workpiece cone makes the roller

closer to the attraction rollers. As a result, a

narrower radius is created at the bend.

Fig. 14: Conically bending, preparation

The above-illustrated hardened bending tool holds the

material to be bent conically during the bending opera-

tion.

NOTE!

The material hardens after each pass.

When processing stainless steel, several passes

must be made because this material is work harde-

ning material.

12 RBM 305 | Version 2.02

Care, maintenance and repair

Fig. 15: Conically bending

Normal bending after conical bending

After conical bending, the rollers must be brought back

into parallel position.

tep 1: Use the handwheels to bring the guide roller and

the lower roller in parallel position to the upper

roller.

tep 2: Lock the rollers.

tep 3: Check the parallelism of the rollers with a gauge.

Removal of the workpiece

tep 1: Pull the locking handle out

tep 2: Pull the guide roller out to the front

tep 3: Remove the guide roller from the anvil

tep 4: Take the formed sheet from the roll.

tep 5: Reassemble the roller in reverse order and lock

the roller.

Fig. 16: wivel guide roller

8.5 Bending wires

Use the smallest possible notch on the lower roll to bend

your wire. lide the wire into the correct notch and turn

the handle to shape it. The remaining procedures and

adjustments are identical to those of bending a sheet.

Fig. 17: Bending of wires

9 Care, maintenance and repair

WARNING!

Never change the safety device. Never try to acti-

vate a function of the machine when the top roller is

open.

Tipps und Empfehlungen

To ensure that the bending machine is always in

good operating condition, regular care and main-

tenance work must be carried out.

DANGER!

Danger due to insufficient qualifica-

tion of persons!

Insufficiently qualified personnel can not assess the

risks involved in maintenance work on the machine

and expose themselves and others to the risk of

serious injury.

- All maintenance work should only be carried out by

qualified persons.

NOTE!

Before servicing and maintaining the plate rolling

machine, the maintenance instructions must be care-

fully read. The handling of the plate rolling machine is

only permitted to persons who are familiar with the

plate rolling machine.

Care, maintenance and repair

RBM 305 | Version 2.02 13

9.1 Cleaning and Maintenance

Regularly clean the bender with a soft, damp cloth.

Treat bare metal work surfaces with anti-rust spray and

clean the rollers regularly.

9.2 Repair

If the bender does not work properly, contact a dealer or

our customer service. The contact details can be found

in chapter 1.2 Customer ervice.

9.3 Lubrication schedule

Fig. 18: Lubrication schedule

If necessary, lubricate the gears. This is a conventional

grease to use without any special requirements.

At best use a grease gun that you attach to the grease

nipple.

Always remove debris from the rollers with a rag or the

like.

9.4 Troubleshooting

DANGER!

After servicing, maintenance and repair work, check

that all panels and guards are properly installed on

the machine again and that there is no more tools in-

side or in the working area of the round bending ma-

chine.

Damaged safety devices and parts must be repaired

or replaced by the customer service.

DANGER!

- Never use solvents to clean plastic parts or painted

surfaces. A surface release and consequential da-

mage may occur.

DANGER!

The rollers must not be lubricated or oiled. You would

allow slipping of the material and thus trigger no ben-

ding process. The rollers are always free from grease

and oil.

DANGER!

Repair work may only be carried out by qualified per-

sonnel.

All protection and safety equipment must be reinstal-

led immediately after completion of repair and main-

tenance work.

DANGER!

If one of the following errors occurs, stop working

with the machine immediately. It could lead to serious

injuries. All repairs or replacement work may only be

carried out by qualified and trained specialist person-

nel.

Fault Possible cause Remedy

The Plate rolling Machine does not

work.

1. The mechanics are broken. 1. Check the mechanics.

2. Contact the dealer.

The Plate rolling Machine does not

bend the material correctly.

1. The material thickness could be

wrong.

2. The wrong material has been in-

serted.

1. max. Note plate thickness.

2. Insert only the correct material

The Plate rolling Machine does not

bend the materials as indicated in the

catalog.

1. The material thickness could be

wrong.

2. The mechanics are faulty.

1. Check the material to be bent.

2. Contact the dealer.

14 RBM 305 | Version 2.02

Disposal, recycling of used devices

10 Disposal, recycling of used devices

Please take care in your own interest and in the interest of

the environment that all component parts of the machine

are only disposed of in the intended and permitted way.

10.1

Decommissioning

Immediately decommission disused machines in order to

avoid later misuse and endangering of the environment

or personal safety.

tep 1: Eliminate all environmentally hazardous operat-

ing materials from the used device.

tep 2: If required, disassemble the machine into easy-

to-handle and usable components and parts.

tep 3: Dispose of machine components and operating

materials by the disposal channels provided.

10.2 Disposal of lubricants

Remove any leaking, used or excessive grease at the lu-

bricating points.

Disposal notes for used lubricants are available from the

manufacturer of the lubricants. If necessary, request the

product-specific data sheets. The disposal instructions

for the lubricants used are provided by the lubricant man-

ufacturer. If necessary, ask for the product-specific data

sheets.

11 Spare parts

11.1 Ordering spare parts

The spare parts may be purchased with the authorised

dealer or directly with the manufacturer. Please find the

corresponding contact data in Chapter 1.2 Customer

service.

Indicate the following basic information for requests or

orders of spare parts:

- Type of device

- Item No.

- Position No.

- Year of construction:

- Quantity

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

pare part orders which do not include the above indica-

tions may not be taken into consideration. If the indica-

tions regarding the mode of dispatch are missing, the

product is dispatched at the discretion of the supplier.

You will find information regarding the device type, item

No. and year of manufacture on the type plate fixed to

the Plate rolling Machine.

Example

The hand crank for the plate rolling machine RBM 305

has to be ordered. This is indicated in the spare parts

drawing with the item number 16.

- Device type: Plate rolling machine

- Item number: 3780112

- Position number: 1

The order No. is: 0-3780112-1

The order number consists of the item number, the spare

parts drawing number, the position number and one digit

in front of the item number.

- Place the digit 0 in front of the item No.

- Also place the digit 0 in front of the position No 1 th-

rough 9.

DANGER!

Danger of injury by the use of

wrong spare parts!

Dangers may result for the user and damages as well

as malfunctions may be caused by using wrong or

damaged spare parts.

- Only use original spare parts of the manufacturer or

spare parts admitted by the manufacturer.

- Always contact the manufacturer in case of uncer-

tainties.

Tips and recommendations

The manufacturer's warranty will become null and

void if non-permissible spare parts are used

Spare parts drawing

RBM 305 | Version 2.02 15

12 Spare parts drawing

In case of service, the following drawing shall help to identify the necessary spare parts. If necessary, send a copy of the

parts drawing with the marked components to your authorised dealer.

Fig. 19: pare parts Drawing RBM 305

16 RBM 305 | Version 2.02

Declaration

Manufacturer / distributor: türmer Maschinen GmbH

Dr.-Robert-Pfleger- tr. 26

D-96103 Hallstadt

We hereby declare that the machine described below, due to its design and construction as well as in the

version we have placed on the market, complies with the relevant basic health and safety requirements.

A declaration of conformity according to Machinery Directive 2006/42 / EC Annex 1 does not require this

machine. In the event of a modification of the machine not agreed with us, this declaration shall lose its

validity.

Product group: Metallkraft® Metalworking machines

Name of the machine: RBM 305

Machine type: Plate rolling machine

Item number: 3780112

Serial number: ___________________

Year of Manufacturer: 20____

Responsible for documentation: Kilian türmer, Dr.-Robert-Pfleger- tr. 26

D-96103 Hallstadt

Hallstadt, 03.05.2014

______________________

Kilian türmer

Manager

13 Declaration

Notes

RBM 305 | Version 2.02 17

14 Notes

www.metallkraft.de

Table of contents

Other Metallkraft Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Emerson

Emerson Aventics G3 Series Technical manual

ABB

ABB HT614819 Operation manual

HESA

HESA TF-6000P installation instructions

dunkermotoren

dunkermotoren PLG Translation of the original assembly instruction

Baileigh

Baileigh BP-3305CNC Maintenance and parts manual

ABB

ABB HT596336 original operation manual