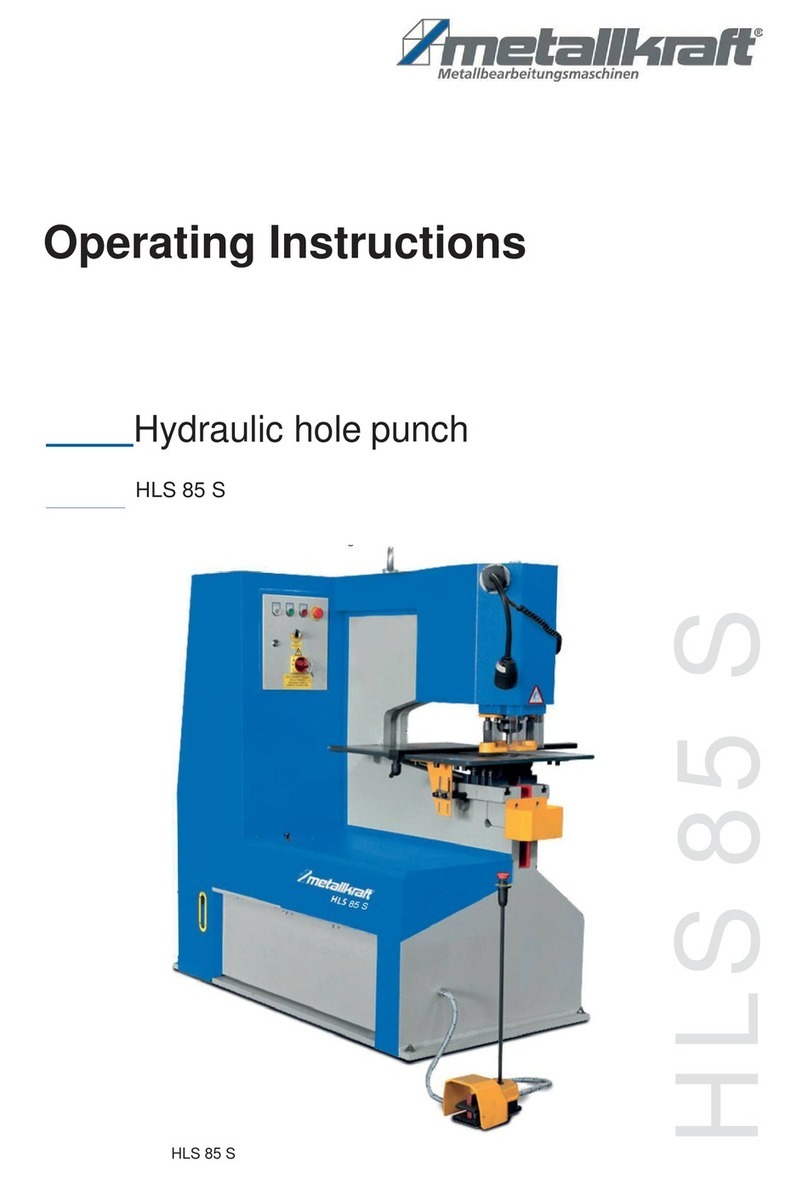

Metallkraft RBM Series User manual

RBM 1270-25 E

Instruction Manual

RBM 1050-30 E

RBM E SERIES

Plate rolling machines

RBM 1270-25 E

RBM 1550-20 E

RBM 2050-15 E

2 RBM E | Version 1.07

Imprint

Product identification

Metallkraft

Plate rolling machine

Mo el Item number

RBM 1050-30 E 3813201

RBM 1270-25 E 3813202

RBM 1550-20 E 3813203

RBM 2050-15 E 3813204

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallsta t

Fax: 0049 (0) 951 96555 - 55

E-Mail: info@metallkraft. e

Internet: www.metallkraft. e

Indications regarding the operating instructions

Original instructions

E ition: 14.05.2019

Version: 1.07

Language: English

Author: ES/MS

Indications regarding the copyright

Copyright © 2019 Stürmer Maschinen GmbH, Hallsta t, Germany.

The contents of these operating instructions are the sole property of the company Stürmer.

Passing on as well as copying of this ocument, the use an istribution of its content are

prohibite if not explicitly permitte . Contraventions are liable to compensation.

Subject to technical mo ifications an error.

RBM E | Version 1.07 3

Contents

1 Introduction .........................................................................4

1.1 Copyright............................................................................................... 4

1.2 Customer service.................................................................................. 4

1.3 Limitation of liability............................................................................... 4

2 Safety....................................................................................5

2.1 Symbol explanation............................................................................... 5

2.2 Responsibility of the operator ............................................................... 6

2.3 Requirements to staff............................................................................ 7

2.4 Personal protective equipment ............................................................. 7

2.5 General safety regulations .................................................................... 8

2.6 Safety lables on the machine................................................................ 8

3 Intended Use ........................................................................9

3.1 Misue .................................................................................................... 9

3.2 Resi ual risks........................................................................................ 9

4 Technical ata ...................................................................10

4.1 Type plate ........................................................................................... 10

5 Transport, packaging, storage.........................................10

5.1 Delivery an transport......................................................................... 10

5.2 Packaging ........................................................................................... 11

5.3 Storage ............................................................................................... 12

6 escription of the machine ..............................................12

6.1 Specification an stan ar equipment................................................ 12

6.2 Optional equipment............................................................................. 13

6.3 Safety switch....................................................................................... 13

7 Set up and connection......................................................14

7.1 Set up.................................................................................................. 14

7.2 Danger zones...................................................................................... 15

7.3 Assembly of the safety line ................................................................. 16

7.4 Lubricate bearings .............................................................................. 16

7.5 Electrical connection........................................................................... 17

7.6 Direction of rotation of the motor......................................................... 18

8 Commissioning .................................................................19

8.1 Operation ............................................................................................ 20

8.2 Ben ing operation............................................................................... 22

9 Maintenance and Cleaning ...............................................28

9.1 Cleaning an lubrication of the machine ............................................ 28

9.2 Troubleshooting .................................................................................. 30

10 isposal, recycling of used devices..............................30

10.1 Decommissioning.............................................................................. 30

10.2 Disposal of electrical equipment ....................................................... 30

10.3 Disposal of lubricants........................................................................ 30

11 Spare parts.......................................................................31

11.1 Or ering spare parts ......................................................................... 31

11.2 Spare parts rawing.......................................................................... 32

12 Electrical-schematic .......................................................33

13 EC eclaration of Conformity ........................................34

14 Notes ................................................................................35

4 RBM E | Version 1.07

Introduction

1 Introduction

You have ma e a goo choice by purchasing the METALLKRAFT machine.

Read the operating manual thoroughly before commissioning the ma-

chine.

It gives you information about the proper commissioning, inten e use an

safe an efficient operation an maintenance of your machine.

The operating manual is part of the Machine package. Always keep this opera-

ting manual in the location where your Machine is being operate . All local ac-

ci ent prevention regulations an general safety instructions for the operating

range of your Machine must also be complie with.

Illustrations in this operating manual serve the general un erstan ing an may

eviate from the actual esign.

1.1 Copyright

The contents of these instructions are copyright. They may be use in con-

junction with the operation of the machine. Any application beyon those es-

cribe is not permitte without the written approval of Stürmer GmbH.

For the protection of our pro ucts, we shall register tra emark, patent an e-

sign rights, as this is possible in in ivi ual cases. We strongly oppose any in-

fringe-ment of our intellectual property.

1.2 Customer service

Please contact your ealer if you have questions concerning your ben ing ma-

chine or if you nee technical a vice. They will help you with specialist infor-

mation an expert a vice.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallsta t

Repair service:

Fax: 0049 (0) 951 96555-111

E-Mail: service@stuermer-maschinen. e

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-maschinen. e

We are always intereste in valuable experience an knowle ge gaine from

using the application-which then coul be share an be valuable to evelop

our pro ucts even further.

1.3 Limitation of liability

All information an notes in these operating instructions were summarise

while taking applicable stan ar s an rules, the state-of-the-art technology

an our long-term knowle ge an experiences into consi eration.

Safety

RBM E | Version 1.07 5

In the following cases the manufacturer is not liable for amages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untraine staff,

- Unauthorize mo ifications

- Technical changes,

- Use of not allowe spare parts.

The actual scope of elivery may eviate from the explanations an presenta-

tions escribe here in case of special mo els, when using a itional or ering

options or ue to latest technical mo ifications.

The obligations agree in the elivery contract, the general terms an con iti-

ons as well as the elivery con itions of the manufacturer an the legal regula-

tions at the time of the conclusion of the contract are applicable.

2 Safety

This section provi es an overview of all important safety packages for the pro-

tection of operating personnel as well as for safe an fault-free operation.

Other task-base safety notes are inclu e in the paragraphs of the in ivi ual

phases of life.

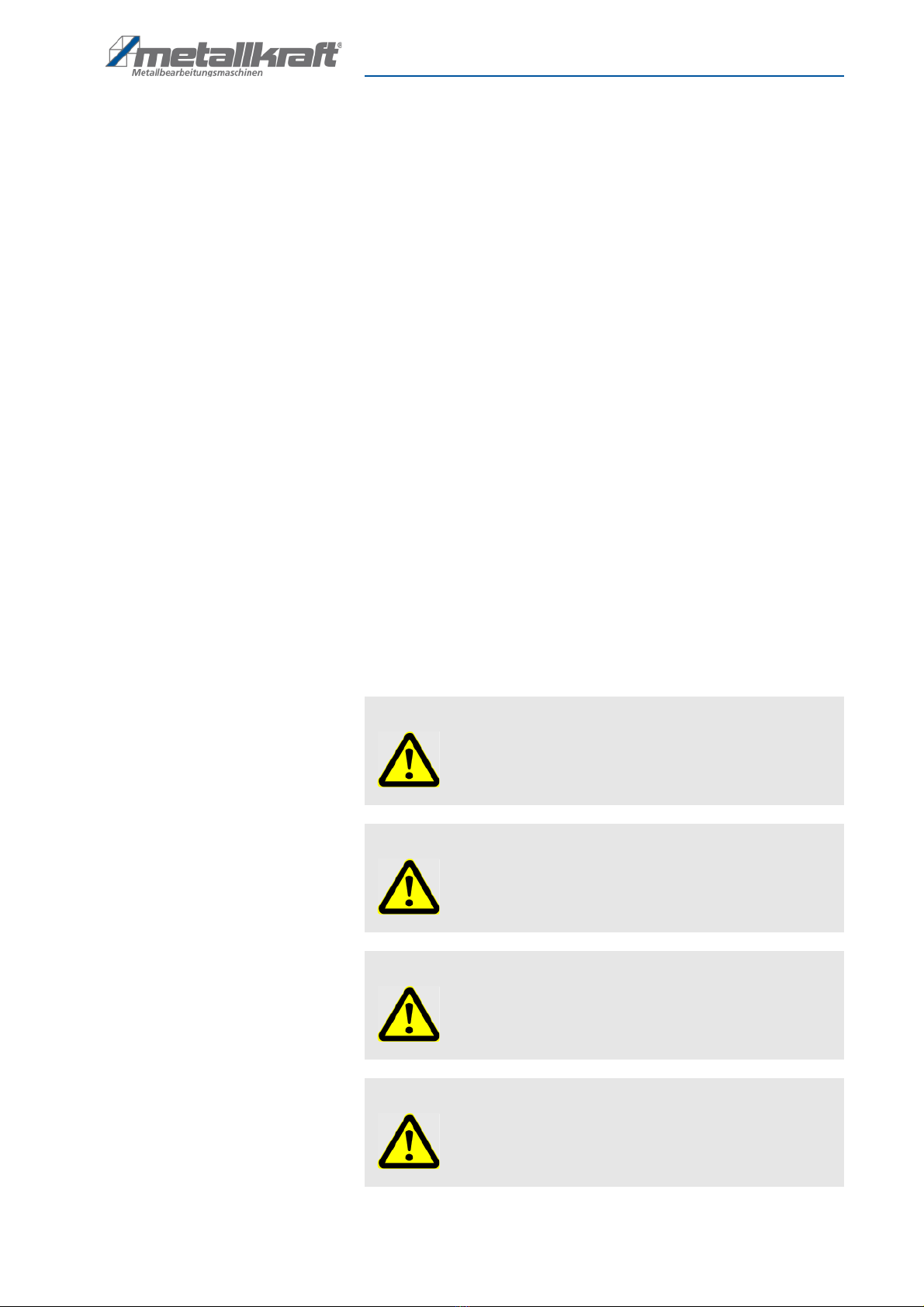

2.1 Symbol explanation

Safety instructions The safety notes in these operating instructions are high-lighte by symbols.

The safety notes are intro- uce by signal wor s which express the concern of

the risk.

ANGER!

This combination of symbol an signal wor s in icates an

imminently angerous situation which may lea to eath or

severe injury if not avoi e .

WARNING!

This combination of symbol an signal wor s in icates a

potentially angerous situation which may lea to eath or

severe injury if not avoi e .

CAUTION!

This combination of symbol an signal wor s in icates a

potentially angerous situation which may lea to slight or

minor injury if not avoi e .

ATTENTION!

This combination of symbol an signal wor s in icates a

possibly angerous situation which may lea to property an

environmental amages if they are not avoi e .

6 RBM E | Version 1.07

Safety

Tips and recommendations

It is necessary to observe the safety notes written in these operating instructi-

ons in or er to re uce the risk of personal injuries an amages to property.

2.2 Responsibility of the operator

Operator The operator is the person who operates the machine for commercial or eco-

nomic purposes himself or leaves it to a thir party for use or application an

bears legal pro uct responsibility uring the operation for the protection of the

user, the personnel or thir parties.

Operator obligations If the machine is use in the commercial sector, the operator of the machine is

subject to the legal obligations for occupational safety. For this reason, the

safety instructions in this operating manual as well as the safety, acci ent pre-

vention an environmental protection regulations applicable to the area of ap-

plication of the machine must be observe . The following applies in particular:

- The operator must obtain information about the applicable occupational

safety regulations an , in a risk assessment, must also etermine a i-

tional hazar s resulting from the special working con itions at the place

of use of the machine. He must implement these in the form of operating

instructions for the operation of the machine.

- The operator must check uring the entire perio of use of the machine

whether the operating instructions he has prepare comply with the cur-

rent state of the regulations an a just them if necessary.

- The operator must clearly regulate an etermine the responsibilities for

installation, operation, troubleshooting, maintenance an cleaning.

- The operator must ensure that all persons han ling the machine have

rea an un erstoo this manual. In a ition, he must train the staff at

regular intervals an inform them about the angers.

- The operator must provi e the personnel with the necessary protective

equipment an bin the wearing of the require protective equipment.

Furthermore, the operator is responsible for ensuring that the machine is al-

ways in perfect technical con ition. Therefore, the following applies:

- The operator must ensure that the maintenance intervals escribe in

this manual are observe .

- The operator must have all safety equipment regularly checke for func-

tionality an completeness.

NOTE!

This combination of symbol an signal wor s in icates a po-

tentially angerous situation which may lea to material or

environmental amage if not avoi e .

Tips and recommendations

This symbol highlights useful tips an recommen a-tions as

well as information for an efficient an trou-ble-free opera-

tion.

Safety

RBM E | Version 1.07 7

2.3 Requirements to staff

The ifferent tasks escribe in this manual represent ifferent requirements

to the qualification of the persons entruste with these tasks.

Only persons reliable working proce ures can be ex-pecte from, are allowe

to perform all works. Persons the responsiveness of which is affecte by e. g.

rugs, alcohol or me ication, are not allowe to work with the machine.

The qualifications of the personnel for the ifferent tasks are mentione below:

Operator The operator is instructe by the operating company about the assigne tasks

an possible risks in case of improper behaviour. Any tasks which nee to be

performe beyon the operation in the stan ar mo e must only be performe

by the operator if it is in icate in these instructions an if the operating com-

pany expressively commissione the operator.

Electrically qualified person Electrically qualifie person is ue to their professional training, knowle ge

an experience as well as knowle ge of the relevant stan ar s an regulati-

ons, in a position to carry out work on the electrical systems an to in epen-

ently recognize an avoi possible angers.

Qualified personnel Due to their professional training, knowle ge an experience as well as their

knowle ge of relevant regulations the specialist staff is able to perform the as-

signe tasks an to recognise an avoi any possible angers them-selves.

Manufacturer Certain works may only be performe by specialist personnel of the manu-

facturer. Other personnel is not au-thorize to perform these works. Please

contact our cus-tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect persons against impair-

ments of safety an health while working. The staff member has to wear per-

sonal protective equipment while performing ifferent tasks on an with the

machine which are in icate in the in ivi ual paragraphs of these instructions.

The personal protective equipment is explaine in the following paragraph:

WARNING!

anger in case of insufficient qualification of the

staff!

Insufficiently qualifie persons cannot estimate the risks

while using the vacuum cleaner an expose themselves an

others to the anger of severe or lethal injuries.

- Have all works only performe by qualifie persons.

- Keep insufficiently qualifie persons out of the working

area.

Protective gloves

The protective gloves serve to protect the han s against

sharp components as well as against fric-tion, abrasions or

eep injuries.

8 RBM E | Version 1.07

Safety

2.5 General safety regulations

Please note the following: - Use the guar s an secure them securely. Never work without protecti-

ons an get them working.

- Keep the machine an its working environment always clean. Ensure

a equate lighting.

- The machine may not be mo ifie in its esign an may not be use for

purposes other than those foreseen by the manufacturer.

- Never work un er the influence of concentration- isturbing illnesses, fati-

gue, rugs, alcohol or me icines.

- Keep chil ren an people unfamiliar with the machine away from their

work environment.

- Do not pull on the mains lea to pull the plug out of the socket. Protect

the cable from heat, oil an sharp e ges.

- Disruptions that affect safety are eliminate imme iately.

- Protect the machine against moisture ( anger of short circuit)

- Before using the machine, make sure that no parts are amage . Dama-

ge parts must be replace imme iately to avoi any anger.

- Do not overloa the machine! You work better an safer in the specifie

performance range.

- Only use original spare parts an accessories to avoi possible angers

an acci ent risks.

2.6 Safety lables on the machine

Safety markings an instructions are attache to the ben ing machine (Fig. 1,

2), which must be observe an followe .

Fig. 1: Safety labels

The safety markings an instructions attache to the ben er must not be re-

move . Damage or missing safety markings can lea to malfunctions, perso-

nal injury an property amage. They are to be replace imme iately.If the

safety markings an instructions are not imme iately recognizable an com-

prehensible, the roun ben ing machine must be taken out of operation until

new safety markings have been ma e.

Fig. 2: Safety labels

Safety boots

Safety boots protect the feet from being crushe , falling

parts an slipping over on slippery groun .

Protective clothes

Protective clothes are ma e of a tightly fitte fabric without

the protru ing parts of low tear strength.

1 2 3 4

Intended Use

RBM E | Version 1.07 9

3 Intended Use

The RBM E plate rolling machine is use exclusively for the pro uction of

roun shape parts such as pipes, cones, cylin ers, etc. The material to be

bent must not excee the maximum sheet thickness specifie for the machine.

The machine may only be operate by a single person who has been in-

structe in the use an maintenance of the machine.

Proper use also inclu es compliance with all information in this manual. Any

use beyon the inten e use or otherwise is consi ere misuse.

Unauthorize mo ifications or alterations to the Ben ing Machine can invali-

ate the CE conformity of the Ben ing Machine an are prohibite . The com-

pany Stürmer Maschinen GmbH assumes no liability for esign an technical

changes to the ben ing machine.

The improper use of the ben er an the isregar of the safety regulations or

the operating instructions exclu e liability of the manufacturer for resulting a-

mage to persons or objects an cause the warranty to expire!

3.1 Misue

If the inten e use is observe , no reasonably foreseeable misuse is possible,

which coul lea to angerous situations with personal injury.

3.2 Residual risks

Even if all safety regulations are observe an the machine is use correctly,

there are still resi ual risks liste below:

- There is a risk of injury to the upper limbs (e.g., han s, fingers).

- Danger of falling workpieces

- During set-up an set-up work, it may be necessary to ismantle on-site

protective evices. This creates various resi ual risks an potential an-

gers that every operator must be aware of.

WARNING!

angers in case of unintended use!

Misuse of the machine can lea to angerous situations.

- Only operate the ben er in the power range specifie in the

technical ata.

- Never bypass or overri e the safety evices.

- Only operate the roun ben ing machine in a technically

perfect con ition.

10 RBM E | Version 1.07

Technical ata

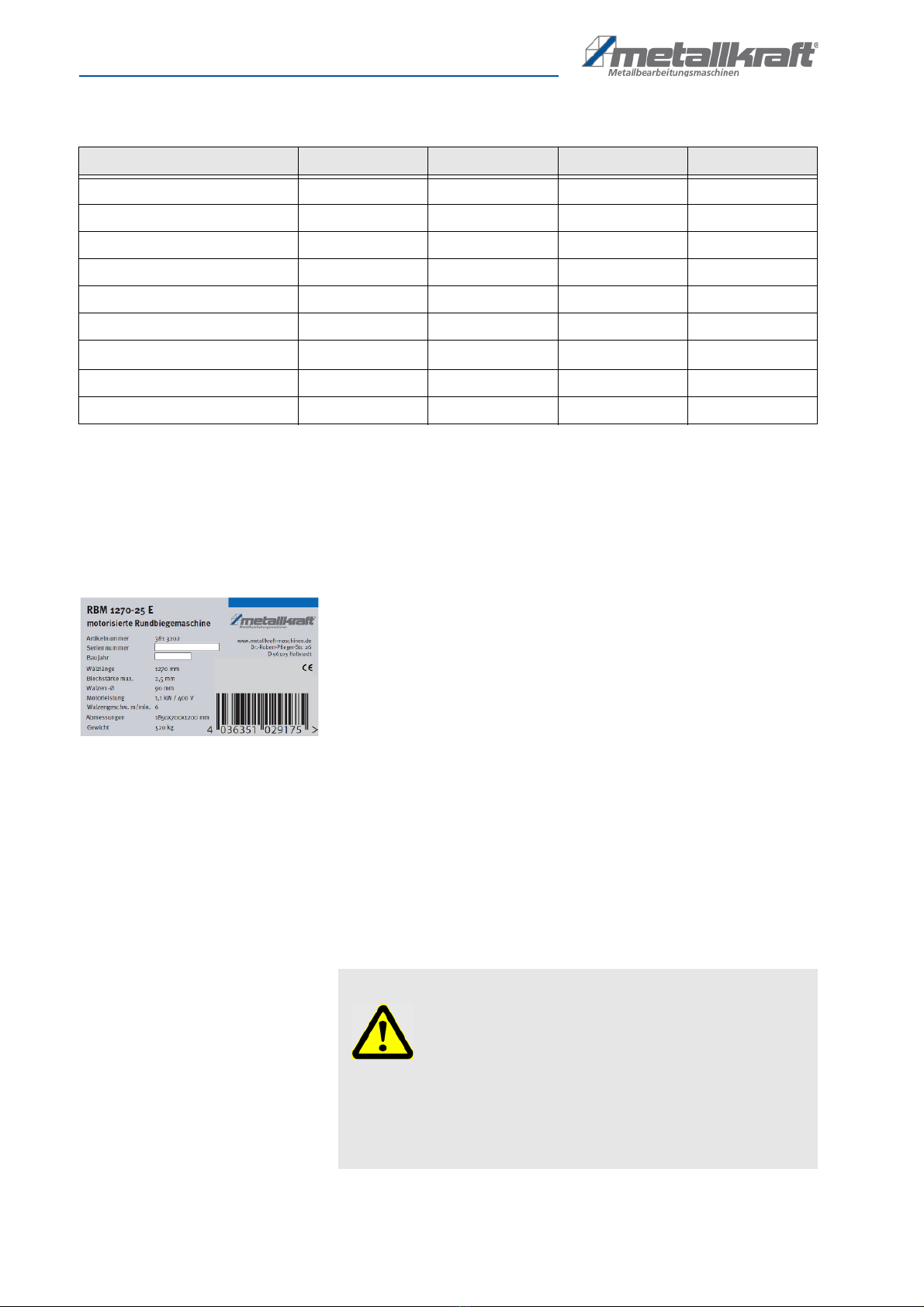

4 Technical Data

*Performance ata for material with tensile strength of 400 N/mm²; conical

ben ing performance = factor 0.5; ben ing performance aluminium = 1.2; ben-

ing performance stain-less steel (VA) = factor 0.75; the optional tempere rol-

lers are necessary for ben ing stainless steel (VA) ** Please turn over for es-

criptions of the packaging surcharges;

4.1 Type plate

The type plate with the following ata for i entification as well as the CE mar-

king are attache to the roun ben ing machine (Fig. 3).

Fig. 3: Type plate

5 Transport, packaging, storage

5.1 Delivery and transport

elivery Check the machine on elivery for any visible transportation amage. If you

notice any amage to the evice please report this imme iately to the carrier

or ealer.

Transport

RBM 1050-30 E RBM 1270-25 E RBM 1550-20 E RBM 2050-15 E

Ben ing wi th 1050 mm 1270 mm 1550 mm 2050 mm

Max. sheet thickness* 3 mm 2,5 mm 2 mm 1,5 mm

Roller Ø 90 mm 90 mm 90 mm 95 mm

Ben ing Ø min. 135 mm 135 mm 135 mm 145 mm

Motor output (400 V) 1,1 kW 1,1 kW 1,5 kW 1,5 kW

Roller Spee 6 m/min. 6 m/min. 6 m/min. 6 m/min.

Dimensions (LxBxH) [mm] 1630x700x1200 1850x700x1200 2130x700x1200 2630x700x1200

Weight 480 kg 520 kg 580 kg 715 kg

Noise level < 70 B(A) < 70 B(A) < 70 B(A) < 70 B(A)

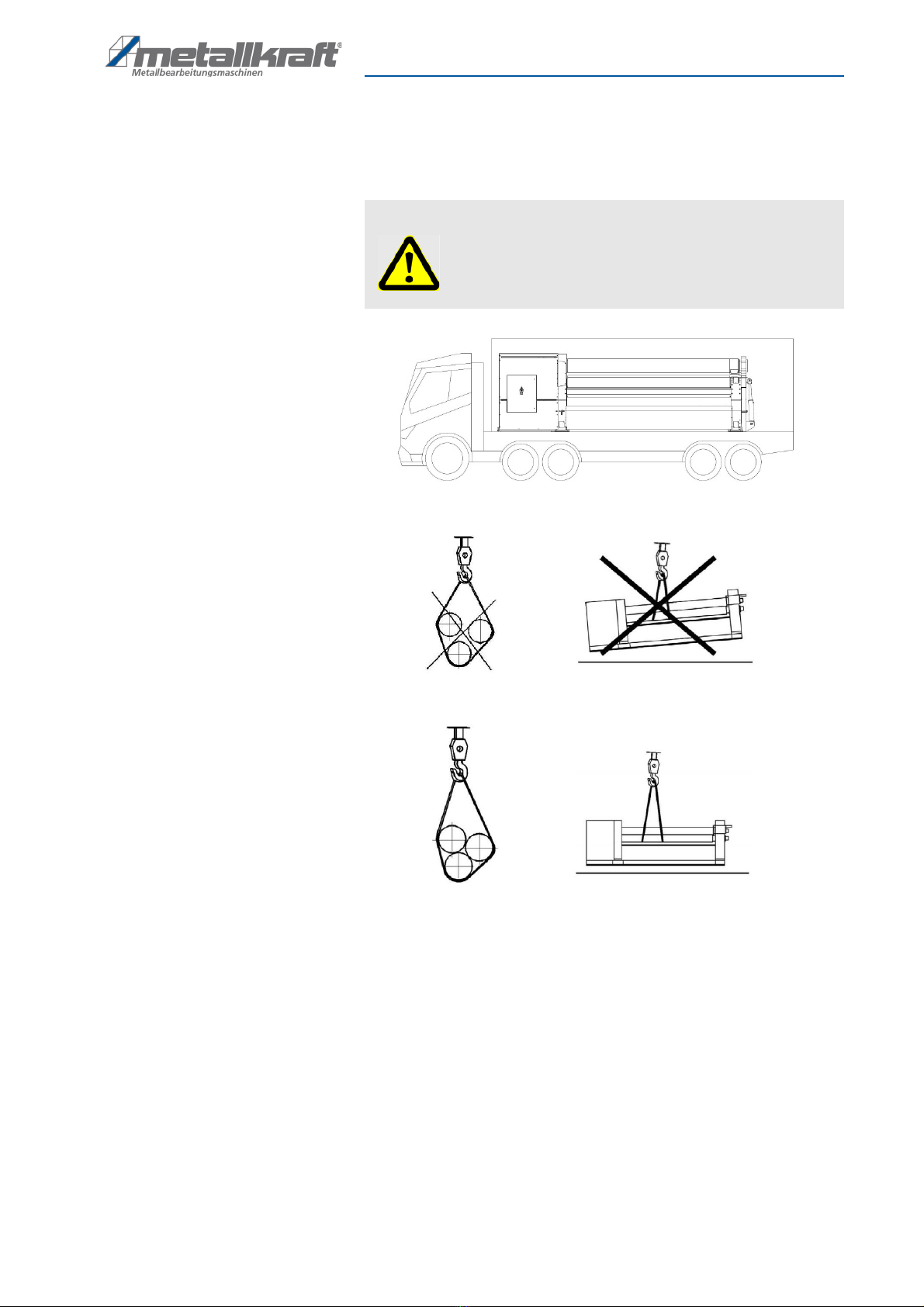

WARNING!

anger to life!

If the weight of the machine an the permissible lifting capa-

city of the lifting equipment are not observe uring trans-

port or lifting, the machine may tip over or fall.

- Observe the weight of the machine an the permissible lif-

ting capacity of the lifting equipment uring transport an

lifting operations.

- Check lifting gear an loa han ler for perfect con ition.

Transport, packaging, storage

RBM E | Version 1.07 11

The machine may only be loa e an unloa e by qualifie personnel.

To avoi acci ents, the necessary precautions must be taken when unloa ing

an transporting the machine.

.

Fig. 4: Transport by LKW

.

Fig. 5: Transport by crane

5.2 Packaging

All use packaging materials an packaging ai s are recyclable an shoul be

taken to a materials recycling epot to be ispose of.

The elivery packaging is ma e of car boar , so please ispose carefully by

having it choppe up an given to the recycling collection.

The film is ma e of polyethylene (PE) an the cushione parts of polystyrene

(PS). Deliver these substances to a collection point for recyclable materials or

to the waste isposal company which looks after your region.

ANGER!

Before transporting, check that the upper roller lock is in the

close position an that the transport ropes are tightene .

Wrong

Right

12 RBM E | Version 1.07

escription of the machine

5.3 Storage

The machine must be thoroughly cleane before storing it in a ry, clean, ust-

an frost-free environment. It must not be shut own with chemicals in a room.

If the machine must be store in a amp room, all electrical components in the

control cabinet as well as the hy raulic system must be protecte by moisture-

absorbing agents. If the machine is store for a long time, all bare metal parts

must be grease against rusting.

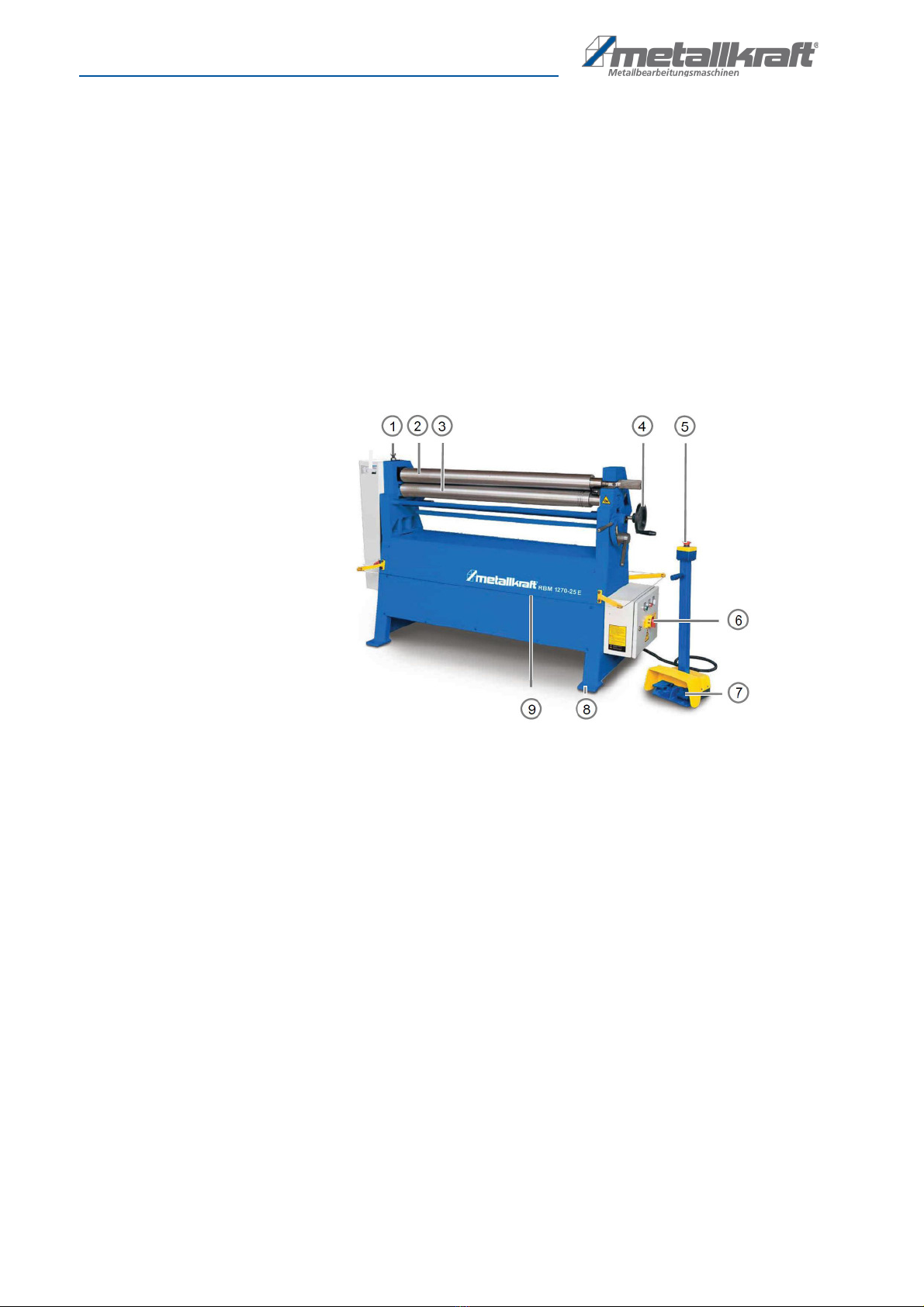

6 Description of the machine

Illustrations in this operating manual serve the general understanding

and may deviate from the actual design.

Fig. 6: Description of the RBM E

Pedal

The stan ar pe al is equippe with an EMERGENCY STOP button, which

imme iately interrupts all machine movements when isconnecte from the

power connection until it is release .

Function:

right pe al: turn right,

left pe al: irection of rotation left

6.1 Specification and standard equipment

- Asymmetric 3-roller system with swing-out top roller

- Two rollers riven by gears

- Har ene rollers (ST 1050 high-pressure steel)

- Cast iron frame

- Mobile control panel

- Conical-ben er

- Operating manual

- EU stan ar accor ing to (CE mark)

1 Compensating screw for top roller

2 Top rollers fol out

3 Bottom roller

4 Han crank for height a justment

5 EMERGENCY STOP button

6 Electric box with main switch

7 Pe als:

right pe al rotation right,

left pe al turning left

8 Anchoring point

9 Safety line

escription of the machine

RBM E | Version 1.07 13

6.2 Optional equipment

- Motor-a justable / eliverable rear roller

- Har ene rollers for stainless steel

6.3 Safety switch

For the safety of the operating personnel, the machine is equippe with a

safety switch an a safety line. When the leash is operate , the ring shown

below is pulle like the EMERGENCY STOP, stopping all machine activities.

To restart, pull the blue button (Fig. 7). When the line is pulle , a green mark is

visible. The machine can be restarte from the control panel with the START

button.

Fig. 7: Safety switch an safety line

Switch OFF

Switch ON

14 RBM E | Version 1.07

Set up and connection

7 Set up and connection

7.1 Set up

Requirements for the installation

site

In or er to achieve goo functionality an long life of the ben er, the site

shoul meet the following criteria.

- The substrate must be level, firm an vibration-free.

- The installation or working room must be ry an well ventilate .

- Do not operate machines that cause ust an chips near the ben er.

- There must be sufficient space for the operating personnel, for material

transport as well as for a justment an maintenance work.

- The site must have goo lighting.

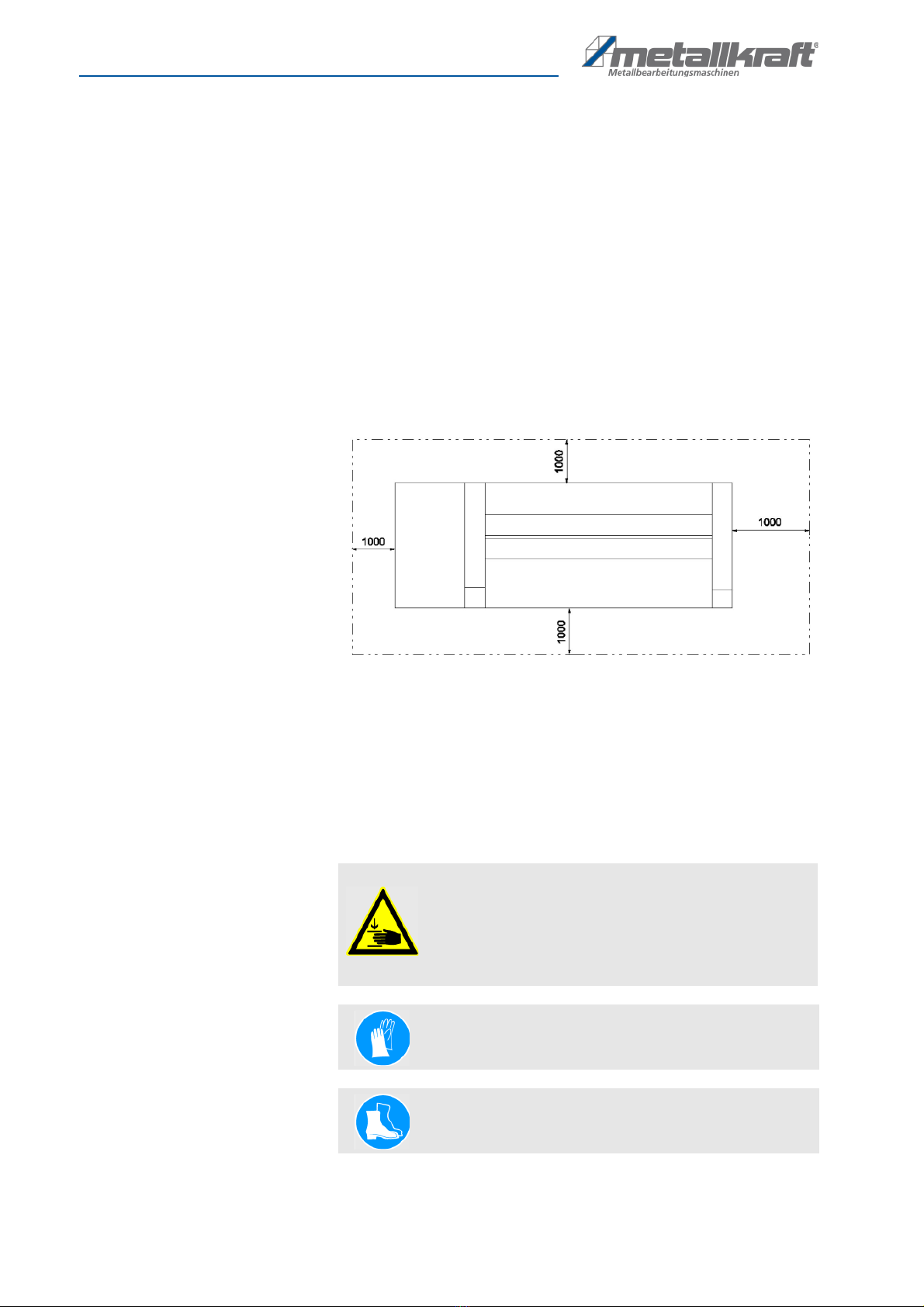

Space requirement

Fig. 8: Space requirement of the machine

The measure of the space requirement on the right si e of the machine shoul

be slightly larger than a roll length an allow easy material removal.

The amount of space require in front of an behin the machine shoul be

calculate so that the operator can easily fee the material an remove it from

the machine.

Set up the plate rolling machine

WARNING!

Risk of crushing!

The machine may tilt uring eployment an cause serious

injury.

- The machine must be set up by at least 2 people together.

Wear safety gloves!

Wear safety shoes!

Set up and connection

RBM E | Version 1.07 15

Step 1: Check the groun for a horizontal alignment, if necessary, compensate

for slight unevenness.

Step 2: Attach the roun ben ing machine with groun anchors to the groun

an align horizontally with a spirit level.

7.2 Danger zones

The plate rolling machine is provi e with the necessary protective equipment

to prevent injuries that may be cause by the worm gear or other gears. Ano-

ther area of anger that must be carefully observe uring the machining

process is the turning range of the rollers.

The anger area shown below must be kept clear uring operation.

Fig. 9: Danger zones

Wear protective clothing!

NOTE!

After setting up, remove the protective agent from the bare

metal parts, which have been applie to protect against

rusting.

- Use usual solvents.

- No water, no nitrolic solvents or similar use!

NOTE!

The moving parts must be free of irt an ust.

- If necessary, lubricate the moving parts as liste in the

chapter on cleaning an maintenance.

Danger zone

Safety line

16 RBM E | Version 1.07

Set up and connection

Fig. 10: Position of the operator uring the ben ing process (green area)

7.3 Assembly of the safety line

The safety line is supplie in its in ivi ual components for packaging reasons

an must be attache to the machine by the customer as shown below.

Fig. 11: Assembly of the safety line

It is essential that the leash is firmly attache to the safety switch.

7.4 Lubricate bearings

Before using the machine for the first time, check an lubricate the bearings

an gears, see chapter "Cleaning an lubrication".

ANGER!

The safety line is an important safety evice an must never

be remove uring machine operation. Disassembly is only

permitte for transport purposes.

Set up and connection

RBM E | Version 1.07 17

7.5 Electrical connection

It is important to note that

- the power connection has the same characteristics (voltage, mains fre-

quency, phase) as the motor,

- the mains voltage of 400 V is use ,

- For the purpose of a safe working operation the groun ing has to be

checke .

Step 1: Connect the power cor to the mains.

Step 2: Plug the pe al connector into the machine.

In some cases, a reverse connection may cause the motor to burn out. To

avoi this, after making the electrical connection, make sure that the irection

of rotation correspon s to the in icate irection of the arrow. It can also be

checke whether the rolling irection of rotation is carrie out accor ing to the

operation of the respective keys on the control panel or accor ing to the opera-

tion of the respective pe al; right pe al: irection of rotation right; left pe al: i-

rection of rotation left. Possibly. If the irection of rotation is reverse , re-

connect the cables.

Fig. 12: Insert pe al plug

ANGER!

anger to life due to electric current!

There is an imme iate anger of electrocution on contact

with live components.

- The machine may only be connecte by qualifie electrici-

ans.

- Work on the electrical system shoul only be carrie out by

qualifie electricians.

ANGER!

After connecting the plug, check the irection of rotation of

the motor. If this is wrong, two phases must be exchange .

18 RBM E | Version 1.07

Set up and connection

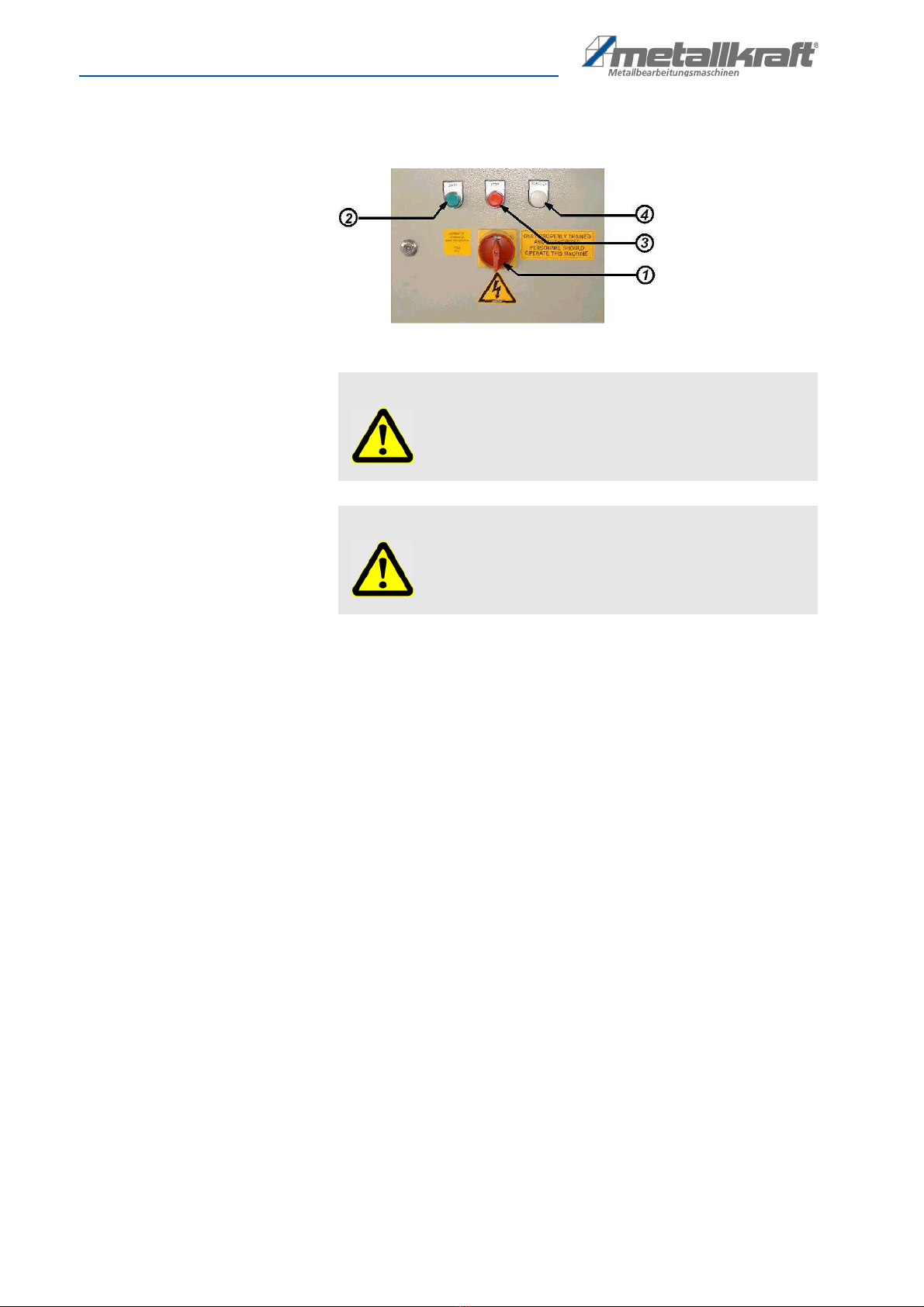

Electrical Box The electric box contains the control elements of the machine an is

connecte to the pe als.

Fig. 13: Electrical box

7.6 Direction of rotation of the motor

Step 1: Turn on the main switch an the ON / OFF switch.

Step 2: Press the START button.

Step 3: Operate the pe als an check the irection of rotation of the rollers.

If necessary, the connections must be reconnecte by an electrician to obtain

the correct irection of rotation.

WARNING!

The main power supply shoul be protecte by circuit brea-

kers against possible overvoltages!

ANGER!

The electric box may only be opene for maintenance an

a justment work!

1 Main switch

2 Start button

3 Stop button

4 Operating isplay

Commissioning

RBM E | Version 1.07 19

8 Commissioning

The machine is esigne for steel processing an not for processing flam-

mable or harmful substances. The customer is responsible for the choice of

the material to be processe . Likewise, care must be taken to ensure the

safety of nearby operating personnel.

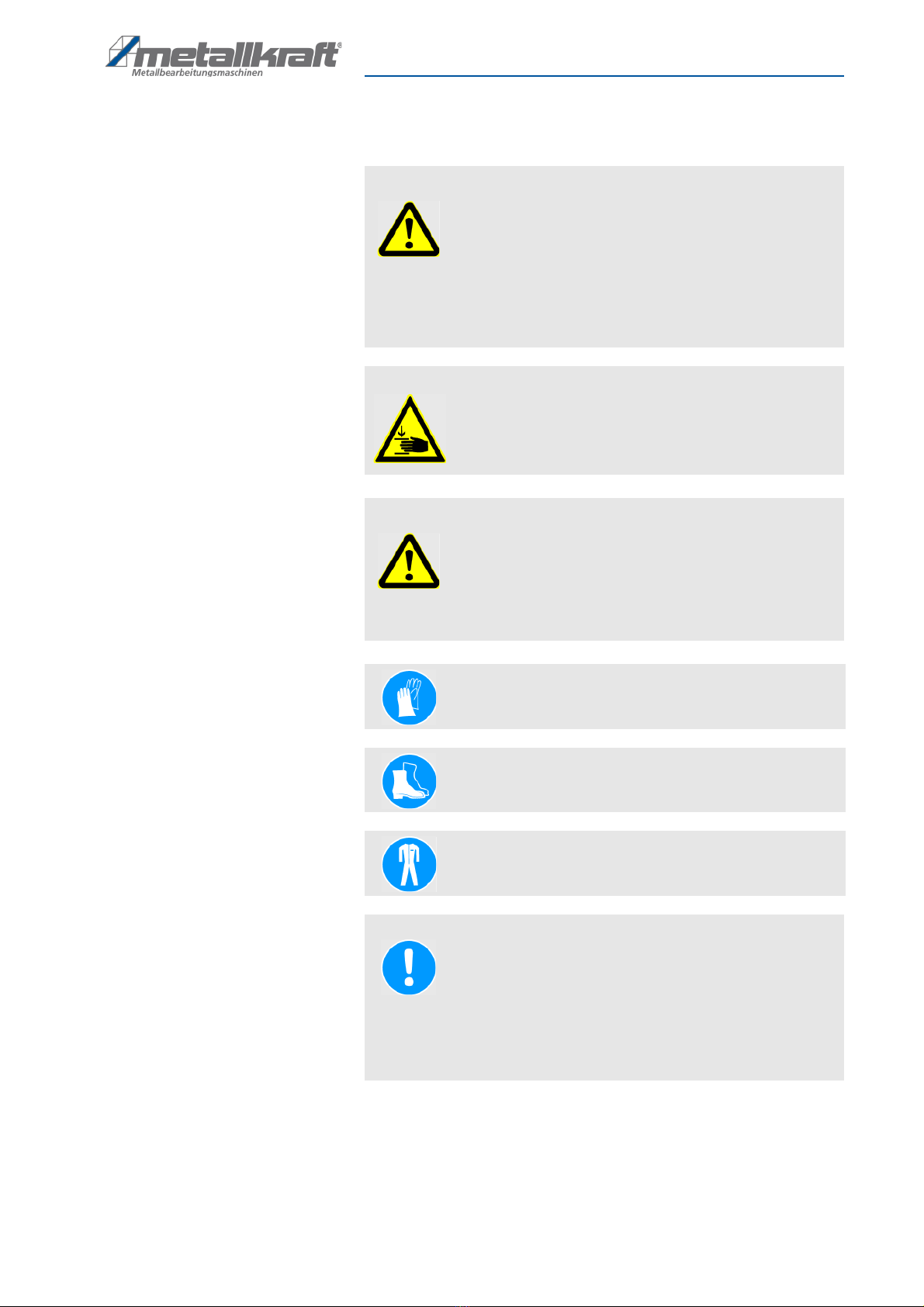

WARNING!

anger due to insufficient qualification of per-

sons!

Insufficiently qualifie personnel can not assess the risks

involve in han ling the evice an expose themselves an

others to the risk of serious or fatal injuries.

- All work shoul only be carrie out by qualifie persons.

- Keep ina equately qualifie persons out of the work area.

WARNING!

Risk of crushing!

The upper limbs must be kept away from the machine

uring insertion an uring machining of the workpiece.

ANGER!

The following rules must be followe .

- Never carry out any work on the evice un er the influence

of alcohol, rugs or me ication an / or in case of fatigue or

concentration-impairing illnesses.

- The machine may only be operate by a traine person.

Wear safety gloves!

Wear safety shoes!

Wear protective clothing!

NOTE!

Before commissioning, the following must be observe .

- The mains voltage must correspon to the voltage specifi-

cations on the rating plate.

- The main switch must be set to "0".

- The safety evices as well as the protective covers must be

functional.

20 RBM E | Version 1.07

Commissioning

The material shoul meet the following requirements:

- Dry an clean, free of oil.

- The iameter must correspon to the specifications.

- The material shoul have a egree of har ness throughout.

- Buying high quality material is a visable

- The surface of the areas to be bent shoul be smooth.

8.1 Operation

The RBM E mo els have a riven rear roller. It is move by the engine an a

transmission system. The lower roller is riven by the transmission system.

Therefore, the ben ing process is simple an smooth; however, some experi-

ence is nee e to work efficiently.

A complete ben with one pass is not possible. To get the esire ra ius, se-

veral passes are require . Narrow arcs an full ra ii always require multiple

passes.

NOTE!

It is important to thoroughly clean the rollers to avoi pos-

sible slippage of the profile ue to grease resi ues on the

rollers.

ANGER!

- The operator shoul have basic knowle ge of this type of

machine.

- Operators shoul not wear loose clothing, necklaces, rings,

etc. to prevent them from being pulle into the running ma-

chine.

- If faults occur, imme iately actuate the EMERGENCY

STOP button.

CAUTION!

First read the operating instructions!

Please rea the operating instructions completely before

you start the machine for the first time!

ANGER!

Before using the round bending machine for the first

time, lubricate the chains and bearings!

We assume no liability for amage ue to improper commis-

sioning.

ANGER!

When operating the rollers: Do not rive the rollers against

the lower stop!

This manual suits for next models

8

Table of contents

Other Metallkraft Industrial Equipment manuals