Metallkraft GS 1100-16 E User manual

GS 1100-16 E

Operating instructions

GS 1200-24 E

Thread Tapping Machine

GS-E SERIES

GS 1100-16 E

GS 1200-36 E

2 GS-E Series | Version 1.09

Imprint

Product identification

Thread Tapping Machine Ite nu ber

GS 1100-16 E 4450116

GS 1200-24 E 4450124

GS 1200-36 E 4450136

Manufacturer

Stür er Maschinen G bH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt/Ba berg

Fax: 0049 (0) 951 96555 - 55

E-Mail: info@ etalkraft.de

Internet: www. etalkraft.de

Information on the operating instructions

Original operating instructions

according to DIN EN ISO 20607:2019

Edition: 14.12.2021

Version: 1.09

Language: English

Author: MS

Copyright information

Copyright © 2021 Stür er Maschinen G bH, Hallstadt,

Ger any.

Technical changes and errors excepted.

Content

1 Introduction ............................................................. 3

1.1 Copyright ............................................................ 3

1.2 Custo er service................................................ 3

1.3 Li itation of liability............................................. 3

2 Safety ....................................................................... 3

2.1 Sy bol explanation ............................................ 3

2.2 Obligations of the operating co pany ................ 4

2.3 Personnel require ents...................................... 5

2.4 Personal protective equip ent ........................... 5

2.5 Safety labels on the thread tapping achine...... 6

2.6 Safety devices .................................................... 6

2.7 Safety data sheets.............................................. 6

2.8 Special safety rules for the thread tapping

achine .............................................................. 6

3 Intended Use............................................................ 7

3.1 Reasonably foreseeable isuse......................... 7

3.2 Residual risks ..................................................... 7

4 echnical Data......................................................... 7

4.1 Table................................................................... 7

4.2 Type plate........................................................... 8

5 ransport, packaging, storage............................... 8

5.1 Delivery............................................................... 8

5.2 Transport ............................................................ 8

5.3 Packaging........................................................... 8

5.4 Storage ............................................................... 8

6 Description of device.............................................. 9

6.1 Representation ................................................... 9

7 Assembly ................................................................. 9

7.1 Setting the tapping direction ............................. 10

7.2 Electrical connection......................................... 10

8 Operation ............................................................... 11

8.1 Operation.......................................................... 11

8.2 Turn on/off ........................................................ 12

8.3 User interface ................................................... 12

8.4 Language settings ............................................ 13

8.5 Deep hole operation ......................................... 13

8.6 Storage and recall of workpiece para eters .... 13

8.7 User para eter................................................. 13

8.8 User para eter for lubricating and scrap

blowing.............................................................. 14

8.9 Adjusting the coupling torque of the collet

chuck ................................................................ 14

9 Cleaning, maintenance and repair....................... 14

9.1 Cleaning and aintenance............................... 14

9.2 Overhaul of the fuse ......................................... 15

9.3 Repair ............................................................... 15

10 Disposal, recycling of old equipment ............... 15

10.1 Deco ission ............................................... 15

10.2 Disposal of electrical equip ent.................... 15

10.3 Disposal via unicipal collection points......... 15

10.4 Disposal of lubricants..................................... 15

11 roubleshooting.................................................. 16

12 Spare parts .......................................................... 17

12.1 Ordering spare parts...................................... 17

12.2 Spare parts drawing....................................... 18

13 Wiring Diagram Control Unit.............................. 20

14 EC-Declaration of Conformity............................ 21

Introduction

GS-E Series | Version 1.09 3

1 Introduction

With the purchase of the METALLKRAFT threading a-

chine you have ade a good choice.

Read the operating instructions carefully before

commissioning.

This is an i portant co ponent and ust be kept close

to the achine and accessible to all users.

The operating instructions infor you about the correct

co issioning, the intended use as well as the safe and

efficient operation and aintenance of the thread cutting

achine

In addition, observe the local accident prevention regula-

tions and general safety regulations for the area of appli-

cation of the thread cutting achine

1.1 Copyright

The contents of these instructions are protected by copy-

right. Their use is per itted within the fra ework of the

use of the thread cutting achine. Any further use is not

per itted without the written consent of the anufactu-

rer. Forwarding and copying of this docu ent, utilization

and co unication of its contents are prohibited unless

expressly per itted. Infringe ents oblige you to pay da-

ages. To protect our products, we report trade arks,

Patent and design rights, if this is possible in individual

cases. We strongly oppose any infringe ent of our intel-

lectual property.

1.2 Customer service

Please contact your specialist dealer if you have any

questions about your threading achine or for technical

infor ation. They will be happy to help you with expert

advice and infor ation.

Germany:

Stür er Maschinen G bH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: 0049 (0) 951 96555-111

E-Mail: service@stuer er- aschinen.de

Spare part order:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuer er- aschinen.de

We are always interested in infor ation and experiences

that result fro the application and can be valuable for

the i prove ent of our products.

1.3 Limitation of liability

All infor ation and notes in the operating instructions

have been co piled taking into account the applicable

standards and regulations, the state of the art and our

any years of knowledge and experience. The anufac-

turer accepts no liability for da age in the following ca-

ses:

- Non-observance of the operating instructions,

- Non-intended use,

- Use of inexperienced personnel,

- Unauthorized odifications,

- Technical odifications,

- Use of non-approved spare parts.

The actual scope of delivery ay deviate fro the expla-

nations and representations described here in the case

of special versions, when additional order options are

used or due to the latest technical changes.

The obligations agreed in the delivery contract, the gene-

ral ter s and conditions as well as the delivery conditi-

ons of the anufacturer and the legal regulations valid at

the ti e of the conclusion of the contract shall apply.

2 Safety

This paragraph will give you an overview of all i portant

safety packages for the protection of the people using it

well as for a safe and undisturbed operation. Other task-

based safety notes are included in the individual chap-

ters.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by sy bols. The safety notes are introduced by

signal words which express the concern of the risk.

4 GS-E Series | Version 1.09

Safety

ips and recommendations

It is necessary to observe the safety notes written in

these operating instructions in order to reduce the risk of

personal injuries and da ages to property.

2.2 Obligations of the operating com

pany

Operator

The operating co pany is the person who operates the

achine for business or co ercial reasons by herself,

or leaves it to a third party for use or application, and who

bears the legal product responsibility for the protection of

the user, the staff or for third parties.

Obligations of the operating company

If the aschine is used for co ercial purposes,

the operating co pany of the achine ust co ply with

the legal working safety regulations. Therefore, the

safety notes in this operating anual, as well as the

safety, accident prevention and environ ent protection

regulations applying for the area of application of the a-

chine ust be et. The following applies in particular:

- The operating co pany ust be infor ed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting fro the special

working conditions at the place of use the achine.

She ust i ple ent these in for of operating

anuals for the operation of the achine.

- During the entire lifeti e of the achine, the oper-

ating co pany ust verify whether the operating

anuals prepared by her correspond to the current

status of the regulations, and ust adapt these if

necessary.

- The operating co pany ust una biguously regu-

late and deter ine the responsibilities for installa-

tion, operation, troubleshooting, aintenance and

cleaning.

- The operating co pany ust ensure that all per-

sons who work with the achine, have read and

understood this anual. Further ore she ust in-

struct the staff in regular intervals and infor the

about the hazards.

- The operator ust provide the necessary protec-

tive equip ent to the staff and order the use of the

necessary protective equip ent in a binding way.

Further ore the operating co pany is responsible to

keep the achine always in a technically flawless state.

Thus, the following applies:

- The operator ust ensure that the aintenance in-

tervals described in this anual are kept.

- The operator ust have all safety devices checked

regularly for their good working order and their in-

tegrity.

DANGER!

This co bination of sy bol and signal word indicates

an i inently hazardous situation which, if not avoi-

ded, will result in death or serious injury.

WARNiNG!

This co bination of sy bol and signal word indicates

a potentially hazardous situation which, if not avoi-

ded, will result in death or serious injury.

Caution!

This co bination of sy bol and signal word indicates

a potentially hazardous situation which, if not avoi-

ded, ay result in inor or oderate injury.

Attention!

This co bination of sy bol and signal word indicates

a possibly hazardous situation which, if not avoided,

ay result in da age to property and the environ-

ent.

NO E!

This co bination of sy bol and signal words indi-

cates a possibly dangerous situation which ay lead

to property and environ ental da ages if they are

not avoided.

ips and recommendations

This sy bol highlights useful tips and reco enda-

tions as well as infor ation for an efficient and trou-

ble-free operation.

Safety

GS-E Series | Version 1.09 5

2.3 Personnel requirements

Qualifications

The various tasks described in this anual place diffe-

rent de ands on the qualifications of the persons entrus-

ted with these tasks.

Only persons who can be expected to perfor this work

reliably are per itted to perfor any work. Persons

whose ability to react is influenced by drugs, alcohol or

edication, for exa ple, are not per itted.

In these operating instructions, the qualifications of the

persons listed below are na ed for the various tasks:

Operator

The operator has been instructed by the operator about

the tasks assigned to hi and possible dangers in case

of i proper behavior. The operator ay only perfor

tasks that go beyond operation during nor al operation

if this is specified in these operating instructions and the

operator has expressly entrusted hi with this task.

Qualified electrician

Due to their professional training, knowledge and expe-

rience as well as knowledge of the relevant standards

and regulations, the electrician is able to carry out work

on electrical syste s and to independently recognize

and avoid potential hazards.

The electrician is specially trained for the work environ-

ent in which he works and knows the relevant stan-

dards and regulations.

Specialist personnel

Due to their professional training, knowledge and expe-

rience as well as knowledge of the relevant standards

and regulations, the qualified personnel are able to carry

out the work assigned to the and to recognize possible

hazards independently and to avoid hazards.

Manufacturer

Certain work ay only be carried out by specialist per-

sonnel of the anufacturer. Other personnel are not aut-

horized to perfor this work. Contact our custo er ser-

vice depart ent to carry out any work that ay be

required.

2.4 Personal protective equipment

The personal protective equip ent is used to protect

persons against i pair ent of safety and health during

work. The personnel ust wear personal protective

equip ent during the various work on and with the de-

vice, which is referred to separately in the individual sec-

tions of these instructions.

The following section explains the personal protective

equip ent:

WARNING!

Danger in case of insufficient quali-

fication of persons!

Insufficiently qualified persons cannot assess the

risks when handling the tapping achine and expose

the selves and others to the risk of serious or fatal

injuries.

- All work ust be carried out by qualified personnel

only.

- Keep insufficiently qualified persons away fro the

work area.

Hearing protection

Hearing protection protects against hearing da age

caused by noise.

Head protection

The industrial hel et protects the head against fal-

ling objects and bu ping against fixed objects.

Face shield

The face shield protects the face fro flying parts.

Suitable protective gloves

The protective gloves protect the hands fro sharp-

edged co ponents, as well as fro friction, abrasi-

ons or deeper injuries.

Safety shoes

The safety shoes protect the feet fro crushing, fal-

ling parts and slipping on slippery surfaces.

Protective work clothing

Protective work clothing is tight-fitting clothing with

low tear resistance.

6 GS-E Series | Version 1.09

Safety

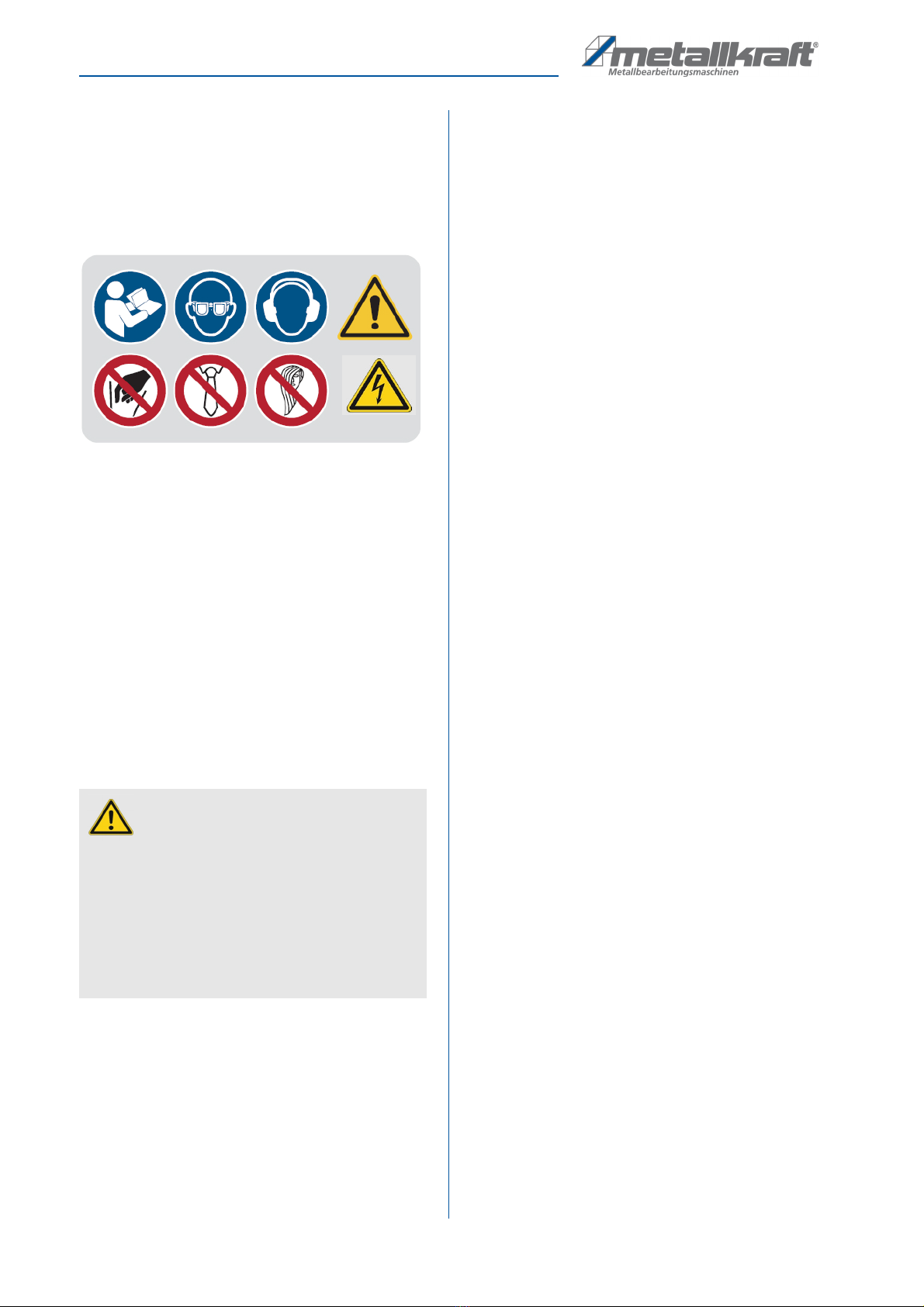

2.5 Safety labels on the thread tapping

machine

Various safety arkings are attached to the thread tap-

ping achine (Fig. 1), which ust be observed and follo-

wed:

Fig. 1: Safety labels - Mandatory sy bols: Read instructions for use,

Wear eye protection, Wear ear protection I Warning sy bols:

General warning sign | Electrical voltage I Prohibition sy bols:

Do not reach in, Do not wear a tie, Do not wear open hair

The safety arkings attached to the thread tapping a-

chine ust not be re oved. Da aged or issing safety

arkings can lead to incorrect actions, personal injury

and aterial da age. They ust be replaced i edia-

tely.

If the safety arkings are not recognizable and co pre-

hensible at first glance, the thread tapping achine ust

be taken out of operation until new safety arkings have

been applied.

2.6 Safety devices

2.7 Safety data sheets

Safety data sheets for hazardous goods can be obtained

fro your specialist dealer or by calling

+49 (0)951 / 96555-0.

Specialist dealers can find safety data sheets in the

download area of the partner portal.

2.8 Special safety rules for the thread

tapping machine

- Do not allow the achine to operate at overload,

especially outside of the tapping capacity.

- Check the wearing parts before using the achine.

Replace and repair the in good ti e.

- Lock the entire handle and secure the workpiece

fir ly.

- Do not touch rotating parts when the electric tap-

ping achine is working.

- Keep children away fro the threading achine.

- Keep people away fro the work area when the

achine is working.

- Do not wear loose clothing or jewellery. They can

get caught in rotating parts. Non-slip footwear is re-

co ended when operating the achine.

- Wear protective hair covering to hold back long

hair.

- Maintain the achine regularly. Keep the tap sharp

and add cutting oil while tapping.

- add cutting oil while tapping.

- Do not pile up the working aterial in the working

area of the achine.

- Always keep the working area clean.

- Do not use the electric tapping achine on fla -

able, explosive, wet,

- undersized and unclean places.

- Do not work with blunt or da aged tools. This ay

cause overstressing of the otor.

- Protect the otor. Make sure that no coolant, water

or other substances enter the otor.

- Metal chips are usually very sharp-edged and hot.

Never touch the with bare hands. Re ove the

with a agnetic chip collector or a chip hook. Only

re ove etal chips when the achine is switched

off.

WARNING!

Danger to life due to non-functio-

ning safety devices!

If safety devices do not function or are disabled,

there is a risk of serious injury or even death.

- Before starting work, check that all safety devices

are functional and correctly installed.

- Never override or bridge safety devices.

- Ensure that all safety devices are always acces-

sible.

Intended Use

GS-E Series | Version 1.09 7

3 Intended Use

The thread cutting achine is designed for the produc-

tion of threads for all aterials ade of etal or etal-

like aterials in all aterial thicknesses. Only thread di-

a eters according to the specifications in the technical

data table ay be cut.

Intended use also includes co pliance with all the infor-

ation in these instructions.

3.1 Reasonably foreseeable misuse

Any use that goes beyond the intended use or is different

is dee ed to be isuse.

Possible isuse can be:

- Use of the thread cutting achine for aterials

other than etal (e.g. processing wood or plastic).

- The tapping achine ust not be used for drilling

or screwing.

- Modifications to the achine or accessories.

- Maintenance work on an unsecured achine.

- Failure to observe the signs of wear and da age.

- Service work by untrained or unauthorized person-

nel.

- Use of accessories or spare parts that are not

approved by the anufacturer.

- Misuse of the achine.

- Operating the thread cutter if the operating instruc-

tions have not been read and understood in full.

- Deliberate or careless handling of the thread cut-

ting achine during operation.

- The use of an inco pletely asse bled achine.

Misuse of the thread cutting achine can lead to dange-

rous situations. Stür er Maschinen G bH assu es no

liability for constructive or technical changes to the

thread cutting achine. Clai s of any kind due to da-

age due to i proper use are excluded.

3.2 Residual risks

Even if all safety instructions are observed and the a-

chine is used according to the instructions, there are still

residual risks, which are listed below:

- Risk of injury to the upper li bs (e.g. hands, fin-

gers)

- Risk of injury fro tripping over cables

- Hearing i pair ent when working for a long ti e

without hearing protection or when it is inadequate

- Electrical hazard fro contact with parts and high

voltage (direct contact) or with parts that are under

high voltage due to a defect in the tap (indirect con-

tact)

- Heat develop ent on co ponents can lead to

burns and other injuries

- Danger fro workpieces being thrown out

- Risk of injury to the eye fro flying parts, even with

protective goggles

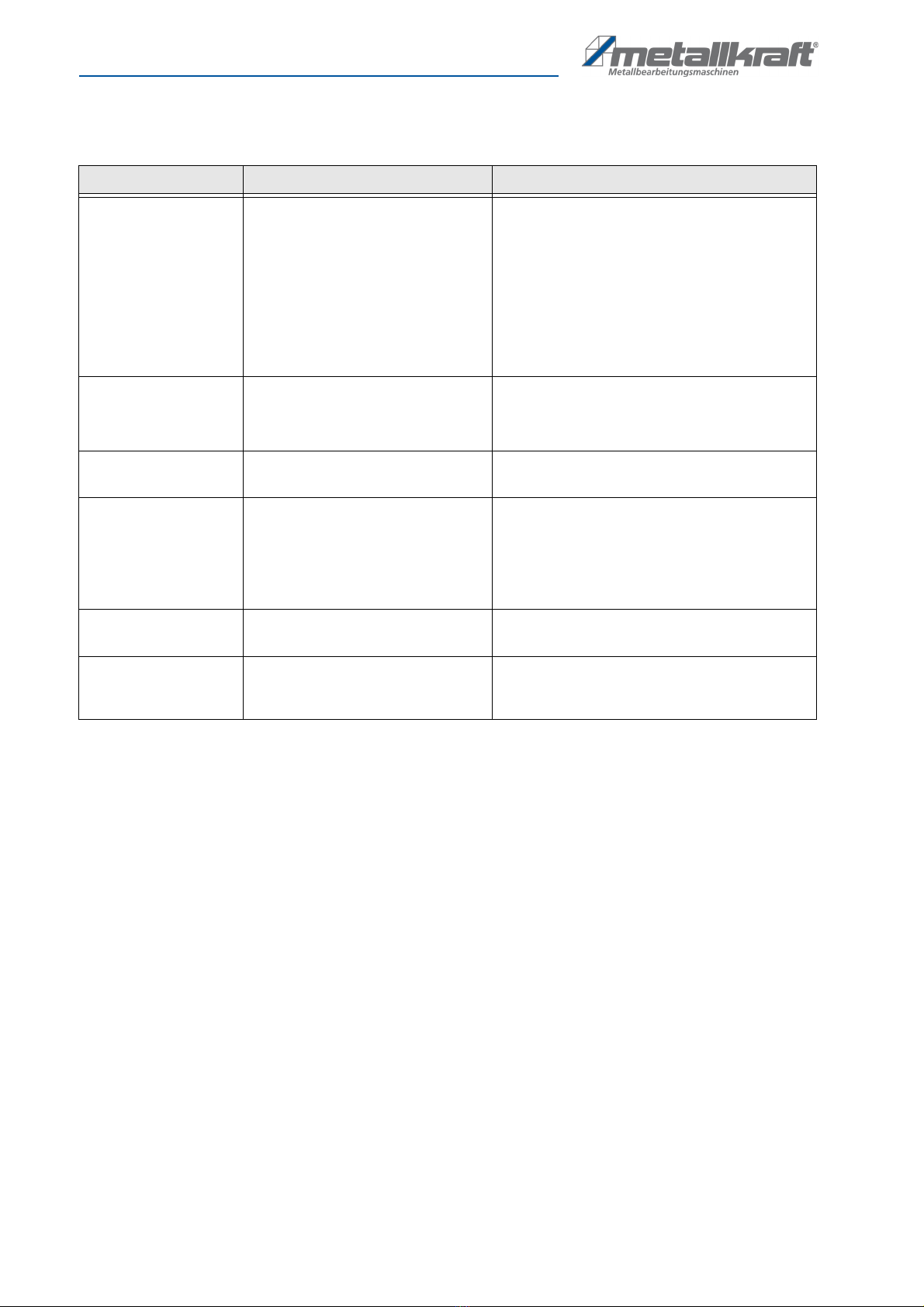

4 Technical Data

4.1 Table

Model GS 1100-16 E 1200-24

E

1200-36 E

Di ensions

(LxWxH)

approx.

930x60x

520

1400x100x700

Weight (Net)

approx.

25 kg 40 kg 42 kg

Supply

voltage

220 V /

50 Hz

220 V /

50 Hz

220 V /

50 Hz

Phase(s) 2 Ph 2 Ph 2 Ph

Stro art

AC/DC

4,5 A 7,3 A 7,3 A

Tapped

holes at

400 N/ ²

[M(x)-M(y)]

M3 - M16 M6 - M24 M6 - M36

Max. speed 312 in¯¹ 200 in¯¹ 156 in¯¹

Sound pres-

sure level Lp

59 dB(A) 73 dB(A) 73 dB(A)

Cutting

direction

universal direction

[vertical/horizontal]

Drive syste electrical

Quick

change

chuck [M]

M3-M6,

M8, M10,

M12,

M14, M16

M6, M8,

M10,M12,

M14,

M16,

M18,

M20,

M22-M24

M6, M8,

M10,M12,

M14,

M16,

M18,

M20,

M22-M24,

M27,

M30,

M33, M36

Cantilever

radius

1100 1200 1200

Adjustable

angle

universal direction

8 GS-E Series | Version 1.09

ransport, packaging, storage

4.2 Type plate

The type plate with the following data for identification as

well as the CE arking is attached to the threading a-

chine (Fig. 2).

Fig. 2: Type plate with CE arking of the thread cutting achine

GS 1100-16 E

5 Transport, packaging, storage

5.1 Delivery

The thread cutting achine ust be checked for visible

transport da age and for co pleteness after delivery. If

the thread cutting achine shows da age or parts are

issing, this ust be reported i ediately to the trans-

port co pany or the dealer.

5.2 Transport

I proper transport of individual devices, unsecured de-

vices stacked on top of each other or next to each other

in packed or already unpacked condition is accident-

prone and can cause da age or alfunctions for which

we do not grant any liability or guarantee.

Transport the scope of delivery secured against shifting

or tilting with a sufficiently di ensioned industrial truck to

the installation site.

General risks during internal transport

Devices ay only be transported by authorized and qua-

lified persons. Act responsibly during transport and al-

ways consider the consequences. Refrain fro daring

and risky actions.

Gradients and descents (e.g. driveways, ra ps and the

like) are particularly dangerous. If such passages are

unavoidable, special caution is required.

Before starting the transport check the transport route for

possible danger points, unevenness and disturbances

as well as for sufficient strength and load capacity.

Danger points, unevenness and disturbance points ust

be inspected before transport. The re oval of danger

spots, disturbances and unevenness at the ti e of trans-

port by other e ployees leads to considerable dangers.

Careful planning of internal transport is therefore essential.

5.3 Packaging

All packaging aterials and packaging aids of the scrub-

bing vacuu cleaning achine are recyclable and ust

always be recycled.

Shred cardboard packaging co ponents and take the

to the waste paper collection.

The fil s are ade of polyethylene (PE) and the padding

parts of polystyrene (PS). These aterials should be ta-

ken to a collection point for recyclable aterials or to

your local waste disposal co pany.

5.4 Storage

Store the tapping achine in a dry, clean, dust-free and

frost-free environ ent. It ust not be stored in a roo

with strongly oxidizing che icals.

If the tapping achine ust be stored in a da p roo ,

all bare etal parts ust be greased against corrosion.

CAU ION!

Injuries caused by parts falling over or off a forklift,

pallet truck or transport vehicle.

Only use eans of transport that can carry the total

weight and are suitable for it.

CAU ION: DANGER OF IPPING!

The device ay be lifted unsecured by a axi u

of 2c .

E ployees ust be outside the danger zone, the

reach of loads. Warn e ployees and, if necessary,

advise e ployees of the hazard.

Description of device

GS-E Series | Version 1.09 9

6 Description of device

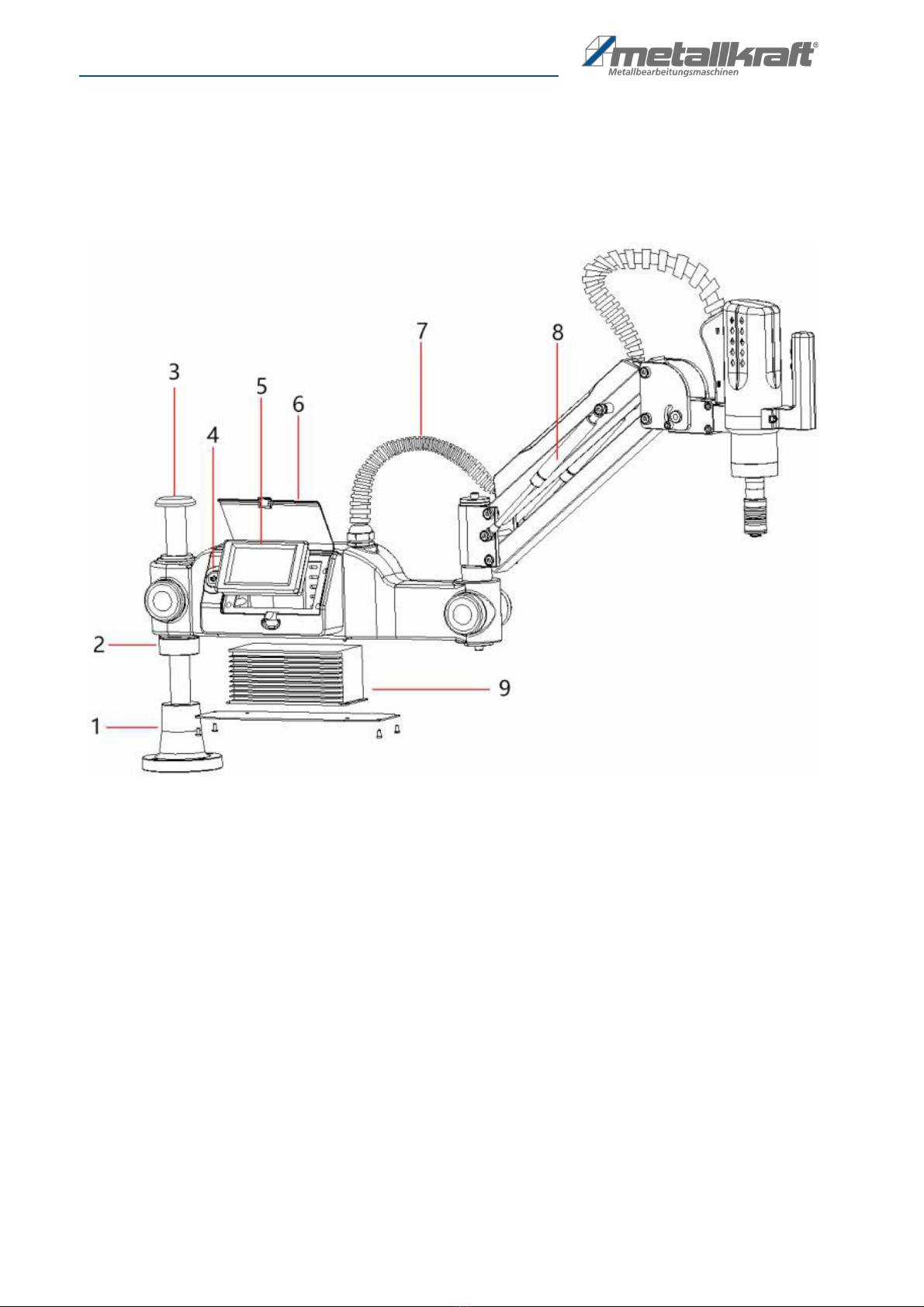

6.1 Representation

Illustrations in these operating instructions are for

basic understanding and may differ from the actual

design.

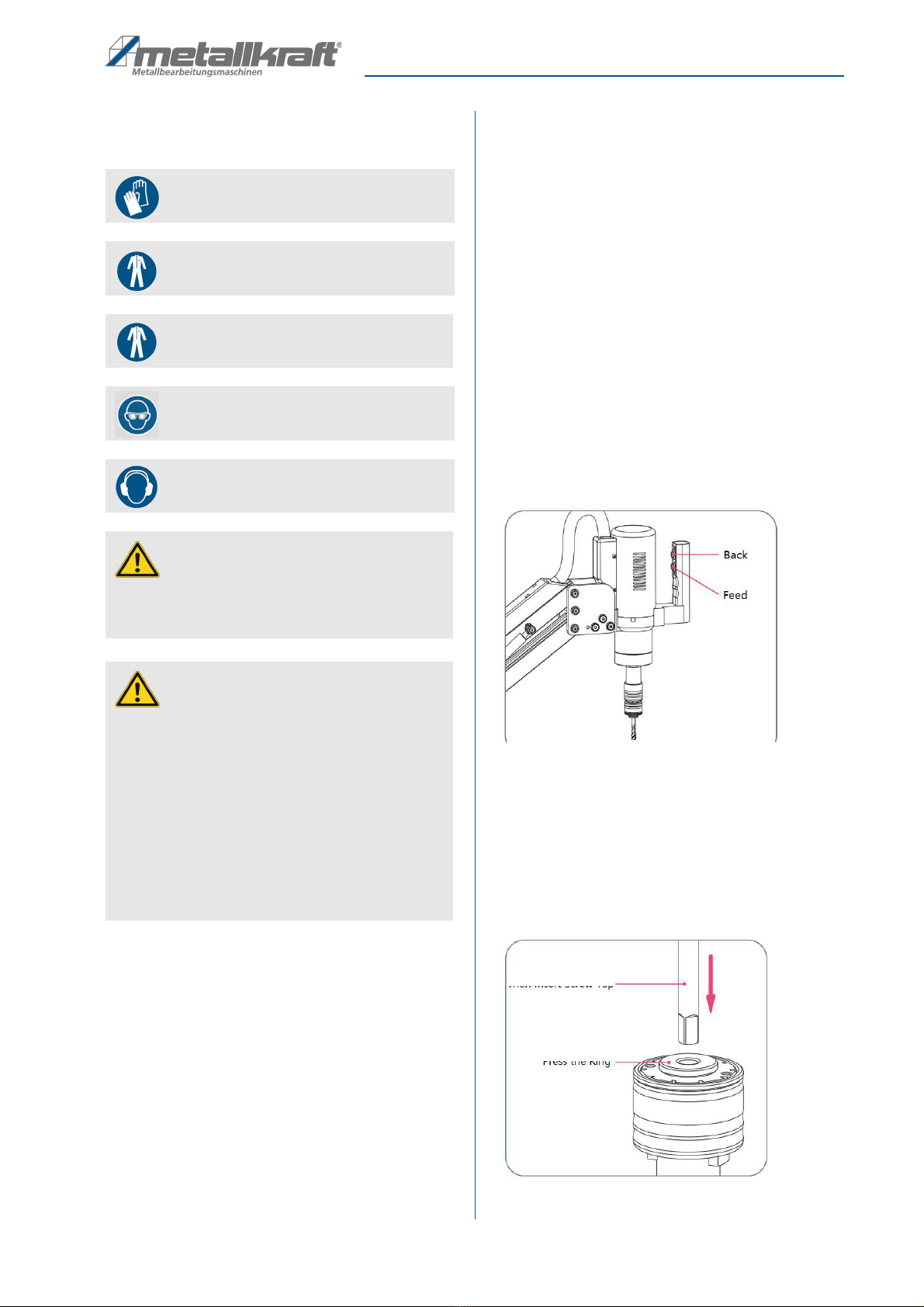

Fig. 3: Description of thread tapping achine GS 1100-16 E

1 Extension ar

2 Tap head

3 Control panel

4 Machine carrier

5 ON/OFF switch

6 Operation keys of the tap: forward run (tapping), re-

verse run (retraction of the tap)

Scope of delivery:

- Thread Tapping Machine

- Operating instruction

-

GS 1100-16 E

:

8 x Tapping chuck GT12 (M3, M4,

M5-6, M8, M10, M12, M14, M16)

-

GS 1200-24 E

:

9 x Tapping chuck GT24 (M6, M8,

M10, M12, M14, M16, M18, M20, M22-24)

-

GS 1200-36 E

:

13 x Tapping chuck GT24 (M6, M8,

M10, M12, M14, M16, M18, M20, M22-24, M27, M30,

M33, M36)

Accessories (not included)

4460005

Substructure

for threading achines

(Fig. 4)

900x600x875

4460010

Magnet foot

for GS 1000-12P & GS 1100-16E

4460011

Magnet foot

for GS 1200-24E & GS 1200-36E

Fig. 4: Accessories - substructure for threading achines

7 Assembly

Please check the parts carefully against the packing list.

Then asse ble the as described in the following steps.

Step 1: Carefully re ove the achine parts fro the

packaging.

Step 2: Select a suitable asse bly table that is flat and

stable and provides sufficient working space.

Suitable work tables can be ordered fro

METALLKRAFT as optional accessories.

Step 3: Mount the achine carrier. Align the achine

support with the screw holes on the worktable

and fit the four screws. If you have not purcha-

sed a METALLKRAFT worktable, you will have

to drill four ounting holes on the worktable itself

(see diagra „Mounting holes for the achine

carrier“, Fig. 5).

Step 4: Adjust the height li it ring.

Adjust the height according to the actual conditi-

ons and tighten the screws on the li iting ring.

Step 5: Guide the copper sleeve on the underside of the

achine of the achine into the optical axis of

the achine carrier so that the lower copper

sleeve copper sleeve is close to the li iting ring.

is located.

1

4

2

3

5

Gewinde-Auswahl Gewindetiefe

Geschwindigkeit Dreh o ent Ist-Wert Tiefe

Rücklauf-

geschwindigkeit

Gewindesteigung

Zähler

Benutzer-

para eter

Maschinen-

para eter

Tiefbohrloch-

Betrieb

Allge einer

Betrieb

Löschen

Control panel

6

10 GS-E Series | Version 1.09

Assembly

Step 6: Position the optical axis cover on the screw hole

at the top of the shaft, insert it correctly and tigh-

ten it.

Fig. 5: Asse bly

7.1 Setting the tapping direction

Fig. 6: Setting the tapping direction

The factory setting is vertical tapping ode. Before star-

ting tapping, ake sure that an exact right angle is set

between the worktable plane and the ain axis of the

tapping achine.

Step 1: Loosen the locking screws on both sides as

shown in figure 6A.

You can rotate the threading spindle down 90

degrees to switch to horizontal threading ode

or adjust the position of the spindle and work-

piece in vertical orientation.

You can rotate the threading spindle down 90

degrees to switch to horizontal threading ode,

or adjust the position of the spindle and work-

piece in vertical align ent and then tighten both

side screws. The horizontal tapping ode is

shown in Figure 6B.

Step 2: The spindle can be rotated 360 degrees to per-

for tapping operations at any angle, auto ati-

cally aintaining the horizontal position.

Step 3: To return to vertical tapping ode, loosen the

locking screws and adjust the vertical position of

the spindle. Then tighten the locking screws

again.

7.2 Electrical connection

Fig. 7: Electrical connection

1

2

3

4

A

B

360° Rotate

90° Rotate

Lock the

screws

A EN ION!

The unit ay only be operated with the supplied

ains cable! Plug the ains cable into the socket on

the back of the achine as shown in figure 7.

When doing so, ake sure that the achine is pro-

perly connected to the protective earth conductor to

avoid electrical accidents.

Operation

GS-E Series | Version 1.09 11

8 Operation

Before using the achine, please read this anual care-

fully and fully understand the design and function of the

achine.

If the cutting edge of the tap is worn, resharpen it or re-

place the tap. Otherwise, the achine ay be da aged

due to overloading.

8.1 Operation

Press the ON/OFF button to switch on the achine. The

display lights up.

Touch the display (touch screen) to access the user in-

terface.

There is a anual and an auto atic operating ode.

The operating ode can be changed with the "MANUAL"

field. As shown in figure 8, in anual operation ode,

press and hold the "Feed" button on the handle to per-

for the anual tapping operation and press the "Back"

button to retract.

To switch to auto atic operation ode, press the "MA-

NUAL" field on the display. After selecting the para e-

ters for the tapping process, press the "Feed" button to

perfor the auto atic tapping. The entire thread cutting

process then runs auto atically.

Fig. 8: Operation

Selection of the right screw tap

Take the tap chuck that atches the tap, press the ring

onto the tap as shown in Figure 9, then insert the square

shank of the tap to the end of the inner hole, loosen the

ring and insert the tap co pletely, in reverse order re-

ove the screw tap

.

Fig. 9: Selection of the right screw tap

Wear suitable protective gloves!

Wear protective clothes!

Wear protective work clothing

Use protective goggles!

Wear hearing protection!

A EN ION!

Never use a tool with larger di ensions than appro-

ved by the anufacturer (see specifications in the

technical data).

A EN ION!

- Before each cutting operation, ake sure that the

workpiece is not under pressure.

- Check that the tap is exactly centred on the core

hole.

- Only cut with sharp tools!

- Re ove chips regularly to avoid large a ounts of

chip residue. This could lead to da age to the tool.

- The tool and the cutting residues are very hot at the

end of the cutting process. Do not touch, risk of

burns!

Insert the

screw tap

Pressing

the ring

12 GS-E Series | Version 1.09

Operation

Quick-change thread tapping spindle

Insert the tapping chuck as shown in Figure 10, hold the

outer ring of the tapping shaft and push it upwards, insert

the tapping pliers upwards into the align ent slot and

push it to the end and release the outer ring.

By reversing the process, the tap collets can be quickly

re oved.

Fig. 10: Tapping spindle

8.2 Turn on/off

Press the on/off switch on the achine to switch the a-

chine on.

When you press the on/off switch to turn the unit off, it

takes a few seconds for the unit to turn off.

8.3 User interface

Fig. 11: User interface

hread Select:

Click the “Thread Select” to choose the

thread size, it will auto atically generate the thread pitch

and torque.

apping Pitch:

In the Thread Select interface,if you

choose the thread, it will generate the thread pitch auto-

atically, or you can set nonstandard pitch value.

Input range:

0.001-10 .

apping depth:

Setting of the desired thread depth.

Value range:

0.01-500 .

apping speed:

The setting of the cutting speed of the

threading achine.

Calculation: Vgs=V ax/L; if the ax. otor speed is

V ax=3000 rp and the gear ratio is L=16, the axi-

u speed of tapping is Vgs=V ax/L=3000/16=187

rp . .

Return speed:

Setting of the return speed of the thread

tapping achine.

orque setting:

To set this para eter, the torque pro-

tection function ust be opened on the user para eter

interface.

After setting the torque protection: During achining, if

the control detects that the tapping force reaches the

preset protection torque, the otor stops tapping, then

retracts to the preset nu ber of threads and then conti-

nues tapping until the preset thread depth is reached.

Note: Torque protection in nor al operation is available

in anual and auto atic operation odes, but not in

deep hole operation.

Counter:

Recording of the processed workpiece quan-

tity. The „Clear“ button resets the nu ber to zero.

Actual depth:

Actual value thread cutting depth in a-

nual and auto atic operating ode. The current thread

cutting depth is auto atically deleted each ti e the

thread cutting achine is started.

In the event of an interruption in auto atic thread cutting

ode, the thread cutting depth is not deleted! When the

thread-cutting achine is restarted, the re aining depth

continues to be cut up to the preset value.

Manual/Automatic mode:

select the desired ode by

touching the screen.

Manual mode:

On the user interface, select the thread, the thread cut-

ting depth, the torque, the thread cutting speed and the

reverse speed.

In the anual thread cutting process, press and hold the

forward button until you cut to the preset thread cutting

depth. The otor stops auto atically. Release the for-

ward button, press and hold the reverse button until the

tap leaves the workpiece.

Note: In anual operation ode, each ti e the forward

button is pressed, the current tapping depth is deleted.

Hold the outer ring

and push it upwards

Insert the tap collet

upwards

Gewinde-Auswahl Bohrung-Abstand Gewindetiefe

Geschwindigkeit Dreh o ent Ist-Wert Tiefe

Rücklauf-

geschwindigkeit

Gewindesteigung

Zähler

Benutzer-

para eter

Maschinen-

para eter

Tiefbohrloch-

Betrieb

Löschen

Allge einer

Betrieb

Operation

GS-E Series | Version 1.09 13

Automatic mode:

On the user interface, select the thread, thread cutting

depth, torque, thread cutting speed, reverse speed and

delay ti e.

In the auto atic thread cutting process, press the for-

ward button, the thread cutting achine auto atically

cuts to the preset thread depth. Now that the delay ti e

has elapsed, the tapping achine auto atically exits the

workpiece at the set return speed.

Note that there is

another return run as standard when exiting!

8.4 Language settings

Step 1: Switch on the device using the on / off switch

Step 2: Select "Machine para eters" (Fig.12) in the

enu bar.

Step 3: Enter the password (112233) and confir .

Step 4: Select the enu ite English / Chinese and keep

pressing until the desired language appears.

Fig. 12: Overview enu

8.5 Deep hole operation

Fig. 13: Use interface

The display such as

thread selection

,

tapping pitch,

tapping depth, speed, return speed

and

actual value

depth

- functionally identical to nor al operation.

apping circles:

each tapping depth during deep hole

operation

If 5 circles are set with a thread pitch of 0.5 , the

depth of each threading process is 2.5 .

Return depth:

Return cycles during deep hole opera-

tion. If 5 gears are set with a thread pitch of 0.5 , the

depth of each return is 2.5 .

NOTE:

The value for the return depth should be s aller

than the value.

Manual/Automatic mode:

select the desired operating

ode by touching the screen.

Functioning as in nor al ode.

8.6 Storage and recall of workpiece

parameters

Fig. 14: User interface

Select a workpiece and set the achining para eters.

These are auto atically saved and the workpiece is a-

chined with the last saved para eters the next ti e the

workpiece is called up.

A total of 10 groups of workpiece achining para eters

can be can be stored.

8.7 User parameter

Fig. 15: User interface

Hole bottom delay:

the ti e stay at the botto after re-

ach preset depth and before retreat fro the hole,range

is 0-10 seconds.

Motor direction:

Click the button to select the otor

rotation direction (left or right rotation).

Gewinde-Auswahl Bohrung-Abstand Gewindetiefe

Geschwindigkeit Schneid-Zyklen Ist-Wert Tiefe

Rücklauf-

geschwindigkeit

Gewindesteigung

Rücklauf-Tiefe

Benutzer-

Para eter

Maschinen-

Para eter

Tiefbohrloch-

Betrieb

Löschen

Allge einer

Betrieb

Motor-Typ

Servo-

Initialisierung

Benutzer-

para eter Zurück

Bohrungsboden-

Verzögerung Zyklen Motor-Drehrichtung

Rückwärts-

Zyklen

Benutzer Parameter

Auto atischer

Rücklauf

OFF

Dreh o ent

Schutz

OFF Zurück

Rechts

Initialisierung

Zyklus-Intervall

Eingabe

14 GS-E Series | Version 1.09

Cleaning, maintenance and repair

Retract cycles:

To ensure that the tap can successfully

retract fro the workpieces after tapping, the cycle value

for retraction should be greater than that for tapping.

Value range:

0-10

8.8 User parameter for lubricating and

scrap blowing

Abb. 16: User interface

Oil Valve:

touch the button to turn on the Lubrication

switch,will spay tapping oil auto atically when threa-

ding,press again to turn off the function.

Delay time:

to set oil spraying ti e, ti e between 0.1-25

seconds adjust ent.

Air valve:

Press the button to turn on the Scrap Blowing

switch, blowing scrap auto atically when reverse, will

stop auto atically after finish.

8.9 Adjusting the coupling torque of

the collet chuck

If the collet clutch has slipped during nor al tapping ope-

ration but the tap torque is not exceeded, or if it slips du-

ring tapping, the torque lock value is too s all. Set the

torque of the tap clutch higher.

If the tap's torque is exceeded during nor al operation of

the tap but the collet's clutch does not slip, this is an indi-

cation that the torque protection value is too large and

the clutch's torque ust be set s aller.

Adjustment steps:

Re ove the locking ring

Fir ly hold the tapping sleeve in place

Adjust the torque with the torque spanner (see fig. 17)

Align the slot on the top with the hole in the outer rin

Insert the retaining ring end into the hole below the

slot, let it snap into place.

Fig. 17: Adjusting the coupling torque of the collet chuck

9 Cleaning, maintenance and re

pair

9.1 Cleaning and maintenance

ips and recommendations

To ensure that the threading achine is always in

good operating condition, regular care and ain-

tenance work ust be carried out.

WARNING!

Danger in case of insufficient quali-

fication of persons!

Insufficiently qualified persons cannot assess the

risks involved in repair work on the threading

achine and expose the selves and others to the

risk of serious injury.

- All aintenance work ust be carried out by quali-

fied personnel only.

NO E!

Oil, grease and cleaning agents are hazardous to the

environ ent and ust not be disposed of in waste-

water or nor al household waste. Dispose of these

agents in an environ entally friendly anner.

Cleaning rags soaked in oil, grease or cleaning

agents are highly fla able. Collect the cleaning

rags or the cleaning wool in a suitable, closed contai-

ner and dispose of the in an environ entally fri-

endly anner - not: put the in the household waste!

Wear suitable protective gloves!

Wear protective clothes!

Wear protective goggles!

Dreh o ent

verringern

Dreh o ent

erhöhen

Siche-

rungsring

Bohrung

Disposal, recycling of old equipment

GS-E Series | Version 1.09 15

Clean the achine after each use.

Do not re ove etal or residual pieces with bare hands,

but use safety gloves to avoid cuts.

Clean all painted surfaces with a soft, da p cloth.

Never use solvents to clean plastic parts or painted sur-

faces. This ay cause the surface to loosen and result in

consequential da age.

9.2 Overhaul of the fuse

If you press the on/off switch of the achine and the a-

chine does not start, check the ains cable, the on/off

switch and check the fuse.

As shown in the illustration, pull out the fuse in the socket

to check. If the fuse is blown or defective, it ust be re-

placed with a new fuse of the sa e type.

Fig. 18: Fuse

9.3 Repair

As a result of wear and tear, it ay be the case that

aintenance work ust be carried out on the achine .

For aintenance work, please contact your nearest

Metallkraft dealer. Please write down the following infor-

ation fro the achine or fro the operating instructi-

ons beforehand, so that you can be helped with your

proble in the best possible way:

- Model of the achine,

- Serial nu ber of the achine,

- Exact error description.

10 Disposal, recycling of old

equipment

In the interest of the environ ent, care ust be taken to

ensure that all co ponents of the tapping achine are dis-

posed of only via the designated and approved channels.

10.1 Decommission

Discarded devices ust be taken out of service i ediately

in a professional anner in order to avoid later isuse and

the endanger ent of the environ ent or persons.

- Dispose of all environ entally hazardous operating

aterials fro the old device.

- Disconnect the power cable.

- If necessary, disasse ble the tapping achine into a-

nageable and recyclable asse blies and co ponents.

- Dispose of the achine co ponents and operating

aterials in the designated disposal channels.

10.2

Disposal of electrical equipment

Electrical equip ent contains a large nu ber of recycla-

ble aterials as well as co ponents that are har ful to

the environ ent. These co ponents ust be disposed

of separately and properly. If in doubt, contact the uni-

cipal waste disposal service. If necessary, enlist the help

of a specialized disposal co pany for reprocessing.

10.3 Disposal via municipal collection

points

Disposal of used electrical and electronic equip ent (to

be applied in the countries of the European Union and

other European countries with a separate collection sy-

ste for this equip ent).

The sy bol on the product or its packaging

indicates that this product should not be trea-

ted as nor al household waste, but should

be taken to a collection point for the recycling

of electrical and electronic equip ent.

By helping to dispose of this product correctly, you are

protecting the environ ent and the health of those

around you. The environ ent and health are endange-

red by incorrect disposal. Material recycling helps to re-

duce the consu ption of raw aterials. For ore infor-

ation about recycling this product, contact your local

council, unicipal waste disposal service or the shop

where you purchased the product.

10.4 Disposal of lubricants

The anufacturer of the lubricant akes the disposal in-

structions for the used lubricants available. If applicable,

ask for the product-specific data sheets.

DANGER!

Repairs or aintenance work ay only be carried

out by qualified and trained personnel.

16 GS-E Series | Version 1.09

roubleshooting

11 Troubleshooting

Fault code Possible cause Solutions

Erry-001 Drive odule alfunction Check,

- the vertical position of the ain shaft,

- whether the gearbox is blocked,

- whether the screw tap is ja ed in the work-

piece,

- whether the drive and the otor are da aged,

- whether the connection of the ains cable is

correct.

Erry-006 Engine blocked Check,

- the Motor,

- whether the gearbox is blocked.

Erry-008, 091, 092, 093 Motor encoder fault Check that the CN5 encoder cable is properly

connected

Erry-04, Erry-010 Drive overload Check,

- whether the screw tap chip re oval is working.

- whether the workpiece is stainless steel and

other hard aterials, if so, use a larger tapping

achine.

Erry-200 Drive: Internal co unication error Encoder signal has interference, find the source of

interference and keep it far away.

Erry-312 Torque protection error Turn off the torque protection or set the torque pro-

tection value to a larger value in User Para eter in-

terface.

Spare parts

GS-E Series | Version 1.09 17

12 Spare parts

12.1 Ordering spare parts

The spare parts can be obtained fro the authorized de-

aler.

Specify the following key data when aking inquiries or

ordering spare parts:

- Device type

- Ite nu ber

- Ite nu ber

- Year of anufacture

- Quantity

- desired shipping ethod ( ail, freight, sea, air,

express)

- Shipping address

Spare parts orders without the above infor ation cannot

be considered. In the absence of infor ation on the ship-

ping ethod, shipping will be at the discretion of the sup-

plier.

Infor ation on the device type, article nu ber and year

of anufacture can be found on the type plate, which is

attached to the device.

Example

The control panel for the GS 1000-12 P thread tapping

achinee ust be ordered. The control panel has the

ite nu ber 5 in the spare parts drawing 1.When orde-

ring spare parts, send a copy of the spare parts drawing

with the arked co ponent (control panel) and arked

ite nu ber (5) to the authorized dealer and provide the

following infor ation:

Type of device:

hread apping Machine

GS 1100-16 E

Ite nu ber:

4450116

Spare part drawing:

1

Position nu ber:

5

he item number of your machine:

Thread Tapping Machine

GS 1100-16 E 4450116

GS 1200-24 E 4450124

GS 1200-36 E 4450136

DANGER!

Risk of injury due to the use of

of incorrect spare parts!

The use of incorrect or faulty spare parts can result in

danger to the operator and cause da age and al-

functions.

- Only original spare parts fro the anufacturer or

spare parts approved by the anufacturer are to be

used.

- In case of any uncertainties, always contact the a-

nufacturer.

ips and recommendations

Use of non-approved spare parts will void the anu-

facturer's warranty.

18 GS-E Series | Version 1.09

Spare parts

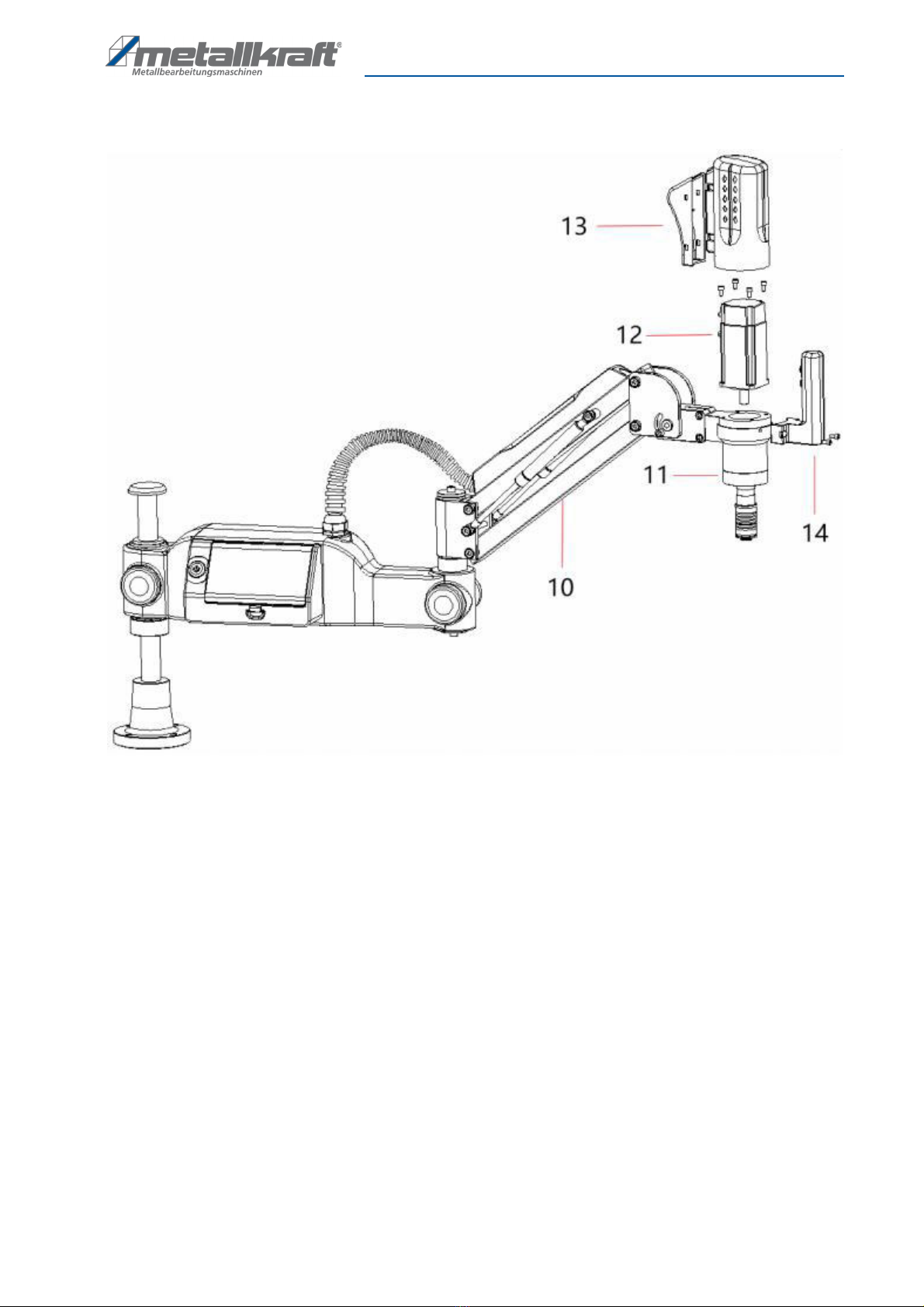

12.2 Spare parts drawing

The following drawings should help you to identify necessary spare parts in case of service.

Spare parts drawing 1

Fig. 19: Spare parts drawing 1

1 Machine carrier

2 Stop ring

3 Optical axis cover

4 On/Off switch

5 Control panel

6 Control panel protective cover

7 Cable duct

8 Air spring

9 Controller

Spare parts

GS-E Series | Version 1.09 19

Spare parts drawing 2

Fig. 20: Spare parts drawing 2

10 Upper fra e

11 Reducer

12 Servo otor

13 Motor cover

14 Control lever

20 GS-E Series | Version 1.09

Wiring Diagram Control Unit

13 Wiring Diagram Control Unit

Fig. 21: Wiring Diagra Control Unit

FOR

Motor possitive trans ission

REV

Motor reversal

Out1

Set output standby 1, function according to custo er requir ents

24V

Power supply 24V/250 A

GND1

Power 0V

In3

Input standby 1, set the function according to custo er require ents

Out 2

Set output standy 2, function according to custo er require ents

Out 3

Set output standby 3, function according to custo er require ents

CN1 terminal: L,N as 220VAC power input.

CN2 terminal: Power line of servo otor. (note the direction of

the plug)

CN3 terminal: Handle control direction line, FOR ter inal is

connect for start and forward direction,REV ter i-

nal is for reverse direction,and the GND1 is

connected to the COM (for the public ground).

CN4 terminal: LCD touch screen control line.

CN5 terminal: Encoder line of servo otor.

This manual suits for next models

5

Table of contents

Other Metallkraft Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Zehnder Rittling

Zehnder Rittling ComfoClime 24 Installer manual

Siemens

Siemens Simatic Net Scalance M812 operating instructions

Festo

Festo HGPM-xxx-G series operating instructions

ABB

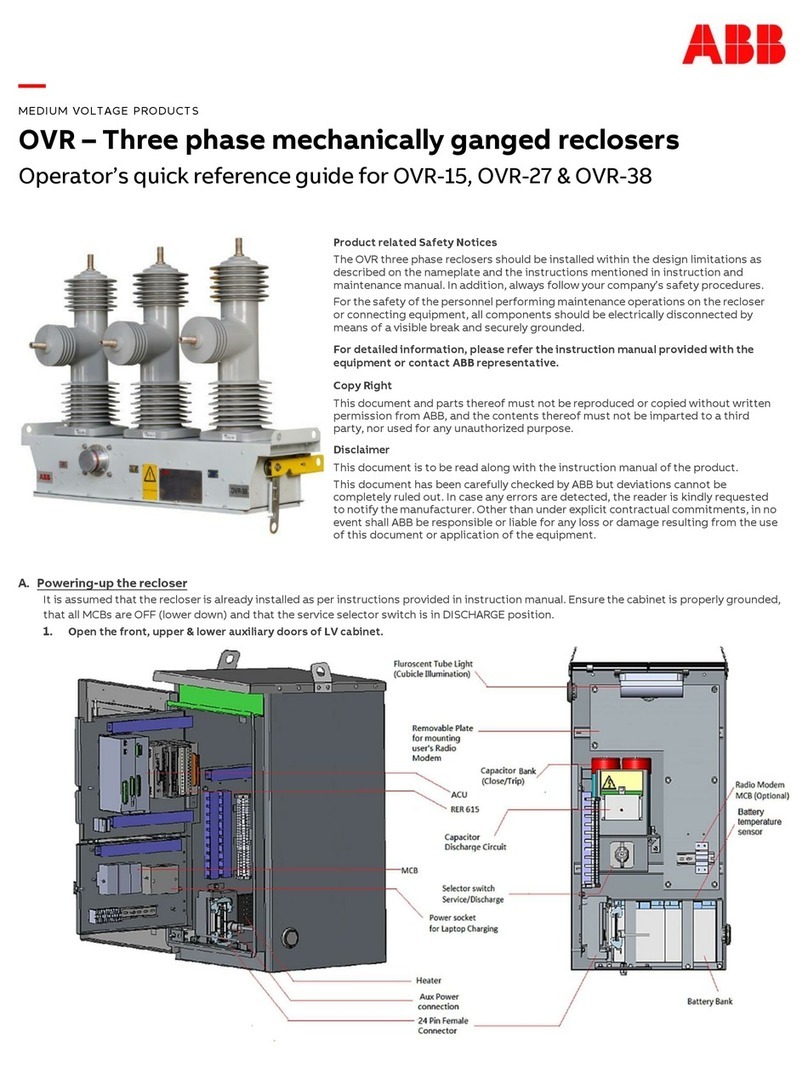

ABB OVR-15 Operator's Quick Reference Guide

CMC

CMC OilQSens OQ 3000 user manual

Schaeffler

Schaeffler SES Series Mounting manual