Metallkraft AKM Series User manual

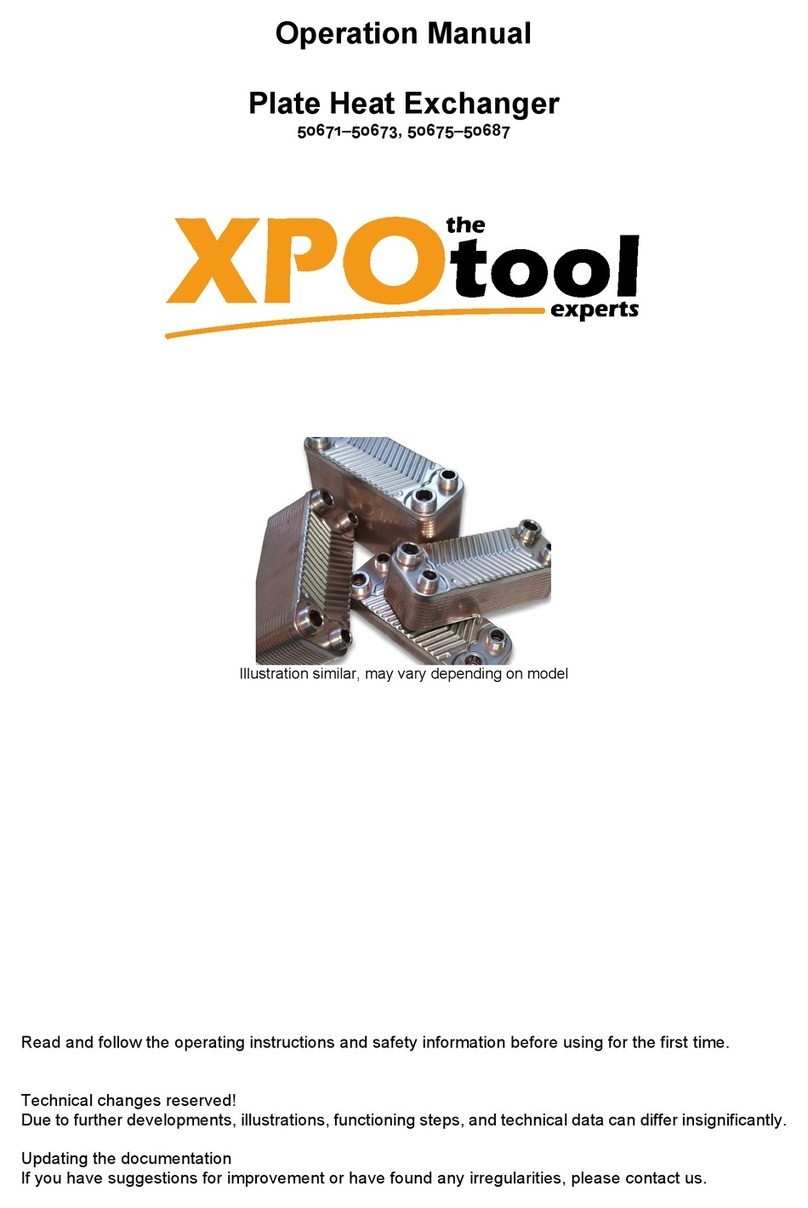

AKM 220-4 H

Operating Instructions

AKM 220-4 H

AKM-SERIES

Hydraulic Notching Machine

AKM 220-6 H

AKM 220-6 H

2AKM-Series 220 | Version 1.07

Imprint

Product identification

Hydraulic Notching Machine Item number

AKM 220-4 H 3834200

AKM 220-6 H 3836200

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Indications regarding the operating instructions

Original instructions

Publication: 29.04.2019

Version: 1.07

Language: English

Author: SN

Indications regarding the copyright

Copyright © 2019 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions is the sole

property of the company Stürmer Maschinen GmbH.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not expli-

citly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Content

1 Introduction .............................................................3

1.1 Copyright............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability ............................................ 3

2 Safety........................................................................3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company............... 4

2.3 Requirements to staff.......................................... 4

2.4 Personal protective equipment........................... 5

2.5 General safety regulations.................................. 5

2.6 Safety labels on the machine ............................. 6

2.7 Safety devices .................................................... 6

3 Intended Use............................................................7

3.1 Improper use ...................................................... 7

3.2 Residual risks ..................................................... 7

4 Technical Data.........................................................8

4.1 Table................................................................... 8

4.2 Type plates......................................................... 8

5 Transport, packaging, storage...............................9

5.1 Delivery and transport ........................................ 9

5.2 Packaging......................................................... 10

5.3 Storage ............................................................. 10

6 Description of device............................................10

6.1 Representation ................................................. 10

6.2 Scope of delivery.............................................. 10

6.3 Accessories...................................................... 10

7 Setting up...............................................................11

7.1 Place of installation........................................... 11

7.2 Electrical connection ........................................ 12

8 Settings ..................................................................14

8.1 Setting the cutting gap tolerance ..................... 14

8.2 Changing the knife ........................................... 15

8.3 Cutter bar - Stroke limit..................................... 17

8.4 Setting the limit stops ....................................... 17

9 Operation ..............................................................19

9.1 Control panel .................................................... 20

9.2 Functional description: ..................................... 20

9.3 Initial commissioning ........................................ 20

9.4 Workflow ........................................................... 21

9.5 Shut down the machine .................................... 21

10 Maintenance and repair ......................................21

10.1 Cleaning and lubricating the machine ........... 22

10.2 Maintenance of the machine .......................... 22

10.2.1 Hydraulic system..................................... 22

10.2.2 Lubrication diagram ................................ 23

10.2.3 Maintenance and inspection intervals .... 24

11 Disposal, recycling of used device....................24

11.1 Decommissioning........................................... 24

11.2 Waste disposal of electric equipment ............ 24

11.3 Disposal of lubricants..................................... 24

12 Disturbances, possible causes and measures.25

13 Sparte parts .........................................................26

13.1 Ordering spare parts ...................................... 26

13.2 Spare parts drawings ..................................... 27

14 Wiring diagrams ..................................................29

14.1 Electrical circuit diagrams............................. 29

14.2 Hydraulic circuit diagram .............................. 30

15 EC Declaration of Conformity ............................31

Introduction

AKM-Series 220 | Version 1.07 3

1Introduction

You have made a good choice by purchasing the notch-

ing machine made by METALLKRAFT.

Thoroughly read the operating instructions before commission-

ing the machine.

It informs you about the proper commissioning, the in-

tended use as well as the safe and efficient operation

and maintenance of your notching machine.

The operating instructions are part the notching ma-

chine. Always keep it at the place of use the notching

machine. Furthermore, the local accident prevention

regulations and the general safety notes are applicable

for the field of application the notching machine.

The illustrations in these operating instructions serve the

general comprehension and may deviate from the ac-

tual type.

1.1 Copyright

The contents of these instructions are copyright. Their

application is admissible in the frame the notching ma-

chine utilisation. An application beyond the described

application is not allowed without written approval of the

manufacturer. For the protection of our products, we

shall register trademark, patent and design rights, as

this is possible in individual cases. We strongly oppose

any infringement of our intellectual property.

1.2 Customer service

Please contact your dealer if you have questions con-

cerning your notching machine or if you need technical

advice. They will help you with specialist information

and expert advice.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service :

Fax: 0049 (0) 951 96555-111

E-Mail: service@stuermer-maschinen.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

We are always interested in valuable experience and

knowledge gained from using the application-which

then could be shared and be valuable to develop our

products even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised taking the applicable standards and

rules, the state-of-the-art and our long-term knowledge

and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use,

- Use of untrained staff,

- Unauthorised modifications,

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-

tions of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This paragraph will give you an overview of all important

safety packages for the protection of persons as well as

for the safe and undisturbed operation. Other task-

based safety notes are included in the individual chap-

ters.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are

highlighted by symbols. The safety notes are introduced

by signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injuries if they are not

avoided.

WARNING!

This combination of symbols and signal words indi-

cates a possibly dangerous situation which may

lead to death or severe injuries if they are not avoi-

ded.

4AKM-Series 220 | Version 1.07

Safety

Tips and recommendation

It is necessary to observe the safety notes written in

these operating instructions in order to reduce the risk of

personal injuries and damages to property.

2.2 Obligations of the operating company

The operating company is the person who operates the

the notching machine for business or commercial rea-

sons by herself, or leaves it to a third party for use or ap-

plication, and who bears the legal product responsibility

for the protection of the user, the staff or for third parties.

Obligations of the operating company

If the the notching machine is used for commercial pur-

poses, the operating company of the notching machine

must comply with the legal working safety regulations.

Therefore, the safety notes in this operating manual, as

well as the safety, accident prevention and environment

protection regulations applying for the area of applica-

tion of the notching machine must be met. The following

applies in particular:

- The operating company must be informed about the

applying industrial safety regulations and further ana-

lyse hazards resulting from the special working condi-

tions at the place of use of

the notching machine

. She

must implement these in form of operating manuals for

the operation of

the notching machine

.

- During the entire lifetime the notching machine, the

operating company must verify whether the operating

manuals prepared by her correspond to the current

status of the regulations, and must adapt these if

necessary.

- The operating company must unambiguously regu-late

and determine the responsibilities for installa-tion, oper-

ation, troubleshooting, maintenance and cleaning.

- The operating company must ensure that all per-sons

who work with the notching machine, have read and

understood this manual. Furthermore she must in-

struct the staff in regular intervals and in-form them

about the hazards.

- The operator must provide the necessary protec-tive

equipment to the staff and order the use of the neces-

sary protective equipment in a binding way.

Furthermore the operating company is responsible to

keep the notching machine always in a technically flaw-

less state. Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices

checked regularly for their good working order

and their integrity.

2.3 Requirements to staff

Qualifications

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

CAUTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may

lead to minor or light injuries if they are not avoided

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may

lead to property and environmental damages if they

are not avoided.

NOTE!

This combination of symbol and signal words indica-

tes a possibly dangerous situation which may lead to

property and environmental damages if they are not

avoided.

Tips and recommendation

This symbol highlights useful tips and recommenda-

tion as well as information for all efficient and

trouble-free operation.

WARNING!

Danger in case of insufficient qualification

of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the notching machine and expose

themselves and others to the danger of severe or

lethal injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the

working area.

Safety

AKM-Series 220 | Version 1.07 5

Operator

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-

formed beyond the operation in the standard mode

must only be performed by the operator if it is indicated

in these instructions and if the operating company ex-

pressively commissioned the operator.

Electrically qualified person

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a po-

sition to carry out work on the electrical systems and to

in-dependently recognize and avoid possible dangers.

Qualified personnel

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect

persons against impairments of safety and health while

working. The staff has to wear personal protective

equipment while performing different works on and with

the notching machine which are indicated in the individ-

ual paragraphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

2.5 General safety regulations

Please observe the following points:

- Use the guards and secure them securely. Never

work without guards and keep them functional.

- Always keep the machine and its working environ-

ment clean. Provide adequate lighting.

- Always secure your workpiece when working with

suitable clamping devices. Ensure a sufficient con-

tact surface.

- Check that the fixed hand guards are correctly instal-

led.

- The design of the notching machine must not be

changed and it must not be used for purposes other

than those foreseen by the manufacturer.

- Never work under the influence of illnesses that im-

pair concentration, drugs, alcohol or medication.

- Keep children and persons unfamiliar with the notch-

ing machine away from their work environment.

- Do not pull the power cord to unplug the plug from

the outlet. Protect the cable from heat, oil and sharp

edges.

- Immediately eliminate malfunctions that reduce

safety.

- Protect the notching machine against humidity (short-

circuit hazard!)

- Before each use of the notching machine, make sure

that no parts are damaged. Damaged parts must be

replaced immediately to avoid sources of danger.

- Before starting the machine, make sure that there are

no dangerous environmental conditions for the ope-

rator which could pose a danger during operation.

- Make sure that there are no tools or objects inside or

on the machine before starting the machine.

- Do not overload the notching machine! You will work

better and safer in the specified performance range.

- Only use original spare parts and accessories in or-

der to avoid possible dangers and accident risks.

Protective goggles

The goggles protect the eyes from flying parts and

liquid splashes

Hearing protection

The hearing protection protect the ears from hea-

ring damage caused by noise..

Breathing protection

Breathing protection serve to protect the respiratory

tract and lungs from the absorption of dust particles.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fal-

ling parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

6AKM-Series 220 | Version 1.07

Safety

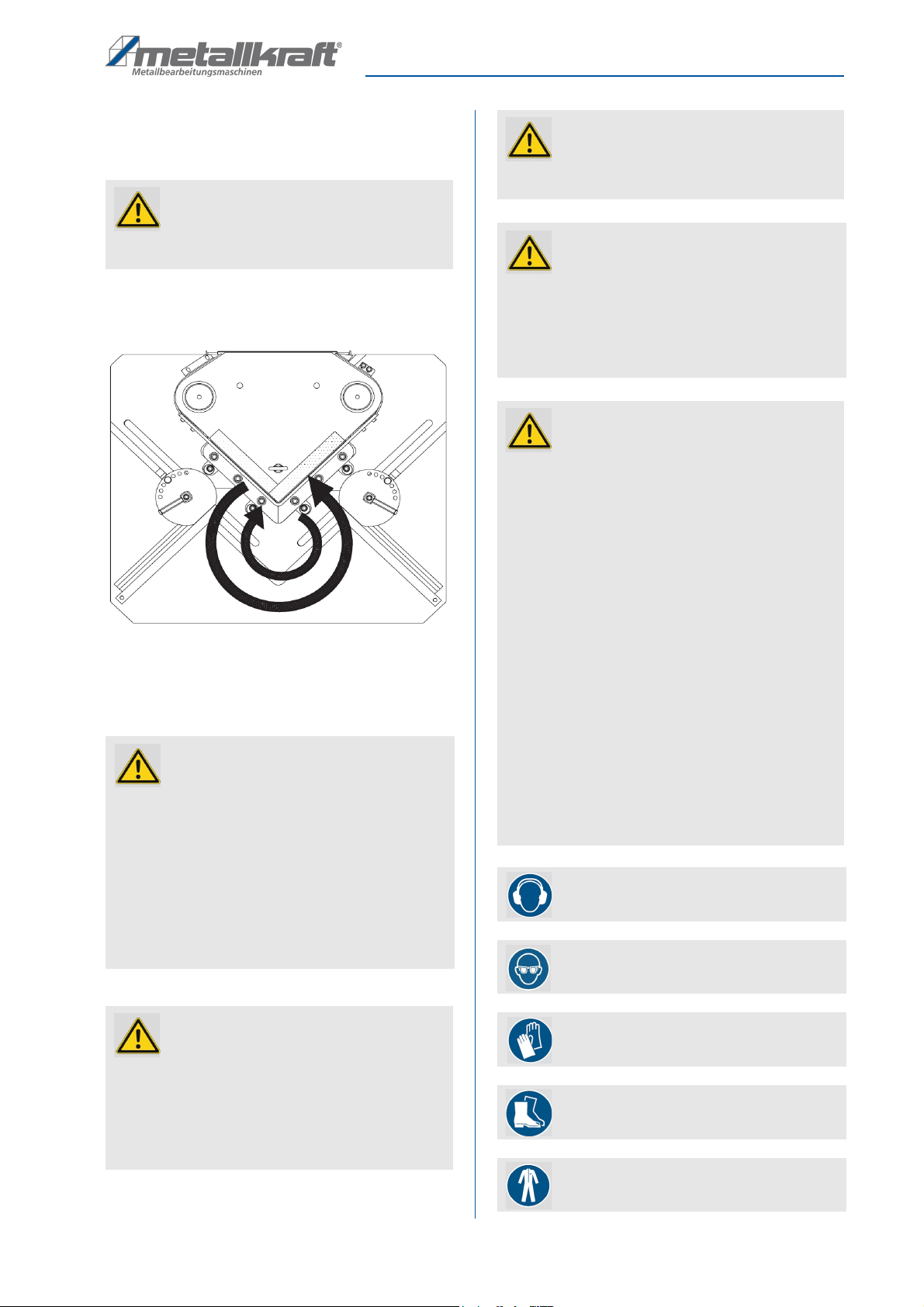

2.6 Safety labels on the machine

Safety labels and instructions are attached to the not-

ching machine (Fig. 1) which must be observed and

followed.

Damaged or missing safety symbols on the machine

can lead to incorrect actions with personal injury and

damage to property. The safety symbols attached to the

machine must not be removed. Damaged safety sym-

bols must be replaced immediately.

The machine must be taken out of operation until the

new labels are attached as soon as the labels are not

immediately recognisable and comprehensible at first

sight.

Fig. 1: Safety labels

2.7 Safety devices

WARNING!

Danger to life due to non-functioning safety

devices!

If the safety devices are not functioning or have

been rendered inoperative, there is a risk of serious

injury or even death.

- Before starting work, check that all safety devices

are functional and correctly installed.

- Never bypass or disable the safety devices.

- Ensure that all safety devices are always acces-

sible.

Intended Use

AKM-Series 220 | Version 1.07 7

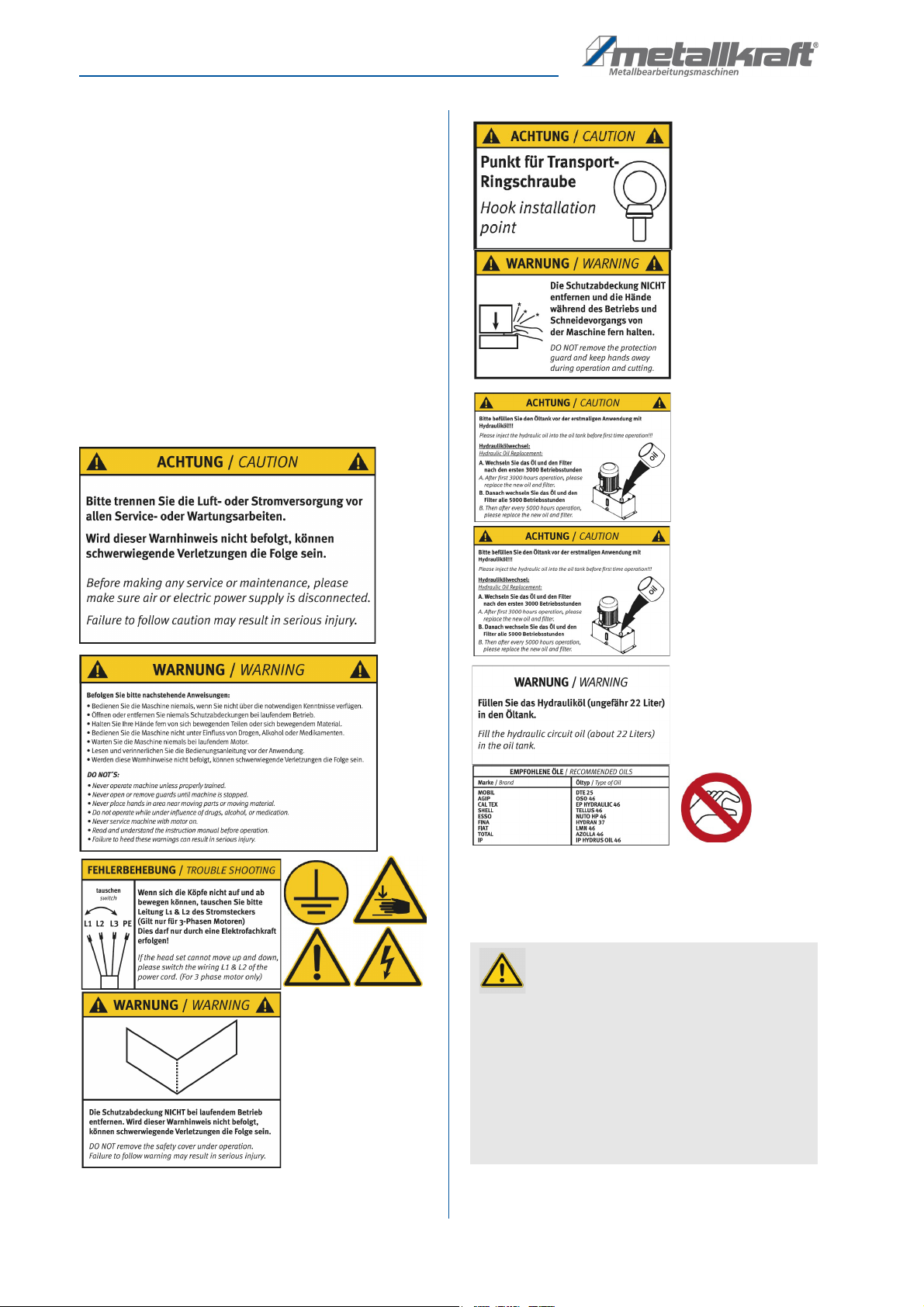

Emergency stop button

Press the emergency stop button (Fig. 2) located on the

control panel and the notching machine will stop imme-

diately. The power supply is switched off or the drives

are disconnected mechanically. After the emergency

stop button has been pressed, it must be unlocked by

turning it so that it can be switched on again.

Fig. 2: Emergency stop button

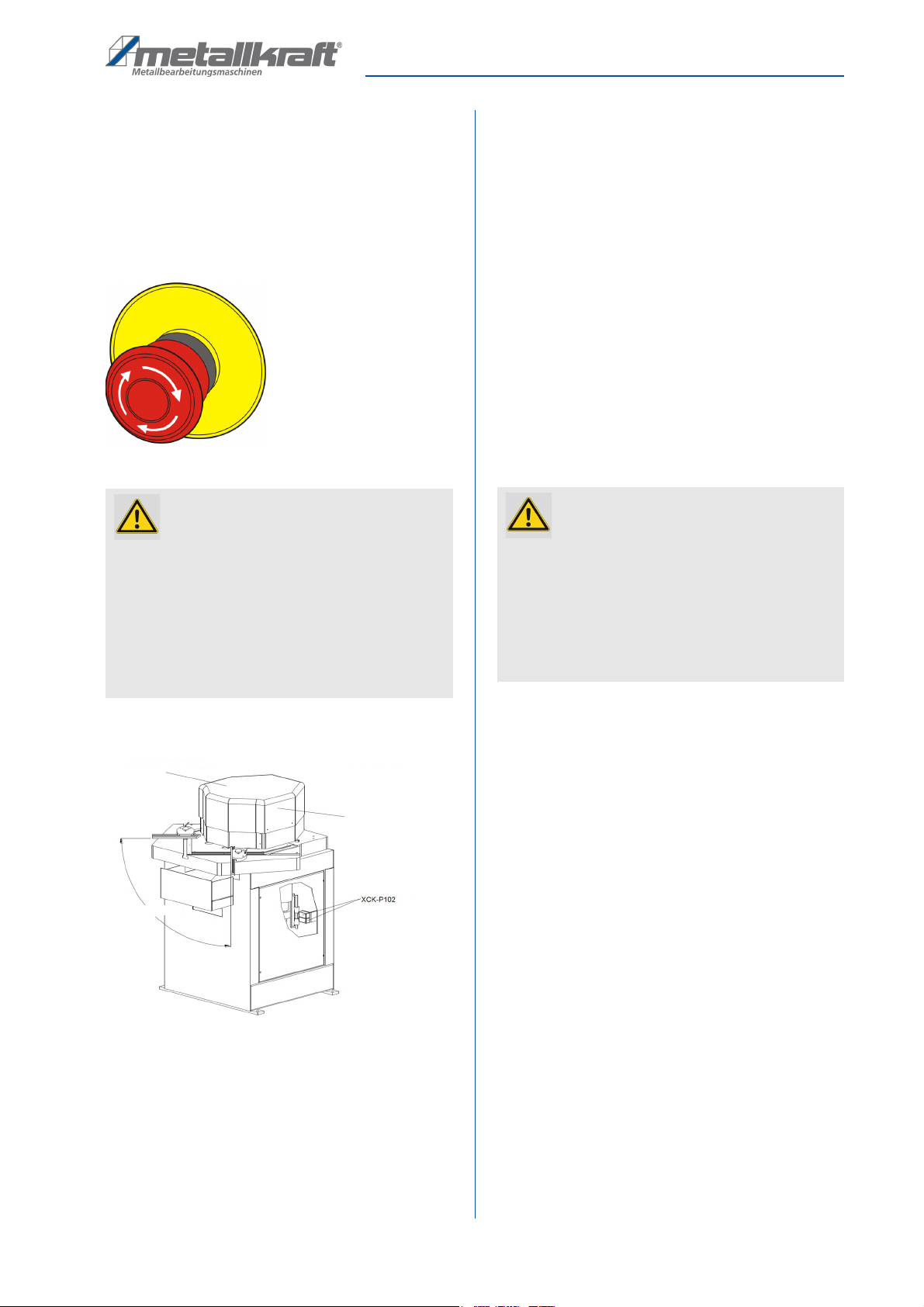

Safety covers and switch

Fig. 3: Safety devices

3 Intended Use

The notching machine is designed exclusively for not-

ching steel or stainless steel sheets. Notching is done

with a fixed angle (90°). The machine is intended and

suitable for commercial use. The machine must not be

used in explosive environments.

The proper use also includes observing all indications in

these operating instructions. Any use beyond the proper

use or any other use is regarded as misuse.

For structural and technical changes to the notching

machine the company Stürmer Maschinen GmbH assu-

mes no liability Claims of any kind due to damage due to

improper use are excluded.

3.1 Improper use

The notching machine must not be used for notching

materials made of light metals (e.g. aluminium or

similar).

3.2 Residual risks

Even if all safety instructions are observed, and the ma-

chine is put to its intended use, there are still residual

risks, which are listed below:

- Risk of injury of upper limbs while equipment is ope-

rating.

- Danger from the falling workpieces.

WARNING!

Risk of uncontrolled restart!

The uncontrolled restart of the machine can lead to

serious injuries.

- Before restarting, ensure that the cause of the

emergency stop has been eliminated and that all

safety devices have been fitted and are fully func-

tional.

- Only unlock the emergency stop button when there

is no longer any danger.

When servicing the

machine, remove the

safety cover. Do not

forget that the upper

body is movable.

Protect your bodies

against injuries.

Safety

cover

Safety switch

Work area

WARNING!

Danger in case of misuse!

Misuse of the notching machine can lead to dange-

rous situations.

- Only operate the notching machine in the power

rangelisted in the technical data.

- Never bypass or override the safety devices.

- Only operate the notching machine in a technically

perfect condition.

8AKM-Series 220 | Version 1.07

Technical Data

4 Technical Data

4.1 Table

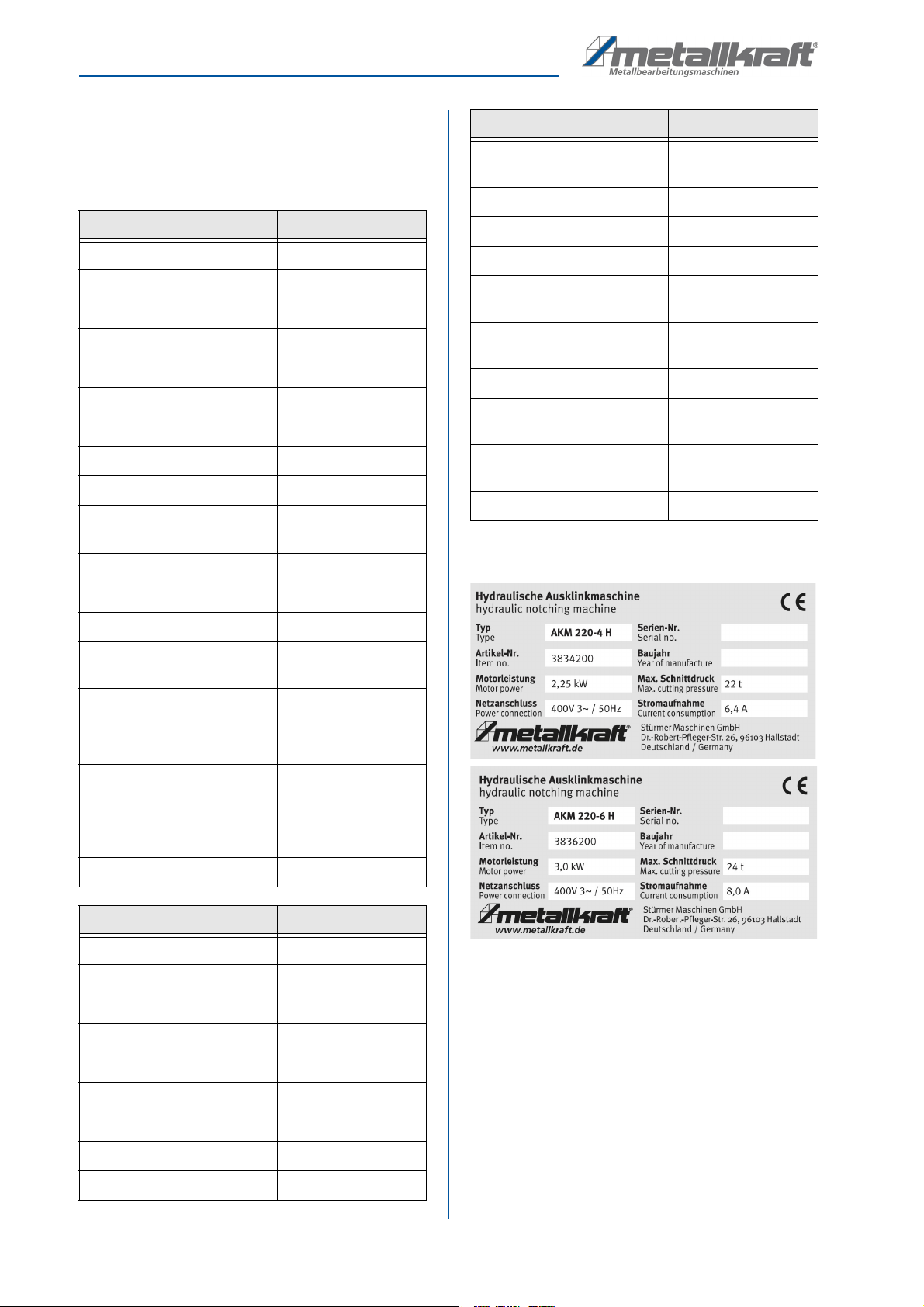

4.2 Type plates

Fig. 4: Type plates AKM 220

Technical Data Model AKM 220-4 H

Dimensions (LxBxH, max.) 1030x900x1050mm

Working pressure 100 bar

Motor output 2,25 kW

Total power consumption 6,4 A

Electrical voltage 400 V

Phase (s) 3 Ph

Mains frequency 50 Hz

Max. cutting pressure 22 t

Cutting area LxB 200x200 mm

Working table dimensions

LxB

700x600 mm

Notching angle 90°

Strokes 50 1/min

Hubverstellung 4 mm

Cutting capacity 90°

(400 N/mm²)

4 mm

Cutting capacity 90°

(600 N/mm²)

2 mm

Oil tank capacity 22l

Sound pressure level opera-

tion (1m distance)

70 dB

Sound pressure level no-

load (1m distance)

62 dB

Weight 375 kg

Technical Data Model AKM 220-6 H

Dimensions (LxBxH, max.) 860x860x1100mm

Working pressure 145 bar

Motor output 3 kW

Total power consumption 8 A

Electrical voltage 400 V

Phase (s) 3 Ph

Mains frequency 50 Hz

Max. cutting pressure 24 t

Cutting area LxB 220mmx220mm

Working table dimensions

LxB

650mmx650mm

Notching angle 90°

Strokes 15 1/min

Hubverstellung 6 mm

Cutting capacity 90°

(400 N/mm²)

6 mm

Cutting capacity 90°

(600 N/mm²)

3 mm

Oil tank capacity 35 l

Sound pressure level opera-

tion (1m distance)

70 dB

Sound pressure level no-

load (1m distance)

62 dB

Weight 495 kg

Technical Data Model AKM 220-6 H

Transport, packaging, storage

AKM-Series 220 | Version 1.07 9

5 Transport, packaging, storage

5.1 Delivery and transport

Delivery

Check the notching machine on delivery for any visible

transportation damage. If you notice any damage to the

device please report this immediately to the carrier or

dealer.

Transport

The notching machine may only be transported stan-

ding up and with the motor switched off.

Transport with a forklift/lift truck:

Always use a forklift with suitable lifting characteristics

for lifting the packaging, taking into account the weight,

when transporting the product in its packaged state:

- Adjust the forks so that the crate is properly balan-

ced (Fig.5).

- Place the crate on the floor.

- Remove the packaging from the machine.

For shipping,the notching machine is firmly mounted on

a pallet so that it can be transported with a forklift truck.

Fig. 5: Transport with a forklift/lift truck:

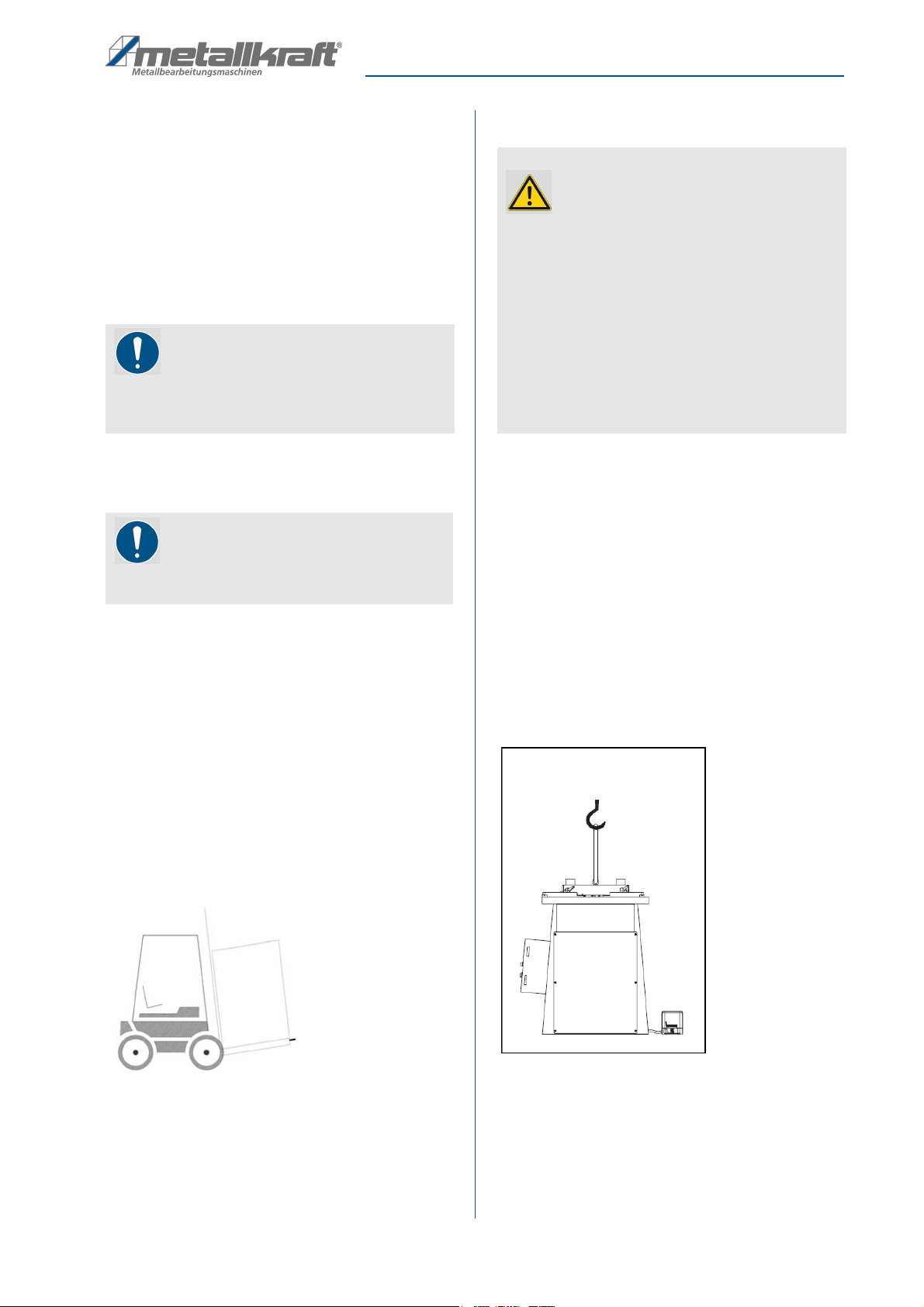

Transport with a crane:

- Remove the screws that secure the machine to the

pallet.

- Remove the reject container located on the machine

worktable to prevent it from falling to the floor while

moving. The container must be positioned on the

left side of the machine.

The machine may only be loaded and unloaded using a

rope. This rope must be attached to the eyebolt, which

must be placed on the top of the machine.

Never move the machine by hand or by any other me-

ans of transport not specified to avoid injury to persons

and damage to the machine.

Fig. 6: Transport with a crane:

On the top side of the notching machine a transport eye

can be attached in which the transport rope can be in-

serted (Fig. 6).

NOTE!

Oil may leak during transport of the notching ma-

chine. Secure the machine accordingly and take

precautions against possible environmental pollution.

NOTE!

The notching machine should be protected from hu-

midity.

WARNING!

Danger to life due to falling load!

If the weight of the notching machine and the per-

missible load capacity of the lifting equipment are

not observed during transport or lifting work, the

machine may tilt or fall.

- Transport with a crane may only be carried out by

specialists!

- When transporting and lifting, observe the weight of

the notching machine and also the permissible load

capacity of the lifting equipment.

- Use the intended attachment points for transport.

- The notching machine must not be rocked.

10 AKM-Series 220 | Version 1.07

Description of device

5.2 Packaging

All used packaging materials and packaging aids are

recyclable and should be taken to a materials recycling

depot to be disposed of.

The delivery packaging is made of cardboard, so

please dispose carefully by having it chopped up and

given to the recycling collection.

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (PS). Deliver these substances to a

collection point for recyclable materials or to the waste

disposal company which looks after your region.

5.3 Storage

Store the notching machine thoroughly cleaned in a dry,

clean and frost-free environment.

Apply protective oil to the upper and lower tools to pre-

vent rusting.

Protect the machine from sunlight.

Keep the machine packed in a suitable place, e.g. pro-

tected and not exposed to bad weather. If the machine

is to be taken out of operation for a short period of time,

clean it thoroughly and cover it with a cloth.

6 Description of device

6.1 Representation

Illustrations in these operating instructions are for basic under-

standing only and may differ from the actual version.

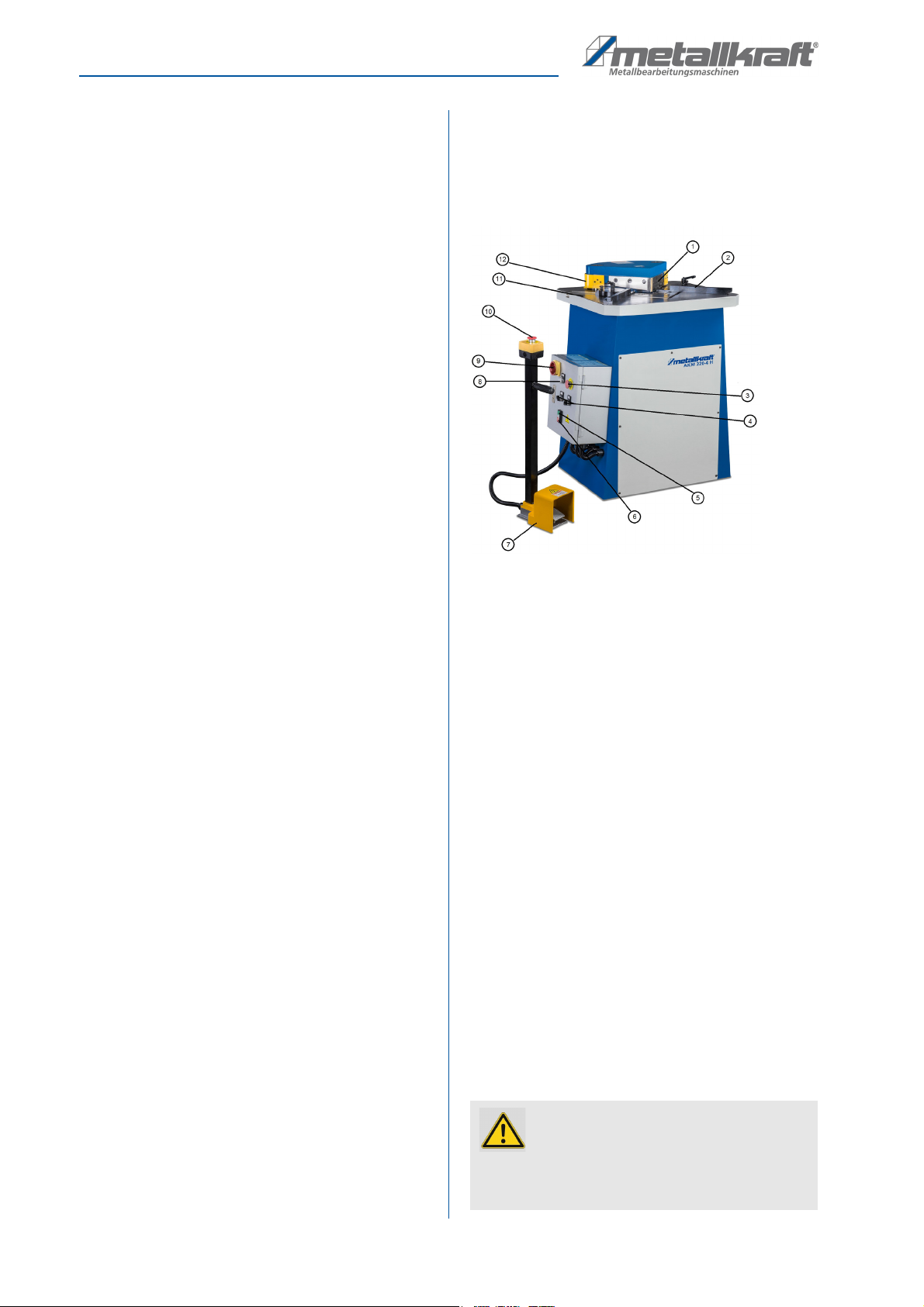

Fig. 7: Description of device AKM 220-4

1 Punching tool

2 Angle gauge

3 Emergency stop button

4 Selector switch „Operating mode“

5 Hydraulic ON

6 Hydraulic OFF

7 Foot control pedal

8 Control lamp

9 Main switch

10 Emergency stop button

11 Work table

12 Safety cover

6.2 Scope of delivery

- Hydraulic Notching Machine

- Foot pedal

- 2 adjustable angle stops

- Internal stop

- Operating instructions

- Bottom knife set for steel

- Top knife set for steel

6.3 Accessories

- Spare knife for steel (1 set)

ATTENTION!

The machine is delivered unfilled. Before commis-

sioning, hydraulic oil must be filled into the tank.

Only use suitable hydraulic oil for refilling.

Setting up

AKM-Series 220 | Version 1.07 11

7 Setting up

7.1 Place of installation

In order to ensure good functioning of the notching ma-

chine and a long service life, the installation site should

meet the following criteria.

- The notching machine may only be installed and

operated in dry, frost-free, well-ventilated rooms.

- Avoid places near machines that cause chips or

dust.

- The place of installation must be vibration-free, i.e.

away from presses, planing machines, etc.

- The ground must be suitable for the work. Pay atten-

tion to the bearing capacity and evenness of the

ground.

- If necessary, protruding parts, such as support ta-

bles, etc., must be secured by on-site measures so

that persons are not endangered.

- Provide sufficient space for set-up and operating

personnel and material transport.

- Also consider accessibility for adjustment and

maintenance work.

- Provide adequate lighting (minimum value: 300 lux).

- The humidity should be in the range of 10% to 90%

and the measured room temperature should be bet-

ween max. 0°C - 50°C.

Setting up the machine:

Step 1: Make sure that the space around the machine is

sufficient for the application (Fig. 8). There must

be sufficient space for the operator and material

transport.

Step 2: Check each part of the machine for proper con-

dition before starting to set it up.

Step 3: Place the control foot pedal in the best position

for the application in front of the work area.

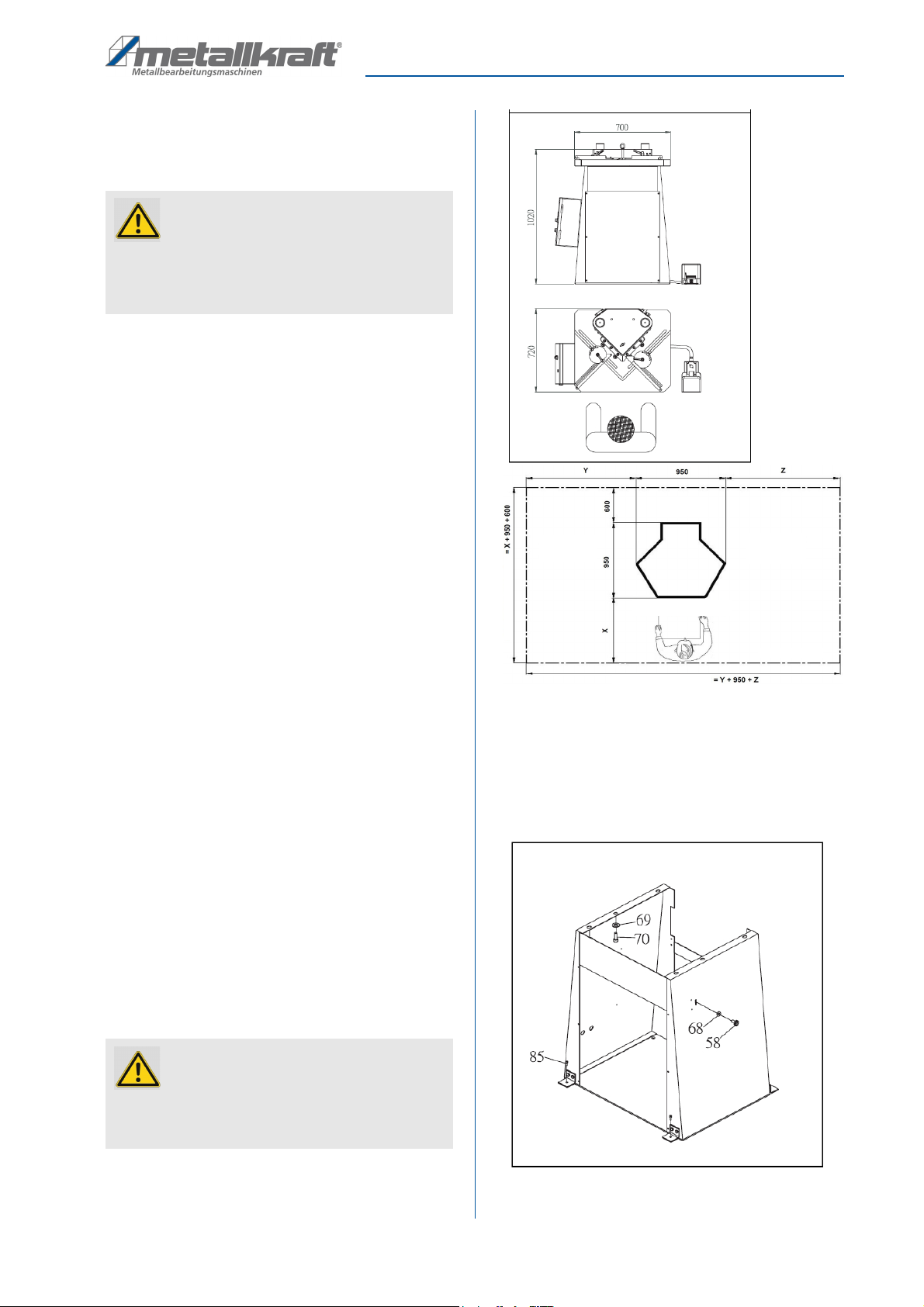

Fig. 8: Setup plan

Step 4: Remove the hexagonal head cap screws 85

(Fig.9).

Step 5: Use a crane to lift the machine from the pallet

and move it to the working position (Fig.10).

Fig. 9: Removing the fixing screws

ATTENTION!

Check the load-bearing capacity of the ground

before you install the machine. The installation place

must be capatable of bearing the weight of the

machine and the workpieces.

ATTENTION!

The machine is delivered unfilled. Before commis-

sioning, hydraulic oil must be filled into the tank.

Only use suitable hydraulic oil for refilling.

Stock area of

cutted material

Free clearance

space

Stock area of material

which will be cut

Free space for operation and

material feed/removal

Required minimum width

Required minimum depth

12 AKM-Series 220 | Version 1.07

Setting up

Fig. 10: Positioning with the crane

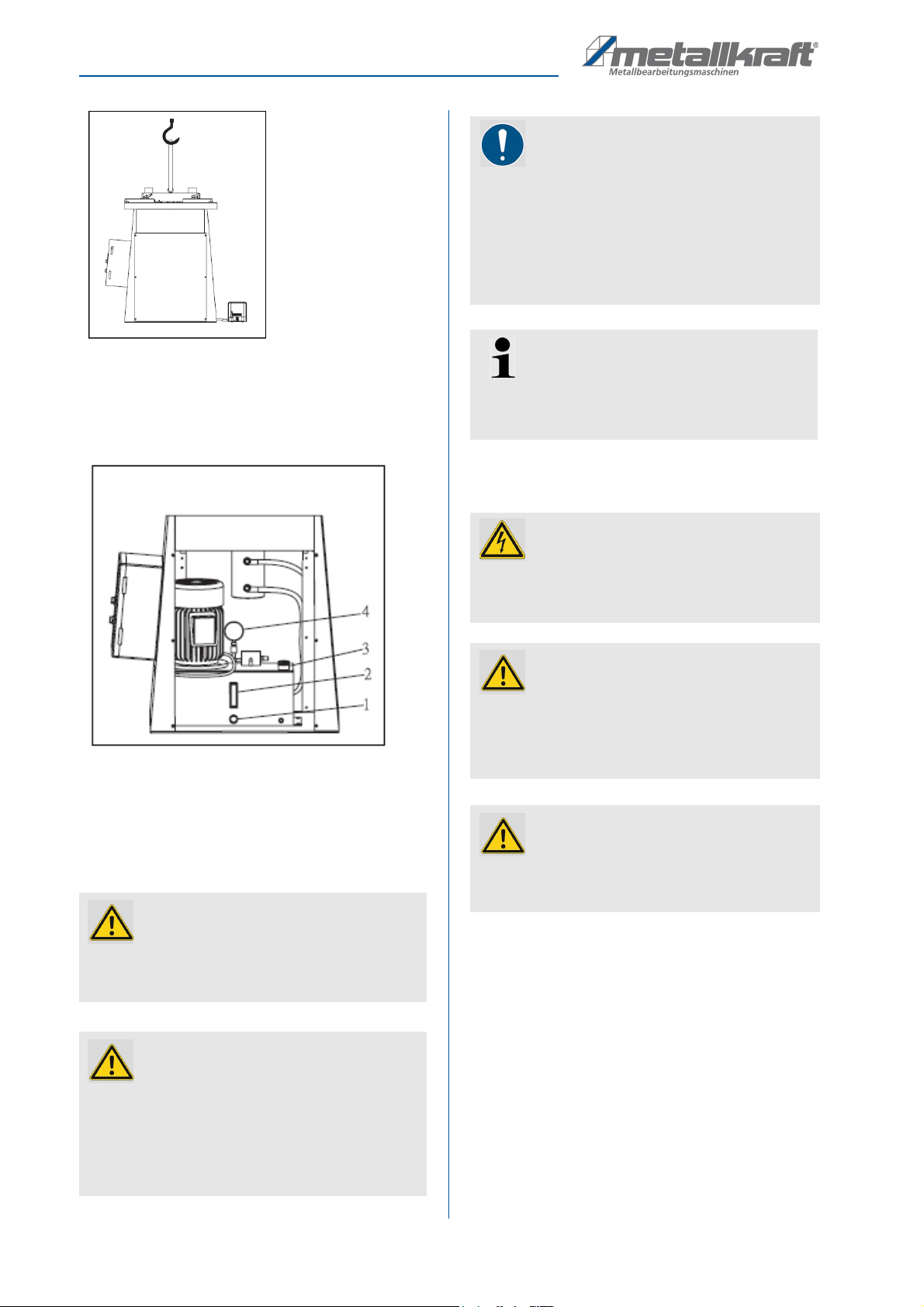

Step 6: Remove the front cover screws and front cover

(Fig.11).

Step 7: Remove the plug 3 (Fig.11).

Fig. 11: Filling the oil tank

Step 8: Fill the hydraulic oil into the hydraulic oil circuit

(approx. 20 litres) until the oil level reaches the

4/5 position of the oil level indicator 2 (Fig. 11).

Step 9: Check that the pressure gauge 4 (Fig. 11) is 150

kg/cm2(2100 psi).

7.2 Electrical connection

With the 3-phase 400 Volt / 50 Hz motor, the notching

machine should be connected to a standard 400V

mains supply.

Mains connection cable and extension cable must have

5 wires = 3P + N + PE (3/N/PE) with a cross-section of

1.5 mm² mm each.

ATTENTION!

The machine is delivered unfilled. Before commis-

sioning, hydraulic oil must be filled into the tank.

Only use suitable hydraulic oil for refilling.

ATTENTION!

When starting up the machine, only use the feet to

operate the foot pedal!

Never use your hands or any available aids to ope-

rate the machine via the foot pedal.

This will prevent injuries to persons and damage to

the machine.

NOTE!

After installation, remove the grease from the blank

metal parts which has been applied for protection.

- Use common solvent for this purpose, e.g. petroleum.

- Do not use water, nitro solvents, etc.!

After the machine has been thoroughly cleaned, all

blank parts must be lightly oiled. Only use resin- and

acid-free machine oil!

Tips and recommendations

For a safe stand, it is recommended that the

machine is fastened to a firm, stable and level

ground via the holes provided in the machine base.

Danger!

Risk of fatal electric shock!

Contact with live components may result in fatal

injury. Switched-on electrical components can make

uncontrolled movements and lead to serious injuries.

ATTENTION!

Never operate the foot pedal when:

- The electrical supply or air pressure supply is not

yet connected.

- Carry out maintenance.

ATTENTION!

All operations on the electrical installation and on the

electrical equipment may only be carried out by qua-

lified electricians!

Setting up

AKM-Series 220 | Version 1.07 13

Make sure that

- the power connection has the same characteristics

(voltage, mains frequency, phase position) as the

motor,

- the mains voltage of 400 V is used,

- a cable cross-section of at least 1.5 mm² is used for

the supply cable,

- the direction of rotation of the motor is correct (see

direction arrow on the motor).

- The unit must be earthed before operation so that in

the event of a malfunction or malfunction, the cur-

rent through the earthing goes the way of least resi-

stance. This reduces the risk of electric shock.

Wired grounded devices:

This device is factory equipped with a specific electrical

cable and plug to prevent the device from being

connected to an inappropriate circuit for use in an ordi-

nary power circuit.

Permanently connected devices:

In this case, the device must be connected to an eart-

hed metal, via a hard-wired wiring system.

Check motor direction of rotation:

Step 1: Check that the notching machine is switched off.

Step 2: Set the cutting gap setting to maximum ma-

nually.

Step 3: Connect the notching machine to the mains.

Step 4: Briefly switch the motor on and off again.

Step 5: Check the direction of rotation when the motor

runs out, see direction of rotation arrow.

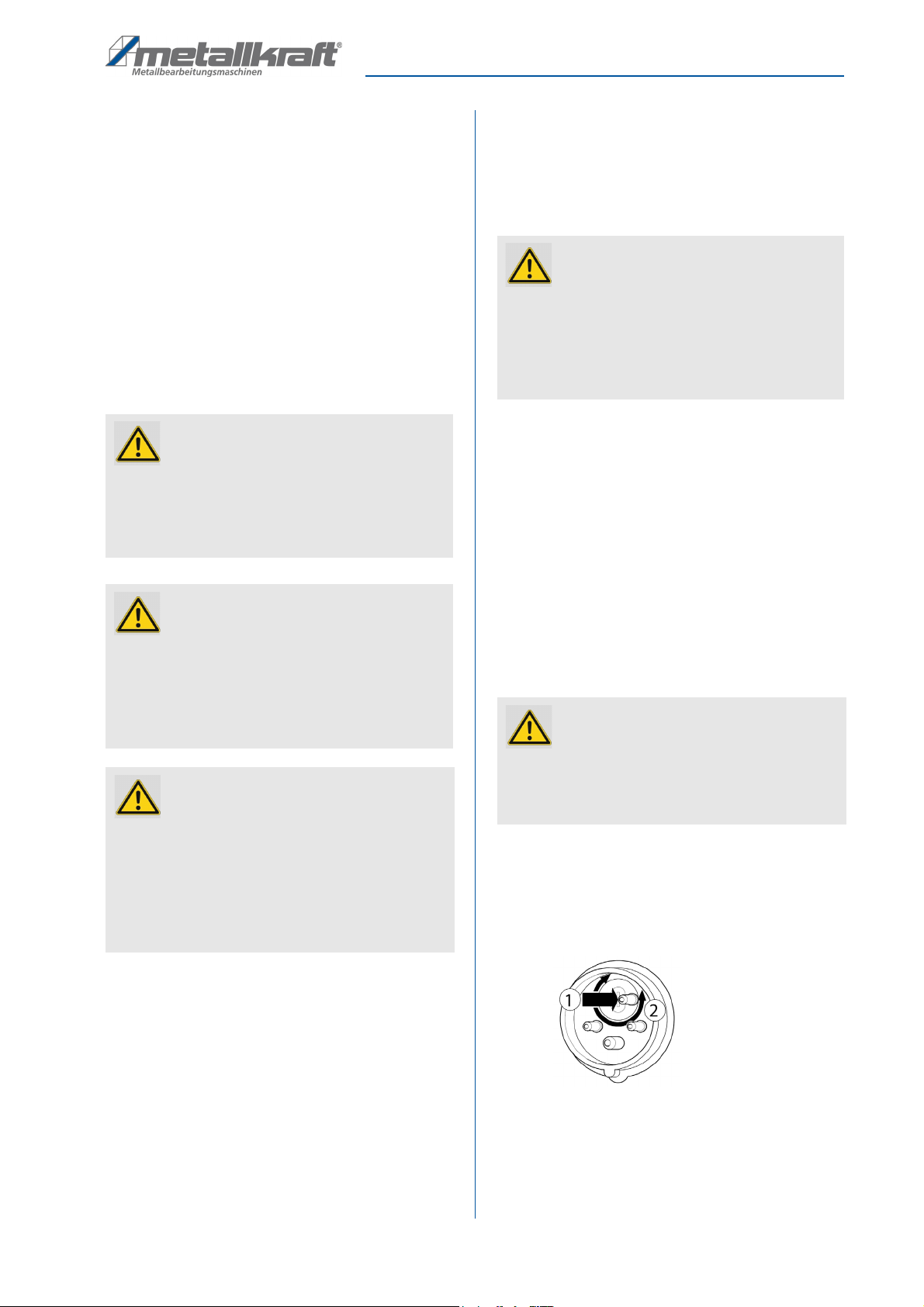

If the motor is rotating in the wrong direction:

Step 1: When equipped with a phase inverter:

Use a screwdriver to push in the washer in the

plug and turn it by 180°.

Fig. 12: Change motor direction of rotation

Without phase inverter:

Have two phases at the electrical connection re-

placed by a qualified electrician.

Step 2: Check the direction of rotation of the motor.

WARNING!

This device is equipped with a protective conductor

and an earthing cable.

The plug may only be connected to a suitable output

that is properly installed and earthed in accordance

with local laws and regulations!

WARNING!

An unsuitable connection of the earth conductor can

result in an electric shock!

Never make any changes to the grounding plug on

the device!

Only have modifications to the grounding plug car-

ried out by qualified personnel!

ATTENTION!

Danger of collision due to incorrectly set upper and

lower knives.

- Ensure that the upper or lower knives cannot collide

when the machine is switched on for the first time.

Have the upper knives dismantled by a specialist

or have the cutting gap on the lower knives increa-

sed accordingly.

WARNING!

Make sure that the socket has the same configura-

tion as the grounding plug!

Never use an adapter between the grounding plug

and the socket!

Have modifications to the grounding plug carried out

by qualified personnel only!

ATTENTION!

An incorrect direction of motor rotation will result in a

hydraulic fault!

Set the cutting gap to maximum before commissio-

ning.

14 AKM-Series 220 | Version 1.07

Settings

8Settings

8.1 Setting the cutting gap tolerance

The cutting gap is adjusted after initial commissioning

and after each knife change.

- If the cutting gap is set too large, the notching

process may result in burr and chip formation. If the

cutting gap is set too small, the knives may be da-

maged and the stroke may block.

- Perform a few test cuts after adjusting the cutting

gap.

Step 1: Disconnect the power supply.

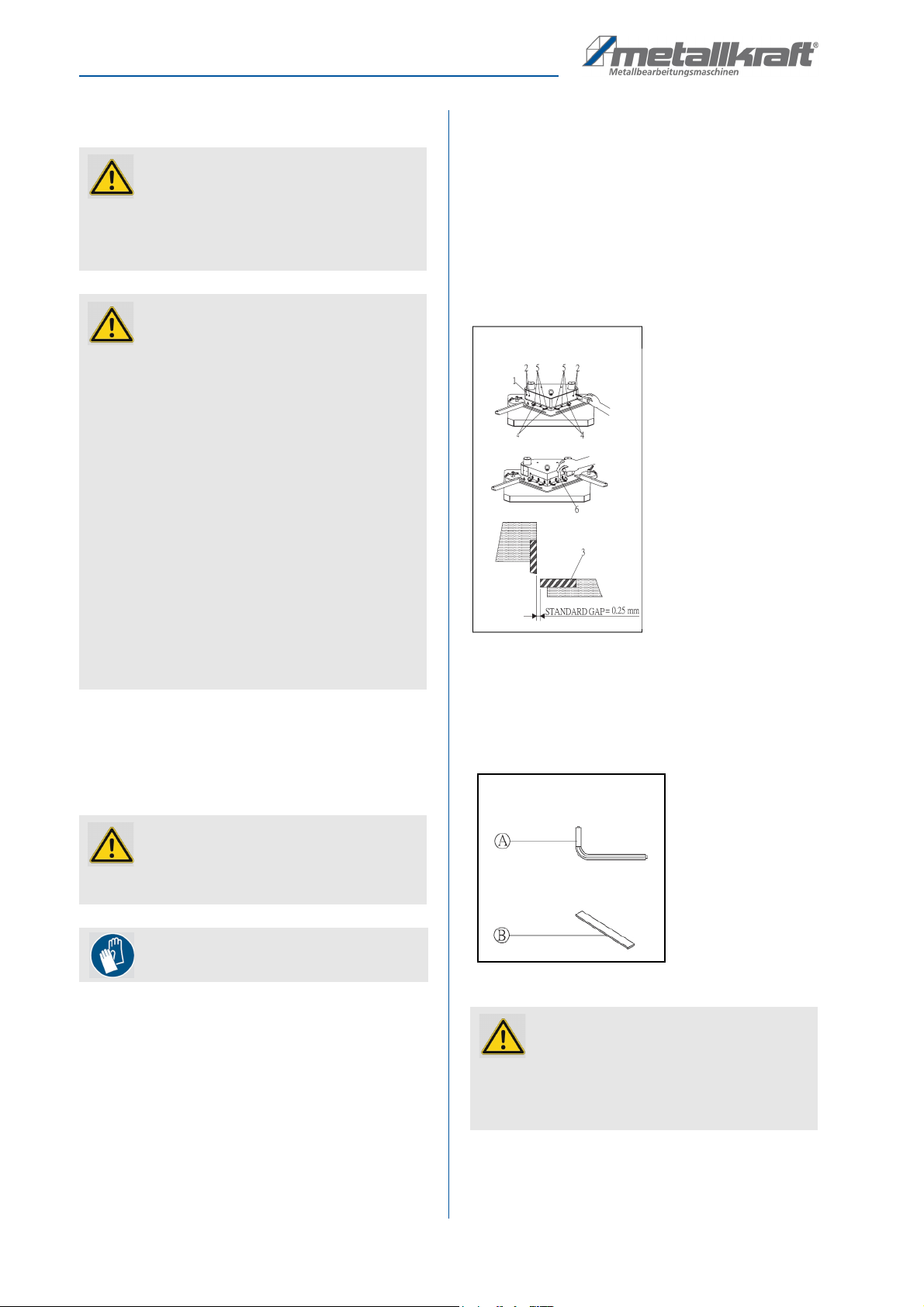

Step 2: Unscrew the screws (Pos. 2, Fig. 13) then re-

move the safety cover (Pos. 1, Fig. 13).

Step 3: Loose the bias screws (Pos. 4, Fig. 13) and

blade screws (Pos. 5, Fig. 13).

Step 4: Measure the tolerance by 0.25 mm thickness

gauge (Pos. 6, Fig. 13).

Step 5: Adjust the upper and lower blades against to the

thickness gauge. The thickness gauge should

be nower removed smoothly.

Step 6: Tight all the screws.

Fig. 13: Disassemble the safety cover

Tools for adjusting the cutting gap width (Fig. 14):

A - Allen wrench for blade screw

B- 0.25 mm thickness gauge.

Fig. 14: Tools for cutting gap adjustment

ATTENTION!

Settings on mechanically acting machine elements

may only be carried out on the machine by trained

specialists or specially trained and instructed per-

sons.

DANGER!

Incorrect mechanical settings can influence the

safety of the machine to such an extent that it cau-

ses a permanent danger. Careless behaviour can

put the personnel and the machine at risk when swit-

ching-on again.

- Before making any mechanical adjustments, al-

ways switch off the machine at the main switch and

secure the main switch against accidental restar-

ting, e.g. by attaching a warning sign.

- After carrying out the adjustment activities, make

sure that all covers and protective devices have

been properly mounted on the machine again.

- Do not leave any tools accidentally inserted during

setting activities. Before switching on the machine

again, make sure that all setting tools have actually

been removed. Make sure that no tools are left in-

side the machine, especially in the working area of

the machine mechanics.

ATTENTION!

There is a risk that the machine will be damaged if

the cutting gap is set incorrectly.

Use protective gloves!

ATTENTION!

No adjustment of the cutting gap is required for dif-

ferent sheet thicknesses. There are spring plates in

the system which automatically adjust the cutting

gap.

Settings

AKM-Series 220 | Version 1.07 15

8.2 Changing the knife

Replace the knives in time. Blunt knives lead to poorer

cutting performance.

- Poor knife quality reduces the service life of the

knives.

- There is a danger that after a knife change the cut-

ting gap is incorrectly set and the machine is dam-

aged.

- Use protective gloves when changing the knives.

- After each knife change, make sure that the cutting

gap is within the permissible setting range of 0.25

mm.

- If necessary, readjust the cutting gap.

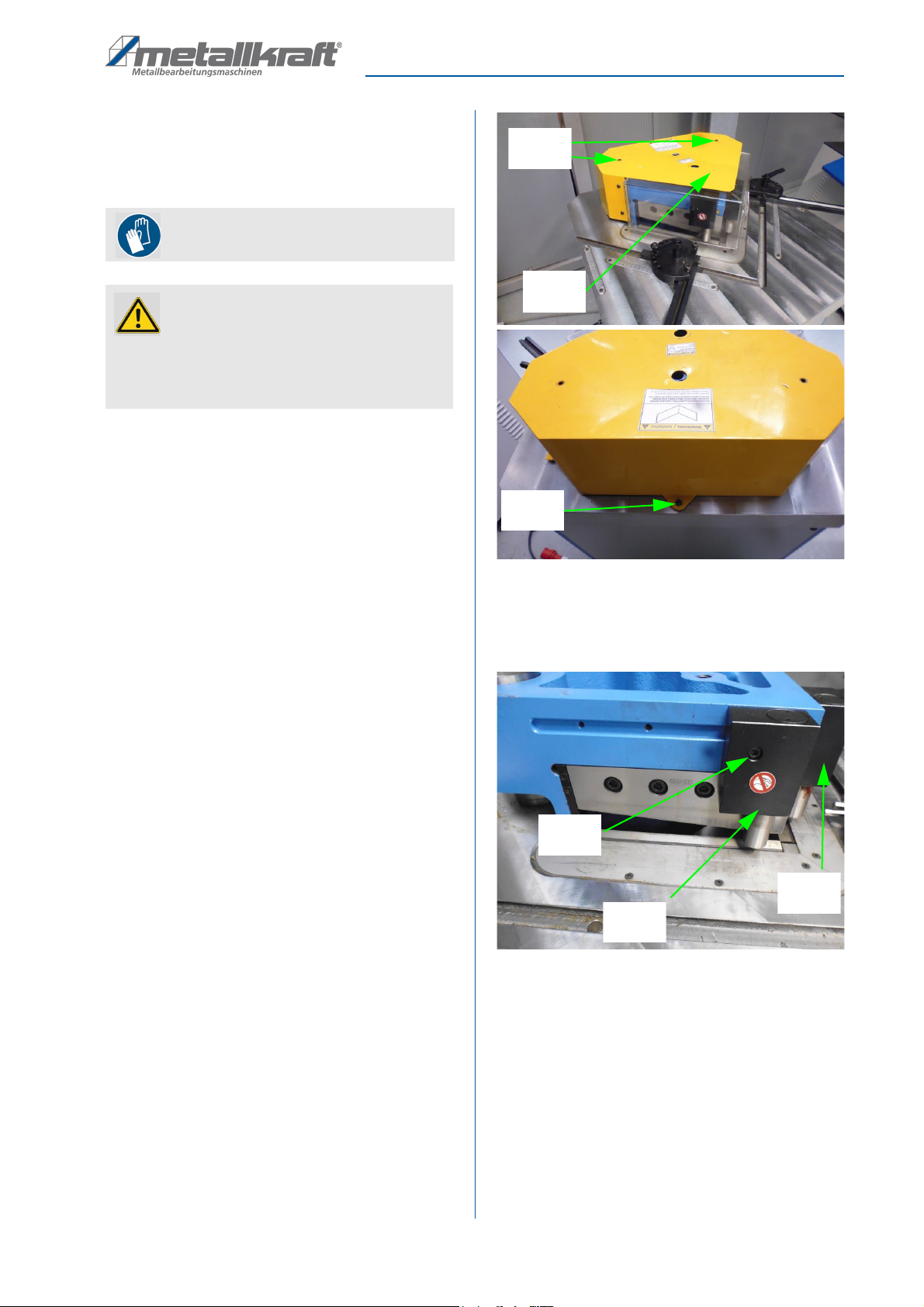

Replacing the upper knives:

Step 1: Move the knife bar to the upper end position and

switch off the machine by actuating the main

switch. Now secure the main switch against be-

ing accidentally switched on again.

Step 2: For removing the protective cover 1, you must

first unscrew the three screws 2 (Fig.15).

Step 3: Dismount the protective cover now. Lift the pro-

tective cover off the cutter bar and store it in a

safe place.

Fig. 15: Disassembling of the protective cover

Step 4: For disassembling the downholder device 3, un-

screw the corresponding fastening screw 4

(Fig.16).

Fig. 16: Change upper knife

Step 5: Remove the respective downholder and place it

at a sufficient distance to be able to disassem-

ble the upper knife (Fig.17) without any problem.

Use protective gloves!

CAUTION!

Use only the recommended original spare blades.

There is a risk that poorer material properties will

lead to knife breakage and cause injury and dam-

age to the machine.

2

2

1

4

3

3

16 AKM-Series 220 | Version 1.07

Settings

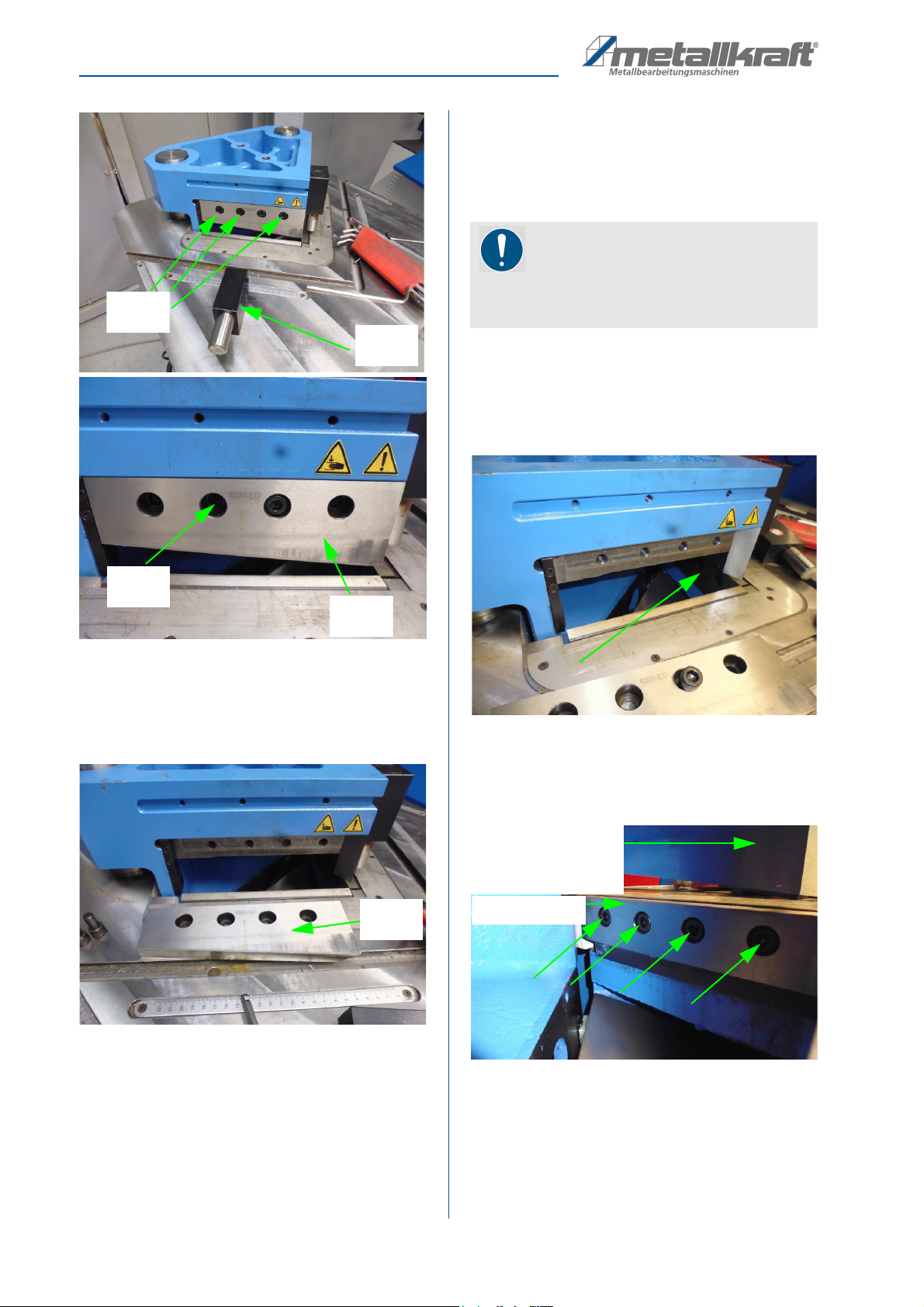

Fig. 17: Dissembling of the upper knife

Step 6: First unscrew the three screws (5, Fig.17).

Step 7: Finally unscrew the fourth screw (6, Fig.17).

Fig. 18: Removing of the upper knife

Step 8: Carefully remove the upper blade (7, Figs. 17

and 18) and store it in a safe place.

Step 9: Take the new upper blade and fasten it by first

screwing in the screw 6 (Fig.17).

Step 10: Then screw in the three screws 5 (Fig. 17).

When tightening all screws, make sure that there is no

gap at the points where the knives are in contact with

each other.

Replacing the lower knives:

First, perform steps 1 to 8 of the section „Replacing the

upper knives“. First disassemble only one upper knife.

Then continue with step 9 in the „Replacing the lower

knives“ section.

Fig. 19: Access to the fixing screws of the lower knife.

Step 9: After the upper knife has been removed, you

can use an Allen key to reach the screws of the

adjacent lower knife (Fig.19 or 20).

Fig. 20: Fixing screws of the lower blade

Step 10: Use a suitable Allen key (Fig.21) to unscrew the

screws and change the lower knife.

3

5

6

7

7

NOTE!

In order to enable the replacement of the lower

knives, first the adjacent upper knife must be dis-

mantled!

Untermesser

Obermesser der

angrenzenden

Seite (von hinten)

Settings

AKM-Series 220 | Version 1.07 17

Fig. 21: Unscrewing of the screws of the lower knife

Step 11: Mount the new lower knife.

Step 12: Check the cutting gap. If necessary, reset it im-

mediately.

Step 13: Mount the upper knife back again.

Step 14: Carry out all necessary steps to change the

second lower knife as well.

Step 15: If there are no further activities in the area of the

knives, replace the protective cover 1 (Fig.15)

and screw it tight.

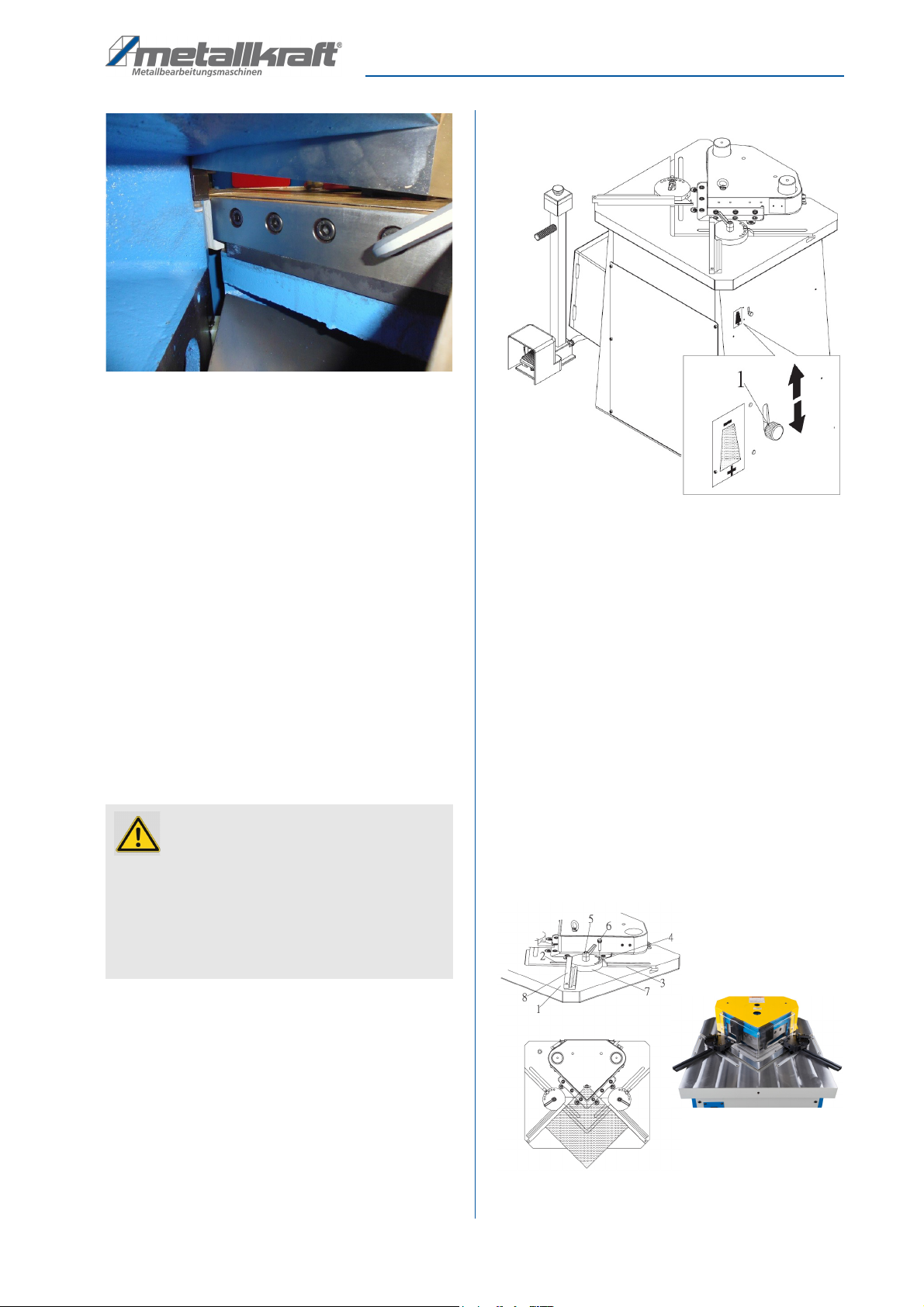

8.3 Cutter bar - Stroke limit

Setting of working head

The setting of the cutting depth, cutting speed and cut-

ting time is determined by the position of knob (Pos. 1,

Fig. 22).

The maximum travel of the cutter bar is 20 mm.

Fig. 22: Stroke limit

8.4 Setting the limit stops

Adjustable stops are used to limit or guide the process-

ing of the sheets.

Step 1: Move the cutter bar to the upper end position

and switch off the machine by pressing the main

switch. Now secure the main switch against ac-

cidental restarting.

Step 2: Set the currently required stops according to the

following information.

Use the setting examples as a basis for the cur-

rently required setting.

Step 3: Loosen the clamping handle (Pos. 5, Fig. 23)

and push the stop out to the required workpiece

length.

Step 4: Remove pin (Pos. 6, Fig. 23) and set the re-

quired number of degrees.

Fig. 23: Limit stops

ATTENTION!

- There is a risk that the machine will be damaged if

the knife bar stroke is set incorrectly.

- Improper adjustment may void the warranty.

- Repairs to the cutter bar stroke limit, such as the re-

placement of defective parts, may only be carried

out by qualified personnel!

18 AKM-Series 220 | Version 1.07

Settings

Fig. 24: Setting the limit stops

Step 5: Adjust the left and right stops (Pos. 8, Fig.23) to

fit the workpiece to the working reference

(Fig.24 and 25).

Fig. 25: Setting the limit stops

Adjustment elements

The stop bar A of the angle stops can be moved across

the T-slot. The angle of the stop bar to the measuring

tape is adjusted via the grid plate B (angle wheel).

Fig. 26: Adjustment elements

The clamping lever C

(Fig. 26) is used to fix the current set-

ting. The measuring tapes embedded in the table are each

provided with an outer and inner scale. The outer and inner

scales are each inclined by 45° to allow precise adjustment

of the stop bars.

Fig. 27: Scales

E

E

D

E

B

A

D

Operation

AKM-Series 220 | Version 1.07 19

B: Grid plate, angle wheel

D: Inner scale

E: Outer scale

.

The two reference display groups can both be set to the

left and to the right within a range of up to 45°.

Fig. 28: Angle adjustment directions of the reference display groups

9 Operation

ATTENTION!

If the setting of the knife position is changed, the

position of the outer stop must be adjusted.

WARNING!

Danger to life!

Failure to observe the following rules entails a risk of

fatal injury for the operator and other persons.

- The operator must not work under the influence of

drugs, alcohol or medication.

- The operator must not work in case of tiredness or if

suffering from an illness that impairs concentration.

- Die Ausklinkmaschine must be operated by one

person only. Additional persons must keep out of

the work area during operation.

DANGER!

Risk of injury!

While working on the notching machine:

- tight clothing must be worn.

- No jewellery may be worn.

- No shawls, ties or the similar must be worn.

- A hair net must be worn for long hair.

DANGER!

Risk of injury!!

There is a risk of injury to the upper limbs (e.g.

hands, fingers).

ATTENTION!

Never step on the foot pedal if:

- You have connected the electrical supply and the

air pressure supply.

- You want to start the application during operation.

- You have completed a started maintenance.

ATTENTION!

- Never change the settings for the hydraulic system.

This is especially true for valves present there.

- Never change the setting of the cutter bar stroke li-

mit.

- Only operate the machine from the front.

- Ensure that the workpieces are fixed when working.

Use the stops for this purpose.

- Adjust the stops only when the machine is swit-

ched off (main switch in the position "OFF").

- When setting the stops, observe the minimum and

maximum cutting length.

- When adjusting the inner stop, make sure that no

collision with the upper knives can occur.

- When cutting metal strips to length, make sure that

the cutting line is not longer than the knife length.

- Always place the metal sheets over their entire sur-

face on the worktable. If necessary, support late-

rally protruding material with stable and stable ma-

terial stands.

Wear hearing protection!

Use protective goggles!

Use protective gloves!

Safety boots

Use protective clothes!

20 AKM-Series 220 | Version 1.07

Operation

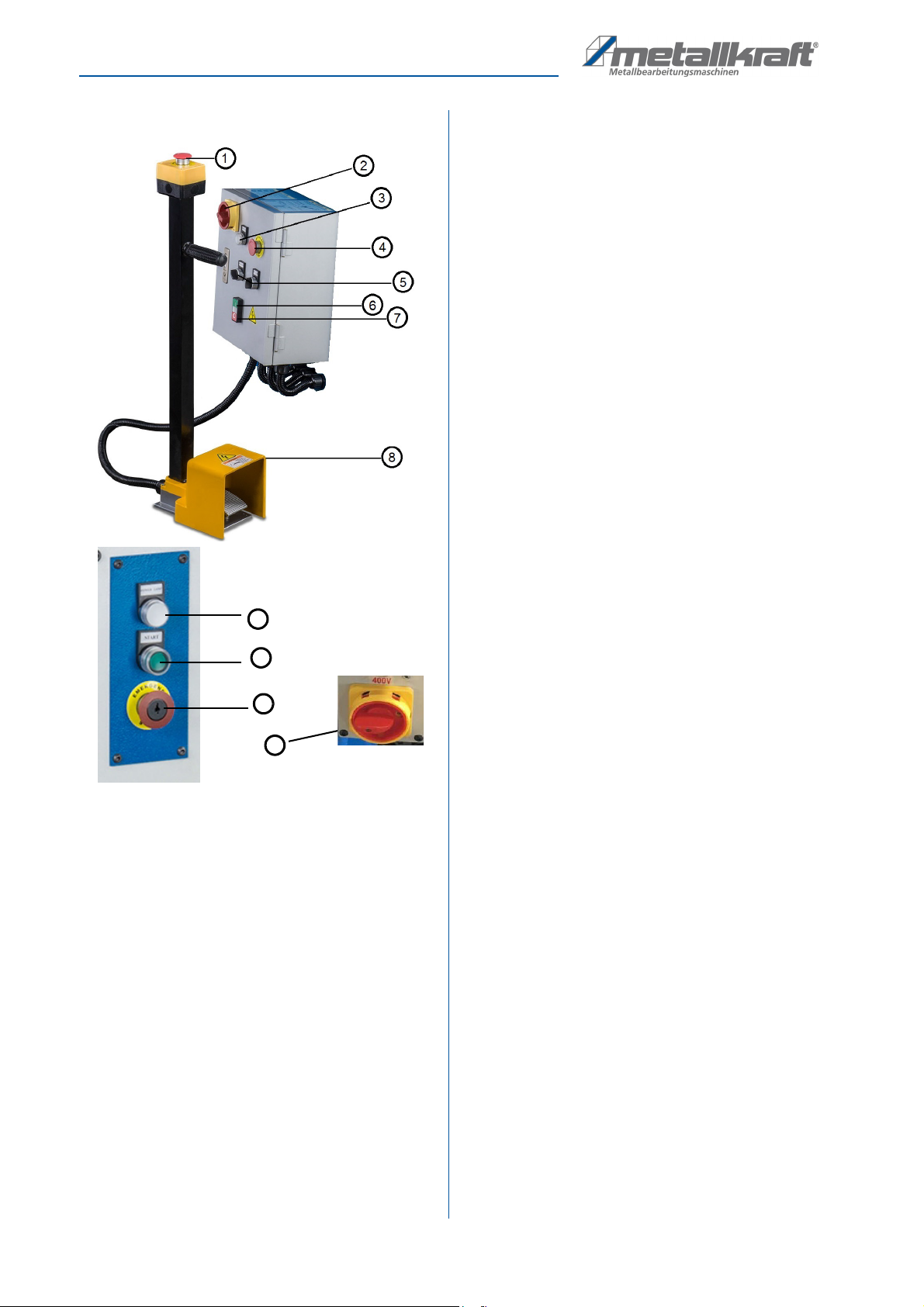

9.1 Control panel

Fig. 29: Control panels AKM 220-4 (top), AKM 220-6 (bottom)

1 Emergency stop button

2 Main switch

3 Control lamp

4 Emergency stop button

5 Toggle switch „Operating mode“

6 Hydraulics ON

7 Hydraulics OFF

8 Foot pedal

9.2 Functional description:

Main switch

Switches the machine on or off when actuated.

Emergency-stop button (pushbutton)

Used in a hazardous situation to switch off the ma-

chine quickly.

The emergency-stop button may only be operated in an

emergency!

Selector switch for operator with signal lamp

Switches the operating mode mode on or off depend-

ing on the switch position.

Selector switch for manual/foot operation with signal lamps

Activates manual or foot opetating mode depending

on switch position.

Button for manual upward movement of the cutter bar with

signal lamp

Moves the upper cutter bar upwards when manual

operation is switched on. Releasing the button stops

the upward movement (jog mode).

Foot pedal (freely adjustable)

When actuated, a working stroke is performed when

foot operation is switched on.

Button for angle adjustment with signal lamp

By turning the switch to the right while pressing the

pedal, you can adjust the angle by moving the angle

stops. To cut, turn the switch to the left.

9.3 Initial commissioning

Before you start the machine for the first time, make sure

that the following points are fulfilled:

- The machine is anchored to the ground at the instal-

lation site,

- The direction of rotation of the motor has been suc-

cessfully checked after connection to the mains,

- Enough hydraulic oil has been filled into the oil tank

to reach the upper level at the oil sight glass,

- The hydraulic system has been checked for proper

installation and safe functioning before initial opera-

tion in accordance with the German Ordinance on

Industrial Safety and Health (BetrSichV) - any de-

fects have been rectified,

- Upper and lower knives cannot (accidentally) col-

lide.

First familiarise yourself with all switching functions as

described in Chapter 7. Do not omit any switching func-

tion to ensure that you can operate all electrical controls

correctly during subsequent operation:

- Ensure that all protective devices are installed. The

side maintenance protection covers must be firmly

screwed to the machine.

- Make sure that the foot pedal is connected and can

be operated with the foot in front of the machine.

- Now switch on the main switch. The machine is

ready for operation.

- Test all the functions of the controls. Note that some

functions are only available if another function is

switched on at the same time.

- If possible, check the emergency stop function now.

If everything is working correctly, then switch off the

machine again with the main switch.

4

6

3

2

This manual suits for next models

4

Table of contents

Other Metallkraft Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB TPS 50B01 Operation manual

Baileigh Industrial

Baileigh Industrial BR-16E-36LT Operator's manual

Emerson

Emerson SA1-2 Series RE-ASSEMBLY INSTRUCTIONS

NTN-SNR

NTN-SNR LINEAR AXIS AXC Series manual

UNITED Fire Systems

UNITED Fire Systems STANDPIPE-PAC SSS-101 Design, Installation, Operation, and Maintenance Manual

Pfannenberg

Pfannenberg PWI 6502 T Series operating manual