Metallkraft KRBS 101 User manual

KRBS 101

Instruction Manual

KRBS 101

KRBS 101

Combined pipe,

section and belt grinding machine

2 KRBS 101 | Version 1.03

Imprint

Product identification

Combined pipe, section and belt grinding machine

KRBS 101 3921001

Manufacturer

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Indications regarding the operating instructions

Original instructions

Edition: 27/05/2019

Version: 1.03

Language: English

Author: ES/FL

Indications regarding the copyright

Copyright © 2019 St rmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions is the sole

property of the company St rmer Maschinen GmbH.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Content

1 Introduction ............................................ 3

1.1 Copyright ........................................................... 3

1.2 Customer service...............................................3

1.3 Limitation of liability............................................ 3

2 Safety ...................................................... 3

2.1 Symbol explanation ........................................... 3

2.2 Obligations of the operating company ............... 4

2.3 Qualification of personnel .................................. 4

2.4 Personal protective equipment .......................... 5

2.5 Safety equipment...............................................5

2.6 Safety signs on the machine..............................5

3 Intended use ........................................... 6

4 Technical Data........................................ 6

4.1 Table.................................................................. 6

4.2 Type Plate.......................................................... 6

5 Transport packaging storage.............. 6

5.1 Delivery and transport........................................ 6

5.2 Packaging..........................................................7

5.3 Storage .............................................................. 7

6 Description of the device ...................... 7

6.1 Image................................................................. 7

6.2 Scope of supply ................................................. 8

6.3 Accessories ....................................................... 8

7 Installation .............................................. 8

7.1 Mounting............................................................ 9

7.2 Set up ................................................................ 9

7.3 Electrical connection.......................................... 10

8 Assembly.................................................10

8.1 Belt sander on the back of the device................10

8.2 Pipe grinder on the front of the device............... 10

8.3 Surface grinding station..................................... 12

9 Operation.................................................12

9.1 Working position pipe grinder ............................ 13

9.2 Working position belt sander ............................. 14

9.3 Working position surface grinder ....................... 15

9.4 Shut down the Machine ..................................... 15

10

Care maintenance and overhaul/repair......

15

10.1 Cleaning and lubrication of the machine.......... 16

10.2 Adjust Belt change and Belt run ...................... 16

10.3 Changing the contact roller.............................. 16

10.4 Troubleshooting...............................................17

11 Disposal recycling of used devices....18

11.1 Decommissioning ............................................ 18

11.2 Disposal of electrical devices...........................18

11.3 Disposal of lubricants....................................... 18

12 Spare parts.............................................18

12.1 Ordering spare parts........................................18

12.2 Spare parts drawings....................................... 19

13 Wiring Diagram......................................23

14 EC Declaration of Conformity...............24

15 Notes......................................................25

Introduction

KRBS 101 | Version 1.03 3

1 Introduction

You have made a good choice by purchasing the Combi-

ned pipe, section and belt grinding machine made by

METALLKRAFT.

Thoroughly read the operating instructions before

commissioning the machine.

It informs you about the proper commissioning, the in-

tended use as well as the safe and efficient operation

and maintenance of your Combined pipe, section and

belt grinding machine.

The operating instructions are part of the Combined

pipe, section and belt grinding machine. Always keep it

at the place of use of the Combined pipe, section and

belt grinding machine. Furthermore, the local accident

prevention regulations and the general safety notes are

applicable for the field of application of the Combined

pipe, section and belt grinding machine. The illustrations

in these operating instructions serve the general com-

prehension and may deviate from the actual type.

1.1 Copyright

The contents of these instructions are copyright. Their ap-

plication is admissible in the frame of the Machine utilisa-

tion. An application beyond the described application is

not allowed without written approval of the manufacturer.

For the protection of our products, we shall register trade-

mark, patent and design rights, as this is possible in indivi-

dual cases. We strongly oppose any infringement of our

intellectual property.

1.2 Customer service

Please contact your dealer if you have questions on the

machine or if you need technical advice. They will help

you with specialist information and expert advice.

Germany:

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Hotline: 0951 96555-100

Fax: 0951 96555-111

E-Mail: [email protected]

Internet: www.metallkraft.de

Spare part orders:

Fax: 0951 96555-119

E-Mail: [email protected]

We are always interested in valuable experience and

knowledge gained from using the application, which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised taking the applicable standards and

rules, the state-of-the-art and our long-term knowledge

and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- Unauthorised modifications

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the expla-

nations and presentations described here in case of spe-

cial models, when using additional ordering options or

due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-

tions of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This paragraph will give you an overview of all important

safety packages for the protection of the people using it

well as for a safe and undisturbed operation. Other task-

based safety notes are included in the individual chap-

ters.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

WARNING!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injuries if they are not

avoided.

4 KRBS 101 | Version 1.03

Safety

Tips and recommendations

It is necessary to observe the safety notes quoted in

these operating instructions in order to reduce the risks

for personal injuries and damages to property.

2.2 Obligations of the operating company

The operating company is the person who operates the

machine for business or commercial reasons by herself,

or leaves it to a third party for use or application, and who

bears the legal product responsibility for the protection of

the user, the staff or for third parties.

Obligations of the operating company:

If the machine is used for commercial purposes, the op-

erating company must comply with the legal working

safety regulations. Therefore, the safety notes in this op-

erating manual, as well as the safety, accident preven-

tion and environment protection regulations applying for

the area of application of der Maschine must be met.

The following applies in particular:

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use the Machine.

She must implement these in form of operating

manuals for the operation the Machine.

- During the entire lifetime of the Machine, the oper-

ating company must verify whether the operating

manuals prepared by her correspond to the current

status of the regulations, and must adapt these if

necessary.

- The operating company must unambiguously regu-

late and determine the responsibilities for installa-

tion, operation, troubleshooting, maintenance and

cleaning.

- The operating company must ensure that all per-

sons who work with the Machine, have read and

understood this manual. Furthermore she must in-

struct the staff in regular intervals and inform them

about the hazards.

- The operator must provide the necessary protec-

tive equipment to the staff and order the use of the

necessary protective equipment in a binding way.

Furthermore the operating company is responsible to

keep die Machine always in a technically flawless state.

Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices checked

regularly for their good working order and their in-

tegrity.

2.3 Qualification of personnel

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

CAUTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to minor or light injuries if they are not avoided.

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

NOTE !

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the Machine and expose them-

selves and others to the danger of severe injuries.

- Have all works only performed by qualified persons.

- Keep insufficiently qualified persons and children

out of the working area.

Safety

KRBS 101 | Version 1.03 5

Operator:

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-

formed beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company expres-

sively commissioned the operator.

Electrical specialist:

Due to his professional training, knowledge and experi-

ence as well as his knowledge of respective standards

and regulations the electrical specialist is able to perform

works on the electrical system and to recognise and

avoid any possible dangers himself.

Specialist staff:

Due to their professional training, knowledge and experi-

ence as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer:

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while

working. The staff has to wear personal protective equip-

ment while performing different works on and with the

Machine which are indicated in the individual paragraphs

of these instructions.

The personal protective equipment is explained in the

following paragraph:

2.5 Safety equipment

To protect against flying sparks on the housing above

the contact wheel, a protective screen attached. The on-

off switch unit is combined with an emergency stop

switch.

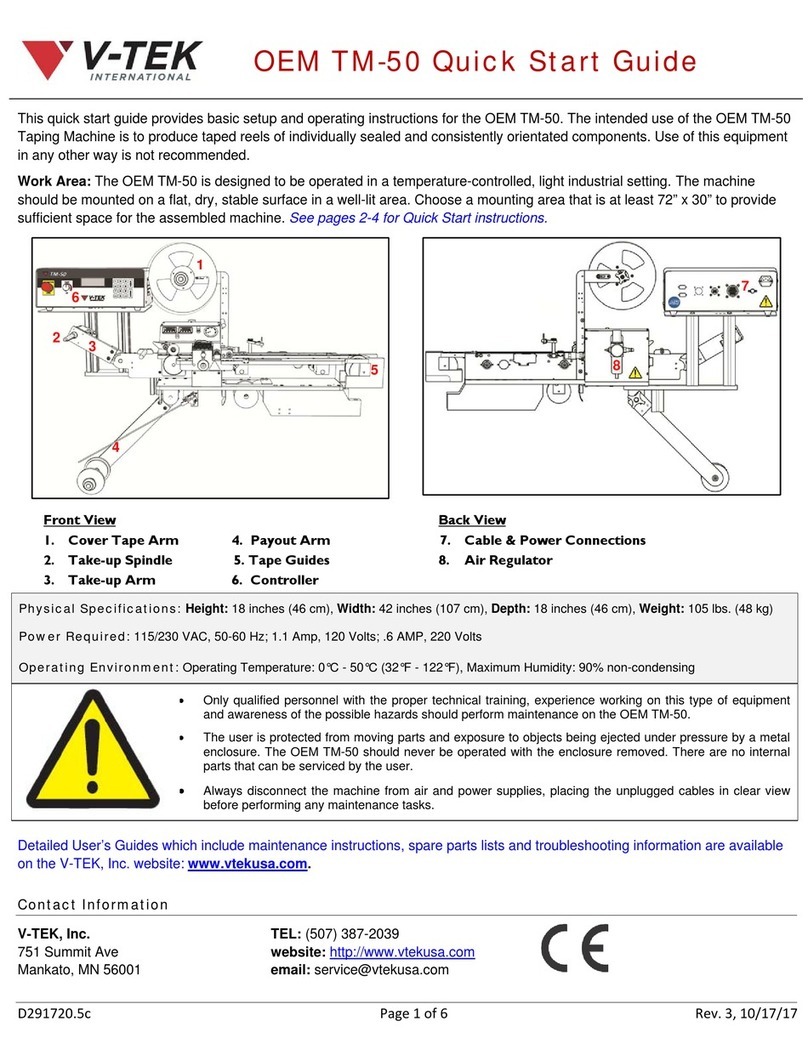

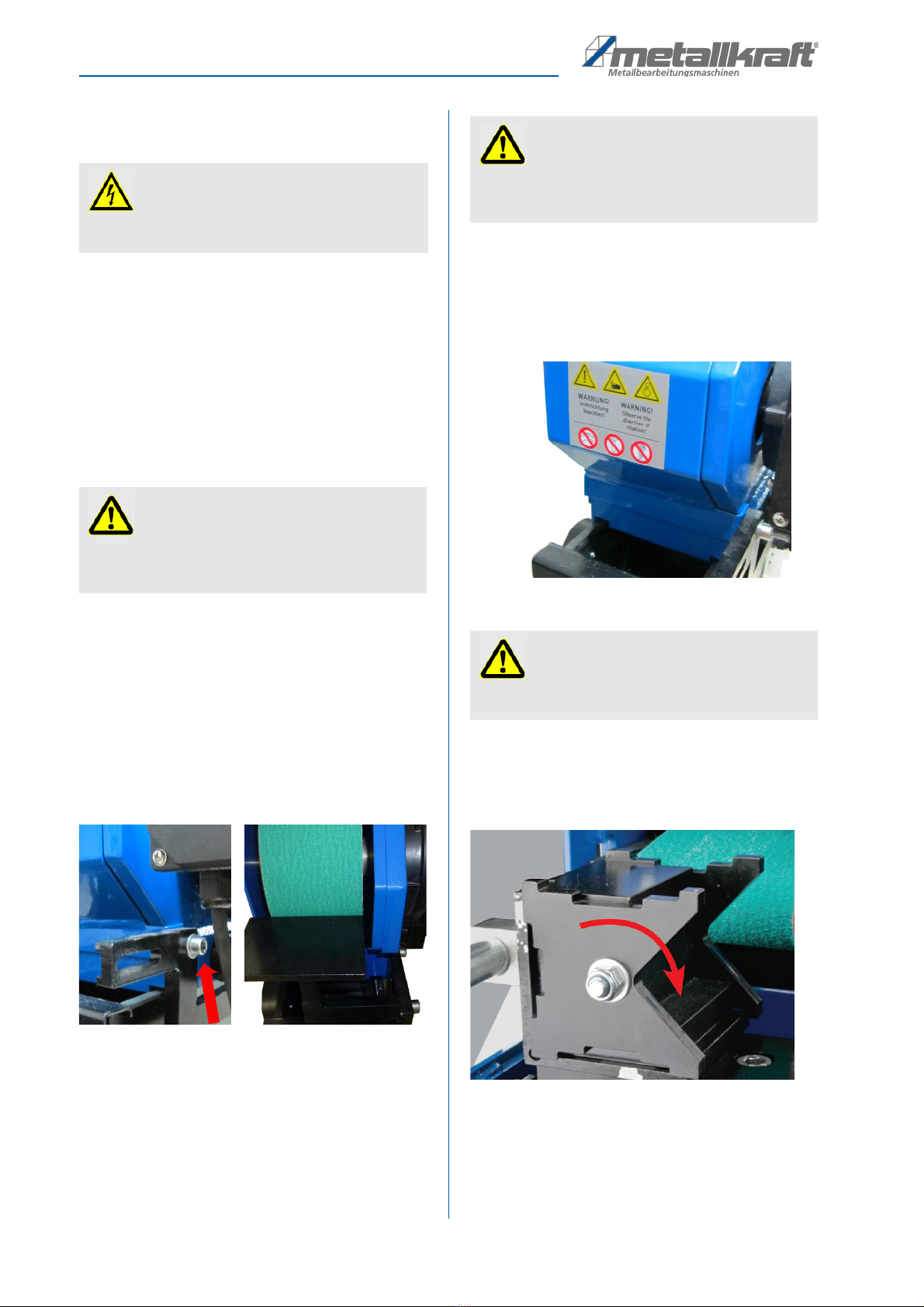

2.6 Safety signs on the machine

The following safety signs and notes are applied on the

Combined pipe, section and belt grinding Machine (Fig.

1), which need to be observed and followed.

Fig. 1: Safety signs

Eye protection

The protective goggles protect the eyes against parts

flying off and splashes of liquids.

Ear protection

The hearing protection protects the ears against

damages of hearing due to noise.

Breathing protection

The breathing protection serves for protecting the

respiratory passages and the lung against the intake

of dust particles.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

The safety boots protect the feet against crushes,

falling parts and slipping over on slippery under-

ground.

Protective clothes

The protective clothes are tight clothes of little ten-

sile strength.

12

3

5

4

6 KRBS 101 | Version 1.03

Intended use

Damaged or missing safety symbols at the machine may

lead to errors with personal and material damages. The

safety symbols which are applied on the machine must

not be removed. Damaged safety symbols must be re-

placed immediately.

The machine must be put out of operation from the mo-

ment when the labels are unable to be recognized and

understood at first glance, until new labels are attached.

3 Intended use

The pipe belt sander is designed exclusively for grinding

and deburring of various metallic, cold and non-combus-

tible materials. It must not be operated in potentially ex-

plosive environments.

For operation at the pipe grinding station on the front of

the device, the workpiece must be tightened with the ex-

isting vise.

For operation on the belt grinding station on the back of

the device, the supplied support table must be mounted

before machining the workpiece.

When working on the various workstations, attention

must be paid to the respective direction of rotation of the

sanding belt (indicated by means of directional arrows at

the respective workstations). The direction of rotation

must be determined by means of a grinding test (eg

sparking of a test piece).

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or oth-

erwise is considered misuse.

Misuse:

The Pipe belt sander must neither be used for grinding

flammable materials (e. g. magnesium, wood or similar).

The company St rmer Maschinen GmbH is not liable for

any design and technical modifications on the the Ma-

chine.

Any claims due to damages because of intended use are

excluded.

4 Technical Data

4.1 Table

4.2 Type Plate

Fig. 2: Type Plate KRBS 101

5 Transport, packaging, storage

5.1 Delivery and transport

Delivery

Check if there are any visible transportation damages af-

ter delivery of the Machine. If the Machine shows any

damages, immediately inform the carrier or the distribu-

tor.

WARNING!

Danger in case of misuse!

A misuse of the Machine can result in dangerous sit-

uations.

- Only operate the Machine in the power range given

in the technical specifications.

- Never bypass or override the safety devices.

- Only operate the Machine in a technically flawless

status.

Technical Data Model KRBS 101

Belt dimensions 100 x 2000 mm

Motor output 2.5 kW/3.3 kW

Electrical connection 400 V/50 Hz

Motor speed 1400/2800 rpm

Belt speed 15–30 m/s

Grindable diameter 20 - 76 mm

Adjustable grinding angle 30 - 90° (0° - 60°)

Extraction duct nominal

width outside

2 x 74 mm

Dimensions L x W x H 1250 x 750 x 1140

mm

Weight 159 kg

Description of the device

KRBS 101 | Version 1.03 7

Transport

The device may only be transported upright and only

when the engine is switched off.

Transport with a forklift / pallet truck:

For shipment, the unit is delivered in a box on a pallet so

that it can be transported by forklift or pallet truck.

Transport by Crane:

The machine has a special transport eyelet. Always use

a crane when assembling and transporting the machine

and only hang the hoists in the lifting lug.

5.2 Packaging

All packaging materials and packaging aids used in the

device are recyclable and must always be recycled.

Packaging components made of cardboard are crushed

to give waste paper collection.

The foils are made of polyethylene (PE) and the uphol-

stery parts made of polystyrene (PS). These substances

must be handed over to a recycling center or to the re-

sponsible disposal company.

5.3 Storage

The Machine must be stored thoroughly cleaned in a dry,

clean and frost-free environment.

6 Description of the device

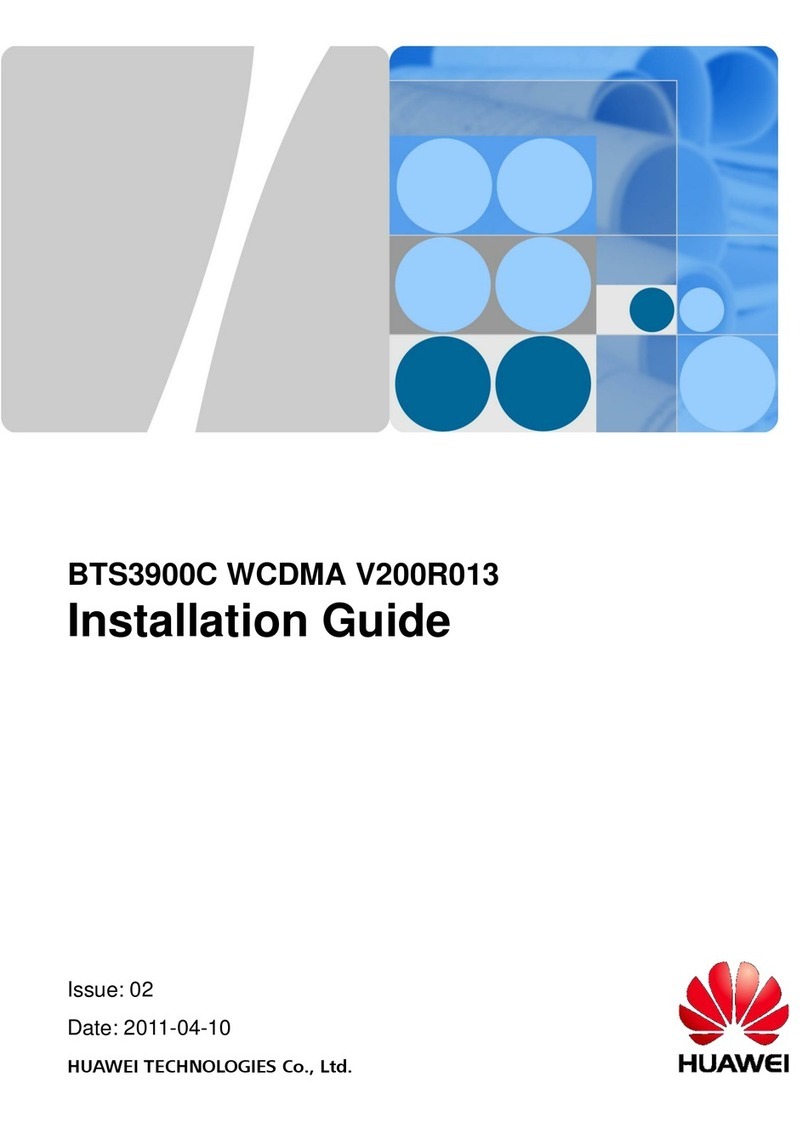

6.1 Image

The illustrations in these operating instructions

serve the general comprehension and may deviate

from the actual type.

Fig. 3: Description of the device

1 Cover for surface grinding station

2 Feed grinding

3 Cover belt grinding station

4 Cover grinding belt

5 Suction

6 Emergency stop button

7 Speed stage switch

8 Changeover switch pipe grinder L - belt sander R

WARNING!

Danger to life due to falling load!

If the weight of the equipment and the permissible lift-

ing capacity of the lifting equipment are not observed

during transport or lifting operations, the machine

may tip over or crash.

- During transport and during lifting work, pay atten-

tion to the weight of the device and the permissible

load capacity of the lifting equipment.

NOTE !

Protect the Machine against humidity.

8 KRBS 101 | Version 1.03

Installation

9 Drilling holes for anchoring

10 Clamping lever for height adjustment

11 Handwheel for adjusting the belt tension

12 Adjustment screw for height of the roller

13 Jaw

14 Clamping lever for clamping jaw

15 Guide cross slide

16 Feed lever

17 Clamping lever for cross slide

18 Grinding angle adjustment

19 Clamping prism

20 Cover tube grinding station

21 Transport lug

22 Adjustment screw

23 Contact rollers

24 START- and STOP Button

25 Workpiece stop

26 Internal hex

6.2 Scope of supply

- 1x Standard-grinding belt 36 grain

- 1x Spanner

- 2x Swarf catchment containers

- 1x Grinding roll Ø 42mm

6.3 Accessories

- Roller for 3/8“ pipe

- Roller for 1/2“ pipe

- Roller for 22 mm pipe

- Roller for 3/4“ pipe

- Roller for 28 mm pipe

- Roller for 1“ pipe

- Roller for 34 mm pipe

- Roller for 1 1/4“ pipe

- Roller for 44 mm pipe

- Roller for 1 1/2“ pipe

- Roller for 50 mm pipe

- Roller for 2“ pipe

- Roller for 62 mm pipe

- Roller for 2 1/2“ pipe

- Roller for 28 mm pipe

- Extraction unit (optional)

7 Installation

In order to attain good functionality as well as a long du-

rability of the Machine the installation site should fulfil

certain criteria.

- The Machine may only be placed and operated in a

dry, venti lated space.

- Do not place the machine in the neighbourhood of

dust- and chips producing machines.

- The place of erection should be free of vibrations,

so away from presses, planers etc.

- The floor hast to be suitable for the work. Pay at-

tention to bearing capacity and levelness of the

floor.

- Protruding parts, like f.i. stop plate grips etc. need

to be made safe in such away that people are not

jeopardized.

- there should be enough place for operation staff

and transport of material.

- Think also of the accessibility for adjustment and

maintenance work.

- Take care of sufficient light (minimal 300 Lux)

ATTENTION!

Check the floor loading capacity before you install

the machine. The place of installation must be capa-

ble of bearing the weight of the machine and the

workpieces.

Installation

KRBS 101 | Version 1.03 9

7.1 Mounting

Fig. 4: Mounting

Step 1: Tighten the machine foot with the four screws on

the ground plate.

Step 2: Lift the machine chassis on the foot. Put an inter-

mediate plate between the pipe notcher and the

foot, before you put him down clefinitely. We acl-

vise you to use a crane. Attention: To litt the

chassis, use the transport eye.

Step 3: Put both screws in and tighten them.

Step 4: Connect the engine cable with the main connec-

tion cable in the chassis.

Fig. 5: Connection of the engine

Step 5: Screw on the feed lever

7.2 Set up

The four mounting points of the machine should be mar-

ked and bare holes should be made for anchorages. The

machine should be rnounted with steel bolts to the floor.

Installation Site

The machine must be set up and operated in a dry, frost-

free and well-ventilated working space. The substrate

must be stable and level, able to support the weight of

the machine and the stresses caused by the operation of

the machine. It must be paid attention to good lighting.

ATTENTION!

The electrical connection of the engine cable has to

be done by an electircan.

NOTE!

After the erection take away the lubrication of the

white rnetal parts, which has been put there for rea-

sons ot protection.

- Use for this the usual solvents

- No water, no nitrosolvents etc.!

10 KRBS 101 | Version 1.03

Assembly

7.3 Electrical connection

You should pay attention that:

- The connection has the same marks (voltage, sup-

ply frequency. phases) as the engine.

- The voltage of 400 V (16A fuse) has to be used.

The plug will be connected to the cables L 1, L2, L3, PE.

Eventually you can operate this machine to with a fixed

connection.

8 Assembly

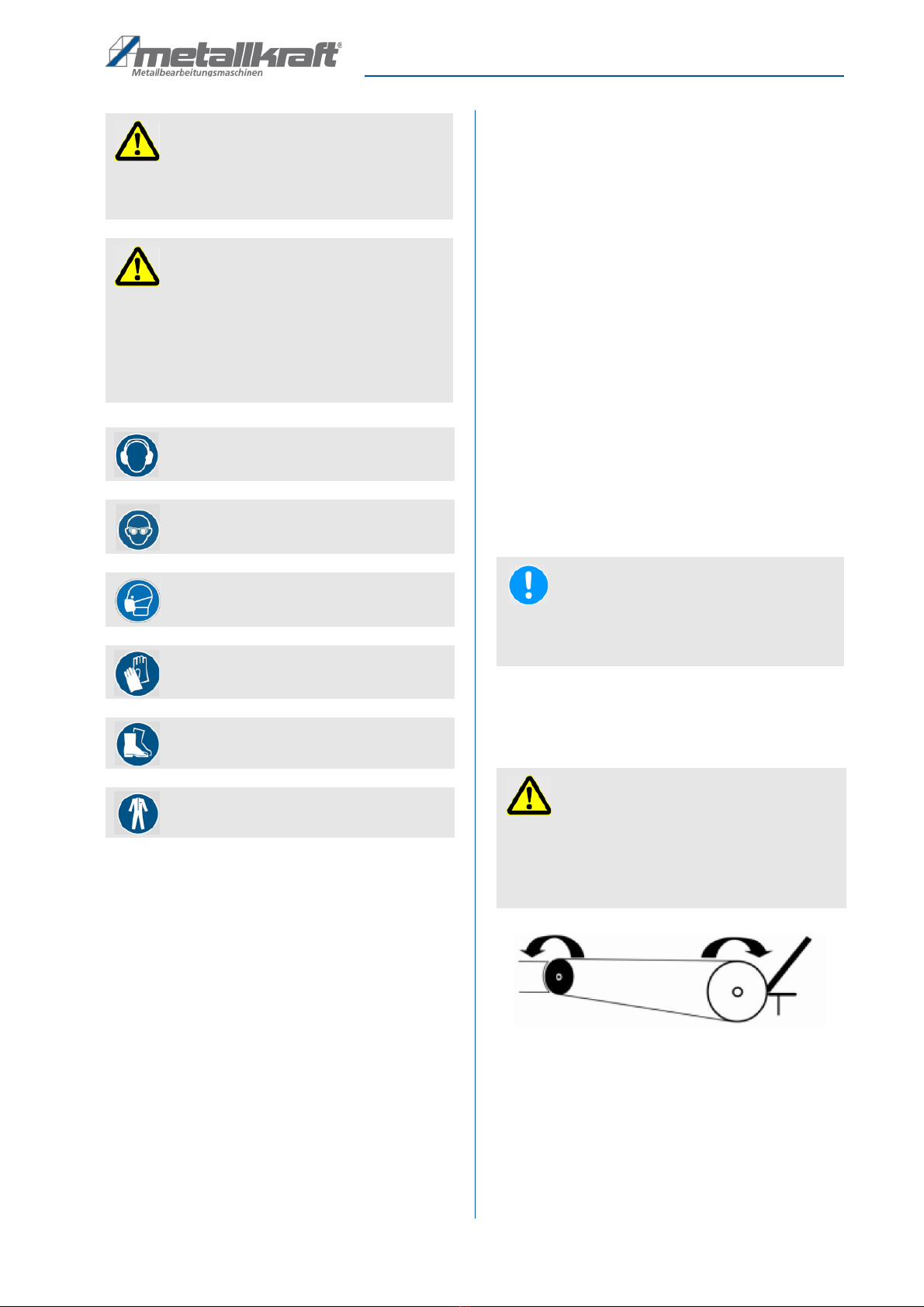

8.1 Belt sander on the back of the de-

vice

Step 1: Pull out the plug.

Step 2: Take out the safety screw and open the cover.

Fig. 6: Adjust the work surface

Step 3: Screw the working surface to the device side with

two Allen screws.

Step 4: Adjust the position of the work surface after loos-

ening the fixing screws on the side of the unit

and then tighten the screws. The distance of the

work surface to the sanding belt may be max. 2

mm.

Step 5: After completion of the work on the rear work sur-

face, the cover must be closed. To do this, fold

down the work surface after loosening the fixing

screws or remove it.

Then close the cover and tighten the fixing

screw.

Fig. 7: Cover on the back of the Machine

8.2 Pipe grinder on the front of the device

Adjust clamping prism

Fig. 8: Prism

The clamping prism has 4 different shots for clamping

different profiles and tubes on the four sides. Depending

on the shape of the workpiece, the most suitable recep-

tacle can be selected and mounted.

DANGER!

Danger by voltage!

Danger by voltage! Working on the electrical connec-

tion may only be done by electricians

ATTENTION!

After connecting the plug. you have to check the run-

ning direction of the engine. Should this be wrong,

you have to change the two phases.

DANGER!

Risk of injury!

Never reach into the gap between the roller and the

housing when the machine is connected to the power

supply!

DANGER!

Risk of injury!

If you do not work at the rear grinding position, the

sanding belt cover must always remain closed!

Assembly

KRBS 101 | Version 1.03 11

Step 1: Loosen the nut on the front of the tension prism

and turn the tension prism so that the desired lo-

cation is on the right side opposite the jaw.

Attention: Both areas of the clamping prism must

always be in the same position!

Fig. 9: Applications

Adjust workpiece angle

The angle of attack of the tool on the sanding belt can be

adjusted with the angle adjustment device in the range of

90 ° (straight workpiece position) to 30 °.

Fig. 10: Adjust workpiece angle

Step 1:To adjust the workpiece angle, loosen the clamp

screw on the angle fixture, turn the workpiece fix-

ture to the desired angle using the scale, and

tighten the clamp screw again.

Adjust feed travel

For the feed travel can be selected from 2 different travel

limits. For this purpose, the feed lever must be screwed

to either the front (A, Fig. 11) or the rear hole (B) at the

bottom of the pipe grinder working position.

Fig. 11: Feed travel

Adjust workpiece stop

In order to process several identical workpieces in the

same way, it is advisable to set a uniform position of the

workpieces in the clamping prism. This is done with the

help of the workpiece stop.

Fig. 12: Workpiece stop

Step 1: Release the clamping lever and move the work-

piece stop to the desired position.

Step 2: Tighten the clamping lever and clamp the work-

piece in the clamping prism. Move the workpiece

stop to the desired position.

Step 3: Fold out the workpiece stop and machine the

workpiece.

Step 4: To process the next workpiece, fold in the work-

piece stop and position the workpiece against

the stop.

A

B

12 KRBS 101 | Version 1.03

Operation

Pipe sander cover

The cover at the pipe grinder working position protects

the operator from workpiece swarf and dust as well as

sparks. The cover must always be mounted and lowered

while the machine is in operation. Due to the transparent

material, the machining process can be well monitored

and controlled.

Fig. 13: Cover

Height adjustment of the contact roller

Fig. 14: Height adjustment

Step 1: Disconnect the power plug.

Step 2: Loosen the two clamping levers R (Fig. 14).

Step 3: Adjust the height of the contact roller with the ad-

justing screw S (Fig. 14). When lowering the con-

tact roller, if necessary, press it down with your

hand. The position of the contact roller (-20 mm -

0 mm - +20 mm) can be read on the scale.

Step 4: Tighten the two clamping levers R.

8.3 Surface grinding station

Step 1: Disconnect the power plug.

Step 2: Open the cover on the upper side of the device

Fig. 15: Surface grinding station

The workpiece must be stopped for processing at the

stop in the running direction of the belt (Fig. 15).

9 Operation

Fig. 16: Never reach into the openings on the Machine

DANGER!

Risk of injury!

The pipe grinder cover must always be folded down

while machining a workpiece!

WARNING!

Danger to life!

There is danger to life for the operator and for other

persons if they do not comply with the following rules.

- The operator must not work if he is under the influ-

ence of alcohol, drugs or medication.

- The operator must not work if he is overworked or

suffers from fatigue and difficulties in concentrating.

- The Machine may only be operated by one person.

Other persons must not enter the working area dur-

ing operation.

Operation

KRBS 101 | Version 1.03 13

Step 1: Check mains plug and cable prior to start of

work.

Step 2: Check whether the workpiece support tables are

firmly tightened.

Step 3: Check whether the correct grinding belt with the

correct grain size is installed.

9.1 Working position pipe grinder

Step 4: Adjust the clamping prism to the workpiece to

be clamped. V-prism for round tubes, stepped

prism for flat and square material.

Step 5: If necessary, adjust the desired grinding angle

via the angle setting. To do this, loosen the Al-

len screw and turn the workpiece clamping

device to the desired degree. After adjust-

ment, tighten the screw again.

Step 6: Depending on the desired feed travel, screw the

feed lever to the appropriate position.

Step 7: If several workpieces with the same dimensions

are to be machined, it is recommended to work

with the workpiece stop.

Step 8: Clamp the workpiece. To do this, place the

workpiece in the clamping prism, push the

clamping block against the material and pull the

clamping lever backwards.

Step 9: Move the carriage transversely until the sanding

belt reaches the entire machining width on the

workpiece. Lock the carriage after setting with

the clamping lever.

Step 10: Check whether the center of the workpiece

matches the center of the roller. If this is not the

case or if a special application is desired, adjust

the height of the contact roller.

Step 11: Set the desired belt speed

Step 12: Select the desired operating mode:

L for pipe grinder (L for surface grinder, R for

belt grinder).

Fig. 17: Operating modes: pipe grinder L , belt grinder R

Step 13: Start the extraction system.

Step 14: Start the sanding belt motor by pressing the

green Start Button.

DANGER!

Danger of injury!

Never put your hands into any openings (e. g.

between grinding belt and housing) of the machine,

as long as it is connected to the mains!

DANGER!

Danger of injury!

During all works with the grinding machine

- well-fitting clothing must be worn.

- no jewellery must be worn.

- no scarfs, ties or similar must be worn.

- in case of long hair, a hairnet must be worn.

Use ear protection!

Use protective glasses!

Use breathing protection!

Use protective gloves!

Use protective boots!

Wear protective clothes!

NOTE!

The belt speed can be changed as required during

the operation of the machine in the preselected direc-

tion of rotation.

DANGER!

Before changing the operation mode pipe grinder or

belt sander the engine must be switched off or stand

still. If the operating mode or direction of rotation is

switched while the engine is running, the machine

shuts off automatically.

14 KRBS 101 | Version 1.03

Operation

Fig. 18: Check the direction of rotation

Step 15: Check the direction of rotation of the grinding

station. The direction of rotation of the sanding

belt must match the corresponding direction of

rotation arrow after selecting the sanding sta-

tion.

Step 16: Fold down the pipe grinder protective cover.

Step 17: Start the grinding process. To do this, push the

clamped workpiece forward against the sand-

ing belt with the feed lever (16, Fig. 3).

Step 18: When the correct radius has been ground, re-

move the tube from the clamp and remove the

outer ridge with the face grinding surface (2).

9.2 Working position belt sander

Step 4: Open the cover on the back of the device. To do

this, unscrew the hexagon socket screw (Fig.

19 left, arrow) and open the cover upwards.

Fig. 19: Open the Cover

Step 5: Screw the work surface with two hexagon socket

screws on the side of the unit and align. The dis-

tance of the work surface to the sanding belt may

be max. 2 mm.

Step 6: Select the desired operating mode:

R for belt sander (L for pipe grinder, L for sur-

face grinder).

Step 7: Start the extraction system.

Step 8: Start the sanding belt motor by pressing the

green START button.

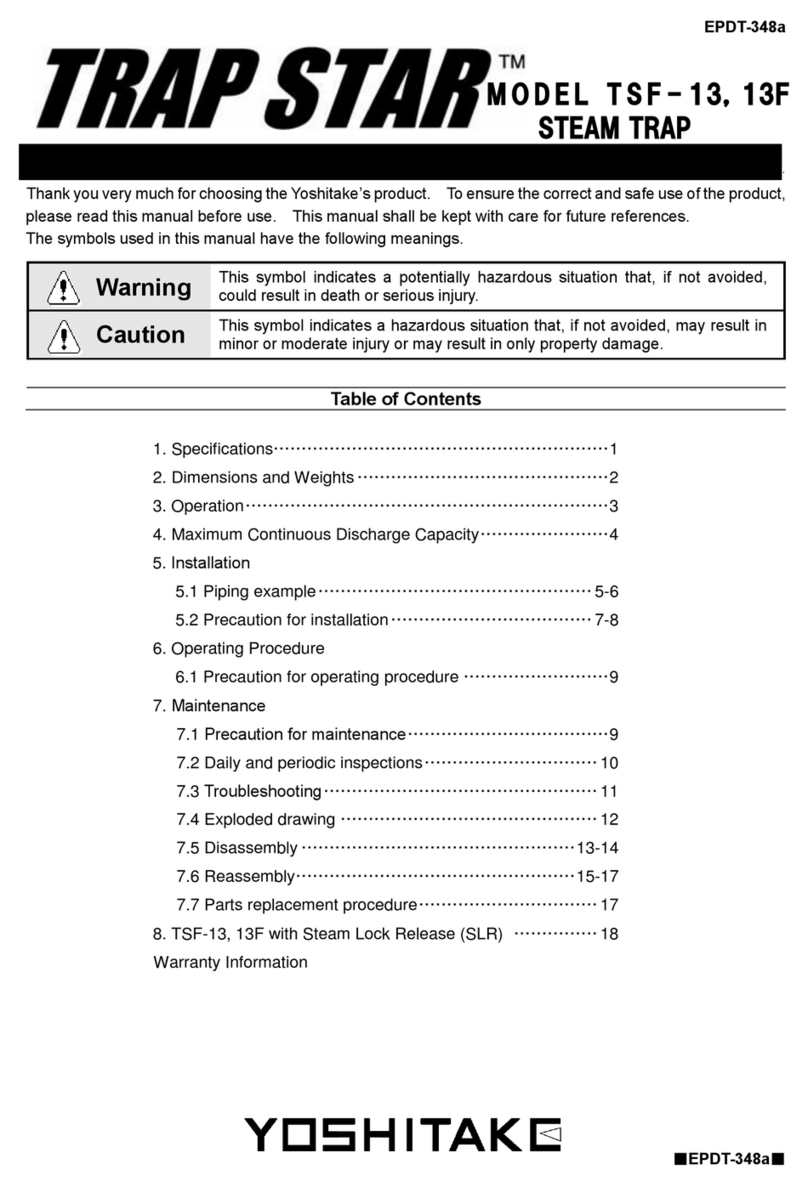

Fig. 20: Check the direction of rotation

Step 9: Check the direction of rotation of the grinding

station. The direction of rotation of the sanding

belt must match the corresponding direction of

rotation arrow after selecting the sanding sta-

tion.

Fig. 21: Flying sparks

Step 10: Start the grinding process. To do this, stop the

workpiece at the work table and guide it against

the sanding belt.

Step 11: If machining of the workpiece on the belt sander

is complete, deburr the workpiece with the sur-

face grinding surface (2, Fig. 3) if necessary.

ATTENTION!

If the sanding belt is turned in the correct direction,

the sparks must be directed downwards! (Fig. 21)

DANGER!

Danger of injury!

Never reach into the gap between the roller and the

housing when the machine is connected to the power

supply!

ATTENTION!

If the sanding belt is turned in the correct direction,

the sparks must be directed downwards! (Fig. 21)

Care maintenance and overhaul/repair

KRBS 101 | Version 1.03 15

Step 12: After completion of the work on the belt grinding

station, the cover must be closed. To do this,

fold down the work surface after loosening the

fixing screws or remove it.

Then close the cover and tighten the fixing

screw.

9.3 Working position surface grinder

Step 4: Open the cover on the upper side of the device.

Fig. 22: Surface grinding station

Step 5. Check the running direction of the sanding belt.

Step 6. Stop the workpiece at the stop in the running di-

rection of the belt and guide it against the sand-

ing belt for processing.

9.4 Shut down the Machine

Step 1: To switch off the Machine, press the red STOP

Button.

Step 2: Switch off the extraction system.

Step 3: Pull the mains plug of the grinding Machine.

10 Care, maintenance and overhaul/re-

pair

Tips and recommendations

In order that the Machine is always in good operat-

ing status, it is necessary to regularly perform care

and maintenance works.

WARNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while performing repair work at the Machine

and expose themselves and others to the danger of

severe injuries.

Have all maintenance works only performed by quali-

fied persons.

DANGER!

Electric shock is life-threatening!

There is a danger of life in case of contact with cur-

rent running through components.

- Always disconnect the mains plug before you start

cleaning and maintenance works.

- Connections and repairs of the electrical equipment

may only be carried out by specialized electrical

staff.

NOTE!

After maintenance, repair and cleaning works, check

if all claddings and protective equipment are prop-

erly reassembled to the machine and that there are

no more tools inside or in the working area of the

Machine.

Damaged protection devices and machine parts must

be properly repaired or replaced by an acknowledged

specialist workshop.

16 KRBS 101 | Version 1.03

Care maintenance and overhaul/repair

10.1 Cleaning and lubrication of the machine

.

The Machine should generally be cleaned after every

use.

Regularly remove the spark arrester and check whether

the interior of the grinding machine must be cleaned.

Brush or wipe all open machine parts in regular intervals

using a broom or a cloth.

Treat blank metallic working surfaces with anti-rust

spray.

Lubricate all moving parts and bearings once per month.

If necessary, replace the graphite support at the level

grinding area.

10.2 Adjust Belt change and Belt run

Step 1: Switch off the machine witt1 the main switch and

unplug the machine.

Step 2: Unscrew the safety screw and open Hie side

coverings plate by turning the lever.

Step 3: Turn the cover of the abrasive wheel (2, Fig. 3)

backwards.

Step 4: Release the bell by turning the hand wheel

(11, Fig. 3).

Step 5: Take out the belt.

Step 6: Put in a new belt.

Step 7: Stretch the belt wilh lhe hand wheel. You have

reached lhe right bell tension if the upper spin-

clle nul is culs out 7 lo 10 mm and the lension is

taken over by the spring only.

Step 8: Afterwareis close lhe cover ancl lighlen the

safety screw again.

Step 9: lt is recommended, to adjust the band running a

bit rough by pushing the belt to the abrasive

wheel and turning the acljustment screw .

Step 10: Close the cover of lhe abrasive wheel and start

the machine.

Step 11: The bell running can now be adjusled by lurning

the acljuslmenl screw. Turn care fully ancl

watch how the bell is cloing. lf you have rea-

ched lhe right adjustmenl, you should be see-

ing lhe same distance on both sicles on lhe

grincling roller.

10.3 Changing the contact roller

Step 1: Disconnect the power plug.

Step 2: Unscrew the safety screw and open the side

cover.

Step 3: Relax the sanding belt by turning the hand-

wheel. Then open the cover of the surface

grinding surface .

Step 4: Remove the sanding belt.

Step 5: Remove the contact roll.

ATTENTION!

- It is indispensable to switch the machine off and to

pull off the mains plug before performing cleaning

and maintenance work!

- Never use solvents or cleaning solutions to clean

plastic parts or lacquered surfaces. The surface may

be dissolved and consequential damage may occur.

ATTENTION!

- Never remove chips or grinding dust with bare

hands. Danger of injuries due to sharp-edged chips.

- Never remove chips or grinding dust with a com-

pressed air blow gun. This can lead to eye injury

and may damage machine parts.

ATTENTION!

Use only belts with the dimension 2000 mm x 100

mm. Check before installation for your own safety

tl1e dimensions of the belt and check it for evt.

structural faults. Always select that belt which suits to

the material to be grinded.

Choose grinding belts with a weid where the opposite

ends are glued together. Grinding belts with the ends

glued together on top, can break when changing the

belt direction.

WARNING!

When changing the sanding belt, the upper limbs between

the drive roller and the sanding belt can be crushed.

WARNING!

Danger of Electric shock!

Disconnect the mains plug before working on the

device.

Care maintenance and overhaul/repair

KRBS 101 | Version 1.03 17

Step 6: Clean the contact surfaces and the receptacle on

the contact roller holder.

Step 7: Insert the new contact roller into the contact roller

holder

Step 8: Apply the sanding belt.

Step 9: Tighten the sanding belt (observe clearance of 7

- 10 mm) and adjust the belt run..

10.4 Troubleshooting

Tension

ATTENTION!

lf one of the following faults takes place, stop the

machine at once. Before searching for lhe mistakes,

switch off and unplug the machine. All repairs ancl

changes may only be clone by qualified ancl trained

staff.

NOTE!

Contact your neared Metallkraft dealer if you are una-

ble to solve the problems with your machine. Please

take the following information from the machine or

from the operating manual so that we can help you in

the best possible way.

- Machine model

- Serial number of the machine

- Year of manufacture

- Exact error description

Fault Possible cause Solution

The machine doesn’t work. 1. The mains plug is not connected

to the power socket.

2. Supply cables defective.

3. Switch defective.

4. Motor defective.

1. Connect the mains plug.

2. Call a service engineer.

3. Call a service engineer.

4. Call a service engineer.

The belt is not running centrically. 1. The belt operation is not adjusted.

2. Bearing damage in the contact

roll.

1. Adjust the belt operation.

2. Remove the contact roll.

The belt contacts the housing at the

level grinding area.

1. The graphite layer is worn. 1. Replace the graphite layer.

Poor grinding result. 1. Wrong grinding belt.

2. Worn grinding belt.

1. Install the correct grinding belt.

2. Change the grinding belt.

18 KRBS 101 | Version 1.03

Disposal recycling of used devices

11 Disposal, recycling of used devices

For environmental benefits it is necessary to ensure that

all components of the machine are only disposed of by

the provided and allowed means.

11.1 Decommissioning

Immediately decommission used machines in order to

avoid later misuse and endangering of the environment

or of persons.

- Dispose of all environmentally hazardous operating

materials of the used device.

- If required, disassemble the machine into easy-to-han-

dle and usable components and parts.

- Supply the machine components and operating materi-

als to the provided disposal routes.

11.2 Disposal of electrical devices

Electrical devices include numerous recyclable materials

as well as environmentally hazardous components.

These components must be disposed of separately and

professionally. In case of doubt, please contact your mu-

nicipal waste management company.

For the recycling process, please request the assistance

of a specialized waste disposal centre if required.

11.3 Disposal of lubricants

The manufacturer of the lubricant makes the disposal in-

structions for the used lubricants available. If applicable,

ask for the product-specific data sheets.

12 Spare parts

12.1 Ordering spare parts

The spare parts may be purchased with the authorised

dealer or directly with the manufacturer. Please find the

corresponding contact data in Chapter 1.2 Customer

service.

Indicate the following basic information for spare part or-

ders:

- Type of device

- Serial number

- Quantity

- Designation

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Spare part orders which do not include the above indica-

tions may not be taken into consideration. If the indica-

tions regarding the mode of dispatch are missing, the

product is dispatched at the discretion of the supplier.

Example

The contact roller for the Combined pipe, section and

belt grinding machine KRBS 101 must be ordered. The

contact roller has the number 218 in the spare parts

drawing 2.

By ordering spare parts, send a copy of the spare parts

drawing (2) with the marked part (contact roller) and

marked positon number (218) to the dealer or spare

parts department and provide the following information:

- Type of device: Combined pipe section and belt

grinding machine KRBS-101

- Item number: 3921001

- Drawing number: 2

- Position nummer: 218

Item number of your device:

Combined pipe, section and belt grinding machine KRBS 101:

3921001

NOTE!

The manufacturer's warranty will become null and

void if non admitted spare parts are being used

DANGER!

Danger of injury by the use of

wrong spare parts!

Dangers may result for the user and damages as well

as malfunctions may be caused by using wrong or

damaged spare parts.

- Only use original spare parts of the manufacturer or

spare parts admitted by the manufacturer.

- Always contact the manufacturer in case of uncer-

tainties.

Spare parts

KRBS 101 | Version 1.03 19

12.2 Spare parts drawings

In case of service, the following drawings shall help to identify the necessary spare parts. If necessary, send a copy of the

parts drawing with the marked components to your authorised dealer.

Fig. 23: Spare Parts Drawing 1 KRBS 101

20 KRBS 101 | Version 1.03

Spare parts

Fig. 24: Spare Parts Drawing 2 KRBS 101

Table of contents

Other Metallkraft Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Eastwood

Eastwood 10049Z operating instructions

Yoshitake

Yoshitake Trap Star TSF-13 manual

SMC Networks

SMC Networks CE Series user manual

OmniCure

OmniCure AC7 Series quick start guide

Ace

Ace SDH38EU Operating and mounting instructions

Graphic Whizard

Graphic Whizard Graphic Whizard GW 6000 instruction manual