Metallkraft HKS 320 User manual

HKS 320

Instruction Manual

HKS 320

HKS 320

Hand-held circular saw

2HKS 320 | Version 1.04

Imprint

Product identification

Hand-held circular saw Item number

HKS 320 3840321

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Information about the operating instructions

Genuine operating instructions

Published: 09.03.2021

Version: 1.04

Language: English

Author: SN

Copyright information

Copyright © 2021 Stürmer Maschinen GmbH, Hallstadt,

Germany.

Stürmer Maschinen GmbH is the sole owner of the con-

tent of these operating instructions.

Forwarding and reproduction of this document as well

as use and notification of its content is not permitted

without explicit consent. Infringements will lead to

claims for damages.

Subject to technical changes and errors.

Contents

1 Introduction .............................................................3

1.1 Copyright............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability ............................................ 3

2 Safety........................................................................3

2.1 Legend of symbols............................................. 3

2.2 Operator responsibility ....................................... 4

2.3 Operating staff qualification ............................... 4

2.4 Personal protective equipment........................... 5

2.5 General safety instructions for power tools ........ 5

2.5.1 General safety instructions.......................... .7

2.6 Specific safety regulations during the sawing

process ............................................................... 7

2.7 Safety data sheets.............................................. 7

2.8 Safety labels on the device ................................ 8

3 Intended use ............................................................8

3.1 Improper use ...................................................... 8

3.2 Residual risks ..................................................... 8

4 Technical Data.........................................................8

4.1 Type plate........................................................... 9

5 Transport, packaging, storage...............................9

5.1 Delivery and transport ........................................ 9

5.2 Packaging........................................................... 9

5.3 Storage ............................................................... 9

6 Description of the device......................................10

6.1 Presentation...................................................... 10

6.2 Scope of delivery.............................................. 11

6.3 Accessories ...................................................... 11

6.4 Saw blade selection ......................................... 11

7 Settings and commissioning ...............................11

7.1 Function of the lower protective cover ............. 11

7.2 Additional safety rules ...................................... 12

7.3 Electrical connection ........................................ 12

7.4 Installation of the saw blade............................. 12

7.5 Removing the saw blade.................................. 13

7.6 Setting the cutting depth .................................. 13

7.7 Using the sighting notch................................... 14

7.8 Application of the saw blade protection device .14

7.9 Kicker lever....................................................... 14

7.10 Dust collection system.................................... 14

7.11 Switch the tool on and off ............................... 15

7.12 Electronic overload protection and load

indicator light ................................................. 15

7.13 Using the device............................................. 16

7.14 Clamping the workpiece................................. 16

7.15 Guide rail ........................................................ 16

8 Care, maintenance and repair .............................17

8.1 Cleaning of the device...................................... 17

8.2 Changing the carbon brushes.......................... 18

8.3 Changing the connecting cable ....................... 18

9 Disposal, recycling of old equipment ................... 18

9.1 Taking out of service ........................................ 18

9.2 Disposal of electrical equipment...................... 18

9.3 Disposal via municipal collection points .......... 18

9.4 Disposal of lubricants....................................... 18

10 Spare parts...........................................................19

11 Wire connection ..................................................21

12 EC-Declaration of Conformity ............................22

Introduction

HKS 320 | Version 1.04 3

1Introduction

You have made an excellent choice in purchasing a

METALLKRAFT metal cutting circular saw.

Carefully read the operating instructions prior to commission-

ing.

They describe correct commissioning, intended use

and safe as well as efficient operation and maintenance

of the metal cutting circular saw. The operating instruc-

tions form part of the metal cutting circular saw. Always

keep them at the metal cutting circular saw's location of

use. In addition to this, the local accident prevention

regulations and general safety provisions for the appli-

cation scope of the metal-cutting circular saw apply.

Figures in this operation manual serve to provide a ba-

sic understanding and may differ from the actual de-

sign.

1.1 Copyright

The contents of these operating instructions are pro-

tected by copyright. Their use is permitted within the

context of using the metal cutting circular saw. Any fur-

ther use shall not be permitted without written consent

by the manufacturer.

To protect our products, we register our rights to our

brands, patents and designs where possible in each in-

dividual case. We take strong action against any viola-

tion of our intellectual property.

1.2 Customer service

Please contact your specialist retailer if you have any

questions regarding your metal-cutting circular saw or

require any technical information. Your specialist retailer

will be happy to support you with specialist advice and

information.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: 0951 96555-111

E-Mail: service@stuermer-maschinen.de

Spare parts orders:

Fax: 0951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

Please submit any information and experiences you

make during application of the machine as these may

be valuable for product improvements.

1.3 Limitation of liability

All data in this operation manual has been compiled on

the basis of the state-of-the-art, valid standards and

guidelines as well as our many years of expertise and

experience.

The manufacturer shall not be liable for damage in the

following cases:

- Failure to comply with the operation manual,

- Unintended use

- Deployment of untrained staff

- Unauthorized conversions,

- Technical changes,

- Use of unauthorised spare parts

The actual scope of delivery may deviate from the de-

scriptions and illustrations in this document as a result of

special variants, optional extras or recent, technical

modifications.

The obligations defined in the supply contract shall ap-

ply in addition to the general terms and conditions and

the manufacturer's general terms and conditions as well

as the statutory regulations valid at the time of the con-

clusion of the contract.

2 Safety

This section provides an overview of all important safety

packages for personal protection as well as safe and re-

liable operation. The individual sections contain addi-

tional, task-specific safety information.

2.1 Legend of symbols

Safety instructions

Safety instructions in this operation manual have been

highlighted with symbols. Safety instructions are indi-

cated by signal terms that express the degree of risk in-

volved.

WARNING!

This combination of symbol and signal term indi-

cates a directly dangerous situation which may

cause death or serious injury if not averted.

CAUTION!

This combination of symbol and signal term indi-

cates a potentially hazardous situation which may

cause minor or light injuries if it is not averted.

4HKS 320 | Version 1.04

Safety

Tips and recommendations

Observe the safety information in these operating in-

structions to minimise the risk of personal injury as well

as material damage and prevent hazardous situations.

2.2 Operator responsibility

Operators are defined as the persons who operate the

machine for commercial or profit-based purposes or

provide the machine to third parties for use or applica-

tion and bear the legal product responsibility in terms of

the protection of users, staff or third parties during oper-

ation.

Obligations of the operator:

If the machine is used for commercial purposes, opera-

tors are subject to the legal stipulations in terms of occu-

pational safety. For this reason, the safety instructions in

these operating instructions as well as the safety, acci-

dent prevention and environmental protection regula-

tions valid at the installation location must be complied

with. In this process, the following shall apply in particu-

lar:

- Operators shall obtain information about valid oc-

cupational safety regulations and determine addi-

tional hazards as part of a risk assessment which

result from the specific operating conditions at the

machine's installation location. Said risk assess-

ment shall be reflected in operating instructions for

machine operation.

- During the entire machine operating time opera-

tors must check whether the operating instructions

they created meet current standards and adapt

the operating instructions where necessary.

- Operators shall clearly manage and specify the re-

sponsibilities for installation, operation, trouble-

shooting, maintenance and cleaning.

- Operators must make sure that all persons han-

dling the machine have read and understood

these operating instructions. Operators must also

regularly train staff and notify of the hazards.

- Operators shall provide staff with the required pro-

tective equipment and wearing the required pro-

tective equipment shall be mandatory.

Operators shall also be responsible for maintaining the

machine in a technically perfect condition. For this rea-

son, the following shall apply:

- Operators shall make sure that the maintenance

intervals described in these operating instructions

are complied with.

- Operators shall regularly check that the safety

equipment is fully functional and complete.

2.3 Operating staff qualification

The different tasks described in these operating instruc-

tions require different levels of skills in terms of the qual-

ifications of operating staff working with the machine.

Exclusively persons of whom it can be expected that

they reliably complete assigned tasks shall be author-

ised to carry out any tasks. Persons whose reactions

have been impaired shall not be authorized, e.g. drug

users, users under the influence of alcohol or medica-

tion.

These operating instructions specify the following per-

sonal qualifications for the different tasks:

ATTENTION!

This combination of symbol and signal term indi-

cates a potentially dangerous situation which may

cause material damage or harm the environment if it

is not averted.

NOTE!

This combination of symbol and signal term indi-

cates a potentially dangerous situation which may

cause material damage or harm the environment if it

is not averted.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for efficient and reliable

operation.

WARNING!

Risk from inadequately qualified persons!

Inadequately qualified persons are unable to assess

the risks when handling the machine, thus putting

themselves and others at risk of severe injuries.

- All work must be carried out by qualified persons

only.

- Keep inadequately qualified persons and children

away from the work area.

Safety

HKS 320 | Version 1.04 5

Operating staff:

Operating staff has undergone an induction by the oper-

ator about the entrusted tasks and potential hazards re-

sulting from improper behaviour. Tasks which go be-

yond normal operation may only be carried out by the

operator if they are listed in the operation manual and

the operator has made him/herself familiar with them.

Qualified electrician

Due to the electrician's specialised training, know-how,

experience and knowledge of pertinent standards and

regulations the electrician is in a position to work on the

electrical systems, and autonomously identify and avoid

potential hazards.

Specialist staff:

As a result of specialist training, expertise, experience

and skills in terms of the relevant standards and regula-

tions, specialist staff is able to complete the tasks they

are entrusted with and independently identify hazards

and avert risks.

Manufacturer:

Certain work must be carried out by manufacturer spe-

cialist staff only. Other staff is not permitted to carry out

this work. Contact our customer service to have the work

carried out.

2.4 Personal protective equipment

Personal protective equipment is intended to protect the

health and safety of persons at work. Staff must wear the

personal protective equipment indicated in individual

sections of these operating instructions when carrying

out the different tasks on the device.

The personal protective equipment is described in the

following section:

2.5 General safety instructions for power tools

Keep all safety notes and instructions for future reference.

1 Workplace safety

a) Keep your work area clean and well lit. Disorder and

unlit work areas can lead to accidents.

b) Do not work with the power tool in a potentially explo-

sive environment containing flammable liquids, ga-

ses or dust. Power tools generate sparks that can

ignite the dust or vapours.

c) Keep children and other persons away when using

the power tool. If distracted, you may lose control of

the power tool.

2 Electrical safety

a) The plug of the power tool must fit into the socket. The

plug must not be altered in any way. Do not use ad-

apter plugs together with earthed power tools.

Unchanged plugs and suitable sockets reduce the

risk of electric shock.

b) Avoid physical contact with grounded surfaces such

as pipes, heaters, cookers and refrigerators. There is

an increased risk of electric shock if your body is

earthed.

c) Keep power tools away from rain or moisture. Water

ingress into a power tool increases the risk of electric

shock.

Eye protection

Protective glasses protect the eyes against pro-

jected parts and splashes of liquid.

Hearing protection

Hearing protection protects the ears against hear-

ing damage caused by noise. .

Respiratory protection

Respiratory protection serves to protect the respira-

tory tract and lungs against absorbing dust parti-

cles.

Protective gloves

Protective gloves protect the hands from compo-

nents with sharp objects as well as friction, abrasion,

and deep-cut injuries.

Safety shoes

Safety shoes protect feet from pinching, falling parts

and slipping on slippery surfaces.

Protective clothing

Protective work clothing means tight-fitting clothing

with low tear resistance.

WARNING!

Read all safety instructions, instructions, illustrations

and technical data provided with this power tool.

Failure to comply with the following instructions may

result in electric shock, fire and/or serious injury.

6HKS 320 | Version 1.04

Safety

d) Do not misuse the connecting cable to carry or hang

up the power tool or to remove the plug from the soc-

ket. Keep the power cord away from heat, oil, sharp

edges or moving parts. Damaged or tangled connec-

ting cables increase the risk of electric shock.

e) If you use a power tool outdoors, only use extension

cords that are suitable for outdoor use. Using an ex-

tension cord suitable for outdoor use reduces the risk

of electric shock.

f) If operation of the power tool in a humid environment

cannot be avoided, use a sensor current circuit brea-

ker. The use of an earth leakage circuit breaker re-

duces the risk of electric shock.

3 Safety of persons

a) Be alert, pay attention to what you are doing and use

common sense when using a power tool. Do not use

a power tool if you are tired or under the influence of

drugs, alcohol or medication. A moment of careles-

sness while using a power tool can cause serious in-

jury.

b) Wear personal protective equipment and always

wear safety goggles. Wearing personal protective

equipment, such as a dust mask, non-slip safety

shoes, safety helmet or hearing protection, depen-

ding on the type and use of the power tool, reduces

the risk of injury.

c) Avoid unintentional commissioning. Make sure that

the power tool is switched off before connecting it to

the power supply and/or battery, picking it up or car-

rying it. If you have your finger on the switch when

carrying the power tool or connect the power tool to

the power supply while it is switched on, this may

cause accidents.

d) Remove adjusting tools or spanners before turning on

the power tool. A tool or spanner that is in a rotating

part of the power tool may cause injury.

e) Avoid abnormal posture. Ensure a secure stand and

keep your balance at all times. This will help you to

control the power tool in unexpected situations.

f) Wear suitable clothing. Do not wear loose clothing or

jewellery. Keep hair and clothing away from moving

parts. Loose clothing, jewellery or long hair can be

caught by moving parts.

g) If dust extraction and collection devices can be fitted,

they must be connected and used correctly. The use

of a dust extraction system can reduce dust hazards.

h) Do not lull yourself into a false sense of security and

do not ignore the safety rules for power tools, even if

you are familiar with the power tool after many uses.

Careless action can lead to serious injury within a

fraction of a second.

4 Use and treatment of the power tool

a) Do not overload the power tool. Use the power tool in-

tended for the job. With the right power tool you will

work better and safer in the specified power range.

b) Do not use a power tool whose switch is defective. A

power tool that can no longer be switched on or off is

dangerous and must be repaired.

c) Unplug the power cord and/or remove a detachable

battery pack before making adjustments to the ma-

chine, changing insert tool parts or putting away the

power tool. This precaution prevents the power tool

from starting accidentally.

d) Keep unused power tools out of the reach of children.

Do not allow anyone to use the power tool who is not

familiar with it or who has not read these instructions.

Power tools are dangerous if they are used by inex-

perienced persons.

e) Carefully maintain power tools and insert tools. Check

that moving parts function properly and do not jam,

that parts are not broken or damaged in such a way

that the function of the power tool is impaired. Have

damaged parts repaired before using the power tool.

Many accidents are caused by poorly maintained po-

wer tools.

f) Keep cutting tools sharp and clean. Carefully mainta-

ined cutting tools with sharp cutting edges are less li-

kely to jam and are easier to guide.

g) Use power tool, insert tool, insert tool, etc. according

to these instructions. Take into account the working

conditions and the task to be performed. The use of

power tools for applications other than those inten-

ded can lead to dangerous situations.

h) Keep handles and grip surfaces dry, clean and free

of oil and grease. Slippery handles and grip surfaces

do not allow safe operation and control of the power

tool in unforeseen situations.

5 Service

a) Have your power tool repaired only by qualified per-

sonnel and only with original spare parts. This will

ensure that the safety of the power tool is maintained.

Safety

HKS 320 | Version 1.04 7

2.5.1 General safety instructions

The following must be observed:

- Use the safety devices and fasten them securely. Ne-

ver work without guards and keep them in working or-

der.

- Always keep the machine and its working environment

clean. Ensure adequate lighting.

- Always secure your workpiece when working. Ensure

that there is an adequate supporting surface.

- The design of the circular metal saw must not be chan-

ged and it must not be used for purposes other than

the operations foreseen by the manufacturer.

- Never work under the influence of concentration disor-

ders, fatigue, drugs, alcohol or medication.

- Keep children and persons not familiar with the circular

metal saw away from their working environment.

- Do not pull on the power cord to remove the plug from

the socket. Protect the cable from heat, oil and sharp

edges.

- Immediately rectify any faults that impair safety.

- Protect the metal circular saw from moisture (danger of

short circuit).

- Before each use of the metal circular saw, make sure

that no parts are damaged. Damaged parts must be

replaced immediately to avoid sources of danger.

- Do not overload the metal circular saw! You will work

better and safer in the specified performance range.

Use the correct saw blade! Make sure that the saw

blade is not damaged.

- Only use original spare parts and accessories to avoid

possible dangers and risks of accidents..

2.6 Specific safety regulations during the sa-

wing process

Keep hands away from the cutting area and the saw

blade. Hold your second arm by the auxiliary handle or

the motor housing. If both hands hold the saw, they can-

not be cut by the saw blade.

Never reach under the workpiece. The cover offers no

protection under the workpiece.

Adjust the cutting depth to the thickness of the work-

piece. Less than one full tooth of the saw blade should

be visible under the workpiece.

Never hold the workpiece in your hands or above your

leg when cutting. Fix the workpiece to a stable platform.

It is important to support the workpiece properly to mini-

mise the strain on the body and prevent loss of control..

Hold the unit in the insulated places when performing an

application where the saw blade may come into contact

with hidden wires or its own cable.

By contact with a "live" wire, exposed metal parts of the

tool become "live" and the operator receives an electric

shock.

Always use a rip fence or straight edge guide when rip-

ping. This improves cutting accuracy and reduces the li-

kelihood of blade jamming.

Always use saw blades with the correct size and shape

(diamond versus round) of the mandrel holes. Saw bla-

des that do not match the mounting parts of the saw run

off-centre and lead to loss of control.

Never use damaged or incorrect mandrel flanges or

screws. The mandrel flanges and bolts have been spe-

cially designed for your saw to ensure optimum perfor-

mance and operational reliability.

Never use damaged or incorrect saw blade washers or

screws. The blade washers and bolts have been speci-

ally designed for your saw to ensure optimum perfor-

mance and reliability.

2.7 Safety data sheets

You can obtain safety data sheets for dangerous goods

from your specialist dealer or by calling +49 (0) 951 /

96555-0

Specialist dealers can find safety data sheets in the

download area of the partner portal.

8HKS 320 | Version 1.04

Intended use

2.8 Safety labels on the device

Safety markings and instructions are attached to the cir-

cular metal saw (Fig.1), which must be observed and

followed.

Fig. 1: Safety labels

Damaged or missing safety symbols on the machine

can lead to incorrect handling with personal injury and

damage to property. The safety symbols attached to the

machine must not be removed. Damaged safety sym-

bols must be replaced immediately.

From the time when the signs are not immediately re-

cognisable and understandable at first sight, the ma-

chine must be taken out of operation until the new signs

are attached.

3 Intended use

This saw is designed exclusively for sawing metal and

aluminium. This machine must not be used for cutting

other materials. Do not use this saw for cutting wood.

The metal circular hand saw may only be operated by

persons who are trained and instructed in the use and

maintenance of these machines.

The compact dimensions of the HKS 320 ensure easy

handling. It is suitable for both private and commercial

use. This saw is not intended for working with wood or

mineral materials.

The machine must not be operated in explosive environ-

ments.

Proper use also includes compliance with all the infor-

mation in this manual. Any use beyond the intended use

or any other use is considered as misuse.

Stürmer Maschinen GmbH accepts no liability for any

design or technical modifications to the machine.

Claims of any kind for damage due to improper use are

excluded.

3.1 Improper use

The metal circular saw must not be used for sawing

flammable materials (e.g. magnesium, wood or similar).

3.2 Residual risks

Even if all safety regulations are observed and the ma-

chine is used in accordance with the instructions, there

are still residual risks, which are listed below:

- There is a risk of injury to the upper limbs (e.g. hands,

fingers).

- Danger from falling or flinging workpieces or chips.

4 Technical Data

1

2

WARNING!

Danger in case of misuse!

Misuse of the circular metal saw can lead to dange-

rous situations.

- Only operate the circular metal saw within the po-

wer range specified in the technical data.

- Never bypass or disable the safety devices.

- Only operate the metal circular saw in a technically

perfect condition.

General data HKS 320

Length (product) approx. [mm] 500

Width/depth (product) approx. [mm] 342

Height (product) approx. [mm] 355

Net weight approx. [kg]

8,4

Supply voltage [V] 230

Phase(s) [Ph] 1

Current type AC

Mains frequency [Hz] 50

Drive motor output [kW] 1,8

Saw blade speed(s) [1/min] 1700

Saw blade diameter [mm] 320

Saw blade bore [mm] 25,4

Saw blade thickness [mm] 2

Sound pressure level [dB(A)] 99

Sound power level [dB(A)] 110

Cutting Depth [mm] 128

Cutting depth on the guide rail [mm] 121

Transport, packaging, storage

HKS 320 | Version 1.04 9

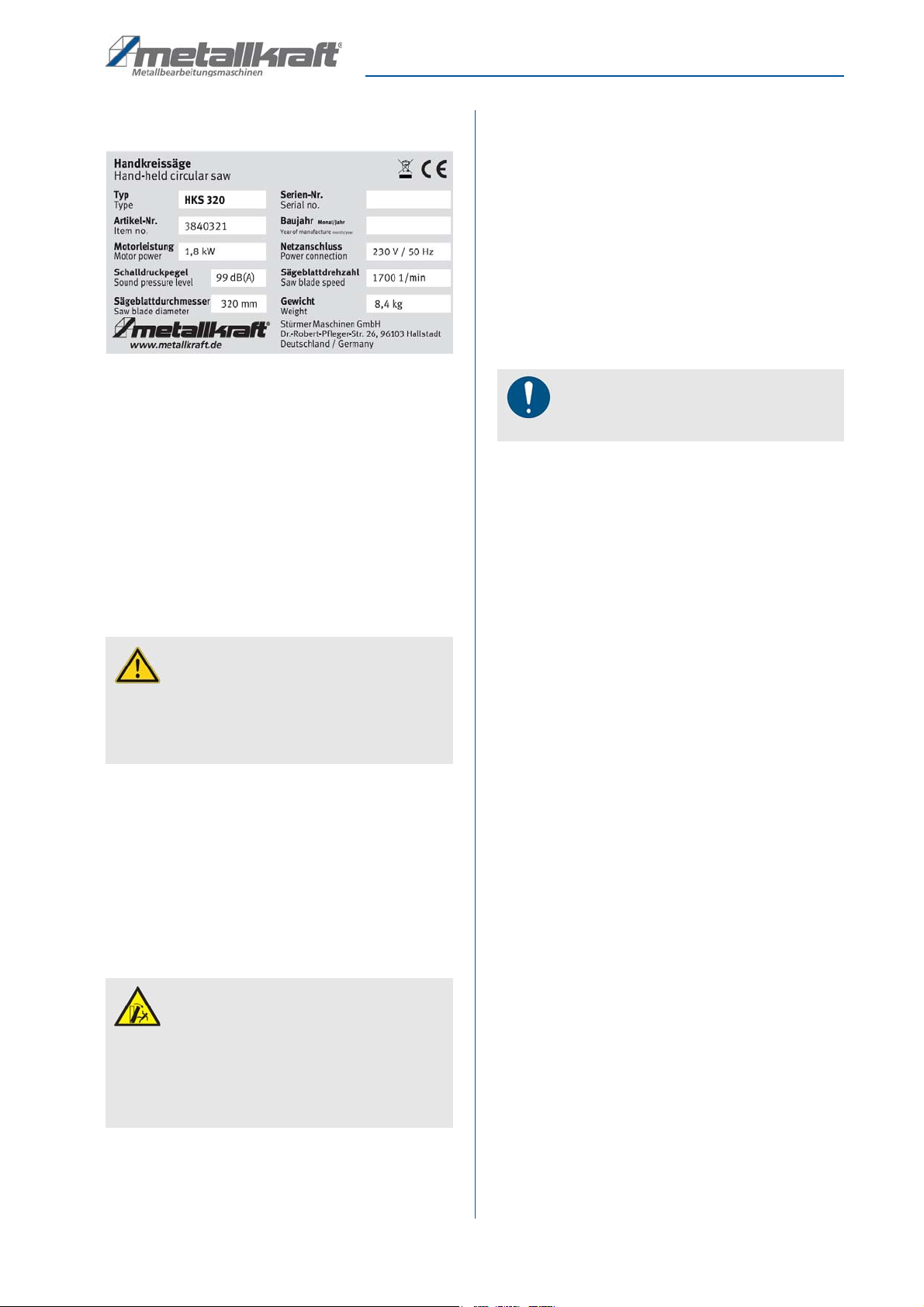

4.1 Type plate

Fig. 2: Type plate HKS 320

5 Transport, packaging, storage

5.1 Delivery and transport

Delivery

Check the metal-cutting circular saw for visible transport

damage upon delivery. In case of visible damage to the

metal-cutting circular saw, immediately notify the carrier

or your retailer.

Transport

Improper transport of individual devices, unsecured de-

vices stacked on top of each other or next to each other

in packed or already unpacked condition is accident-

prone and can cause damage or malfunctions for which

we do not grant any liability or guarantee.

Transport the scope of delivery secured against shifting

or tilting with a sufficiently dimensioned industrial truck

to the installation site.

General risks during internal transport

Devices may only be transported by authorized and

qualified persons. Act responsibly during transport and

always consider the consequences. Refrain from daring

and risky actions.

Gradients and descents (e.g. driveways, ramps and the

like) are particularly dangerous. If such passages are

unavoidable, special caution is required.

Before starting the transport check the transport route

for possible danger points, unevenness and disturban-

ces as well as for sufficient strength and load capacity.

Danger points, unevenness and disturbance points

must be inspected before transport. The removal of

danger spots, disturbances and unevenness at the time

of transport by other employees leads to considerable

dangers.

Careful planning of internal transport is therefore essen-

tial.

5.2 Packaging

All packaging materials and packing aids of the metal-

cutting circular saw are suitable for recycling and must

always be disposed of using material-based recycling

systems. Packaging materials made of cardboard must

be shredded and recycled as waste paper. The foils are

made of polyethylene (PE), padding is made of polysty-

rene (PS). Dispose of these substances at a recycling

centre or hand them over to a qualified waste disposal

company.

5.3 Storage

Store the metal circular saw thoroughly cleaned in a dry,

clean and frost-free environment. It must not be placed

in the same room with chemicals. During storage, the

metal circular saw should be covered with a plastic foil.

All bare metal surfaces must be provided with a suitable

rust protection.

CAUTION!

Injuries caused by parts falling over or off a forklift,

pallet truck or transport vehicle.

Only use means of transport that can carry the total

weight and are suitable for it.

CAUTION: DANGER OF TIPPING!

The device may be lifted unsecured by a maximum

of 2cm.

Employees must be outside the danger zone, the

reach of loads. Warn employees and, if necessary,

advise employees of the hazard.

NOTE!

Protect the metal circular saw from moisture.

10 HKS 320 | Version 1.04

Description of the device

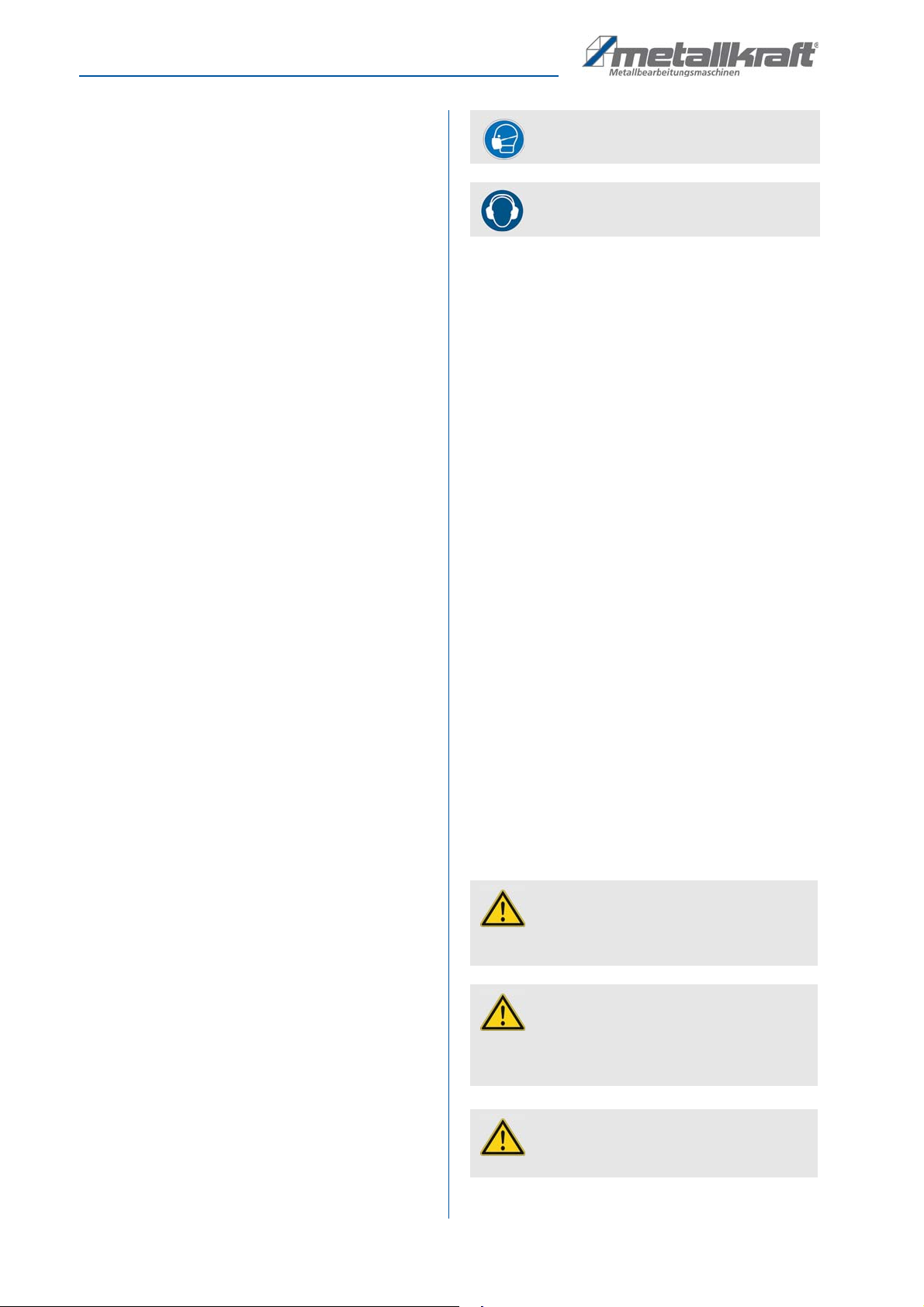

6 Description of the device

6.1 Presentation

Illustrations in these operating instructions are for basic un-

derstanding and may differ from the actual design.

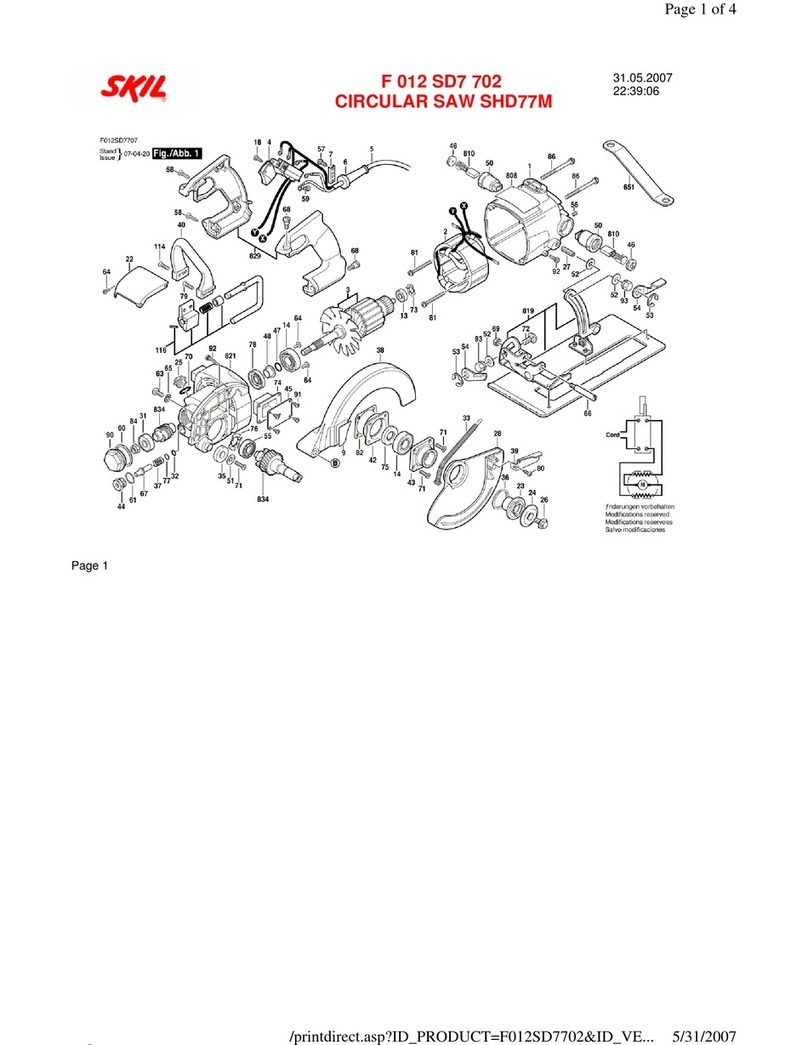

Fig. 3: Description of the HKS 320

1 Load indicator lamp

2 Release button of the locking device

3 Vacuum cleaner connection

4 Main handle

5 Power cable

6 Release switch

7 Depth locking lever

8 Depth scale

9 Base plate

10 Motor unit

11 Clip switch

12 Dust connection cap

13 Vacuum cleaner connection

14 Cover of the dust chamber

15 Lower saw blade protection

16 Upper saw blade guard

17 Guide play adjusters

18 Mandrel locking lever

19 Side handle

20 Kicker lever

21 L-hexagon key stored in the main handle

1

2

3

4

21

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Settings and commissioning

HKS 320 | Version 1.04 11

6.2 Scope of delivery

- Metal circular hand saw HKS 230

- Allen key

- Operating instructions

6.3 Accessories

- Guide rail 1400 mm

Item number: 3850030

- Saw blade for stainless steel Ø 320 x 2,2 x 25,4 mm Z84

Item number: 3853203

- Saw blade for steel Ø 320 x 2,2 x 25,4 mm Z80

Item number: 3853204

6.4 Saw blade selection

When sawing with a metal circular saw, make sure that

you choose the right saw blade or the correct tooth pitch

of the saw blade.

If the tooth pitch is too small and the cutting length too

long, the cut material cannot be absorbed by the

spaces between the teeth.

If the tooth pitch is too large, the saw tooth will start to

chop; this can cause teeth to break out.

7 Settings and commissioning

Causes of a setback and related warnings

A kickback is a sudden reaction to a jammed, jammed

or misaligned saw blade. It causes an uncontrolled lif-

ting of the saw out of the workpiece towards the opera-

tor.

If the saw blade is jammed or tied up by closing the kerf,

the saw blade stops and the motor reaction quickly

drives the unit back towards the operator.

If the saw blade is twisted or misaligned during cutting,

the teeth on the rear edge of the blade can dig into the

top of the wood, causing the blade to climb out of the

kerf and jump back towards the operator.

The kickback is a result of misuse of the saw or incorrect condi-

tions. This can be avoided by taking precautions.

a) Hold the saw with both hands and position your arms

so that they can withstand kickback forces. Position

your body on both sides of the saw blade, but not in

line with the blade. A kickback can cause the saw to

jump backwards. However, the kick-back forces can

be controlled by the operator if the appropriate

precautions are taken.

b) If the saw blade is jammed or if a cut is interrupted for

any reason, release the switch and hold the saw mo-

tionless in the material until the saw blade comes to a

complete stop.

c) Never attempt to remove the saw from the workpiece

or pull the saw backwards while the blade is moving.

Doing so may result in kickback.

d) When restarting a saw in the workpiece, centre the

saw blade in the kerf and check that the teeth do not

interfere with the material. If the saw blade is jam-

med, it may run up or kick back from the workpiece

when the saw is restarted.

e) Support large panels to minimise the risk of the blade

jamming and kickback. Large panels tend to sag un-

der their own weight. Supports must be placed on

both sides under the plate near the cut line and near

the edge of the plate.

f) Do not use blunt or damaged saw blades. Dull saw

blades create a narrow kerf that causes excessive

friction, blade jamming and kickback.

g) The locking levers for blade depth and bevel must be

set firmly and securely before cutting. If the saw

blade setting shifts during cutting, this can cause

jamming and kickback.

h) Be especially careful when blindly sawing into exi-

sting walls or other areas. The protruding blade may

cut objects that may cause kickback.

7.1 Function of the lower protective cover

a) Before each use, check that the lower guard is pro-

perly closed. Do not operate the saw if the lower guard

does not move freely and close immediately. Never

clamp or tie the lower guard in the open position. If the

saw is accidentally dropped, the bottom guard may

be bent. Lift the lower guard with the pull-back handle

and ensure that it moves freely and does not touch the

blade or other parts at any angle or depth of cut.

b) Check the function of the lower protection spring. If the

protection and the spring do not function properly, they

must be serviced before use. The lower protection may

be sluggish due to damaged parts, rubbery deposits

or accumulation of dirt.

DANGER!

Verwenden Sie nur Sägeblätter, deren maximal

zulässige Drehzahl der Maximaldrehzahl der Säge

entspricht oder darüber liegt.

12 HKS 320 | Version 1.04

Settings and commissioning

c) The lower guard may only be retracted manually for

special cuts such as "plunge cuts" and "compound

cuts". Raise the lower guard by pulling back the

handle. As soon as the blade enters the material, the

lower guard must be released. For all other sawing

applications the lower guard should work automati-

cally.

d) Always make sure that the lower guard covers the

saw blade before placing the saw on the workbench

or floor. An unprotected rotating saw blade causes

the saw to run backwards and cut everything in its

path. Note that it takes a while for the saw blade to

stop after the switch is released.

7.2 Additional safety rules

- Tighten the saw blade holding screw and all

clamps before operation.

- Secure the workpiece properly. The workpiece

should be straight and firmly clamped to avoid

possible movement and jamming.

- Allow the saw blade to come to a complete stop

before removing or securing the workpiece or

changing the workpiece angle.

- Check the inner surfaces of the mandrel flanges

and the sides of the saw blade for foreign objects.

- Check the saw blade for cracks or other damage

before operation. Replace the cracked or dama-

ged saw blade immediately.

- Never start the tool with the workpiece against the

saw blade.

- Let the motor reach full speed before cutting.

- Important: When the cut is complete, release the

switch and wait until the rotating saw blade has

come to a complete stop before stopping the saw.

- Never operate the tool in an area with combustible

solids, liquids or gases. Sparks from the commuta-

tor / carbon brushes can cause a fire or explosion.

- There are certain applications for which this tool is

designed. The manufacturer strongly recom-

mends NOT to modify and/or use this tool for ap-

plications other than those for which it was desi-

gned. If you have any questions about the

application, DO NOT use the tool, but contact the

manufacturer.

- When cutting plastics, avoid melting the plastic by

using a saw blade specially designed for cutting

plastics.

- Do not overheat the tips of the saw blade. The use

of excessive force will not speed up the cutting

process. Let the tool determine the best feed

speed.

7.3 Electrical connection

The mains voltage must correspond to the voltage indi-

cated on the tool's nameplate.

Under no circumstances should the tool be used if the

power supply cable is damaged. A damaged cable

must be replaced immediately by an authorised service

agent. Do not attempt to repair the damaged cable

yourself. Using damaged power cords may result in

electric shock.

Extension cable

If an extension cable is required, it must have a suffi-

cient cross-section to avoid excessive voltage drop or

overheating. An excessive voltage drop will reduce the

power and may cause the motor to fail. Use only U.L.

and CSA listed extension cords. Never use two exten-

sion cords together. Use a long cable instead.

Saw blade

Only use saw blades with a diameter according to the

markings on the tool's nameplate: Only use saw blades

with a blade set (cutting width) of 1.8 mm to 3.6 mm and

a blade core thickness of at least 1.5 mm to a maximum

of 3.0 mm.the saw blades must be suitable for speeds

of up to 1700 rpm or faster. Do not use a grinding wheel

on this machine.

7.4 Installation of the saw blade

Wear breathing protection!

Wear hearing protection!

WARNING

Disconnect the machine from the electrical mains

before installing or removing the saw blade.

CAUTION

Only use saw blades that are permissible in terms of

dimensions and maximum speed. For your own

safety, only use original metal power saw blades.

CAUTION

Avoid injuries by touching the saw teeth.

Settings and commissioning

HKS 320 | Version 1.04 13

Step 1: Remove all accumulated residue in the guards

and around the assembly mandrel.

Step 2: Clean the inner flange of the mandrel (Fig.4)

Align the flange so that the correct side faces

the saw blade and place the new saw blade

on the shaft. Make sure that the teeth are poin-

ting forward.

Step 3: Place the outer mandrel flange on the mandrel

with the correct side towards the saw blade.

Step 4:Replace the saw blade holding screw and

tighten it hand-tight by turning it clockwise.

Step 5: Push the mandrel locking lever in and turn the

mandrel by hand until the lock engages the

mandrel. Tighten the saw blade holding

screw. Turn the arbor with the spanner to en-

sure that the arbor lock has loosened and re-

lease the arbor lock.

Fig. 4: Mounting the saw blade

7.5 Removing the saw blade

Removal is in the reverse order to the installation of the

saw blade. However, special care must be taken to en-

sure that no one is injured by the saw blade.

Step 1: Push the saw blade locking lever in and turn the

shaft with the spanner on the holding bolt until

the lock engages the shaft. Loosen the saw

blade holding bolt with the spanner supplied

and release the mandrel lock.

Step 2: Loosen the saw blade holding screw completely

and lift it and the outer flange away. Make sure

that the saw blade does not fall down.

Step 3: Carefully turn the lower blade guard out of the

way. The saw blade can now be removed.

7.6 Setting the cutting depth

Set the required cutting depth. A depth scale is availa-

ble.

Step 1: Release the depth adjustment locking lever.

Step 2: Set the value to the required depth.

Protective gloves

Wear protective gloves for all work connected with

the saw blade.

NOTE!

Use saw blades with a suitable arbor hole. The saw

blade must be designed for the maximum nominal

speed of the machine or higher. Avoid contact with

the blade teeth to prevent injury.

NOTE!

Make sure that the saw blade is centred (it is possi-

ble to tighten the saw blade at an angle between the

flanges).

WARNING

Disconnect the machine from the electrical mains

before adjusting the cutting depth.

14 HKS 320 | Version 1.04

Settings and commissioning

Step 3: Tighten the lever (Fig.5)

Fig. 5: Setting the cutting depth

7.7 Using the sighting notch

To facilitate free-hand cutting, there is a sight notch on

the front of the base (Fig.6). Align the cutting line on the

workpiece with the visor notch. In addition, the saw

blade is visible through small gaps in the cover to per-

fectly align the saw blade to the intended cutting line.

Fig. 6: Sighting notch

7.8 Application of the saw blade protection de-

vice

To test the function of the lower blade guard, rotate the

guard the entire stroke. Make sure that the guard can

fully return to the closed position under its own spring

tension. If the guard is found to be sluggish or stuck in

any position, the problem must be corrected before the

unit is used again. It usually only needs to be cleaned.

To clean, first remove the saw blade and then clean the

swivel joint of the guard all around. All other repairs

should be carried out by an authorized service techni-

cian.

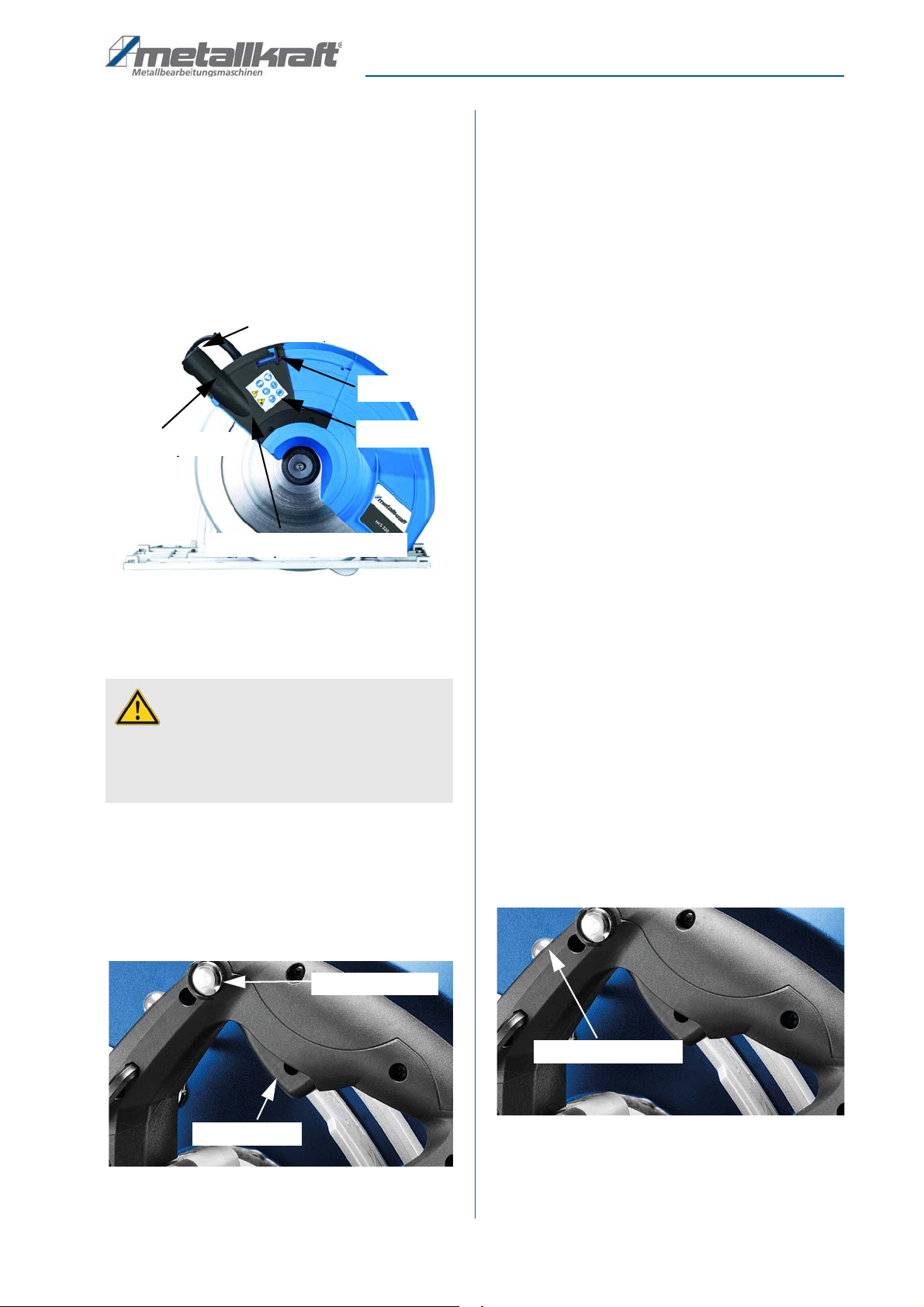

7.9 Kicker lever

When cutting materials with a soft core, such as a com-

posite panel, the lower saw blade guard often does not

open automatically. In this case, the kicker lever (Fig.7)

can be used so that the lower saw blade guard (Fig.8)

can open just enough. Simply press the lever with the

thumb of your left hand without taking your hand off the

side handle. Let the protection work automatically as

usual after starting.

Fig. 7: Lever

Fig. 8: Lower blade guard

7.10 Dust collection system

A suction device should always be used. Connect a

suitable hose and an extraction system to the dust ex-

traction port of the machine.

If no suction system is available, close the cap of the

dust port (Fig.9). There is a dust chamber in which a

small amount of dust or chips can accumulate. The dust

WARNING

The locking lever for the depth adjustment must be

firm and secure before cutting. If the saw blade

adjustment shifts during cutting, this can cause jam-

ming and kickback.

Locking lever for the

depth setting

Depth scale

Sighting notch

Kicker lever

Lower blade guard

Settings and commissioning

HKS 320 | Version 1.04 15

chamber is built into the upper saw blade guard. Clean

the dust chamber frequently to avoid overfilling.

Step 1: To clean the dust chamber, push the clip

upwards.

Step 2: Turn the dust chamber cover to the open posi-

tion and release the dust.

Step 3: When you are finished, put the cover back in the

closed position.

Fig. 9: Dust chamber

7.11 Switch the tool on and off

Step 1: Hold the device with both hands. Hold the de-

vice by the main handle and the side handle.

Switch on

Step 2: Press the button (Fig.10) to unlock.

Step 3: Press the release button (Fig.10).

Fig. 10: Trigger switch

Switch off

Step 1: Release the trigger switch.

Step 2: Wait until the saw blade stops rotating.

Step 3: Make sure that no body parts come into contact

with the saw blade while it is still rotating!

Step 4: Always have the lower saw blade guard closed

as soon as you remove the device from the

workpiece.

In this way the saw blade is again completely covered

by the outer protective cover.

7.12 Electronic overload protection

and load indicator light

This unit is equipped with a load indicator light that

shows the operator the load conditions, and whenever

the switch is turned on and the load conditions are nor-

mal, the indicator light is solid green (Fig. 11).

When the load approaches the overload conditions, the

indicator light will flash red.

If the operator continues to operate the machine under

overload conditions for an extended period of time, the

electronic overload protection unit will shut down the

machine.

The higher the overload, the faster the machine swit-

ches off.

In this case, always remove the machine from the work-

piece and let the machine run without load for a few mi-

nutes to allow the motor to cool down before continuing.

This prevents the motor from burning out.

Fig. 11: Load indicator light

WARNING

Make sure that the voltage of the circuit corresponds

to the voltage indicated on the machine's name-

plate and that the switch is set to "OFF" before

connecting the tool to the circuit.

Dust chamber

Clip

Dust port cap

Dust extractor port

Dust chamber cover

Lock release button

Trigger switch

Load indicator light

16 HKS 320 | Version 1.04

Settings and commissioning

7.13 Using the device

Effective control of this powerful saw requires two-hand

operation for maximum protection.

Do not use this tool continuously for 30 minutes. Pro-

perly support the workpiece and hold the saw BOTH

HANDS to avoid loss of control that could result in injury.

Always hold the side handle with your left hand and the

rear handle with your right hand to properly support the

saw by hand. Protect your eyes from injury with safety

glasses. Do not use cutting fluids or lubricants for the

saw blade.

Sawing

The unit must reach full speed before cutting starts and

should only be switched off after cutting is finished.

Operate the saw only away from you (push the circular

saw forward) and never in your direction (do not pull the

circular saw backward).

If you saw in your direction, there is a risk that the circu-

lar saw will accelerate out of the cutting groove (kick-

back) and cause serious injury.

The lower saw blade guard should open automatically

when it hits the edge of the workpiece. If it does not

open automatically, help it at the beginning of the cut by

pressing the kicker lever with the thumb of the left hand.

This will open the lower saw blade guard by about 20

degrees.

Saw cut:

Step 1: Make sure that the cutting depth is set as desi-

red.

Step 2: Place the front part of the sawing plate on the

workpiece.

Step 3: Switch on the machine.

Step 4: Push the device in cutting direction. Make sure

that the sawing plate remains firmly on the

workpiece.

Step 5: Switch off the device and let the lower blade

guard close completely after the cutting pro-

cess is finished.

Immersion cut

Step 1: Set the depth stop to the maximum cutting depth

and manually open the lower saw blade guard

until the saw blade touches the workpiece.

Step 2: When the device dips, the circular saw must be

held very securely, otherwise there is a risk of

kickback!

Step 3: Switch on the machine, let it reach full speed

and dip the saw into the workpiece.

Step 4: As soon as the saw is completely cut, push the

machine forward.

Step 5: When the cutting is complete, turn the machine

off and let it stop before removing it from the

workpiece.

7.14 Clamping the workpiece

Secure the workpiece properly. The workpiece should

be straight and firmly clamped to avoid possible move-

ment and jamming when the cut is almost complete.

Provide adequate support for long or wide workpieces.

Never position large or long workpieces so that they

bend in the middle or on the cutting surface, as this can

cause the saw blade to jam and bounce back. Instead,

support the workpiece with several wooden slats near

the cutting surface. Make sure that the saw blade has

come to a complete stop before removing, securing or

changing the workpiece angle.

Do not force the cut. Let the saw cut at the speed all-

owed by the type of cut and the workpiece.

7.15 Guide rail

Guide rails (Fig.12) help to achieve precise straight cuts

and increase safety (This is an optional accessory). The

guide rail can be secured with C-clamps on request.

There are 2 guide play adjusters for optimum fit and sa-

fety. Adjust them evenly so that there is no looseness

and the base still slides freely.

Fig. 12: Guide rail

DANGER!

Keep the cable away from the cutting area so that it

does not get caught in the workpiece.

Guide clearance adjustor

Care, maintenance and repair

HKS 320 | Version 1.04 17

Visor / shatter protection:

The visor / shatter protection strip must be cut over its

entire length before first use. The rubber strip must be

backed up when first cutting from a workpiece.

If no backing workpiece is used for the first cut, the rub-

ber strip can be torn or damaged by the saw blade.

Once it is cut, it perfectly matches the cut edge and pro-

tects the material from splinters. Once the size is deter-

mined, the operator can see at a glance exactly where

the cutting line is located. This saves a lot of time and ef-

fort for precise cuts.

8 Care, maintenance and repair

8.1 Cleaning of the device

.

The metal circular saw should always be cleaned after

each use.

Blow out all air channels with dry compressed air at re-

gular intervals. All plastic parts should be cleaned with a

soft, damp cloth.

Wear protective goggles when using compressed air.

Clean all parts of the lower saw blade protection mecha-

nism to ensure smooth operation.

Cleaning and maintenance table

Treat bare metallic work surfaces with anti-rust spray.

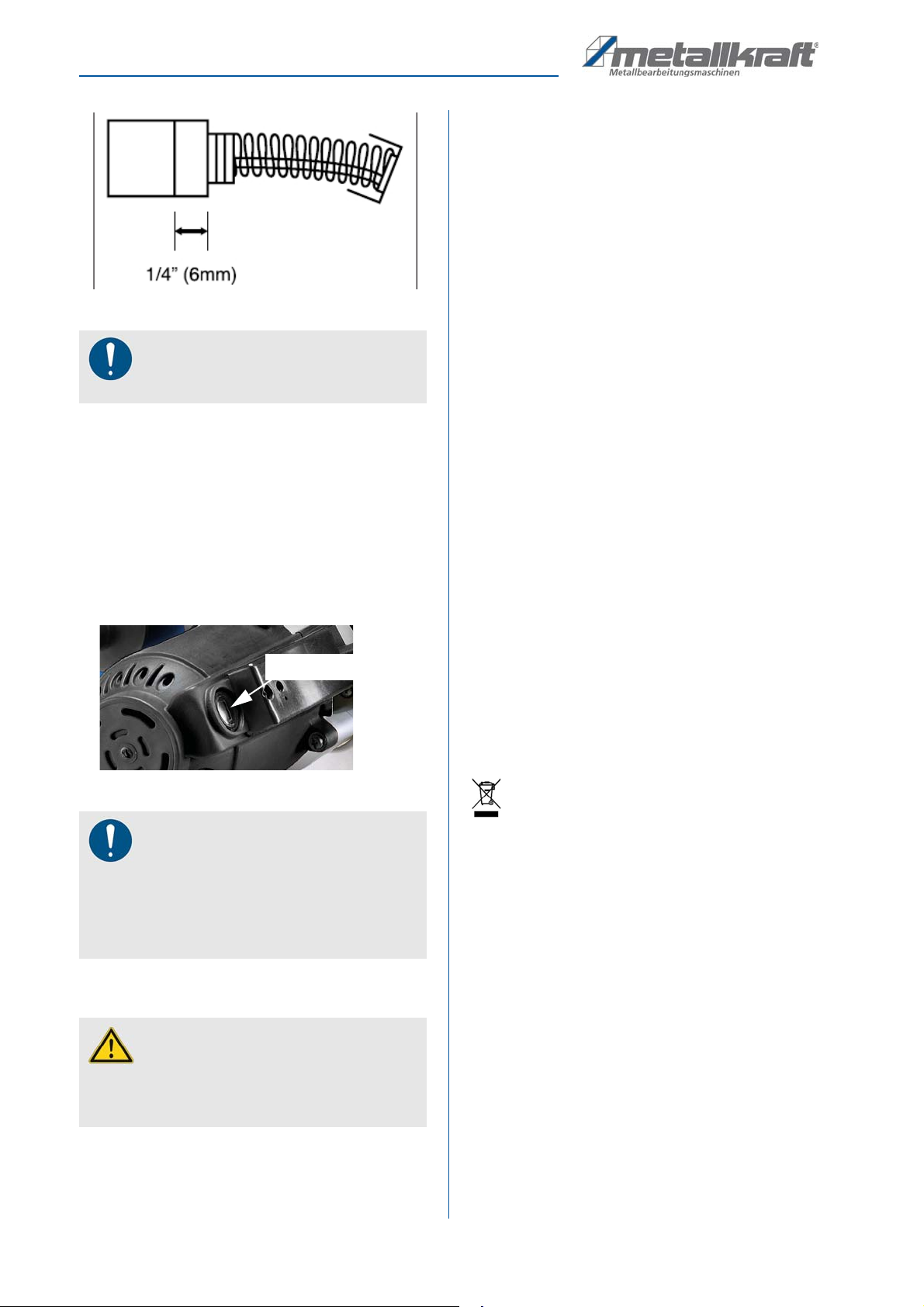

8.2 Changing the carbon brushes

The carbon brushes are subject to normal wear and

must be replaced when they reach the end of their ser-

vice life (Fig.13).

DANGER

Before each use of the circular saw, the space

inside the saw blade guard must be cleared of chips

and deposits.

DANGER!

Before starting cleaning and maintenance work on

the machine, pull the mains plug.

Tips and recommendations

To ensure that the metal circular saw is always in

good operating condition, regular care and main-

tenance work must be carried out.

WARNING!

Danger with insufficient qualification of

persons!

Insufficiently qualified persons cannot assess the

risks involved in repair work on the device and

expose themselves and others to the risk of serious

injury.

Have all maintenance work performed only by quali-

fied personnel.

DANGER!

Danger to life through electric shock!

Contact with live components may cause danger to

life.

- Always disconnect the mains plug before starting

cleaning and maintenance work.

- Connection and repair of the electrical equipment

may only be carried out by a qualified electrician.

NOTE!

After care, maintenance and repair work, check

whether all coverings and protective devices have

been properly reinstalled on the machine.

Damaged safety devices and machine parts must be

repaired or replaced by the customer service.

DANGER!

- Never use solvents to clean plastic parts or painted

surfaces. Dissolving of the surface and resulting

consequential damage can occur.

Maintenance

interval in

operating hours

Maintenance point

every day before

use

Remove chips and clean ma-

chine

every day before

use

Check saw blade, replace if

necessary.

ATTENTION!

Never remove the chips or grinding dust with your

bare hand. There is a risk of cuts from sharp-edged

chips.

18 HKS 320 | Version 1.04

Disposal, recycling of old equipment

Fig. 13: Wear carbon brushes

Proceed as follows:

Step 1: Remove the brush caps (Fig.14) and pull out the

old brushes.

Step 2: Replace them with new brushes (always replace as

a pair).

Step 3: Make sure they are properly aligned and slide

freely. Installation is in reverse order to removal.

Step 4: Then put the brush caps back on.

Fig. 14: Brush cap

8.3 Changing the connecting cable

9 Disposal, recycling of old equipment

In the interest of the environment, care must be taken to

ensure that all components of the machine are disposed

of only via the designated and approved channels.

9.1 Taking out of service

Discarded equipment must be taken out of service im-

mediately in a professional manner in order to avoid la-

ter misuse and danger to the environment or persons.

- Dispose of all environmentally hazardous operating

materials from the old device.

- If necessary, disassemble the machine into manage-

able and recyclable assemblies and components.

- Dispose of the machine components and operating

materials in the designated disposal route.

9.2 Disposal of electrical equipment

Electrical devices contain a large number of recyclable

materials and environmentally harmful components.

These components must be disposed of separately and

professionally. In case of doubt, contact the municipal

waste disposal service. If necessary, use the services of

a specialized waste disposal company for processing.

9.3 Disposal via municipal collection points

Disposal of used electrical and electronic equipment

(Applicable in the countries of the European Union and

other European countries with a separate collection sy-

stem for this equipment).

The symbol on the product or its packaging in-

dicates that this product should not be treated as nor-

mal household waste, but should be handed in at a col-

lection point for the recycling of electrical and electronic

equipment. By helping to dispose of this product cor-

rectly, you will help protect the environment and the

health of those around you. Environment and health are

endangered by incorrect disposal. Material recycling

helps to reduce the consumption of raw materials. For

more information about recycling this product, contact

your local authority, municipal waste disposal service or

the store where you purchased the product.

9.4 Disposal of lubricants

The lubricant manufacturer provides the disposal inst-

ructions for the lubricants used. If necessary, ask for the

product-specific data sheets.

NOTE!

The carbon brushes must always be replaced in pairs.

NOTE!

If you have removed the carbon brushes only for

inspection, make sure that you reinsert them in the

same place and in the same order. Otherwise, the

result would be a reduction in performance and

increased brush wear.

DANGER!

Danger to life through electric shock!

To avoid danger from electricity, work on the power

supply line may only be carried out by the manu-

facturer or an authorized specialist workshop.

Brush cap

Spare parts

HKS 320 | Version 1.04 19

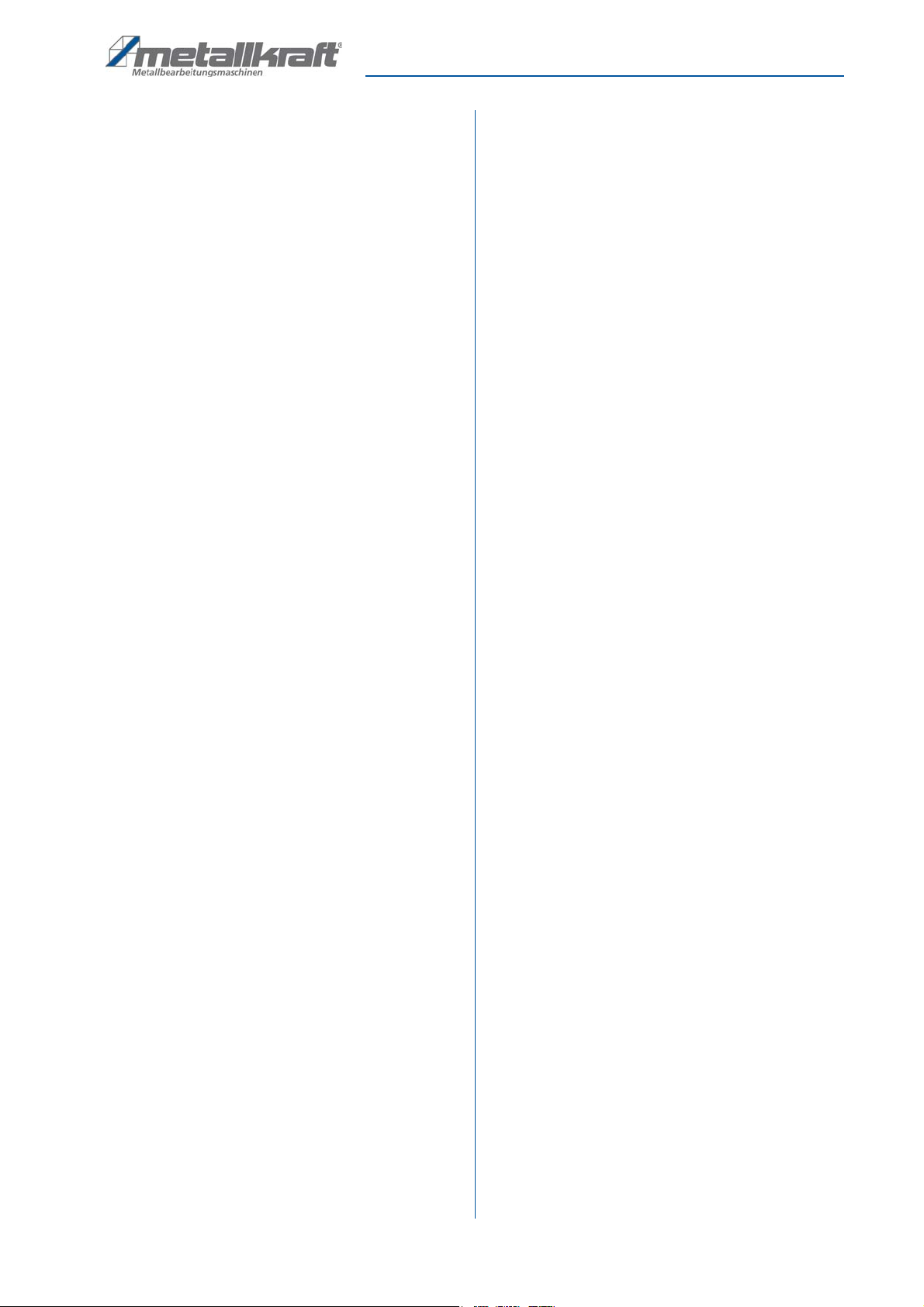

10 Spare parts

10.1 Ordering spare parts

The spare parts can be obtained through the authorized

dealer or directly from the manufacturer.

Contact details:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatzteile@stuermer-maschinen.de

Please specify the following key data when making in-

quiries or ordering spare parts:

- Device type

- Item number

- Position number

- Year of manufacture

- Quantity

- desired mode of shipment (mail, freight, sea, air,

express)

- Shipping address

Orders for spare parts without the above information

cannot be considered. In the absence of information

about the mode of shipment, the shipment will be made

at the discretion of the supplier.

Information on the device type, article number and year

of manufacture can be found on the type plate attached

to the device.

Example

The handle for the Hand-held circular saw HKS 320

must be ordered. The handle has the number 49 in the

spare parts drawing 1.

By ordering spare parts, send a copy of the spare parts

drawing (1) with the marked part (handle) and marked

positon number (49) to the dealer or spare parts depart-

ment and provide the following information:

- Type of device: HKS 320

- Item number: 3840321

- Position number: 49

- Drawing number: 1

NOTE!

The manufacturer's warranty is void if non-approved

spare parts are used.

DANGER!

Risk of injury due to use of incorrect spare

parts!

The use of incorrect or faulty spare parts can cause

danger for the operator and damage and malfuncti-

ons.

- Only original spare parts from the manufacturer or spare

parts approved by the manufacturer must be used.

- In case of any uncertainties, always contact the manu-

facturer.

20 HKS 320 | Version 1.04

Spare parts

10.2 Spare parts drawing

The following drawing should help to identify necessary spare parts in case of service.

Fig. 15: Spare parts drawing 1

This manual suits for next models

1

Table of contents

Other Metallkraft Saw manuals