3

TABLE SAW SAFETY

1. ALWAYS USE SAW BLADE GUARD, riving knife and

antikickback pawls assembly for every through–sawing

operation. Through–sawing operations are those in which

the blade cuts completely through the workpiece when

ripping or crosscutting. Always be sure blade guard is

tightened securely.

2. ALWAYS HOLD WORKPIECE FIRMLY against the miter

gauge or rip fence.

3. ALWAYS USE a push stick or push block, especially when

ripping narrow stock. Refer to ripping instructions in this

Operator’s Manual where the push stick is covered in

detail. A pattern for making your own push stick is

included on page 25.

4. NEVER PERFORM ANY OPERATION FREEHAND, which

means can using hands to support the workpiece, but

always use either the fence OR the miter gauge to

position and guide the workpiece.

18. ALWAYS USE IN A WELLVENTILATED AREA. Remove

sawdust frequently. Clean out sawdust from the interior

of the saw to prevent a potential re hazard. Attach a

vacuum to the dust port for additional sawdust removal.

19. NEVER LEAVE THE SAW RUNNING UNATTENDED. Do

not leave the saw until the blade comes to a complete

stop.

20. For proper operation follow the instructions in this

Operator’s Manual entitled ASSEMBLY AND

ADJUSTMENTS (Page 8). Failure to provide sawdust

fall-through and removal hole will allow sawdust to build

up in the motor area resulting in a re hazard and

potential motor damage.

21. USE ONLY saw blades recommended with the warning

that the riving knife shall not be thicker than the width of

the groove cut by the saw blade and not thinner than the

body of the saw blade.

22. USE PUSH-STICK OR PUSH BLOCK to feed the

workpiece past the saw blade. The push-stick or push

block should always be stored with the machine when not

in use.

SAW BLADE GUARD ASSEMBLY, ANTI-KICKBACK

ASSEMBLY AND RIVING KNIFE

Your table saw is equipped with a blade guard assembly,

anti-kickback assembly and riving knife that covers the blade

and reduces the possibility of accidental blade contact. The

riving knife is a at plate that ts into the cut made by the saw

blade and effectively ghts kickback by lessening the tendency

of the blade to bind in the cut. The blade guard assembly and

antikickback assembly can only be used when making through

cuts that sever the wood. When making rabbets and other

cuts that make non through cuts, the blade guard assembly

and antikickback assembly must be removed and riving knife

lowered to the non through cut position marked on the riving

knife. Two anti-kickback pawls are located on the sides of the

riving knife that allow the wood to pass through the blade in

the cutting direction but reduce the possibility of the material

being thrown backwards toward the operator. Use all

components of the guarding system (blade guard assembly,

riving knife and anti-kickback assembly) for every operation

for which they can be used including all through cutting.

If you elect not to use any of these components for a

particular application exercise additional caution regarding

control of the workpiece, the use of push sticks, the position

of your hands relative to the blade, the use of safety glasses,

the means to avoid kickback and all other warnings contained

in this manual and on the saw itself. Replace the guarding

systems as soon as you return to thru-cutting operations.

Keep the guard assembly in working order.

KICKBACKS

KICKBACKS: Kickbacks can cause serious injury. A kickback

occurs when a part of the workpiece binds between the saw

blade and the rip fence, or other xed object, and rises from

the table and is thrown toward the operator. Kickbacks can be

avoided by attention to the following conditions.

How to Avoid Kickbacks and Protect Yourself from

Possible Injury:

a. Be certain that the rip fence is parallel to the saw blade.

b. Do not rip by applying the feed force to the section of the

workpiece that will become the cut-off (free) piece. Feed

force when ripping should always be applied between the

saw blade and the fence; use a push stick for narrow work,

6 in. (152 mm) wide or less.

5. NEVER STAND or have any part of your body in line with

the path of the saw blade. Keep your hands out of the

saw blade path.

6. NEVER REACH behind or over the cutting tool for any

reason.

7. REMOVE the rip fence when crosscutting.

8. DO NOT USE a molding head with this saw.

9. DIRECTION OF FEED. Feed work into a blade against the

direction of rotation of the blade.

10. NEVER use the rip fence as a cut-off gauge when

crosscutting.

11. NEVER ATTEMPT TO FREE A STALLED SAW BLADE

without rst turning the saw OFF. Turn power switch OFF

immediately to prevent motor damage.

12. PROVIDE ADEQUATE SUPPORT to the rear and the

sides of the saw table for long or wide workpieces.

13. AVOID KICKBACKS (work thrown back towards you) by

keeping the blade sharp, the rip fence parallel to the saw

blade and by keeping the riving knife, anti-kickback pawls

assembly and guards in place, aligned and functioning.

Do not release work before passing it completely beyond

the saw blade. Do not rip work that is twisted, warped or

does not have a straight edge to guide it along the fence.

Do not attempt to reverse out of a cut with the blade

running.

14. AVOID AWKWARD OPERATIONS and hand positions

where a sudden slip could cause your hand to move into

the saw blade.

15. NEVER USE SOLVENTS to clean plastic parts. Solvents

could possibly dissolve or otherwise damage the material.

Only a soft damp cloth should be used to clean plastic

parts.

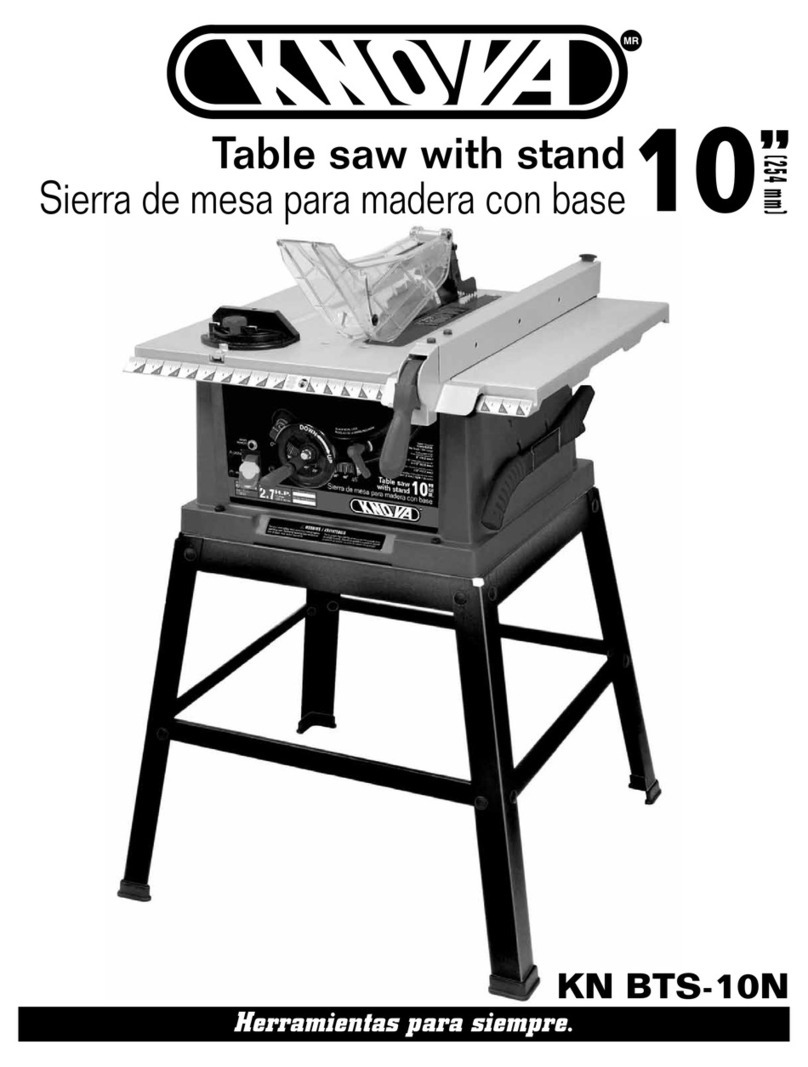

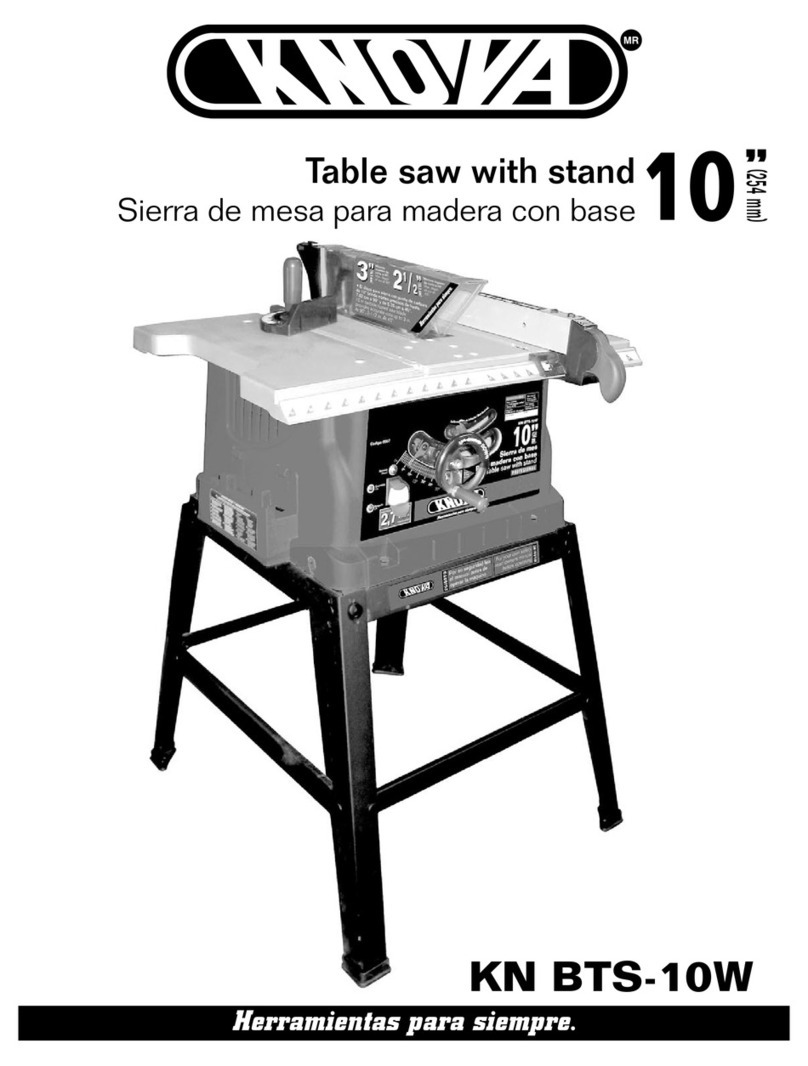

16. MOUNT your table saw on a bench or stand before

performing any cutting operations. Refer to ASSEMBLY

on page 8. Secure tool properly to prevent unexpected

movement.

WARNING

FREEHAND CUTTING IS THE MAJOR

CAUSE OF KICKBACK AND FINGER/HAND

AMPUTATIONS. NEVER USE THE MITER GAUGE

AND FENCE SIMULTANEOUSLY.

WARNING

17. Never cut metals or masonry products with this

tool. This table saw is designed for use on wood

and wood-like products only.