Metallkraft HKS 230 User manual

HKS 230

Instruction Manual

HKS 230

HKS 230

Metal-cutting manual circular

2HKS 230 | Version 3.06

Imprint

Product identification

Metal-cutting manual circular saw Article number

HKS 230 3840231

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Germany

Fax: +49 (0) 951 96555 - 55

E-mail: [email protected]

Internet: www.metallkraft.de

Information about the operating instructions

Genuine operating instructions

according DIN EN ISO 20607:2019

Published: 22.11.2021

Version: 3.06

Language: English

Author: MS

Copyright information

Copyright © 2021 Stürmer Maschinen GmbH, Hallstadt,

Germany.

Subject to technical changes and errors.

Contents

1 Introduction .............................................................3

1.1 Copyright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety........................................................................3

2.1 Legend of symbols.............................................. 3

2.2 Operator responsibility........................................ 4

2.3 Operating staff qualification ................................ 4

2.4 Personal protective equipment ........................... 5

2.5 General safety precautions................................. 5

2.6 Safety labels on the metal cutting circular saw... 6

2.7 Safety data sheets .............................................. 6

3 Intended Use............................................................6

3.1 Reasonably foreseeable misuse......................... 6

3.2 Residual risks ..................................................... 6

4 Technical Data.........................................................7

4.1 Table................................................................... 7

4.2 Type plate ........................................................... 7

5 Transport, packaging, storage...............................7

5.1 Delivery and transport......................................... 7

5.2 Packaging........................................................... 7

5.3 Storage ............................................................... 7

6 Machine Description ...............................................8

6.1 Illustrations.......................................................... 8

6.2 Scope of supply .................................................. 8

6.3 Selecting the saw blade...................................... 8

7 Settings and commissioning .................................8

7.1 Installing the saw blade ...................................... 8

7.2 Setting the cutting depth..................................... 9

7.3 Setting the bevel angle ....................................... 9

7.4 Using the cutting guide display......................... 10

7.5 Switching the circular saw on and off ............... 10

7.6 Setting the rip fence.......................................... 10

7.7 Saw blade guard function ................................. 11

7.8 Handling the manual circular saw..................... 11

7.9 Securing workpieces......................................... 12

8 Care, Maintenance and Repairs ...........................12

8.1 Cleaning the machine ....................................... 13

8.2 Changing the carbon brushes........................... 13

8.3 Changing the power supply cable..................... 13

9 Disposal, Recycling of used Device..................14

9.1 Decommissioning ............................................. 14

9.2 Waste disposal of electric equipment ............... 14

9.3 Disposal of lubricants........................................ 14

10 Spare Parts ..........................................................14

10.1 Ordering spare parts....................................... 14

10.2 Spare parts drawing....................................... 15

11 EC Declaration of Conformity ............................18

12 Notes ....................................................................19

Introduction

HKS 230 | Version 3.06 3

1Introduction

You have made a good choice by purchasing the

METALLKRAFT hand-held circular saw.

Read the operating instructions carefully before using the ma-

chine.

These are an important part of the machine and must be

kept near the machine and accessible to every user.

The operating instructions inform you about the proper

commissioning, the intended use as well as the safe and

efficient operation and maintenance of the metal hand-

held circular saw.

In addition, observe the local accident prevention regula-

tions and general safety regulations for the area of appli-

cation of the metal hand-held circular saw.

1.1 Copyright

The contents of these instructions are protected by copy-

right and are the sole property of Stürmer Maschinen

GmbH. Their use is permitted within the scope of use of

the metal hand-held circular saw. Any other use is not

permitted without the written consent of the manufac-

turer.

Passing on and reproduction of this document, utilisation

and communication of its contents are prohibited unless

expressly permitted. Violations will result in liability for

damages. We register trademark, patent and design

rights to protect our products, insofar as this is possible

in individual cases. We emphatically oppose any in-

fringement of our intellectual property.

1.2 Customer service

Please contact your specialist retailer if you have any

questions regarding your metal-cutting circular saw or

require any technical information. Your specialist retailer

will be happy to support you with specialist advice and

information.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Germany

Repair service:

Fax: +49 (0) 951 96555-111

email: service@stuermer-maschinen.de

Spare parts orders:

Fax: +49 (0) 951 96555-119

email: ersatzteile@stuermer-maschinen.de

Please submit any information and experiences you

make during application of the machine as these may be

valuable for product improvements.

1.3 Limitation of liability

All data in this operation manual has been compiled on

the basis of the state-of-the-art, valid standards and

guidelines as well as our many years of expertise and

experience.

The manufacturer shall not be liable for damage in the

following cases:

- Failure to comply with the operation manual,

- Unintended use

- Deployment of inexperienced staff

- Unauthorized conversions,

- Technical changes,

- Use of unauthorised spare parts

The actual scope of delivery may deviate from the de-

scriptions and illustrations in this document as a result of

special variants, optional extras or recent, technical

modifications.

The obligations defined in the supply contract shall apply

in addition to the general terms and conditions and the

manufacturer's general terms and conditions as well as

the statutory regulations valid at the time of the conclu-

sion of the contract.

2 Safety

This section provides an overview of all important safety

packages for personal protection as well as safe and reli-

able operation. The individual sections contain addi-

tional, task-specific safety information.

2.1 Legend of symbols

Safety instructions

Safety instructions in this operation manual have been

highlighted with symbols. Safety instructions are indi-

cated by signal terms that express the degree of risk in-

volved.

4HKS 230 | Version 3.06

Safety

Tips and recommendations

Observe the safety information in these operating in-

structions to minimise the risk of personal injury as well

as material damage and prevent hazardous situations.

2.2 Operator responsibility

The operator is the person who operates the machine

himself for commercial or economic purposes or who

makes it available to a third party for use or application

and who bears the legal product responsibility for the

protection of the user, the personnel or third parties dur-

ing operation.

Obligations of the operator:

If the machine is used for commercial purposes, opera-

tors are subject to the legal stipulations in terms of occu-

pational safety. For this reason, the safety instructions in

these operating instructions as well as the safety, acci-

dent prevention and environmental protection regula-

tions valid at the installation location must be complied

with. In this process, the following shall apply in particu-

lar:

- Operators shall obtain information about valid oc-

cupational safety regulations and determine addi-

tional hazards as part of a risk assessment which

result from the specific operating conditions at the

machine's installation location. Said risk assess-

ment shall be reflected in operating instructions for

machine operation.

- During the entire machine operating time operators

must check whether the operating instructions they

created meet current standards and adapt the op-

erating instructions where necessary.

- Operators shall clearly manage and specify the re-

sponsibilities for installation, operation, trouble-

shooting, maintenance and cleaning.

- Operators must make sure that all persons han-

dling the machine have read and understood these

operating instructions. Operators must also regu-

larly train staff and notify of the hazards.

- Operators shall provide staff with the required pro-

tective equipment and wearing the required protec-

tive equipment shall be mandatory.

Operators shall also be responsible for maintaining the

machine in a technically perfect condition. For this rea-

son, the following shall apply:

- Operators shall make sure that the maintenance in-

tervals described in these operating instructions

are complied with.

- Operators shall regularly check that the safety

equipment is fully functional and complete.

2.3 Operating staff qualification

The different tasks described in these operating instruc-

tions require different levels of skills in terms of the quali-

fications of operating staff working with the machine.

Exclusively persons of whom it can be expected that

they reliably complete assigned tasks shall be author-

ised to carry out any tasks. Persons whose reactions

have been impaired shall not be authorized, e.g. drug us-

ers, users under the influence of alcohol or medication.

These operating instructions specify the following per-

sonal qualifications for the different tasks:

DANGER !

This combination of symbol and signal word indicates

an imminently hazardous situation which, if not avoi-

ded, will result in death or serious injury.

WARNING!

This combination of symbol and signal word indicates

a potentially dangerous situation that will result in

death or serious injury if not avoided.

CAUTION!

This combination of symbol and signal word indicates

a potentially hazardous situation which, if not avoi-

ded, may result in minor or slight injury.

ATTENTION!

This combination of symbol and signal word indicates

a potentially hazardous situation which, if not avoi-

ded, may result in damage to property and the env-

ironment.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for efficient and reliable

operation.

WARNING!

Risk from inadequately qualified persons!

Inadequately qualified persons are unable to assess

the risks when handling the machine, thus putting

themselves and others at risk of severe injuries.

- All work must be carried out by qualified persons

only.

- Keep inadequately qualified persons and children

away from the work area.

Safety

HKS 230 | Version 3.06 5

Operating staff:

Operating staff has undergone an induction by the oper-

ator about the entrusted tasks and potential hazards re-

sulting from improper behaviour. Tasks which go beyond

normal operation may only be carried out by the operator

if they are listed in the operation manual and the opera-

tor has made him/herself familiar with them.

Qualified electrician

Due to the electrician's specialised training, know-how,

experience and knowledge of pertinent standards and

regulations the electrician is in a position to work on the

electrical systems, and autonomously identify and avoid

potential hazards.

Specialist staff:

As a result of specialist training, expertise, experience

and skills in terms of the relevant standards and regula-

tions, specialist staff is able to complete the tasks they

are entrusted with and independently identify hazards

and avert risks.

Manufacturer:

Certain work must be carried out by manufacturer spe-

cialist staff only. Other staff is not permitted to carry out

this work. Contact our customer service to have the work

carried out.

2.4 Personal protective equipment

Personal protective equipment is intended to protect the

health and safety of persons at work. Staff must wear the

personal protective equipment indicated in individual

sections of these operating instructions when carrying

out the different tasks on the machine.

The personal protective equipment is described in the

following section:

2.5 General safety precautions

Note the following:

- Use the safety devices and fasten them securely.

Never work without safety equipment and keep it in

good working order.

- Keep the machine and your work environment clean at

all times. Ensure sufficient illumination.

- Always secure the workpiece when working. Ensure a

sufficient support surface.

- The metal-cutting circular saw's design must not be

changed; the machine must not be used for work not in-

tended by the manufacturer.

- Never work under the influence of illnesses that impair

concentration, drugs, alcohol or medication.

- Keep children and persons who are not familiar with the

metal-cutting circular saw clear of your work environ-

ment, the machine and tools.

- Do not use the mains cable to pull the plug out of the

socket. Protect the cable against heat, oil and sharp

edges.

- Immediately resolve malfunctions that impair safety.

- Protect the metal-cutting circular saw against humidity

(risk of short circuit!).

- Before using the metal-cutting circular saw, make sure

that no parts are damaged. Replace damaged parts im-

mediately to avoid sources of danger!

- Never overload the metal-cutting circular saw! Working

within the stated performance limits is better and safer.

Use the right saw blade! Make sure that the saw blade

is not damaged.

- Use only genuine spare parts and accessories to avoid

potential risks and risk of accident.

Eye protection

Protective glasses protect the eyes against pro-

jected parts and splashes of liquid.

Hearing protection

Hearing protection protects the ears against hearing

damage caused by noise. .

Respiratory protection

Respiratory protection serves to protect the respira-

tory tract and lungs against absorbing dust particles.

Suitable protective gloves

Protective gloves protect the hands from compo-

nents with sharp objects as well as friction, abrasion,

and deep-cut injuries.

Safety shoes

Safety shoes protect feet from pinching, falling parts

and slipping on slippery surfaces.

Protective clothing

Protective work clothing means tight-fitting clothing

with low tear resistance.

6HKS 230 | Version 3.06

Intended Use

2.6 Safety labels on the metal cutting

circular saw

The following safety labels and instructions are attached

to the metal-cutting circular saw (Fig. 1) and must be ob-

served.

Fig. 1: Safety labels -

1 Warning symbols | 2 Ground symbol | 3 Mandatory sign

If safety labels on the machine are damaged or missing,

this can cause errors, personal injury and material dam-

age. The safety symbols attached to the machine must

not be removed. Damaged safety symbols must be re-

placed immediately.

As soon as the signs are not clearly visible and compre-

hensible at first glance, the machine must be stopped

until new signs have been attached.

2.7 Safety data sheets

Safety data sheets on hazardous goods can be obtained

from your specialist dealer or by calling +49 (0)951/

96555-0. Specialist dealers can find safety data sheets in

the download area of the partner portal.

3 Intended Use

The metal hand-held circular saw is intended exclusively

for sawing solid or hollow profiles made of steel and

other metallic materials. The processing possibilities

also depend on the operating conditions of the suitable

saw blades used.

Intended use also includes compliance with all the infor-

mation in these instructions.

3.1 Reasonably foreseeable misuse

Any use beyond the intended use or any other use is

considered misuse.

Possible misuses can be:

- The metal hand-held circular saw must not be used

for sawing flammable materials (e.g. magnesium

or similar).

- Use of the metal hand-held circular saw for materi-

als other than aluminium, PVC or wood materials

(e.g. machining of hard metal or similar, plastic,

etc.).

- Modifications to the machine or accessories.

- Maintenance work on an unsecured machine

- Non-observance of wear and damage marks.

- Service work carried out by untrained or unauthor-

ised personnel.

- Use of accessories or spare parts not approved by

the manufacturer.

- Misuse of the machine

- Operating the metal hand-held circular saw if the

operating instructions have not been fully read and

understood.

- Deliberate or careless handling of the metal hand-

held circular saw during operation.

- Using an incompletely assembled machine.

Misuse of the metal hand-held circular saw can lead to

dangerous situations. Stürmer Maschinen GmbH ac-

cepts no liability for design and technical modifications to

the metal hand-held circular saw. Claims of any kind for

damage due to improper use are excluded.

3.2 Residual risks

Even if all safety instructions are observed and the ap-

pliance is used according to the instructions, there are

still residual risks, which are listed below:

- Risk of injury to the upper limbs (e.g. hands, fingers).

- Risk of injury from tripping over cables.

- Impairment of hearing during prolonged work without

hearing protection or if this is defective.

- Electrical hazard due to contact with parts and high

voltage (direct contact) or with parts under high

voltage due to a defect in the metal hand-held circular

saw (indirect contact).

- Heat build-up on components can cause burns and

other injuries.

- Risk of breakage or ejection of workpieces.

- Risk of injury to the eye from flying parts, even with

safety goggles on

12 3

Technical Data

HKS 230 | Version 3.06 7

4 Technical Data

4.1 Table

4.2 Type plate

Fig. 2: Type plate HKS 230

5 Transport, packaging, storage

5.1 Delivery and transport

Delivery

Check the metal-cutting circular saw for visible transport

damage upon delivery. In case of visible damage to the

metal-cutting circular saw, immediately notify the carrier

or your retailer.

5.2 Packaging

All packaging materials and packing aids of the metal-

cutting circular saw are suitable for recycling and must

always be disposed of using material-based recycling

systems. Packaging materials made of cardboard must

be shredded and recycled as waste paper. The foils are

made of polyethylene (PE), padding is made of polysty-

rene (PS). Dispose of these substances at a recycling

centre or hand them over to a qualified waste disposal

company.

5.3 Storage

Always store the metal-cutting circular saw in a clean

condition and a dry, clean and frost-free environment. It

must not be stored in the same room as chemicals. Dur-

ing storage, the metal-cutting circular saw must be cov-

ered with a plastic film. All bare metal surfaces must be

protected with corrosion protection agent.

General data HKS 230

Idle speed 2200 rpm

Adjustment range for an-

gled cuts

0° - 45°

Gross weight 13.6 kg

Net weight 7.1 kg

Dimensions (L x W x H) 620 x 320 x 270 mm

Electrical data

Voltage 230 V/50 Hz

Output 1700 W

Fuse min. 10 A

Connecting cable length 2.8 m

Cutting data

Maximum cutting depth below 90° 80 mm

below 45° 56 mm

Saw blade data

max. perm. speed 2200 rpm

max. outer diameter 230 mm

max. saw blade width 2.4 mm

Hole diameter 25.4 mm (1")

Emissions

Noise levels approx. 91 dB

Vibration 3.6 m/s2

Ambient data

Transport/storage temper-

ature

0 °C - 40 °C

Deployment temperature 0 °C - 40 °C

NOTE!

Protect the metal-cutting circular saw against mois-

ture.

8HKS 230 | Version 3.06

Machine Description

6 Machine Description

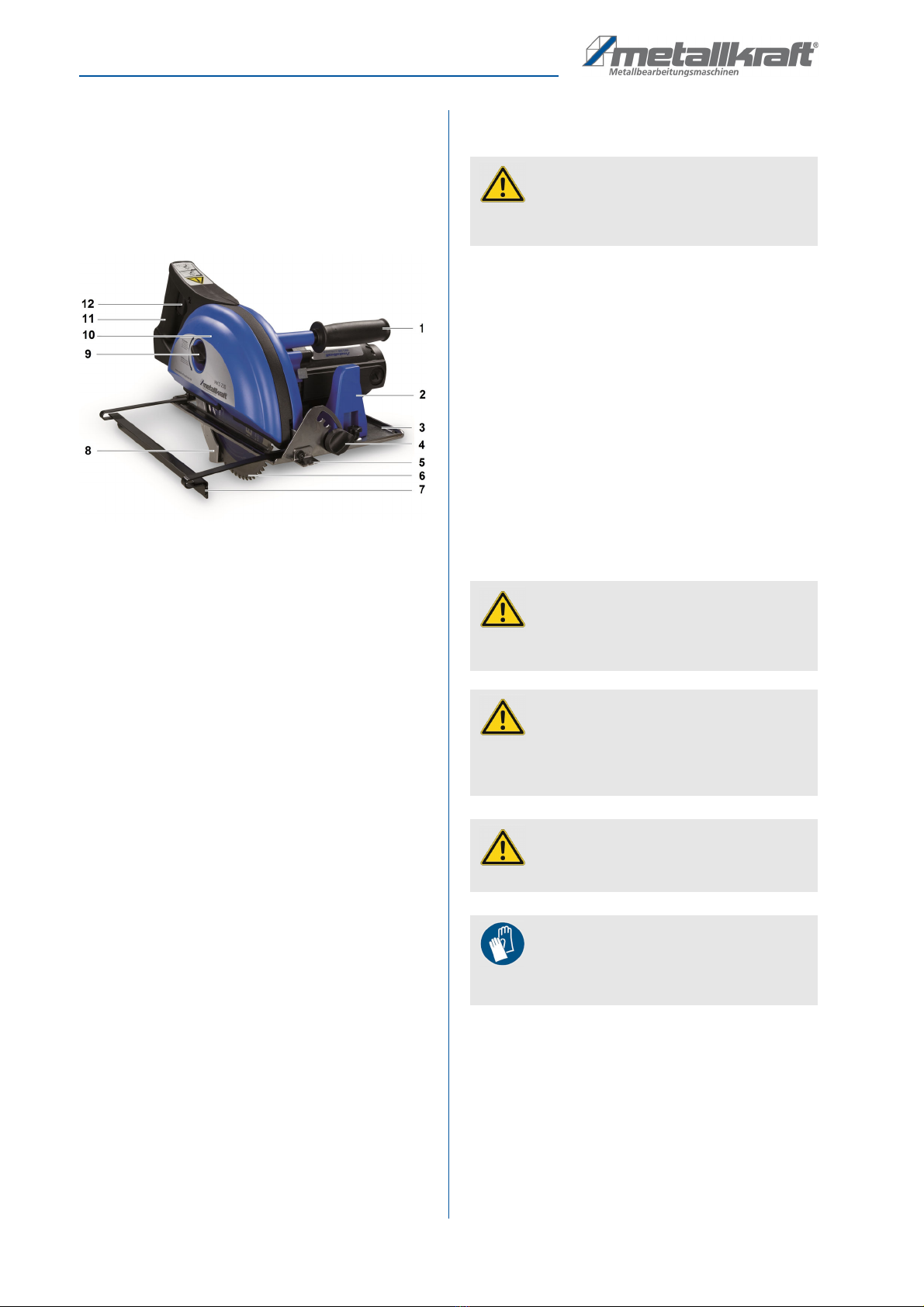

6.1 Illustrations

Figures in this operation manual serve to provide a basic under-

standing and may differ from the actual design.

Fig. 3: Machine description HKS 230

1 Handle at side

2 Housing

3 Machine support

4 Clamping screw for adjusting the bevel angle

5 Cutting guide display

6 Saw blade

7 Rip fence

8 Saw blade guard

9 Lock on saw blade cover

10 Cutting depth adjustment (hidden)

11 Hand grip

12 On/off switch

6.2 Scope of supply

- Metal-cutting manual circular saw HKS 230

- Rip fence

- Hexagon spanner

- Operating manual

- Bag with screws and fastening material

6.3 Selecting the saw blade

During sawing with the metal-cutting circular saw, pay at-

tention to the choice of the correct saw blade, or the cor-

rect tooth form and set of the saw blade.

If the TPI value is too small and the cutting length is too

long, the cut material cannot be easily taken up by the

gullet.

If the TPI value is too high, the saw teeth starts to chop;

this can lead to teeth breaking out.

7 Settings and commissioning

7.1 Installing the saw blade

Step 1: For assembly (also removal) it is necessary to re-

move the outer saw blade cover.

Step 2: Open the cutting depth adjustment clamp with a

hexagon spanner and rotate the saw blade to the

top limit position in order to reveal the saw blade

screw connection at the side.

Step 3: To remove a saw blade, press the saw blade lock

and release the saw blade screw connection.

ATTENTION!

Only use saw blades whose maximum rotational

speed matches or exceeds the maximum saw speed.

WARNING!

Disconnect the machine from the power supply

before installing or removing the saw blade

ATTENTION!

Only use saw blades that are permissible in terms of

dimension and maximum rotational speed. For your

own safety, only use original Metallkraft saw blades.

CAUTION!

Avoid injuries caused by touching the saw teeth.

Suitable protective gloves

During all work related to the saw blade, wear protec-

tive gloves.

Settings and commissioning

HKS 230 | Version 3.06 9

Step 4: Wearing protective gloves, remove the saw

blade and insert the new blade in its place on the

contact flange. Make sure that the teeth are

pointing forwards. In case of doubt, check the di-

rectional display printed on the saw blade.

Step 5: Position the outer saw blade flange with the flat

side facing the saw blade; then fit the fastening

screw and hand-tighten (Fig. 3).

Step 6: Use a hexagon socket wrench to turn the fasten-

ing screw clockwise. Press the saw blade lock

while doing so, and turn the saw blade support

with the wrench until you notice it engage.

Step 7: After the saw blade lock has engaged, tighten

the fastening screw to final torque by turning

clockwise.

Step 8: Before operating the saw, make sure that the

saw blade lock is back in its original position.

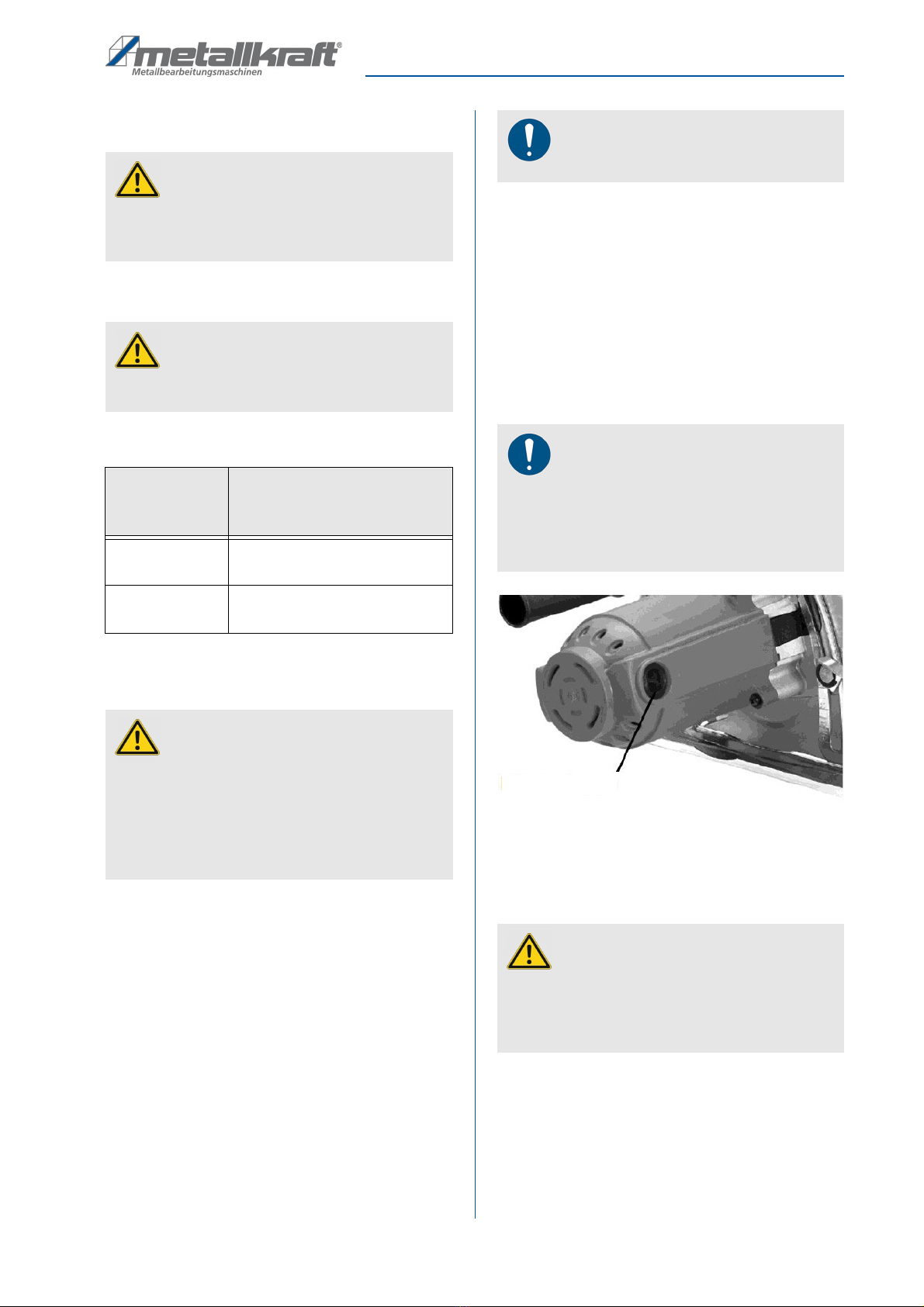

Fig. 4: Saw blade assembly

7.2 Setting the cutting depth

Adjust the cut so that the saw blade can penetrate the

entire depth of cut.

Step 1: Lift the cutting depth adjustment lever.

Step 2: Raise or lower the saw housing until you reach

the desired cutting depth. You can read off the

set value at the pointer on the integrated scale.

Step 3: Push the clamping lever fully down to ensure suf-

ficient clamping.

Fig. 5: Adjusting the cutting depth

7.3 Setting the bevel angle

When setting the bevel angle make sure that the saw

blade can penetrate through the entire material thick-

ness.

Step 1: Loosen the clamping screws for the bevel angle

at the front and rear (Fig. 6).

Step 2: Set the desired bevel angle.

Detents for bevel angles of 0°, 15°, 30° and 45° are

provided on the front. If other angles are required,

clamp the clamping screw at the desired position

outside the detents.

Step 3: Firmly tighten the clamping screw on the back.

Saw blade

Screw

Flange

Sawblade

lock

Cutting depth adjust-

ment

WARNING!

Disconnect the machine from the power supply

before setting the cutting depth.

WARNING!

Never cut material thicker than 9 mm

WARNING!

Disconnect the machine from the power supply

before setting the bevel angle.

Clamping lever

Scale depth of cut

10 HKS 230 | Version 3.06

Settings and commissioning

Fig. 6: Setting the bevel angle

7.4 Using the cutting guide display

To support manually guided sawing, the cutting guide

display is located on the front end of the machine sup-

port.

During sawing, align the orientation slots with the cut

line.

Use the right orientation slot (between the two marks) for

straight cuts.

Use the left orientation slot for cuts below a bevel angle

of 45°.

Fig. 7: Cutting guide display

7.5 Switching the circular saw on and

off

Proceed as follows to switch on the manual circular saw:

Step 1: Connect the manual circular saw to the power

supply using the power plug.

Step 2: Press the button on the safety lock to release the

on/off switch.

Step 3: Press the on/off switch to start the machine.

Step 4: To switch off the manual circular saw, release

the on/off switch and allow to snap back to its

original position.

Fig. 8: On/off switch

7.6 Setting the rip fence

For cuts parallel to a straight workpiece edge, you will

achieve more precise straight ahead motion by using the

rip fence while guiding the cut than by guiding the work-

piece with your free hand.

Step 1: Insert the rip fence into the mounting straps pro-

vided on the machine support.

Clamping screw for bevel

angle (front)

Scale

Clamping screw for

bevel angle (rear)

Orientation groove

for 45 ° cuts

Orientation groove

for 90 ° cuts

ATTENTION!

Make sure that the connection voltage of the power

supply matches the value printed on the type plate.

Make sure that the on/off switch is on off position

before you connect the power plug to the power sup-

ply.

ATTENTION!

Before setting the rip fence disconnect the manual

circular saw from the power supply.

ON/OFF

Switch

Lock

Settings and commissioning

HKS 230 | Version 3.06 11

Step 2: Set the desired gap between the rip fence and

the cutting guide display.

Step 3: Fix the rip fence in the set position using the

clamping screws provided for the purpose.

Fig. 9: Adjusting the rip fence

7.7 Saw blade guard function

The bottom part of the saw blade guard which folds back

is a safety device that is essential for accident prevention

during use of the machine. Before using the manual cir-

cular saw, always ensure that the saw blade guard can

move freely and does not jam at any point. Make sure

that the guard quickly and fully snaps back into the

closed original position.

7.8 Handling the manual circular saw

The machine hast two positions at which the second

handle can be fitted: on the saw blade cover or the ma-

chine base.

Only use the assembly position on the machine base for

mitre cutting because it allows for more stable handling

of the manual circular saw (see Fig. 10).

WARNING!

A soiled and clogged saw blade guard may jam and

not fold back. Before using the manual circular saw,

always clean the space inside the saw blade guard to

remove chips and deposits.

Using a machine with the saw blade guard not work-

ing, or not working correctly, is prohibited.

Immediately hand over machines with a saw blade

malfunction for repair to an authorised or qualified

workshop.

ATTENTION!

Before using the manual circular saw, any chips and

deposits must be removed from the space inside the

saw blade guard.

ATTENTION!

Never lubricate the bearing and guide parts of the

saw blade guard. The bearings on the saw blade

guard are equipped with dry lubrication. Additional

lubrication with grease or oil can impair the anti-fric-

tion effect.

Side stop

ATTENTION!

Never using cutting oils or cooling lubricant when

using the manual circular saw. The machine is exclu-

sively designed for dry cutting.

ATTNETION!

When sawing, make sure that the power supply

cable does not enter the cutting area of the saw

blade.

ATTENTION!

For your own protection, use the manual circular saw

in combination with the handle at the side only. This

grab handle gives you the ability to guide the

machine safely with both hands.

ATTENTION!

Never use the manual circular saw for longer than 30

minutes without interruption.

NOTE!

Adjust the feed speed and contact pressure to suit the

material and achieve optimum cutting results. In-

crease the contact pressure when sawing thicker ma-

terial sections and reduce it for thinner materials.

NOTE!

Always hold the machine with your right hand on the

rear handle, and your left hand on the handle at the

side.

12 HKS 230 | Version 3.06

Care, Maintenance and Repairs

Fig. 10: Handling

Follow these steps for sawing:

Step 1: Mark the desired cutting line, using a marker pen

for example.

Step 2: Clamp the workpiece and make sure that it is se-

curely clamped.

Step 3: Locate the front edge of the machine support on

the workpiece. Make sure that the cutting

guide display lines up with the desired or

marked cutting line and that the saw blade is

parallel to the cutting line and pointing in its di-

rection. The swivelling saw blade guard must

not be open at this point, not even partially.

Step 4: Release the safety lock and then press the on/off

switch.

Step 5: Allow the saw blade to run up to final speed and

then move the manual circular saw forward.

While doing so, make sure that the saw blade

guard swivels back without jamming.

Step 6: After completing the cut, release the pressure on

the on/off switch without letting go of the ma-

chine. Make sure that the saw blade is at a

standstill and the saw blade protection is

closed before taking the machine off the work-

piece.

7.9 Securing workpieces

Clamp the workpiece correctly on a suitable and stable

support and using suitable aids. Support long work-

pieces to prevent them dropping or tilting.

8 Care, Maintenance and Re-

pairs

ATTENTION!

Secure the workpiece carefully against bending or

slipping before machining. Note that the saw blade

can be trapped by the cut-off dropping at the end of

machining.

ATTENTION!

Make sure that the saw blade has fully run down and

is at a standstill before changing the clamping situa-

tion, for example, the clamping position or the cut-

ting angle

ATTENTION!

Before starting cleaning and maintenance work of

the machine, disconnect the power plug.

Tips and recommendations

To keep the metal-cutting circular saw in a good

operational condition at all times, regular care and

maintenance work must be performed.

WARNING!

Risk due to inadequately qualified persons!

Inadequately qualified persons are unable to assess

the risks in case of repairs to the machine, thus put-

ting themselves and others at risk of severe or fatal

injuries.

All maintenance work must be carried out by quali-

fied persons only.

DANGER!

Risk of fatal injury through electric shock!

There is a risk of fatal injury on touching live compo-

nents.

- Before starting cleaning and maintenance work, al-

ways unplug the mains connector.

- The machine's electrical equipment must be con-

nected and repaired by a qualified electrician only.

NOTE!

After cleaning, maintenance and repairs, make sure

that all panels and protective guards are once again

correctly in place on the machine and that there are

no tools on the inside or outside of the machine.

Damaged protective guards and machine parts must

be professionally repaired by an approved workshop,

or replaced.

Care, Maintenance and Repairs

HKS 230 | Version 3.06 13

8.1 Cleaning the machine

.

The metal-cutting circular saw should always be thor-

oughly cleaned after use.

Cleaning and maintenance table

Brush or wipe off all open machine parts with a brush or

cloth at regular intervals.

Treat bare metal work surfaces with anti-corrosive spray.

8.2 Changing the carbon brushes

The carbon brushes are subject to normal wear and

must be replaced when they reach their end-of-life.

The machine is equipped with a self-disconnecting brush

type. In other words, the motor will no longer run after

reaching the wear limit. For this reason, the carbon

brushes first need to be checked and possibly replaced if

the machine unexpectedly fails to start.

Proceed as follows:

Step 1: Unscrew and remove the brush caps with a suit-

able screwdriver.

Step 2: Pull the carbon brushes out of the holder.

Step 3: Insert the brushes.

Step 4: Replace the brush caps and screw them back

down.

Fig. 11: Brush cap

8.3 Changing the power supply cable

ATTENTION!

- Never use solvents for cleaning plastic parts or

painted surfaces. This may cause the surface to

disintegrate and cause consequential damage.

ATTENTION!

All moving parts must be free of dirt and dust and

regularly greased or oiled (e.g., bolts).

Maintenance

interval in

operating hours

Maintenance point

Daily before use Remove chips and clean the ma-

chine

Daily before use Check the saw blade; replace if

needed.

ATTENTION!

- Never remove chips or grinding dust with your bare

hands. There is a risk of cuts through sharp edged

chips!

- Never remove chips or grinding dust with a com-

pressed air gun. This can lead to eye injuries and

damage machine components.

NOTE!

Always replace the carbon brushes as a pair.

NOTE!

If you only removed the carbon brushes for inspec-

tion, make sure that you reinsert them at the same

position and in the same order. Otherwise this will

cause reduced performance and increased brush

wear.

DANGER!

Risk of fatal injury through electric shock!

To reduce the risk due to electricity, work on the

power supply cable may only be performed by the

manufacturer or an authorised professional work-

shop.

Brush cap

14 HKS 230 | Version 3.06

Disposal, Recycling of used Device

9 Disposal, Recycling of used

Device

Please take care in your own interest and in the interest of

the environment that all component parts of the machine

are only disposed of in the intended and permitted way.

9.1 Decommissioning

Immediately decommission disused machines in order to

avoid later misuse and endangering of the environment

or personal safety.

- Eliminate all environmentally hazardous operating

materials from the used device.

- If required, disassemble the machine into easy-to-

handle and usable components and parts.

- Dispose of machine components and operating ma-

terials by the disposal channels provided.

9.2 Waste disposal of electric equip-

ment

Please note that electrical devices contain a variety of re-

cyclable materials as well as environmentally harmful

components.

You contributes to that these components are disposed of

separately and properly. In case of doubt, please contact

your municipal waste disposal. As necessary, a specialized

waste disposal company can help be used for the treatment.

9.3 Disposal of lubricants

Please pay attention to an environmentally friendly dis-

posal of the used coolants and lubricants.Observe the

disposal instructions of your municipal disposal compa-

nies. Disposal notes for used lubricants are available

from the manufacturer of the lubricants. If necessary, re-

quest the product-specific data sheets.

10 Spare Parts

10.1Ordering spare parts

The spare parts may be purchased with the authorised

dealer or directly with the manufacturer. Please find the

corresponding contact data in Chapter 1.2 Customer

service.

Indicate the following basic information for requests or

orders of spare parts:

- Type of device

- Item No.

- Position No.

- Year of construction:

- Quantity

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Example

The handle for the HKS 230 metal hand-held circular

saw must be ordered. The saw blade has the number 42

in the spare parts drawing.

When ordering spare parts, send a copy of the spare

parts drawing with the marked component (handle) and

marked item number (42) to the authorised dealer and

provide the following information:

Type of appliance: Metal hand-held circular saw

HKS 230

Item number: 3840231

Item number: 42

DANGER!

Danger of injury by the use of wrong spare

parts!

Dangers may result for the user and damages as well

as malfunctions may be caused by using wrong or

damaged spare parts

- Only use original spare parts of the manufacturer or

spare parts admitted by the manufacturer.

- Always contact the manufacturer in case of uncer-

tainties.

Loss of warranty!

The manufacturer's warranty will become null and

void if non-permissible spare parts are used.

Spare Parts

HKS 230 | Version 3.06 15

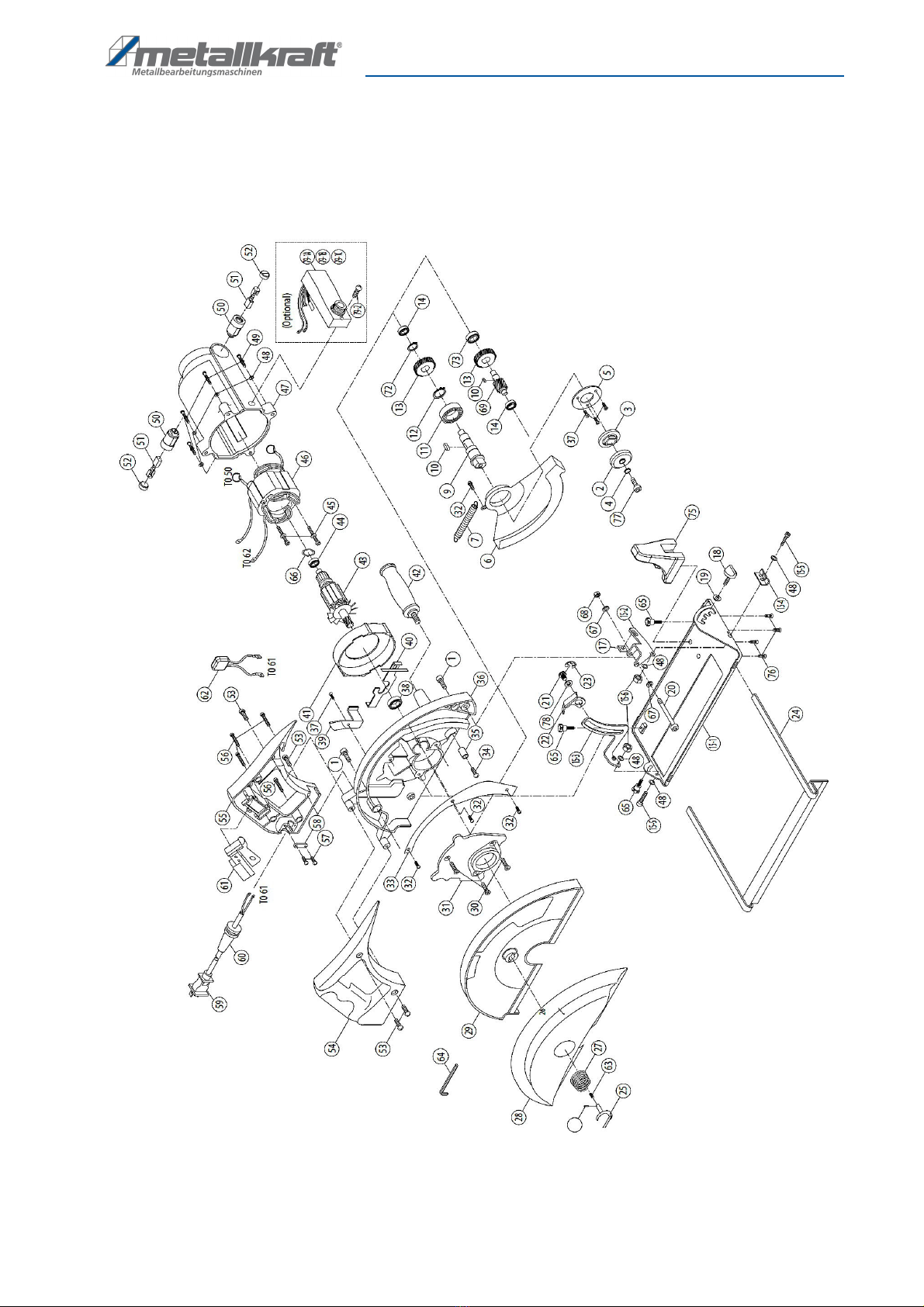

10.2 Spare parts drawing

Spare parts drawing HKS 230

The following drawing is intended to identify the required spare parts in the event of service. If applicable, submit a copy

of the parts drawing including the highlighted components to your authorised retailer.

Fig. 12: Spare parts drawing

16 HKS 230 | Version 3.06

Spare Parts

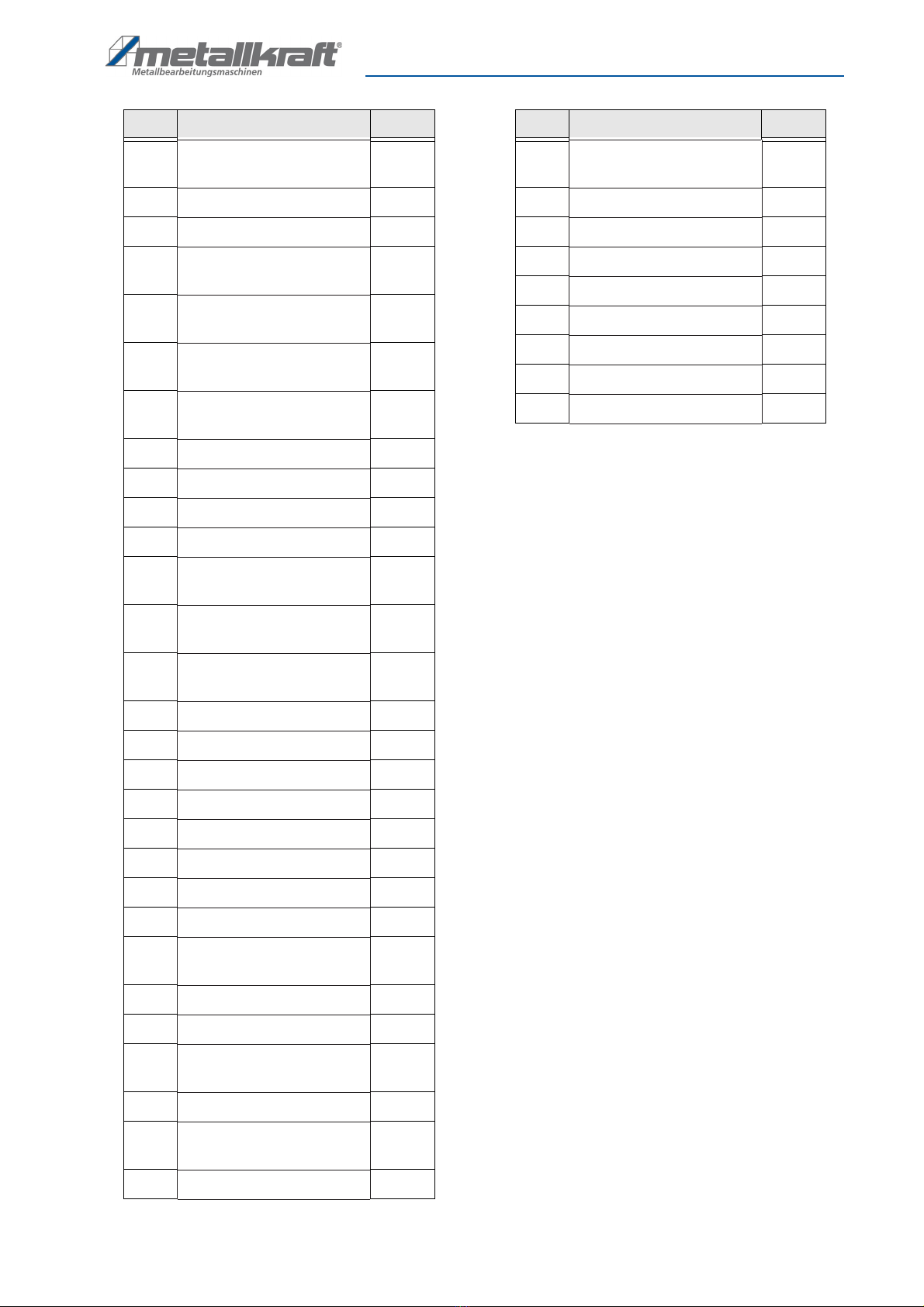

Parts list

Pos. Description Qty,

1 INTERNAL CIRCLIP (R-19) 1

2 Flat washer

(Ø10xØ18.5x0.810xØ18.5x

0.8)

1

3 Water seal (Ø12x15) 1

4 Spring

(Ø1.2xØ10xØ12.4x11Tx54)

1

5 Lock pin (12,3mm) 1

6 Panhead machine screw

(M3x4xP0,5)

1

7 Lock pin spring 1

8 Check ball (Ø 8 mm) 1

9 Spindle (141mm) 1

10 Ring ( Ø40xØ44x9 schwarz) 1

11 Collar pin ( Ø 8 mm ) 1

12 Qick release collar 1

13 Spring

(Ø2.3xØ39xØ43.6x3Tx30L)

1

14 Spring seat ring

(Ø35.1xØ44.5x2)

1

15 External circlip ( S-35) 1

16 Internal circllip ( R-47) 1

17 Ball bearing ( 6005) 1

18 Qill tube 1

19 External circlip ( S-25) 3

20 Gear plate 1

21 Bushing ( Ø30xØ36x12 ) 1

22 Output gear ( M1.25x47T ) 1

23 Bushing( Ø30xØ36x12 ) 1

24 Ball bearing ( 608 ) 1

25 Bevel gear (M1.0x46T) 1

26 Parallel key (4x4x7) 1

27 Input shaft (M1.25x9T) 1

28 Panhead tapping screw-b

(M5x25)

2

29 Panhead tapping screw-b

(M5x30)

2

30 Gear housing 1

31 Panhead machine screw-

Washer (M5x25xP0.8)

1

32 Ball bearing (6001) 1

33 Armatur (220V-73x42x45) 1

34 Panhead tapping screw-b

(M5x60)

1

35 Stator (220V-73x42x45) 1

36 Motor housing (BLUE-

7462C)

1

37 Carbon brush (7x11x17) 2

38 Carbon brush holder (7x11) 2

39 Hex nut (M4xP0.7) 2

40 Brush spring (0.35x3x3T) 2

41 Panhead machine screw

(M4-0.7x10)

2

43 Motor tail Casting 1

44 Panhead tapping screw-b

(M4x25)

2

45 Crank spindle (Ø28) 1

46 Bushing ((Ø28xØ32x12) 2

47 Pressure disc

(Ø25.5xØ40x2)

2

49 Check ball (Ø5) 2

50 Crank hub 1

51 Spring

(Ø0.6xØ4.1xØ5.3x4Tx6.5L)

1

55 Crank handle 1

57 Socket cap screw

(M6x30xP1.0)

2

58 Spring washer (M6) 3

59 LED lamp 1

60 Flat head machine screw

(M4x6xP0.7)

1

61 Electromagnet (164x80x48) 1

62 Panhead machine screw-

washer (M4x12xP0.7)

1

63 Cable clip 1

65 Power supply cable 1

66 Motor switch 1

67 Magnet switch 1

Pos. Description Qty,

Spare Parts

HKS 230 | Version 3.06 17

68 Panhead machine screw

(M4-0.7x8)

8

69 Switch bracket 1

70 Mouting plate 1

71 Rectifier and EMC

(110V&220V)

1

72 Socket set screw

(M5x10xP0.8)

1

73 Socket cap screw (M6-

1.0x16)

1

74 Panhead machine screw-

washer (M4x16xP0.7)

1

75 External star washer (M5) 1

76 Wave sping (Ø30xØ38.5) 2

77 Seal (5cm) 1

78 Strap cover 1

79 Flat head machine screw

(M5x15xP0.8)

1

80 Flat hear machine screw

(M5x20xP0.8)

1

81 Bevel washer

(Ø10.1xØ14x1.2)

1

82 Safety belt 1

84 Wire lead (1015-16#18CM) 2

85 Female spade terminal 4

86 Spade terminal boot 6

87 Crimp cab connector (C4) 1

88 Zip tie (2.5x100MM) 1

92 O-Ring (Ø12x4) 1

93 E-Clip(E-3) 1

94 Panhead tapping

screw(M4x12)

4

98 Bracket top 1

99 Bracket bottom 1

100 Panhead tapping screw-b

(M4x16)

2

101 Hex nut (M5xP0.8 1

103 Socket set screw

(M4x8xP0.7)

1

105 Flat washer (Ø6xØ13x1) 2

Pos. Description Qty,

106 Butterfly screw

(M6x10xP1.0)

1

107 Plunger 1

108 Fan baffle 1

109 Earting marking 1

111 Seal 1

112 Wire lead (1015-16#9CM) 2

113 Male spade terminal 2

114 Terminal cover 2

115 Chip guard 1

Pos. Description Qty,

18 HKS 230 | Version 3.06

EC Declaration of Conformity

As per machine directive 2006/42/EC, Appendix II 1.A

Manufacturer/distributing company: Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Straße 26

D-96103 Hallstadt, Germany

hereby declares that the following product (hereafter)

Product group: Metallkraft® metalworking machines

Machine type: Metal-cutting manual circular saw

Machine designation: HKS 230

Serial number: ______________________

Year of manufacture: 20___

complies with all relevant regulations of the aforementioned directive as well as any other, applicable directives (subse-

quently added) – including the changes applicable at the time the declaration was made.

Applicable EU directives 2014/30/EU EMC Directive

The following, harmonised standards have been applied:

DIN EN 16093:2017-10 Machine tools - Safety - Sawing machines for cold metal (ISO 16093:2017)

DIN EN ISO 12100:2010 Safety of machinery - general design principles -

Risk assessment and reduction of risks (ISO 12100:2010)

EN 60204-1:2007-06 Safety of machinery - Electrical equipment of machines –

Part 1: General requirements

Responsible for documentation: Kilian Stürmer, Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, 15 April 2014

______________________

Kilian Stürmer

Managing Director

11 EC Declaration of Conformity

Notes

HKS 230 | Version 3.06 19

12 Notes

www.metallkraft.de

This manual suits for next models

1

Table of contents

Other Metallkraft Saw manuals