Metasys LDM Series User manual

Fire Management Accessories Manual 445

Lamp Driver Modules Section

Technical Bulletin

Issue Date 0394

© 1994 Johnson Controls, Inc. 1

Order No. 445-161

LDM Lamp Driver Modules

Introduction Page 3

●

Description *3

Design Considerations 5

●

Limits *5

●

Wire Runs *5

●

Wiring Specifications 5

●

Receive Only Annunciators 6

●

Receive/Transmit Annunciators *6

●

Lamp Driver Electrical Ratings *7

●

Calculating the Power Supply Requirements *9

Installation 11

●

Cable Sets for LDM-32 and LDM-E32 Outputs to Lamps or

LEDs*11

●

Installing LDM Modules *11

●

Wiring the Lamp Driver Module *14

●

LDM Terminal Wiring *14

●

Connecting the Supervisory Input*16

●

Wiring Point LEDs and Relays *16

●

Lamp Driver Power*18

●

Connecting the Main Power Supply *20

Operating the Lamp Driver 21

●

Lamp Test/Acknowledge 21

●

Online LED 21

●

Another Use for the Lamp Driver Module 22

* Indicates those sections where changes have occurred since the last printing.

2 Lamp Driver Modules—LDM Lamp Driver Modules

LDM-32 and the IFC-1010/2020 Page 23

●

Capabilities 23

●

Software Required *23

●

Hardware Required*23

●

Programming for Remote Annunciation*24

●

Operating the LDM-32 with the IFC-1010/2020 25

●

Configuring the Lamp Driver for the IFC-1010/2020 *25

LDM-32 and the FC-2000 31

●

Capabilities *31

●

Software Required *31

●

Hardware Required*31

●

Operating the LDM-32 with the FC-2000 *31

●

Configuring the Lamp Driver for the FC-2000*32

●

AIM-200 Point Annunciation*34

●

LDM Switch Control Functions *36

* Indicates those sections where changes have occurred since the last printing.

Lamp Driver Modules—LDM Lamp Driver Modules 3

Introduction

Description

1

2

3

4

5

6

7

1

2

3

4

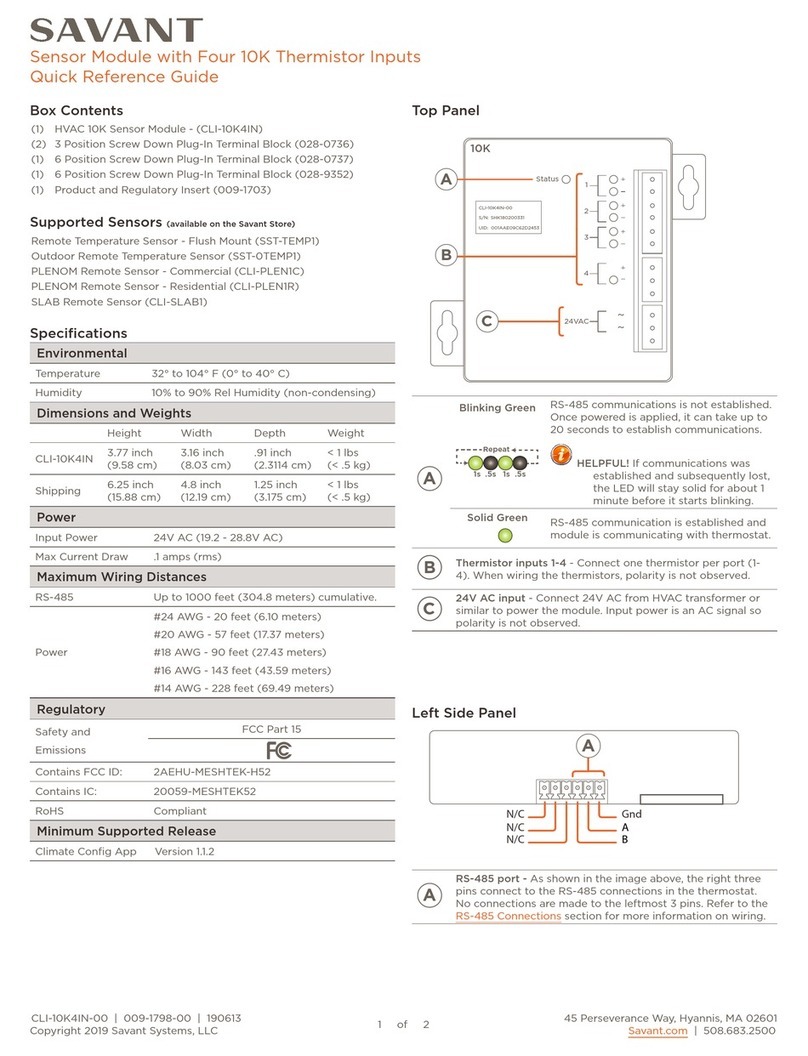

This document describes how to install the LDM Series

Lamp Driver with an IFC-1010/2020 Intelligent Fire

Controller, IFC-200 Intelligent Fire Controller, or an

FC-2000 Fire Controller. The Lamp Driver Module (LDM)

provides the IFC-1010/2020, IFC-200, or FC-2000 with a

direct interface to a custom graphic display. The LDM-32

(Figure 1) features 32 points for annunciation (Alarm Only

Mode operation) or 16 points of annunciation and control

(Alarm/Trouble Mode operation). It can be expanded to 64

points (for each LDM-32 address) with the addition of

optional LDM-E32 Expander Modules (Figure 1). These

Lamp Drivers turn their outputs ON and OFF as commanded

by the control panel. With custom switches installed, the

LDM can be used to report selected switch activations to the

control panel for action. Each module may be configured to

provide 32 alarm indications or alternately, 16 alarm,

16 trouble, and 16 control switch points.

An optional LDM-R32 Relay Module (Figure 1) provides 32

dry normally open contacts for electrical isolation when

connecting the control panel to other equipment. One side of

each contact is connected to a common terminal. A separate

common is provided for each group of eight relays.

The LDM-32, LDM-E32, and LDM-R32 modules mount on

four standoffs inside of the custom graphic annunciator

cabinet. Alternately, the modules can be installed in a

standard CHS-4L low-profile chassis for mounting in a

CAB-x3 series cabinet.

Communication between the CPU and the LDMs is

accomplished over a two-wire serial interface employing an

RS-485 annunciator communication trunk. Power for the

LDM is provided via a separate power circuit from a

regulated power supply inherently supervised by the LDM

(loss of power results in an annunciator communication

failure at the control panel).

4 Lamp Driver Modules—LDM Lamp Driver Modules

Expander Ribbon Cable (75120)

Cable sets for connecting LDM-32 and LDM-E32 outputs to

lamps or LEDs are provided through the optional

LDM-CBL24 (24 inch long) and LDM-CBL48 (48 inch

long) assemblies. Each cable has a plug on one end for

connection to the annunciator module and stripped and tinned

ends on the other end of the assembly. Each cable supports

eight output lamps. The LDM-CBL24 and LDM-CBL48 are

cable sets that provide several cables, sufficient for most

applications.

Lamp Driver Modules—LDM Lamp Driver Modules 5

Note: The LDM-32 is functionally identical to the

ACM-16AT or ACM-32A Annunciator Control Modules.

The terms “lamp driver” and “annunciator” are used

interchangeably throughout this document. Although the

term “lamp” is used, the LDM is most often used to drive

Light-Emitting Diodes (LEDs).

1

2

3

4

5

6

7

8

1

2

3

4

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

1

2

3

4

LDM-32 LDM-E32 LDM-R3

2

Figure 1: LDM Lamp Driver Annunciator Modules

6 Lamp Driver Modules—LDM Lamp Driver Modules

Design Considerations

When considering the design of your LDM annunciator system, there

are two different types of configurations available: Receive Only

Annunciators or Receive/Transmit Annunciators.

Limits

Up to 32 annunciators may be installed on an RS-485 circuit.

The actual number of annunciator modules may be larger,

depending on the number of expander modules employed.

Note:The FC-2000 can address four annunciator/expander

combinations (address 1-4). All other annunciators installed in

the FC-2000 must be set to “Receive Only.”

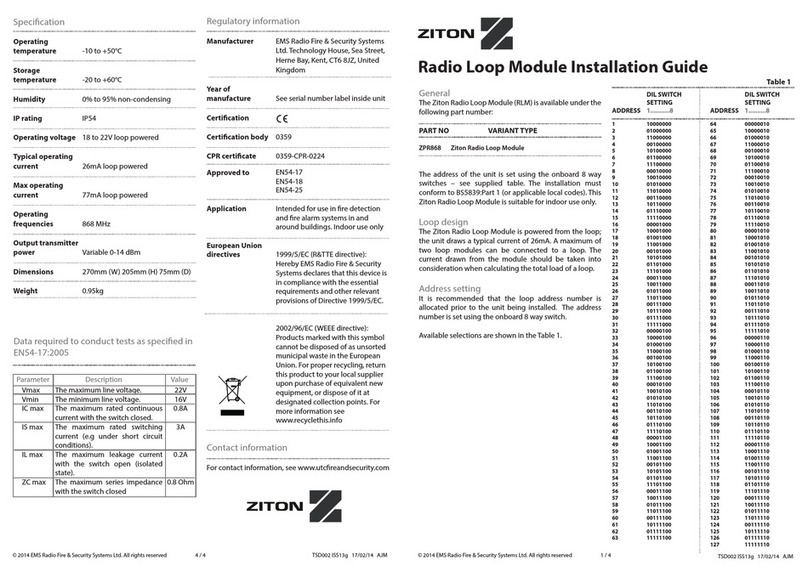

Wire Runs

Communication between the Fire Alarm Control Panel and the

LDM is accomplished over a 2-wire RS-485 annunciator trunk.

This communication, to include the wiring, is supervised by the

Receive/Transmit LDM. Power is provided via a separate power

circuit from the control panel, which is supervised by the LDM.

Loss of power also results in a communication failure at the

control panel.

Fire Alarm Control Panel

1

2

3

4

5

6

7

1

2

3

4

Lamp Driver

Power for LDM

(18 to 14 AWG)

Two-wire RS-485

Annunciator Trunk Circuit

(Maximum of 6000 feet)

ldmannun

Figure 2: LDM Annunciator Wire Runs

Wiring Specifications

●The RS-485 annunciator trunk circuit must be twisted shielded

pair cable and cannot be T-Tapped; it must be wired in a

continuous fashion from the control panel to each annunciator.

●The maximum RS-485 annunciator trunk wiring distance

between the panel and the last annunciator is 6000 feet when 16

AWG is used and 4000 feet when 18 AWG is used.

●The RS-485 annunciator trunk wiring must be an 18 AWG to

16 AWG twisted shielded pair.

●Limit the total wire resistance to 100 ohms on the RS-485

annunciator trunk circuit, and 10 ohms on the annunciator power

circuit.

Lamp Driver Modules—LDM Lamp Driver Modules 7

●Do not run cable adjacent to, or in the same conduit as, 120

VAC service, noisy electrical circuits that power mechanical

bells or horns, audio circuits above 25 volts (RMS), motor

control circuits, or SCR power circuits.

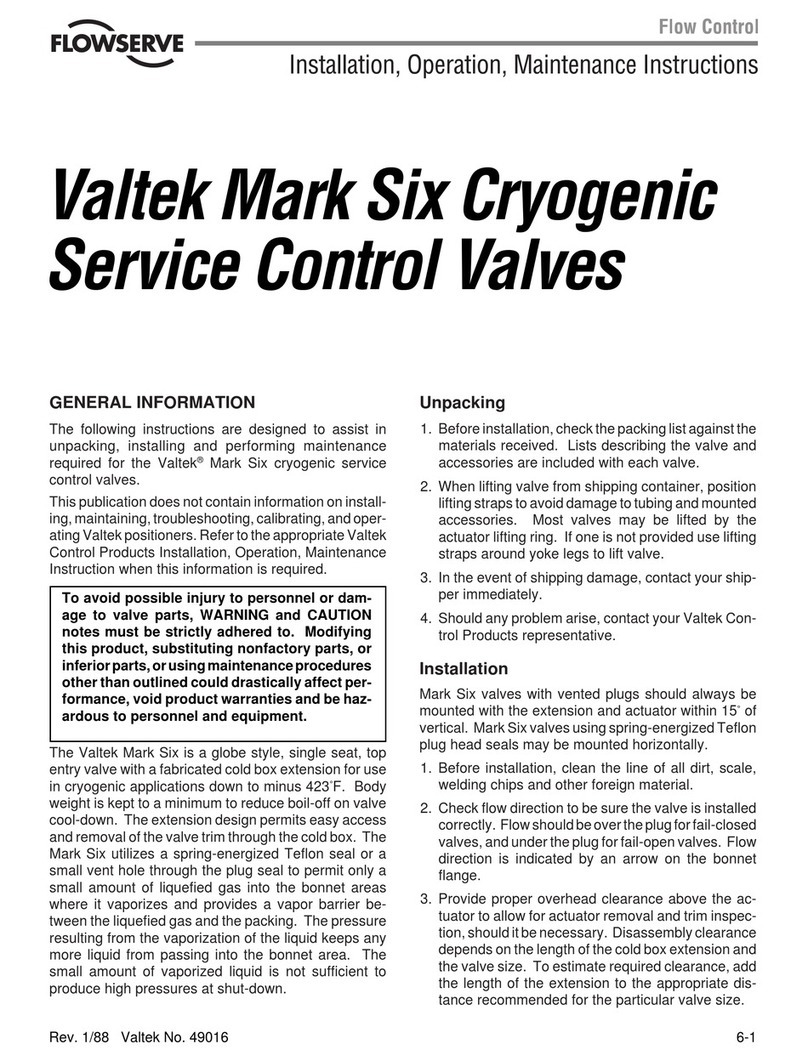

Receive Only Annunciators

For redundant annunciation of system points, annunciators can

be configured as Receive Only annunciators. Receive Only

annunciators must be set to the same address as the

“Receive/Transmit” annunciators they duplicate. Receive Only

annunciators are not fully supervisable. Receive Only

annunciators intercept information being transmitted to a

“Receive/Transmit” annunciator so that this information can be

duplicated at another display location. When configured for

Receive Only operation, they can not send annunciator status

information to the control panel or perform system functions

such as Acknowledge, Silence, or Reset. In addition, they can

not manually override addressable devices such as M510CJ

control modules or XPC-8 or XPR-8 control modules. Control

switches on Receive Only annunciators can be used for local

lamp test only. Wiring to Receive Only annunciators may be

supervised by installing a Receive/Transmit annunciator at the

end of the RS-485 annunciator trunk.

Receive/

Transmit Annunciators

Annunciators configured to serve as full-function annunciators

can receive device and/or zone status information as well as

transmit commands and annunciator status to the control panel.

They can also transmit or override commands to control modules

and control points using custom-wired point control switches.

This capability allows the annunciator to execute system

functions from a remote location in addition to displaying the

status of system points. You must place a Receive/Transmit

annunciator at the end of the RS-485 circuit to provide

supervision of the power supplied to the annunciator(s) and the

RS-485 circuit.

8 Lamp Driver Modules—LDM Lamp Driver Modules

"Receive Only" Annunciator

Set to Address "X"

Full Function "Receive/Transmit"

Annunciator Set to Address "X"

RS-485

Annunciator

Trunk

Circuit *

* RS-485 Annunciator

Trunk Circuit (6000 feet max)

is supervised and power-limited.

ldmannun

LDM-32 LDM-E32

1

2

3

4

5

6

7

1

2

3

4

Fire Alarm Control Panel

LDM-32 LDM-E32

1

2

3

4

5

6

7

1

2

3

4

Figure 3: Connecting Receive Only LDM Annunciator

Lamp Driver Electrical Ratings

The LDM module may use either 24 VDC (regulated) or internal

5 VDC for power connected LEDs. The 5-volt usage conserves

power, but limits the current available to drive the LEDs. Refer

to Figures 13 and 14 for connection illustrations.

Table 1: 5-Volt LED power Limitations

LED Current Maximum Number of Modules

Desired (mA) Number of LEDs LDM-32 LDM-E32

2 130 1 3

5661 1

10 34 1 0

20 17 1/2 0

Lamp Driver Modules—LDM Lamp Driver Modules 9

Notes:

1. The LDM-32 has 34 LED s and each LDM-E32 adds 32 more

LEDs. An LDM system configured for Alarm and Trouble

Mode and employing three expanders could have as many as 130

LEDs.

2. 5-volt power is not used with the LDM-R32 relay module

configurations. The LDM-R32 is compatible with 24 VDC

operation.

Maximum Current per Output: 100 mA (external circuit must

limit current)

Voltage Rating on Output Drivers: 20 VDC

Circuit (typical rating): 5 volts DC at 0.5 mA

Characteristics: Output Driver: Bipolar Darlington Open

Collector NPN Transistor

LDM-32 and LDM-E32 Ratings

Maximum Current per Output: 100 mA (external circuit

must limit current)

Voltage rating on Output Drivers: 30 VDC

Circuit (typical rating): 5 volts DC @ 0.5 mA

Output Driver: Bipolar Darlington Open Collector NPN

Transistor

LDM-R32 Ratings (LDM-R32)

Contact Rating (UL): 1 amp, 30 VDC (resistive)

Contact Material: Gold Clad Silver Alloy

Supervision of LDM Points

Any LEDs or lamps connected to the LDM-32 or LDM-E32

are not supervised for failure. In addition, the dry contacts of

the relays on the LDM-32 cannot be supervised. Therefore,

circuits connected to the relay contacts, as well as all LEDs

or lamps, must be located within 20 feet of the LDM series

modules. If the lamps are in a separate cabinet from the

LDM modules, the inter-cabinet wiring must be enclosed in

conduit or metal raceway.

10 Lamp Driver Modules—LDM Lamp Driver Modules

Calculating the Power Supply Requirements

The LDM series annunciators can draw their power from the

MPS-24A or PS5-BFS-24-UL power supply and must be

considered when calculating primary and secondary power

requirements.

Table 2: Standby Current Draw for LED Power at 24 VDC

Standby Current

[ ] No. of LDM-32 Modules X 40 mA =

The 40 mA can be reduced to 30 mA for modules with

Piezo Disable or Flash Inhibit modes selected.

[ ] No. of LDM-E32 Modules X 2 mA =

[ ] No. of LDM-R32 Modules X (see note) =

Standby Total at 24 VDC =

Note:Enter data here only if the LDM-R32 is connected to an

LDM-32 (not an LDM-E32 expander) AND the LDM-32 has not

been set for the 8-point shift (FC-2000). If both conditions have

been met, then add 18 mA for each LDM-R32 in Alarm and

Trouble Mode, or 9 mA in Alarm Only Mode.

Table 3: Alarm Current Draw for LED Power at 24 VDC

Alarm Current

[ ] No. of LDM-32 Modules X 56 mA =

[ ] No. of LDM-E32 Modules X 18 mA =

[ ] No. of LDM-R32 Modules X 288 =

[ ] No. of LEDs X [ ] mA per LED =

Alarm Total at 24 VDC =

Table 4: Standby Current Draw for LED Power at 5 VDC

Standby Current

[ ] No. of LDM-32 Modules X 40 mA =

[ ] No. of LDM-E32 Modules X 2 mA =

Standby Total at 5 VDC =

Table 5: Alarm Current Draw for LED Power at 5 VDC

Alarm Current

[ ] No. of LDM-32 Modules X 56 mA =

[ ] No. of LDM-E32 Modules X 18 mA =

[ ] No. of LEDs X [ ( ) mA/3 ] =

Alarm Total at 5 VDC =

Lamp Driver Modules—LDM Lamp Driver Modules 11

12 Lamp Driver Modules—LDM Lamp Driver Modules

Installation

The LDM-32 and LDM-E32 modules mount on four standoffs inside

a custom annunciator graphic box. Alternately, the modules may be

installed in a standard CHS-4L chassis (not CHS-4) in a CAB-x3

series enclosure. The module size is approximately 4.4 in. x 7.1 in.

If you are using a CHS-4L chassis to mount the LDM, see Figure 4.

See Figure 5 for instructions on connecting expander modules

together. Refer to Figures 6 and 7 for the procedure on installing the

LDM-R32 modules. See the appropriate installation document for

more information about installing in a CHS-4L in a CAB-x3 series

cabinet.

Note: Remember to ground the enclosure to a solid metallic ground.

Cable Sets for LDM-32 and LDM-E32 Outputs to Lamps or LEDs

The LDM-CBL24 (24 inch) and LDM-CBL48 (48 inch) are

cable sets for connecting the LDM-32 and LDM-E32 outputs to

lamps or LEDs. Each cable set provides several cables (listed in

Table 6), sufficient for most applications.

Table 6: LDM Cable Sets

LDM-CBL24 LDM-CBL48

75116 75147

75117 75148

75118 75149

75122 75150

Cable information and descriptions can be found in the Fire

Management Cable Reference Guide in this manual.

Installing LDM Modules

Mount all modules to the chassis or enclosure as shown in Figure

4. One expander may be added for Alarm Only Mode operation.

One to three expanders may be installed when the lamp driver is

configured for Alarm/Trouble Mode operation. To install the

LDM-32 and LDM-E32, follow the steps below and refer to

Figure 4.

1. Slip the bottom edge of the LDM-32 into the slot on the

CHS-4L chassis and swing the module toward the standoffs

(Figure 4).

2. If not employing the optional relay expander (LDM-R2),

secure the LDM-32 to the chassis with the screws provided

(Figure 4).

3. Repeat for installation of any LDM-E32 expander modules on

the chassis (Figure 4).

Lamp Driver Modules—LDM Lamp Driver Modules 13

LDM-32

CHS-4L

ldminstl

Figure 4: Installing the LDM Module in the CHS-4L

Chassis

Connecting LDM-E32 Expander Modules (Optional)

Connect an expander ribbon cable between the LDM-32

(Connector J2) and the LDM-E32 expander modules

(Connector J3) as illustrated in the figure below.

1

2

3

4

5

6

7

1

2

3

4

Expander Ribbon Cables (75120)

LDM-E32 LD

LDM- 32 LDM-E32

Figure 5: LDM Ribbon Cable Connection

Installing LDM-R32 Relay Modules (Optional)

The outputs on the LDM-32 or LDM-E32 module, instead of

driving LEDs, may be used to activate the LDM-R32 relay

module. This option provides the system with up to 32

electrically isolated outputs per relay module. If employing

an LDM-R32, install it using the following steps and refer to

Figures 6 and 7.

1. Secure the LDM-R32 to the LDM-32 with the standoffs

provided. (See Figure 6.)

14 Lamp Driver Modules—LDM Lamp Driver Modules

2. Attach ribbon cables between the LDM-32 and the

LDM-R32 for each group of relays needed (connector J5 to

J5, J6 to J6, etc.) as illustrated at in Figure 6.

Note: The relay module can also be connected to an

LDM-E32.

ldmconn

LDM-32 LDM-R32

(75119)

Standoff Standoff

Chassis LDM-32

(or LDM-E32) LDM-R32

Figure 6: Installing LDM-R32 Relay Modules

3. Connect the relay power ribbon cable (75119) between

J10 on the LDM-R32 and J10 on the LDM-32 or LDM-E32

(Figure 6). This connection supplies the power needed to

energize the LDM-R32’s 24 VDC relay coils during

activation.

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Relay

J10

J5 J6 J8J7

TB1 TB4

1

2

3

4

5

6

7

8

Relay

J10

J5 J6 J8J7

1

2

3

4

5

6

7

8

LDM-32

(or LDM-E32)

LDM-R32

ldmrelay

Figure 7: Powering LDM-R32 Relay Modules

Terminating the Shield

Lamp Driver Modules—LDM Lamp Driver Modules 15

Wire the RS-485 annunciator trunk circuit using a

twisted-shielded pair cable. Do not run cable adjacent to, or

in the same conduit as, 120 VAC service, noisy electrical

circuits powering mechanical bells or horns, audio circuits

above 25 VRMS, motor control circuits, or SCR power

circuits. All enclosures, including the control panel backbox,

must be connected to earth ground! Never use the shield for

grounding purposes. Terminate the RS-485 annunciator

trunk shield at the Fire Alarm Control Panel only.

When the RS-485 Annunciator Trunk Shield is in Conduit

Connect the shield to system reference (system common).

The shield can enter the cabinet, but must be insulated

from the cabinet (not electrical contact). Between

annunciators, wire-nut multiple shields together. The

shields may be inside of the respective enclosure).

When the RS-485 Annunciator Trunk Shield is Not in

Conduit

Terminate the shield at the outside of the control panel

backbox (ground). Do not allow the shield to enter or

even touch the cabinet. Between annunciators, wire-nut

multiple shields together outside of the respective

enclosures.

Shield

LDM

Shield

IFC Controller Enclosure

Figure 8: Terminating the Shield

Wiring the Lamp Driver Module

Up to 32 annunciator devices may be installed on the RS-485

annunciator trunk circuits. However, if you use both RS-485

annunciator circuits, a total of 64 devices can be installed, but the

number of addresses is limited to 32. Communication between

the control panel and the LDM is accomplished over a 2-wire

RS-485 annunciator trunk serial interface.

LDM Terminal Wiring

Figure 9 shows the LDM annunciator trunk and power

terminations. Figure 10 illustrates how to wire multiple LDM

modules. When wiring the LDM module, follow these

guidelines:

●Do not T-Tap the RS-485 annunciator trunk circuit.

16 Lamp Driver Modules—LDM Lamp Driver Modules

●Leave the 120-ohm ELR resistor installed across the RS-485

Out terminals at the last annunciator on the circuit. (See Figure

10). Remove this resistor from all other annunciators.

●Connect earth ground to a mounting screw on the backbox or

cabinet.

●The 24 VDC power supplied to the annunciator need not be

supervised by an end-of-line power supervision relay. This

power is inherently supervised (as long as the last annunciator on

the RS-485 annunciator trunk is in the Receive/Transmit

configuration). The control panel registers a loss of

communications during loss of power to the annunciator.

TB2

N.C. Trouble

Inputs

Common In (-)

Common Out (-)

Power In (+24 VDC)

Power Out (+24 VDC)

Earth Ground

RS-485 In (-)

RS-485 Out (-)

RS-485 Out (+)

RS-485 In (+)

ldmwire

1

2

3

4

TB1

1

2

3

4

5

6

7

Figure 9: LDM Terminal Wiring

The RS-485 annunciator trunk circuits must be twisted shield type cable with a maximum

distance of 6000 feet with 16 AWG or 4000 feet with 18 AWG.

ldmwire

TB2

RS-485 (-)

RS-485 (+)

TB2

120 ohm ELR

Part No.

71244

First AnnunciatorControl Panel Last Annunciator

SIB

Figure 10: Wiring Multiple Annunciators

(4000-Foot Maximum Run at 18 AWG)

Note:IFC-1010/2020 users: Refer to the Installing the

IFC-1010/2020 document in the IFC-1010/2020 Technical

Manual, FAN 448, for RS-485 annunciator trunk connections at

the SIB-2048 or SIB-N2.

Connecting the Supervisory Input

Lamp Driver Modules—LDM Lamp Driver Modules 17

The Trouble Input on P3, terminals 6 and 7 can be used for

supervising local power sources or other devices containing a

normally closed contact. If employed, all changes in status (to

and from the trouble state) will be sent to the control panel in the

event of device failure or restoral. If not used, a jumper must be

installed across these terminals on TB1. A trouble signal will be

registered by the control panel if a short circuit does not exist

across these terminals. See Figure 11.

Note:When not using the trouble input, jumper terminals 7 and 6

together.

supvdvce

1

2

3

4

5

6

7

Trouble

Input

1

2

3

4

5

6

7

Trouble

Input

TB1

Normally Closed

Trouble Contacts

Device to be Supervised

5 VDC at 0.5 mA

Unused Trouble Input

TB1

Figure 11: Wiring the Trouble Supervisory Contact

Wiring Point LEDs and Relays

The LDM-32 must be set via SW4 (Figure 19) for Alarm/Trouble

Mode to enable the point control switches to function. (The

Acknowledge/Lamp Test switch, connected to J1, works in either

mode.) A maximum of 16 points per module are available under

this configuration (switch inputs 1-16 and annunciator control

points 1-16, respectively). Not all switches need to be used--

switches can be wired only for desired functions (Figure 12).

Control Switch Security

A key-lock switch wired to J4 on the LDM-32 provides

access security for all control switches wired to that module.

Switches will not function when the key-lock switch is in its

closed position.

Note: Switches must be UL Listed to switch 5 volts DC @

0.5 mA. Switches must be either key-lock type or they must

be secured in a locked enclosure or a key switch, such as the

AKS-1, to control access and must be installed and wired to

J4 (if any of the switch inputs are used to control system

functions). All switches must be installed in the same room

as, and no more than 20 feet from, the LDM enclosure.

Switch wiring must be in conduit.

18 Lamp Driver Modules—LDM Lamp Driver Modules

ldmpcs

LDM-32

(or LIM-E32)

J5

Outputs

J4 Keyswitch

J1

Switch

Matrix

12

11

10

9

8

7

6

5

4

3

2

1

Switch 14

Switch 13

Switch 12

Switch 11

Switch 10

Switch 9

Switch 8

Switch 7

Switch 6

Switch 5

Switch 4

Switch 3

Switch 2

Switch 1

Switch 16

Switch 15

Acknowledge/

Lamp Test

Switch

Figure 12: Connecting Optional Point-Control

Switches

Lamp Driver Power

Lamp driver outputs can be powered from 24 VDC or 5 VDC,

depending on the loading required. Figures 13 and 14 illustrate

connection of the desired voltage, as well as the system trouble

LED. Connection of LDM operating power from a main power

supply is illustrated in Figure 15. The MPS-24A, or other UL

Listed regulated 24 VDC power supply, powers the LDM

annunciator.

Lamp Driver Modules—LDM Lamp Driver Modules 19

J5 J6 J7 J8

+5 V

Common

Outputs J11 (optional)

Keyswitch

J4 J10

Relay

Exp

1

2

J9

1

2

3

Lamp

Power

Point Status LEDs:

Use red for alarm points,

yellow for trouble points,

and green for output points.

Use 60 ohm, 1/4 watt resistors

for each point.

Figure 13: Typical LDM-to-Custom Annunciator

Connection @ 5 VDC

(Using High Efficiency 2 mA LEDs)

Note:To find the resistor size for LEDs other than 2 mA, use this

formula:

(Voltage supplied from LDM -Voltage draw of LED)

LED impedance value

20 Lamp Driver Modules—LDM Lamp Driver Modules

Key-

switch

J11

J5 J6 J8J7

+5 V

Common

(opt.)

J4 J10

Relay

EXP

1

2

Lamp

PWR

1

2

3

J9

+24 V

Point Status LEDs:

Use red for alarm points,

yellow for trouble points,

and green for output points.

All LEDs must be

located in the

same room as

the modules.

System

Trouble

LED:

(Yellow)

To find the resistor size for

LEDs other than 2 mA, use th

i

formula:

(Voltage supplied from L

D

-Voltage Draw of LED).

LED Impedance Value

ldm-nga1

Use 10K ohm, 1/4-watt

resistors for each point.

Figure 14: Typical LDM-to-Custom Annunciator

Connection @ 24 VDC (Using High Efficiency 2 mA

LEDs)

This manual suits for next models

3

Table of contents

Other Metasys Control Unit manuals

Popular Control Unit manuals by other brands

Roco and Fleischmann

Roco and Fleischmann z21start user manual

CLA-VAL

CLA-VAL 49-01/649-01 Installation, operation and maintanance manual

Enerpac

Enerpac VP Series instruction sheet

Protectoseal

Protectoseal 7800 Series Installation & maintenance

Beninca

Beninca KER manual

RDZ

RDZ WI-SA Technical installation manual