Metasys SCM Synchronization User manual

Fire Initiating Devices and Notification Appliances Technical Manual 408

Notification Appliances Section

Technical Bulletin

Issue Date 1095

© 1995 Johnson Controls, Inc. 1

Code No. LIT-408255

Introduction Page 3

●

General Description 3

Installation Procedures 7

●

Mounting 7

●

Wiring Installation Guidelines 8

●

Limitations 10

SCM Synchronization (Sync) Control Module

2 Notification Appliances—SCM Synchronization (Sync) Control Module

Notification Appliances—SCM Synchronization (Sync) Control Module 3

Introduction

The SCM synchronization (sync) control module is UL Listed under

Standard 1971 for emergency signaling devices for the hearing impaired

and for indoor use by the Fire Protective Service. The SCM is

manufactured by Wheelock for use with the Johnson Controls systems and

is designed to work with the SL, SLM, and SHW sync strobes to provide

synchronized flashes when the sync strobes are activated. This feature

offers an easy way to comply with Americans with Disabilities Act (ADA)

recommendations concerning photosensitive epilepsy.

All inputs are polarized for compatibility with standard reverse polarity

supervision of a Notification Appliance Circuit (NAC) wiring by a Fire

Alarm Control Panel (FACP) or system NAC control devices.

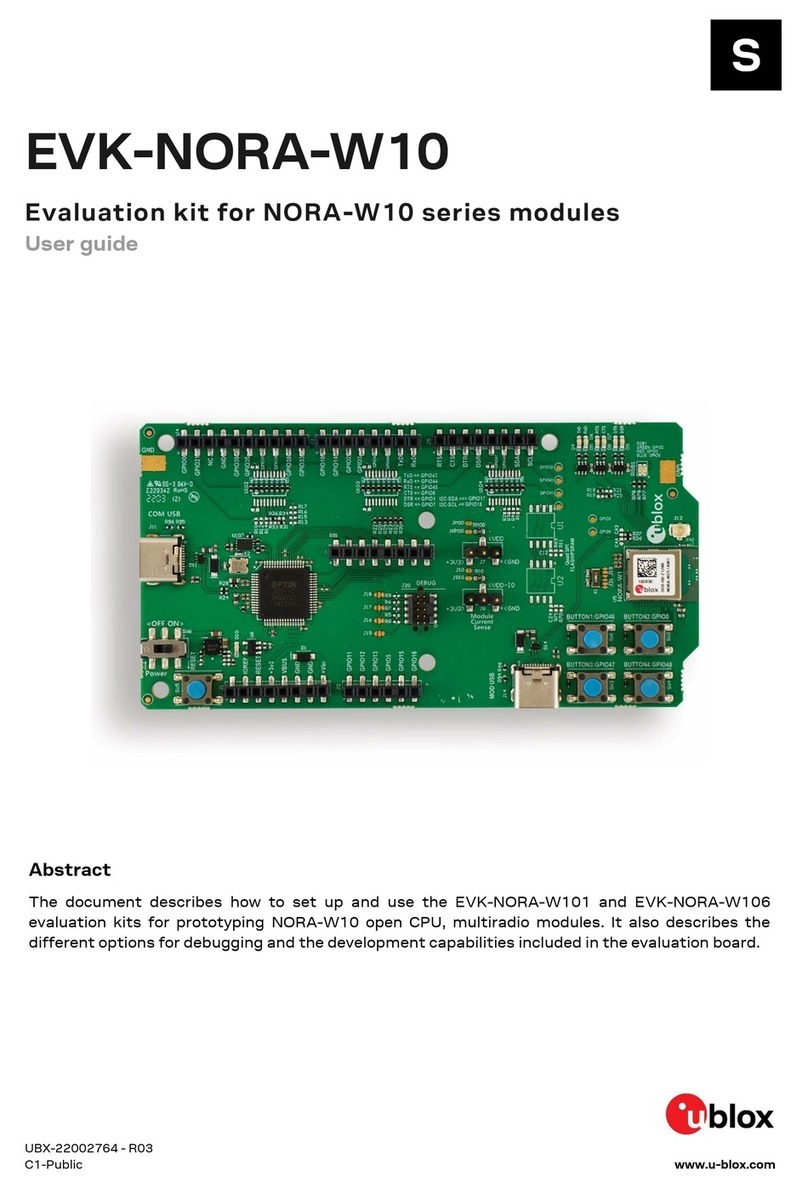

2-3/8 in.

4-1/2 s

q

. in.

1-7/8 in.

scm1

Figure 1: Dimensions

Note: In order to ensure proper operation, this product should be applied

as specified in the applicable National Fire Protection Association

(NFPA) codes and in compliance with its UL listing.

!

WARNING: Personal injury hazard. Failure to follow these

directions may result in the failure of the device to

report an alarm or trouble condition.

Johnson Controls is not responsible for devices that have been improperly

installed, tested, or maintained by others.

The SCM sync control module is UL Listed for indoor use with a

temperature range of 32 to 120°F (0 to 49°C) with a maximum relative

humidity of 85%.

General

Description

4 Notification Appliances—SCM Synchronization (Sync) Control Module

The UL Listed rated input voltage is 20-31 VDC using either filtered

(regulated) DC or unfiltered (unregulated) Full-Wave Rectified (FWR)

voltage. To verify that the signaling device is operating at rated voltages,

determine the voltage drop caused by the resistance of the Notification

Appliance Circuit (NAC) wiring. Then, subtract this voltage from both

the maximum and minimum power supply and battery voltages. The flash

rate induced by the sync control module is one flash per second across a

voltage range of 20-31 VDC/FWR.

Note: Sync strobes and sync control modules are not designed to be used

on coded systems in which the applied voltage is cycled on and off.

This equipment has been tested and complies with the limits for a Class B

digital device, pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference in

installations. This equipment generates, uses, and radiates radio frequency

energy. If not installed and used in accordance with the instructions, this

equipment may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by turning the

sync strobe and/or audible equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

1. Reorient or relocate the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Consult the dealer or an experienced radio/TV technician for help.

!

CAUTION: Equipment damage hazard. Although UL

testing has verified these products function at 80%

of their minimum rating and 110% of their

maximum rating, Johnson Controls recommends

that the voltage applied to these products be within

their rated input voltage range. The application of

improper voltage may result in degraded operation

or damage to these products.

Table 1: SCM Series Sync Control Module Specifications

Model Nominal Voltage

(VDC) Rated Input

Voltage (VDC) Mounting

Option

SCM-24-R 24 20-31 A

Note: Ratings per UL 1971.

Notification Appliances—SCM Synchronization (Sync) Control Module 5

Table 2: Sync Control Module Current Requirements

Voltage Rated Average

Current Rated Peak Current Rated Inrush

Current

20 VDC 0.010 0.040 0.060

24 VDC 0.013 0.045 0.070

31 VDC 0.015 0.055 0.090

20 VFWR* 0.013 0.055 0.085

24 VFWR* 0.017 0.063 0.099

31 VFWR* 0.020 0.078 0.127

* All VFWR voltage ratings are measured with a DC voltmeter. Multiply VFWR

voltage by 1.11 to convert to VRMS.

!

WARNING: Personal injury hazard. Make sure that the total

current required by all devices that are connected

to the sync control module does not exceed

1.6 amperes. Overloading these sources could

result in loss of power and failure to alert

occupants during an emergency.

To calculate the total current:

1. Use the sync strobe current requirement tables in the SL and SLM

Series Synchronized (Sync) Strobe Signals and SHW Series

Synchronized (Sync) Strobe Signals Technical Bulletins to determine

the highest value of rated average current for an individual sync

strobe.

2. Multiply this value by the total number of the sync strobes on the

circuit.

3. Add the current for the sync control module and for any other devices,

including any required safety factors.

Make sure that all fuses used on signaling circuits are rated to handle the

maximum inrush or peak current from all devices on those circuits.

Failure to do this may result in loss of power to the signaling circuit and

the failure of all devices on the circuit to operate.

If the power supply being used has an electronic circuit designed to

comply with National Electrical Code requirements for power limited

circuits, verify that the power supply reaction time to inrush current is

longer than 2 milliseconds for the SL and SLM strobes, and is longer than

6 milliseconds for the SHW strobe, or that that the total inrush current

presented to the power supply is less than its current capacity rating.

Total Current

6 Notification Appliances—SCM Synchronization (Sync) Control Module

Inrush current refers to current that exceeds the nominal voltage when the

strobe is first turned on. Once the strobe is turned on, it flashes one flash

per second. Peak current indicates the current rising above the nominal

voltage right after each strobe flash.

To calculate maximum inrush or peak current:

1. Use the sync strobe current requirement tables in the SL and SLM

Series Synchronized (Sync) Strobe Signals and SHW Series

Synchronized (Sync) Strobe Signals Technical Bulletins to determine

the highest value of rated inrush current or rated peak current

(whichever is higher) for an individual sync strobe.

2. Multiply this value by the total number of sync strobes on the circuit.

3. Add the inrush or peak currents from the sync control module and any

other devices on that circuit. Include any required safety factors.

Note: The time duration of the maximum inrush or peak current is

2 milliseconds for SL and SLM, and 6 milliseconds for

SHW models.

Peak and Inrush

Current

Notification Appliances—SCM Synchronization (Sync) Control Module 7

Installation Procedures

NFPA 72 and ANSI 117.1 provide a means for determining equivalent

illumination using fewer, higher intensity sync strobes within the same

protected area. For detailed information about installing sync strobes, see

the SL and SLM Series Synchronized (Sync) Strobe Signals and SHW

Series Synchronized (Sync) Strobe Signals Technical Bulletins.

Refer to Figure 2 when installing the sync control module. Mounting

hardware is provided with the product.

!

CAUTION: Equipment damage hazard. The National

Electrical Code (NEC) Article 370-6 limits the

maximum number of conductors that can enter a

backbox based on the size of the backbox and the

size of the wiring used. Johnson Controls

recommends that you adhere to the conductor

limitations shown in the table following the

mounting option.

Select the conduit entrance to the backbox to ensure sufficient wiring

clearance for installed equipment.

Note: If a sheathed multiconductor cable or 3/4 in conduit fitting is used,

check that the installed product has sufficient clearance and wiring

room prior to installing the backboxes and conduit.

!

CAUTION: Equipment damage hazard. Check the

installation instructions of the manufacturers of

other equipment used in the system for any

guidelines or restrictions on wiring and/or locating

signaling circuits and signaling devices.

Mounting

8 Notification Appliances—SCM Synchronization (Sync) Control Module

scm2

Standard

2-Gan

g

x 3-1/2 inch

Deep Backbox

(

4

)

No. 6 32 x 1 inch

Screws

Figure 2: Flush Mounting (Option A)

Table 3: Mounting Option A Conductor Limitations

AWG 18 AWG 16 AWG 14 AWG 12

4444

Use care and proper techniques when positioning the field wires in the

backbox. Be sure to use the minimum required space and avoid undue

stress on the product. This is especially important for stiff, heavy gauge

wires and wires with thick insulation or sheathing.

Do not used more lead length than required when terminating field wires.

Excess lead length may result in insufficient wiring space for the signaling

device. Do not pass additional wires (used for equipment other than the

signaling device) through the backbox. Excessive wires may result in

insufficient wiring space for the signaling device.

Figure 3: Sync Strobes Connection Diagram

Mounting Option A

Wiring

Installation

Guidelines

scm3

Fire Alarm

Control Panel

(FACP)or

System NAC

Control Device

Input Output

Sync

Control

Module

SCM-24

Strobe

or Combination

Strobe

and Audible No. N

End-of-Line Resistor

(EOLR)

Strobe

or Combination

Strobe

and Audible No. 2

Strobe

or Combination

Strobe

and Audible No. 1

Notification Appliances—SCM Synchronization (Sync) Control Module 9

Figure 4: SCM Sync Control Module Wiring Diagram

Sync strobe signals have in/out wiring terminals that accept two

No. 12 to 18 AWG wires at each screw terminal.

1. Strip wire leads approximately 3/8 inch for connection to terminals.

2. Break wire run at wiring terminals to provide electrical supervision

(Figure 5). Do not loop wires under the terminals.

The polarity shown in the wiring diagrams is for the operation of the

signals. The polarity is reversed by the FACP during supervision.

wire1

Figure 5: Proper NAC Wire Termination

Connect the signaling device to the backbox using the lock washer

(provided in the hardware bag) under the head of each mounting screw.

(+) (+)(-) (-)

In Out

From FACP

or S

y

stem NAC

ControlDevice To S

y

nc Strobe

scm4

Wiring the Device

Grounding

10 Notification Appliances—SCM Synchronization (Sync) Control Module

Test your alarm system per the applicable codes and standards specific to

the location and use of your facility.

The audible device and/or sync strobe will not work without power. The

audible device/sync strobe gets its power from the fire/security panel

monitoring the alarm system. If power is cut off for any reason, the

audible device/sync strobe will not provide the desired audio or visual

warning.

The audible device may not be heard. The loudness of the audible device

meets or exceeds current Underwriters Laboratories standards. However,

the audible device may not alert a sound sleeper, one who has recently

used drugs, or one who has been drinking alcoholic beverages. The

audible device may not be heard if it is placed on a different floor from the

person in hazard, or if it is placed too far away to be heard over ambient

noise such as traffic, air conditioners, machinery, or music appliances that

may prevent alert persons from hearing the alarm. The audible device

may not be heard by persons who are hearing impaired.

The signal sync strobe may not be seen. The electronic visual warning

signal that flashes at least once every three seconds meets or exceeds

current Underwriters Laboratories Standard 1971, and uses an extremely

reliable xenon flashtube. The visual warning signal is suitable for direct

viewing and must be installed within an area where it can be seen by

building occupants. The sync strobe must not be installed in direct

sunlight or in areas of high light intensity (over 60 foot candles) where the

visual flash might be disregarded or not seen. The sync strobe may not be

seen by the visually impaired.

The signal sync strobe may cause seizures. Individuals who have a

positive photic response to visual stimuli with seizures, such as epileptics,

should avoid prolonged exposure to environments in which sync strobe

signals, including this sync strobe, are activated.

Johnson Controls recommends that the audible and signal sync strobes be

used in combination to minimize risk.

The signal sync strobe cannot operate from coded power supplies. Coded

power supplies produce interrupted power. The sync strobe must have an

uninterrupted source of DC power in order to operate correctly.

Limitations

Notification Appliances—SCM Synchronization (Sync) Control Module 11

Notes

12 Notification Appliances—SCM Synchronization (Sync) Control Module

Notes

Controls Group FAN 408

507 E. Michigan Street Fire Initiating Devices and Notification Appliances Technical Manual

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201

This manual suits for next models

1

Table of contents

Other Metasys Control Unit manuals

Popular Control Unit manuals by other brands

Paradox

Paradox Digiplex Liberator DGP-319 Installer's guide

Alfalaval

Alfalaval Unique Mixproof 3-body instruction manual

Paradox

Paradox APR3-HUB2 instructions

red lion

red lion MODULAR CONTROLLER SERIES manual

System air

System air PKI-C Series Installation, operation and maintenance manual

SIGMA TEK

SIGMA TEK C-DIAS manual