MAN#650507C

For HDX systems follow these steps:

•Make sure the BIM units are all connected to the gauge control box.

•With the ignition on, press and hold both switches to enter SETUP. With external switches hold either one while

turning the ignition on. Release the switches when SETUP is shown.

•Press and release either switch until BIM is selected. Press and hold either switch to enter BIM setup menu.

•Release the switch. A list of the BIM’s found should be shown. If NONE FOUND is displayed then check

connections to the BIM-19-2.

•Press and release either switch until BIM-19-2 is selected with the desired location label shown.

•Press and hold either switch to enter setup for this module.

•Release the switch. The menu will show FORMAT, LABEL, WARN LO, WARN HI, CALIBRATE, BACK. Any

menu that does not apply to this BIM will be grey and cannot be selected.

•Use either switch to select the option you wish to change, (refer to the HDX manual for specifics).

•When you are finished select BACK to return to the BIM selection menu.

•When you are finished, select BACK to return to the BIM list menu, select BACK to return to the main menu, and

then select EXIT SETUP to return to normal operation.

With HDX systems the setup can also be done with the Dakota Digital app for Apple and Android devices.

Troubleshooting quick tips:

While the BIM is operating, the dot in the upper left corner of the display will indicate the status. On steady indicates it is

powered up but not receiving any bus activity. Flashing indicates it is communicating on the bus.

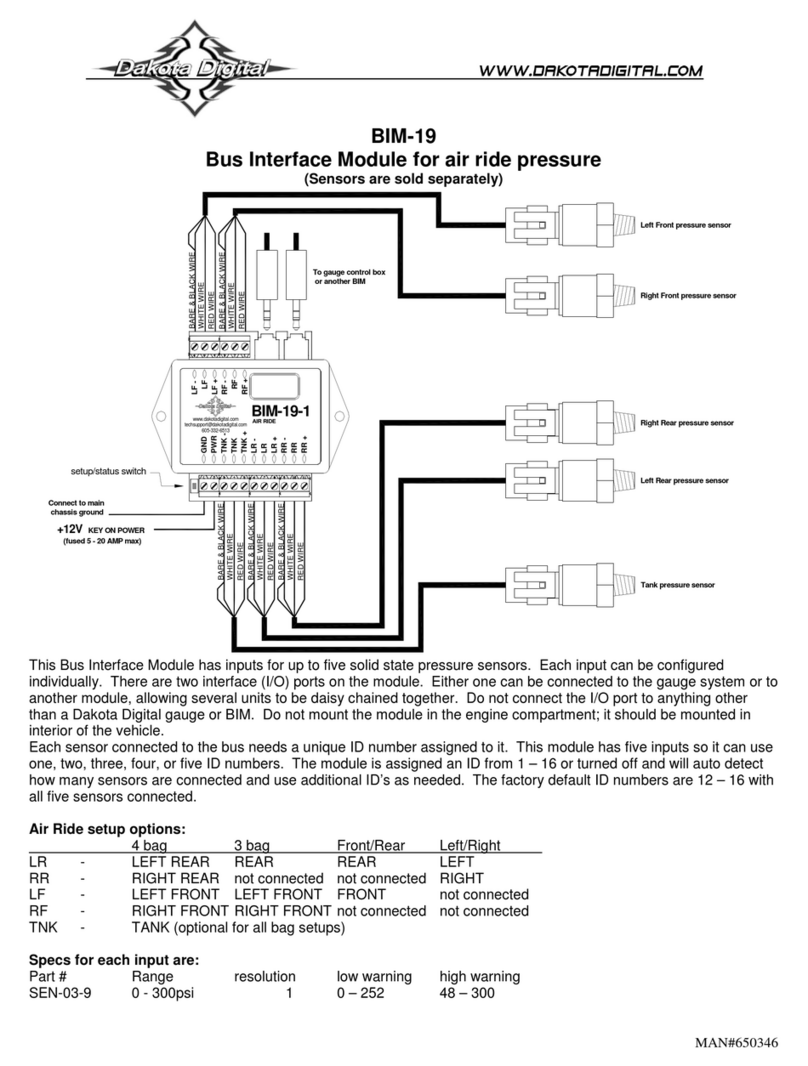

To see the sensor and channel status on the BIM display, press and hold the switch. The display will cycle through three

screens. The first will show the sensor input status. The first digit shows the status for the tank sensor. The second digit

shows the status for the Left Front and Left Rear. The third digit shows the status for the Right Front and Right Rear. ‘’

indicates there is a bus ID conflict on that channel ID. A solid ‘’ indicates the sensor is connected properly (tank uses

center dash, front uses top dash, and rear uses bottom dash). A flashing ‘-’ indicates the sensor signal is too low or too

high. Blank indicates that there is no sensor connected.

The second screen will show the beginning ID number assigned. The third screen will show the number of sensors

connected.

Troubleshooting guide.

Problem Possible cause Solution

Sensor does not show on PWR terminal does not have power. Connect to a location that has power.

gauge readout. GND terminal does not have a good Connect to a different ground location.

BIM will not light up at all. ground.

Module is damaged. Return for service. (see instructions)

Sensor does not show on Interface cable is not connected. Connect the supplied 3.5mm data cable between the BIM unit and

gauge readout. the gauge control box.

BIM has a steady dot lit Interface cable is loose. Make sure both ends of the cable are seated in securely.

On VHX systems, the BIM display Follow instructions in VHX manual to enable the BIM display screen.

for this channel is disabled.

Another BIM is set with the same Test module works when connected to control box alone. Change ID

channel ID. on one of the modules so each module uses unique ID.

Gauge lights up, but does Loose connection on sensor wires. Inspect and reconnect wires.

not read correctly. Connector not seated on sensor. Reattach the sensor plug, making sure the locking tab clicks in place.

Voltage or wiring problem in the Check wiring harness for loose or damaged wires.

vehicle wiring harness.

Gauge reading is blank and Sensor is not connected to BIM. Connect terminals on BIM to sensor wires. (see wiring diagram)

no ‘-‘ on BIM

Gauge lights up, but displays Sensor wire is shorted to ground. Check wire for damaged insulation. Replace if necessary.

“---”. (flashing ‘-’ on BIM) Wire between gauge and sensor is Test and replace wires.

damaged or broken.

Sensor is damaged. Replace sensor.

Module is damaged. Return module for service. (see instructions)

Gauge lights up, but displays Wire between gauge and sensor is Test and replace wires.

“EEE”. (flashing‘-’ on BIM) damaged or broken.

Sensor is damaged. Replace sensor.

BIM display shows “”Data cable is damaged. Inspect and replace 3.5mm data cable or power/data harness.

Another module on the bus is damaged Inspect other modules on the data bus.

or connected improperly.

Sensor voltage tests: (test with BIM powered and sensor connected.)

red wire: 4.5 –5.0 V

white wire: 0.4 –4.5V (0.4 –0.6V with 0 psi)

black wire: 0 volts