1 x PRINTED SHEET - Components for all buildings.

1 x PLAIN GREY CARD X- Interior strengthening parts.

1 x PLAIN GREY CARD Y- Interior strengthening parts.

1 x LASER-CUT CARD - Canopy edging and brackets.

1 x GLAZING SHEET.

2 x INSTRUCTION SHEETS.

1 x Ridge Tile Sheet.

1 x Chimney pots, posters and extra doors sheet

PN138 N GAUGE

WAYSIDE STATION KIT

INSTRUCTION SHEET 1

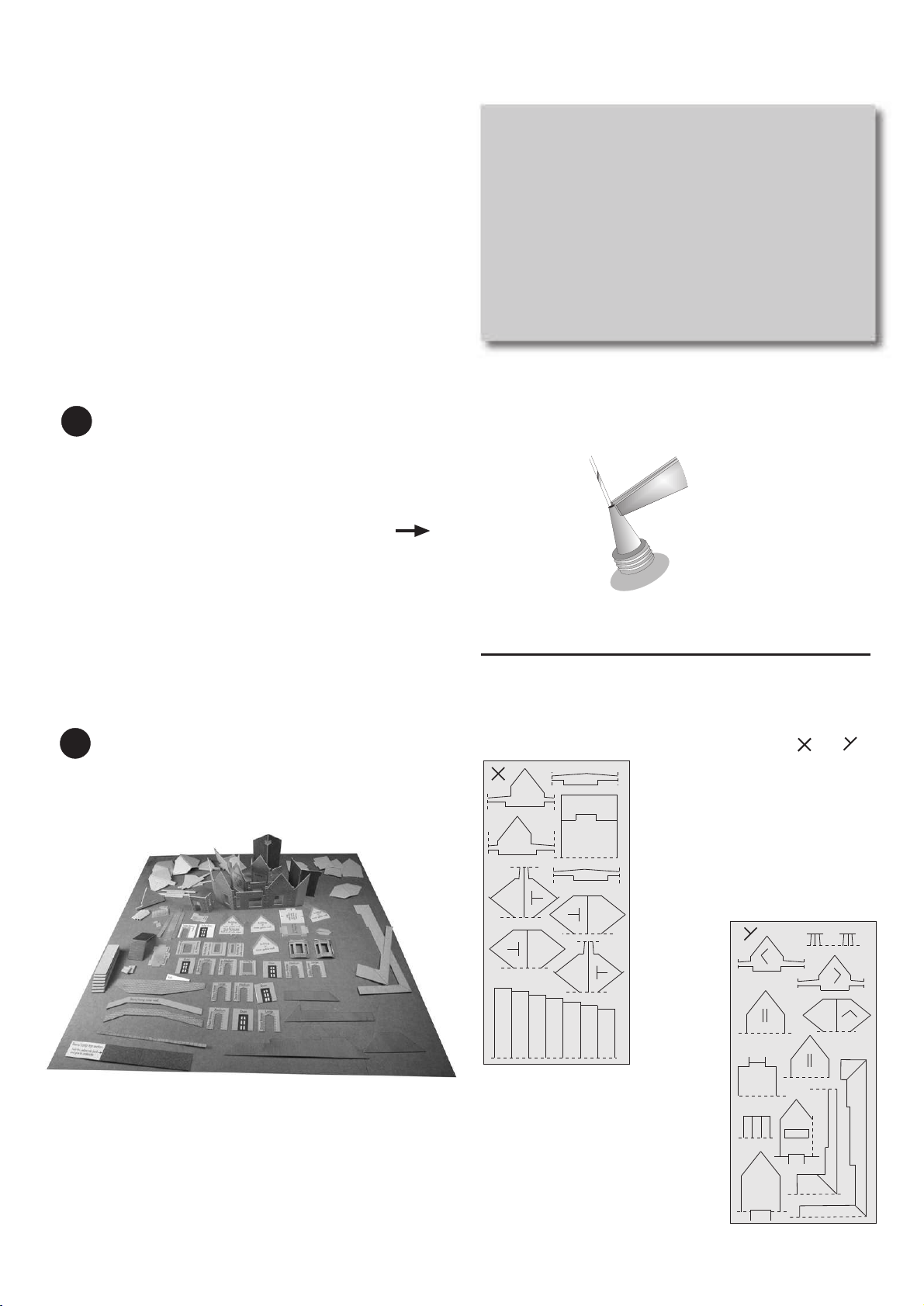

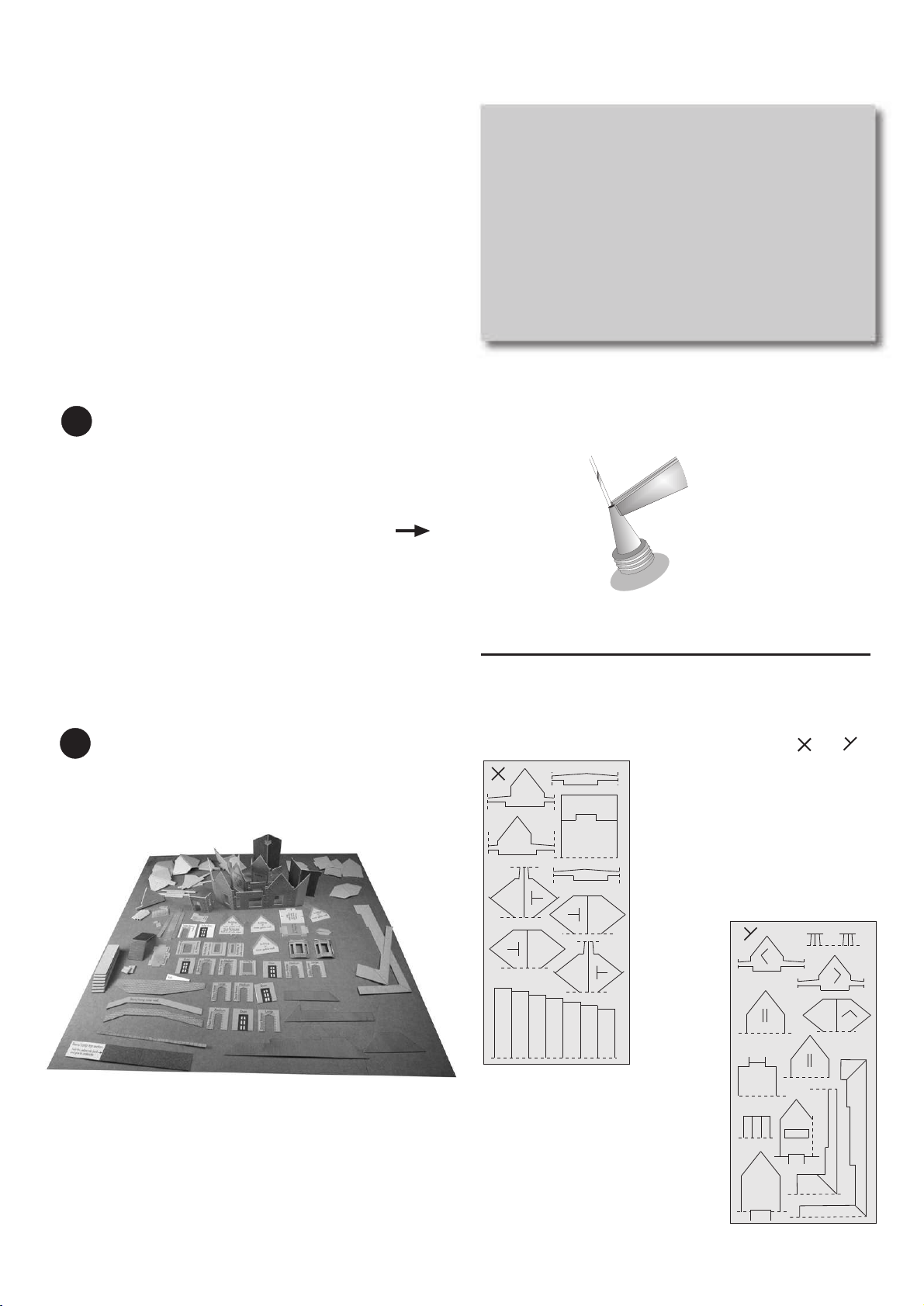

To make the

nozzle smaller,

put a piece of

wire from a

medium size

paper clip or a

large pin inside.

Although the 20ml. tubes of UHU have narrow nozzles, they

are still a bit too big

If using the glue frequently, it is not necessary to keep

replacing the pin in the nozzle. Simply place the tube

upright in an empty cup when not in use.

Then with a pair of pliers

nip one side of the nozzle

tightly, so that it squeezes

the soft metal around

the pin.

Keep the pin in the nozzle

when not in use to stop

it from blocking up.

UHU GLUE TUBES

To construct this kit you will need the following:

1. A Modellers knife.

2. A pair of sharp pointed scissors.

3. A steel ruler.

4. Glue - UHU Clear Adhesive is our favourite.

5. A cutting surface - a sheet of card or a cutting mat.

6. Fine point tweezers to hold the smaller components.

7. Water colour paints and a very fine brush, for

painting the edges and corners (optional).

READ THROUGH ALL THE

INSTRUCTIONS BEFORE YOU START.

GETTING STARTED

CHECK LIST

This kit pack should contain the following:

The awnings and brackets have been laser cut for finer detail

and are contained on a separate cream coloured sheet.

THESE ARE BEST LEFT ALONE ON THIS SHEET UNTIL

YOU HAVE BUILT THE MAIN BODY OF THE KIT.

The diagram (Fig. 15.) show the lines that you will need

to cut to release the components from the sheet.

PLEASE NOTE: Don’t throw anything away. Keep all offcuts

and waste card in a box until the kit is finished, just in case

you can’t find anything. The chances are that it will be there.

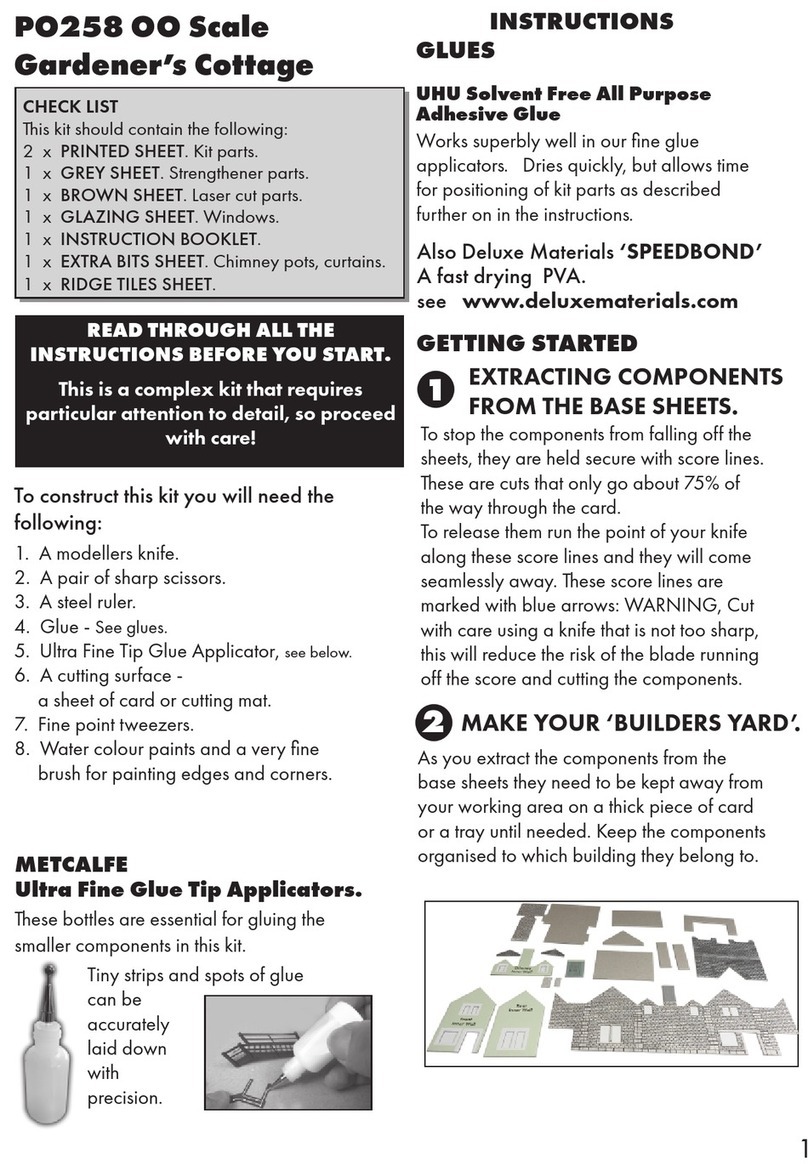

PLAIN GREY CARD COMPONENTS.

These thick card pieces are used within the kit to strengthen

and thicken parts of the kit. The dotted lines indicate where

you need to cut to release from base sheet.

There are two sheets of card, marked top corner and

2

1

1

3

3

4

4

5

5

6

7

8

9

10

11

12 13

14 15

16

8

10

SHEET X.

1. Building B roof & canopy support.

2. Building A inner floor.

3. Building B canopy supports x 2.

4. Building A gable inner wall spacers x 2.

5. Building A roof & canopy supports x 2.

6. Platform steps x 7

SHEET Y.

7. Small canopy beams x 2

8. Building C roof & canopy supports x 2.

9. Building C gable wall spacer.

10. Building B gable inner wall spacers x 2.

11. Building B inner floor thickener.

12. 3 x Large chimney stack inner formers.

13. Building C inner gable end wall.

14. Building B inner gable end wall.

15/16 Canopy lower roof units.

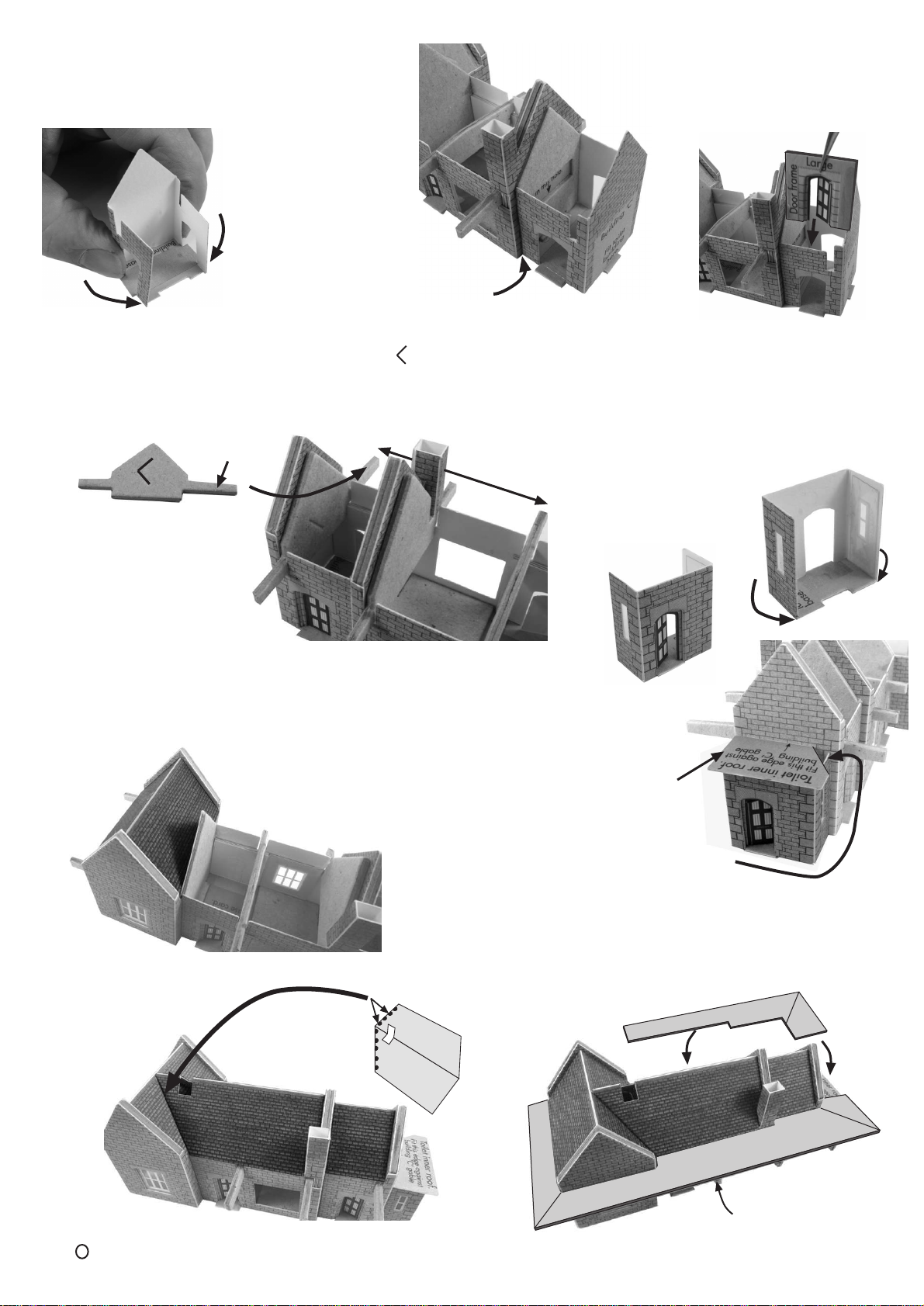

To stop the components from falling off the sheets, they

are held secure with scorelines. These are cuts that only

go about 75% of the way through the card.

To release them simply run the point of your knife along

the scorelines and they will come seamlessly away.

These scorelines are indicated with blue arrows:

WARNING, Cut with care using a knife that is not too

sharp, this will reduce the risk of the blade running out

of the score and cutting the kit components.

1EXTRACTING COMPONENTS FROM SHEETS.

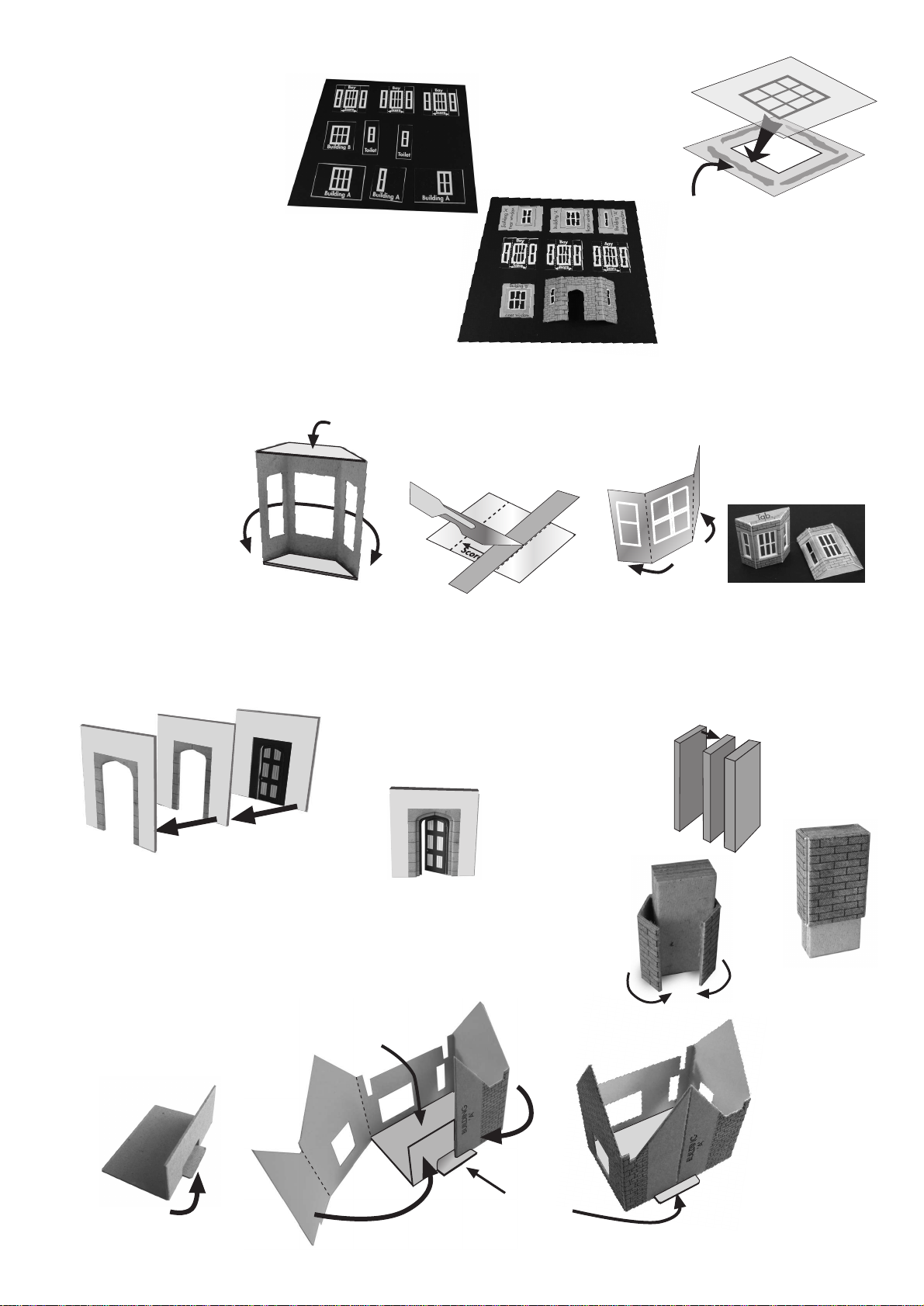

2MAKE YOUR ‘BUILDERS YARD’.

This is an area kept away from your working surface, where

you store ALL components extracted from the base sheets

until needed.

Use a piece of thick card or a tray to make your builders yard.

LASER CUT SHEET.

Your WORKING area should have a clean flat surface, and

should only contain the kit parts you are actually working on.

EVERYTHING ELSE SHOULD BE KEPT NEATLY ARRANGED

IN THE BUILDERSYARD, UNTIL NEEDED.