METER GROUP AquaLab 4TE User manual

AQUALAB® SERIES 4

i

TABLE OF CONTENTS

1. Introduction.............................................................................................. 1

2. Operation ...................................................................................................2

2.1 Installation ................................................................................................2

2.2 Sample Preparation ................................................................................... 3

2.2.1 Sample Composition........................................................................4

2.2.2 Sample Temperature........................................................................ 6

2.3 Taking a Reading ........................................................................................7

2.4 Viewing Data .............................................................................................. 9

2.5 Using Moisture Content (AQUALAB DUO Only).......................................... 10

2.5.1 Obtaining Product Isotherm Models .............................................. 11

2.5.2 Loading and Organizing Product Isotherm Models......................... 11

2.5.3 Measuring Moisture Content ......................................................... 12

2.5.4 Moisture Content Model Offset...................................................... 14

2.5.5 Restore Moisture Content Default Settings ................................... 17

2.5.6 Deleting Models............................................................................. 19

3. System....................................................................................................... 21

3.1 Specifications.......................................................................................... 21

3.2 Components ............................................................................................ 22

3.2.1 Cords and Cables ........................................................................... 23

3.2.2 Sample Chamber............................................................................ 23

3.2.3 Buttons.......................................................................................... 24

3.2.4 Display Screen ............................................................................... 25

13484-14

6.15.2018

ii

3.3 Computer Interface.................................................................................. 36

3.3.1 AquaLink 4 Software...................................................................... 36

3.3.2 Using a Terminal Program .............................................................. 37

3.4 Theory...................................................................................................... 37

3.4.1 Moisture Content........................................................................... 37

3.4.2 Water Activity ................................................................................ 38

3.4.3 Chilled-Mirror Dew Point Limitations............................................. 40

3.4.4 Water Potential .............................................................................. 41

3.4.5 Sorption Isotherms ........................................................................ 41

4. Service....................................................................................................... 43

4.1 Verification and Calibration................................................................... 43

4.1.1 Water Activity Verification ............................................................. 43

4.1.2 Linear Offset .................................................................................. 46

4.1.3 Multipoint Calibration (TEV Only)................................................... 48

4.1.4 Restore Factory Defaults ............................................................... 51

4.2 Cleaning................................................................................................... 52

4.2.1 Cleaning Kit ................................................................................... 53

4.2.2 AQUALAB 4TEV Special Considerations ......................................... 53

4.2.3 Cleaning Procedure........................................................................ 53

4.3 Maintenance Packages............................................................................ 55

4.4 Repair ...................................................................................................... 55

4.5 Troubleshooting....................................................................................... 56

4.6 Customer Support.................................................................................... 59

4.7 Terms and Conditions .............................................................................. 59

Reference....................................................................................................... 60

Index ................................................................................................................. 61

1

1. INTRODUCTION

Thank you for choosing the AQUALAB®4 Series Water Activity Meter from METER Group.

AQUALAB is the most accurate and most reliable instrument available for measuring water

activity (aw ).

The AQUALAB 4 Series includes four models:

• AQUALAB 4TE uses a chilled-mirror dew point sensor and thermoelectric (Peltier)

components to maintain a user-selectable internal temperature.

• AQUALAB 4TEV uses both a chilled-mirror dew point sensor and a capacitance sensor for

measuring nonvolatile and volatile substances, respectively. Either sensor is selected using

the instrument menu system.

• AQUALAB 4TE DUO uses a chilled-mirror dew point sensor and programmed models

obtained from isotherm data to give the user both water activity and moisture content

simultaneously in 5 min or less.

• AQUALAB 4TEV DUO uses both a chilled-mirror dew point sensor or capacitance sensor

as well as programmed models obtained from isotherm data to give the user both water

activity and moisture content simultaneously for samples containing both nonvolatile and

volatilesubstances.

This manual includes instructions for setting up, verifying the calibration, preparing samples,

taking readings, and maintaining AQUALAB instruments.

Verify all instrument contents shipped and appear in good condition:

• AQUALAB Water Activity Meter

• Calibration certificate

• Power cord

• USB A to USB B cable

• 50 disposable sample cups

• AQUALAB Cleaning Kit

• Two vials each of the following verification solutions:

0.760 aw6.00 mol/kg NaCl

0.500 aw8.57 mol/kg LiCl

0.250 aw13.41 mol/kg LiCl

2

OPERATION

2. OPERATION

Please read all instructions before operating the AQUALAB to ensure it performs to its

full potential.

Please observe the following considerations carefully.

• Only allow personnel qualified by METER to carry out service work on the electrical

components.

• Never remove the cover of the instrument. There are no parts inside the housing that can be

serviced or replaced by the user.

WARNING: There is a risk of damaging the instrument or of causing serious injury if live components are touched.

• Only operate this instrument with a main power voltage specified (100 to 240 V AC).

• Plug the instrument into a grounded outlet or power strip.

• Only use the fuse type and rating specified for this instrument (Section3.1).

If the instrument is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

PRECAUTIONS

METER sensors are built to the highest standards, but misuse, improper protection,

or improper installation may damage the sensor and possibly void the manufacturer’s

warranty. Before integrating AQUALAB into a system, follow the recommended installation

instructions and arrange proper protections to safeguard the instrument from damage.

2.1 INSTALLATION

Follow the steps listed in Table 1 to set up the AQUALAB.

Table 1 Installation

Preparation

Select Clean, Level Location

Select a location where the temperature remains fairly stable to avoid

temperature changes that can affect accuracy (away from air conditioner and

heater vents, open windows, etc.).

Observe clean practices to prevent contamination of the sample chamber.

Maintain a level surface to reduce the chance of spilling sample material and

contaminating the sample chamber.

3

AQUALAB

Table 1 Installation (continued)

Installation

Plug In Instrument

Plug the power cord into the back of the AQUALAB unit and into an outlet.

Only use the supplied power cord or one rated for AQUALAB 4 and certied for

the country of use. The cord must be a minimum of 18 AWG and have a rating

for 10 A or greater.

WARNING: An incorrect main power voltage can damage the instrument.

Turn the Unit ON.

Allow the AQUALAB a 15-min warm-up period to ensure accurate readings.

2.2 SAMPLE PREPARATION

Proper sample preparation is important to keep the AQUALAB clean and achieve repeatable

results. Carefully prepare and load samples to lengthen time between cleanings and help

avoid downtime. Be consistent in sample preparation methods (e.g., crush, grind, slice the

sample) to obtain reproducible results.

More specific considerations regarding sample composition and sample temperature are

discussed in Section2.2.1 and Section2.2.2, respectively.

Follow the steps listed below to prepare samples:

1. Make sure the sample to be measured is homogeneous.

Multicomponent samples (e.g., mufns with raisins) or samples that have outside

coatings (like deep-fried, breaded foods) can be measured, but they need to have

representative portions in the cup and may take longer than other sample types

toequilibrate.

2. Place the sample in a disposable sample cup.

a. Completely cover the bottom of the cup, if possible, to provide enough sample to get

an accurate reading.

The AQUALAB is able to accurately measure a sample that does not (or cannot) cover

the bottom of the cup. For example, raisins only need to be placed in the cup and do

not need to be attened to cover the bottom.

A larger sample surface area increases instrument efciency by providing more

stable infrared sample temperatures. It also speeds up the reading by shortening the

time needed to reach vapor equilibrium.

b. Do not fill the sample cup more than half full.

Overlled cups can contaminate the chamber and do not make the readings faster or

more accurate.

3. Wipe any excess sample material from the rim and outside of the sample cup with a

clean KIMWIPES®tissue.

4

OPERATION

Material left on the rim or the outside of the cup can contaminate the chamber and be

transferred to subsequent samples.

4. If a sample cannot be measured immediately, put the disposable sample cup lid on the

cup to restrict water transfer.

For longer term storage of no more than 4 h, seal the lid by placing tape or Paralm®

laboratory lm completely around the cup to lid junction.

2.2.1 SAMPLE COMPOSITION

The nature of some samples results in longer reading times. These materials may need

additional preparation to ensure accurate readings. Contact Customer Support for

questions on sample composition.

Use the following steps to determine if further sample preparation is necessary:

1. Take several readings of the sample to see if the readings (awand time) stabilize

(Section2.3).

2. If the readings take less than 6 min to stabilize, the sample can be handled normally.

If the readings take longer than 6 min, remove the sample and take a reading of a

verication standard (Section4.1.1).

3. If the verication standard takes less than 6 min to test, the sample itself is causing the

long read time. Refer to the following sections for pertinent sampling considerations.

If the verication standard also takes longer than 6 min to test, the chamber may

be dirty and will need to be cleaned (Section4.2). Retest the sample after cleaning

thechamber.

2.2.1.1. COATED AND DRIED SAMPLES

Samples with high sugar or fat coatings often require multiple readings, because it

equilibrates very slowly with the sample chamber.

Crush or slice the sample before sampling to reduce the time needed to take a water

activity reading for coated or dried samples. This increases the surface area of the sample,

thus decreasing reading times. However, modifying some samples may alter their water

activityreadings.

For example, a candy may have a soft chocolate center and a hard outer coating. The water

activity reading for the center and the outer coating are different, so one would need to

evaluate which part of the sample needed to be measured before crushing it. When the

candy is crushed, the water activity represents the average water activity of the entire

sample; whereas leaving the candy whole gives a reading for the coating, which may act as a

barrier to the center.

To reduce test time when testing whole samples, see Section3.2.4.2 to set Low-Emitting

mode.

5

AQUALAB

2.2.1.2. LOW WATER-EMITTING SAMPLES

Some extremely dry, dehydrated, highly viscous, water-in-oil emulsions (e.g., butter), high

fat, or glassy compositions may require multiple readings because of their slow water-

emitting properties. This is because the slow emission of water decreases the change in

water activity sufficiently that the instrument determines the test to be complete, even

though changes in water activity are still occurring.

The most effective way to test these types of samples is to run them in the AQUALAB using

Continuous or Custom mode and wait for the water activity readings to stabilize.

For faster reading, it is important to have the relative humidity of the chamber at or below

the water activity of these types of samples. This causes the sample to release water to the

vapor phase and equilibrate with the chamber. If the relative humidity of the headspace is

greater than the water activity of the sample, the sample will require a long period of time to

reach equilibrium.

To reduce test time when testing low water-emitting samples, see Section3.2.4.2 to set

Low-Emitting mode.

2.2.1.3. VOLATILE SAMPLES

Samples with certain volatiles in high enough concentrations may give inaccurate water

activity values in the AQUALAB 4TE and AQUALAB 4TE DUO models. Volatiles condense on

the mirror during the reading process but do not evaporate from the mirror as water does.

As a result, the reading on samples with volatiles may not be accurate. The concentration

of volatiles that causes interference is variable and matrix dependent.

The AQUALAB 4TEV measures volatiles such as propylene glycol and ethanol. The AQUALAB

4TEV contains both a chilled-mirror dew point and a capacitance sensor. The capacitance

sensor has a lower accuracy of ±0.015 awthan the dew point sensor, which has an accuracy

of ±0.003 aw.

To determine if volatiles are a problem, compare dew point readings to capacitance readings.

If the dew point readings are >0.018 awhigher than the capacitance readings, volatiles are

likely a problem and the AQUALAB 4TEV, AQUALAB 4TEV DUO, or AQUALAB TDL will need to be

used for the sample.

After measuring volatiles with the capacitance sensor, clean the chamber (Section4.2),

place charcoal in the chamber, and seal for a minimum of 5 min before switching to the dew

point sensor.

2.2.1.4. LOW WATER ACTIVITY

A sample’s water activity value may be below the cooling capacity of the AQUALAB. The

AQUALAB will display an error message indicating the lowest reading it attained on that

particular sample. The AQUALAB may also give the error message even if the sample is not

below 0.03 aw. Section4.5 provides possible solutions to the error message.

6

OPERATION

If a sample has a water activity of <0.03 aw, a < symbol in the Measurement tab indicates the

sample is too dry to be accurately measured by the AQUALAB (Figure1).

Figure1 Low water activity reading

If the measured awappears lower than the known sample water activity, the instrument

sensors may have been contaminated and need to be cleaned or serviced (Section4.2).

2.2.2 SAMPLE TEMPERATURE

The ambient temperature of the AQUALAB should be between 15 and 50 °C. The AQUALAB

4TE and AQUALAB 4TEV have internal temperature control capabilities that enable them to

read samples at temperatures different from the ambient temperature, but no higher than

50 °C and no lower than 15 °C.

Samples that are more than 4 °C colder or warmer than the instrument chamber

temperature need to equilibrate to instrument temperature before taking a reading, ideally

within 1 or 2 °C of the chamber temperature. Rapid changes in temperature over short

periods of time causes the water activity readings to rise or fall until the temperature

stabilizes. Proceed with normal measurements when the temperature stabilizes within an

optimal 1 or 2 °C of the chamber temperature.

High water activity samples that are warmer than the chamber temperature can cause

condensation inside the measuring chamber, which adversely affects subsequent readings.

A warning message appears if the sample temperature is more than 4 °C above chamber

temperature (Figure2).

Figure2 Sample is too hot! message

7

AQUALAB

If this error message appears,

1. Remove the sample from the instrument.

2. Place a lid on the cup.

3. Allow the sample to cool to within 4 °C of the instrument before measuring.

To check the differences in temperature between the sample and the chamber prior to

beginning a reading, set the sample in the chamber, close the lid without latching it, and

press the RIGHT or LEFT button. Figure3 provides an example of this screen.

Figure3 Temperature difference between sample and sample chamber

2.3 TAKING A READING

The AQUALAB provides readings in 5 min or less. Readings are reliable, providing ±0.003 aw

accuracy.

CAUTIONS

• Never leave a sample in the AQUALAB after a reading has been taken. The sample may spill

and contaminate the instrument chamber if the instrument is accidentally moved or jolted.

• Never move the instrument after a sample has been loaded. Movement may cause the

sample material to spill and contaminate the sample chamber.

• Do not measure a sample that has a temperature greater than ±4 °C than the AQUALAB

chamber (Section2.2.2). Remove the sample until it is at room temperature.

NOTE: After measuring volatiles with the capacitance sensor, clean the chamber (Section4.2), place charcoal in the

chamber, and seal for a minimum of 5 min before switching to the dew point sensor.

Perform the following steps to take a reading.

1. Ensure the AQUALAB is plugged in and turned on.

The splash screen will appear, followed by the main Measurement tab (Section3.2.4.1).

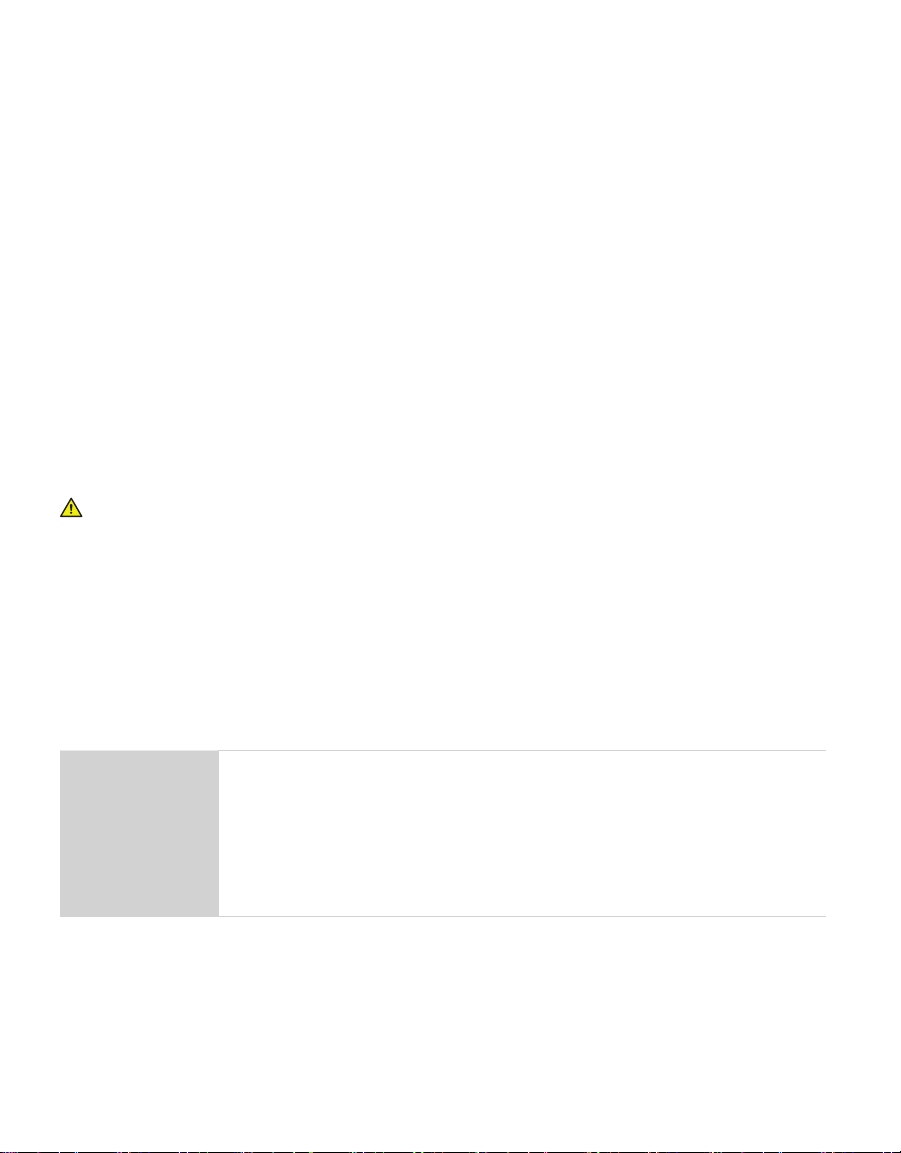

2. For AQUALAB DUO instruments (Section2.5), use the UP and DOWN buttons to scroll

through all available product models that may be used (Figure4).

The moisture content value adjusts based on the selected model.

8

OPERATION

Figure4 Measurement screen for AQUALAB DUO Milk Powder product model

3. Verify cleanliness (Section4.2), calibration (Section4.1), and sample preparation

(Section2.2).

NOTE: The device fan can blow powdery substances; always verify the cleanliness of the sample chamber before

reading a new sample.

4. Move the chamber lever to the OPEN position and lift the chamber lid.

5. Check the top lip and outside surfaces of the sample cup to ensure they are free from

sample residue and conrm the sample cup is not overlled.

NOTE: Overfilling the sample cup may contaminate the chamber sensors.

The sample cup lid must be removed for correct functionality.

6. Place the prepared sample cup in the chamber.

7. Close the chamber lid.

8. Move the lever to the READ position to seal the sample chamber. The reading will

automatically start.

In 1 to 2 min, the rst measurement will display on the screen (this is an intermediate

reading). The instrument crosses the dew threshold numerous times to ensure

equilibrium and the accuracy of readings. Length of read times may vary depending

on temperature differences between the chamber and the sample as well as on other

properties of the sample (Section2.2). The default AQUALAB reading cycle continues

until the rates of change of three consecutive intermediate readings are <0.0005 awof

each other.

When the instrument has nished its read cycle, results will display. The SAVE icon

replaces the spinning measurement icon, and, if enabled, a series of beeps sounds. The

results will include the water activity, read time, temperature, and, for AQUALAB DUO

instruments (Section2.5), moisture content for the selected product model (Figure5).

NOTE: Autosave only saves the moisture content value of the model selected at the end of the reading. Overwrite

the autosave by selecting the correct model using the UP and DOWN buttons and selecting SAVE.

9

AQUALAB

Figure5 Completed test results with both water activity and moisture content

9. Autosave (default setting) retains the data without any annotation (Section3.2.4.2).

To add an annotation, select SAVE, add desired letters, and select SAVE again (Figure6).

Figure6 Keyboard screen to annotate data results

2.4 VIEWING DATA

To view prior test results, use the following steps:

1. Press MENU to navigate to the Data tab (Figure7).

Figure7 Data tab

2. Select ENTER.

3. Scroll through the list of saved tests using UP and DOWN (to move one item at a time) or

RIGHT and LEFT (to move a page at a time).

10

OPERATION

Figure8 List of saved tests

4. Select ENTER.

The detailed test results screen will appear (Figure9). Tests can also be scrolled through

using the arrow buttons on this detailed screen.

Figure9 Detailed test results screen

5. Select OK to return to the list of tests.

6. Select CANCEL to return to the Data tab.

2.5 USING MOISTURE CONTENT (AQUALAB DUO ONLY)

The relationship between water activity and moisture content is called the moisture

sorption isotherm, and it is complex and unique to each product type.

AQUALAB DUO models generate water activity values and moisture content. The DUO models

use preloaded product-specific isotherm models to calculate moisture content and present

it on the screen with the water activity (Figure10). The AQUALAB 4TE and AQUALAB 4TEV can

be upgraded to an AQUALAB 4TE DUO and AQUALAB 4TEV DUO, respectively.

11

AQUALAB

Figure10 AQUALAB DUO display with water activity and moisture content readings

2.5.1 OBTAINING PRODUCT ISOTHERM MODELS

The isotherm relationship for each product is unique, and each product isotherm model

must be determined experimentally prior to testing moisture content with the AQUALAB

DUO.

There are several strategies that can be used to generate models. Please contact Customer

Support for information on model development.

2.5.2 LOADING AND ORGANIZING PRODUCT ISOTHERM MODELS

A product model must be loaded onto the AQUALAB DUO before it can calculate

moisture content. Models can be loaded onto the instrument by METER or by using

the AquaLink4 software (Section3.3.1). As many as 100 models can be stored on the

instrument.

The AquaLink 4 software uses a model loading tool to add and remove product models from

the AQUALAB DUO, allowing the user to control and organize product models.

The following steps explain how to load new models:

1. Download AquaLink 4 software from software.metergroup.com onto a computer.

2. Save the model les onto the same computer.

3. Open AquaLink software.

4. Connect the AQUALAB to the computer using the USB cord (or an RS-232 cord).

5. Turn the AQUALAB on.

6. In the AquaLink window, select the appropriate COM port from the dropdown menu.

7. Click Connect.

When the instrument is connected, the button will change to Disconnect.

8. Click Models.

12

OPERATION

The Model Manager window will show all current models (Figure11). If no models have

been loaded, the window will be empty.

Figure11 AquaLink 4 model loading tool

9. Click Import.

10. Navigate to the model saved on the computer and select.

Each model will need to be imported individually. The models should now show up in the

Model Manager window.

11. Click in the Sync box next to each model name that will be uploaded to the AQUALAB.

12. Click Apply.

13. After a few seconds, use UP and DOWN on the AQUALAB instrument to test if the

instrument can scroll through the new models (visible at the top of the Measurement

tab). The display screen should also have a placeholder for moisture content

measurements.

14. In the AquaLink window, click Disconnect.

15. Close the AquaLink program.

16. Unplug the AQUALAB from the computer.

2.5.3 MEASURING MOISTURE CONTENT

With product models loaded onto the instrument, the AQUALAB DUO can generate moisture

content and water activity simultaneously while taking a reading.

1. Press MENU to navigate to the Configuration tab (Figure12).

13

AQUALAB

Figure12 Changing moisture content model on the Conguration tab

2. Select %Moisture.

A list of available models appears, organized by name (Figure13).

Figure13 Product models for moisture content

3. Select the model for the product to be analyzed.

If the listed models do not apply, select None. No moisture content will appear on the

Measurement tab.

4. Select SAVE.

5. Navigate to the Measurement tab.

6. Take a reading (Section2.3).

The moisture content measurement (%MC) will appear below the water activity measurement

(Figure14) in the test results.

14

OPERATION

Figure14 AQUALAB DUO display with water activity and moisture content readings

2.5.4 MOISTURE CONTENT MODEL OFFSET

The AQUALAB DUO calculates moisture content values based on water activity readings

by utilizing models stored within the instrument. Because moisture content results vary

between reference methods, it is important to ensure that the model in the instrument

correlates well with the values obtained from the selected reference method (e.g., Karl

Fischer titration or oven loss on drying). Moisture content differences among various

methods are usually linear and can be easily corrected with a linear offset. Therefore, if

moisture contents calculated with the AQUALAB DUO instrument are not agreeing with the

reference method, the problem can likely be addressed by adjusting a linear offset.

Reference methods can differ between laboratories, so check for a linear offset upon receipt

of a new isotherm model from METER. In addition, the linear offset should be adjusted if

moisture contents calculated by the AQUALAB DUO instrument are consistently higher or

lower for a product than reference method values over several samples.

The following steps describe how to adjust for linear offset or how to create a new model

based off an old model:

1. Ensure the instrument is verified (Section4.1).

2. Collect three subsamples of the product for analysis.

3. Place one subsample into a sample cup (Section2.2).

4. Cover sample cup with a lid to limit exposure to ambient conditions.

5. Use the reference method to determine the average moisture content of the other

twosubsamples.

6. On the AQUALAB, press MENU to navigate to the Conguration tab.

7. Select Calibration.

8. Select %Moisture from the list of calibration types (Figure15).

NOTE: If %Moisture is not an option,the instrument may not be an AQUALAB DUO.Contact Customer Support.

15

AQUALAB

Figure15 Select %Moisture on the Calibration tab

The %Moisture Calibration screen will appear (Figure16).

Figure16 %Moisture Calibration screen

9. If creating an existing model, select New.

If editing an existing model, select Edit.

10. Scroll through the reference models for the desired product (Figure17).

Figure17 Moisture content model list

11. Select ENTER.

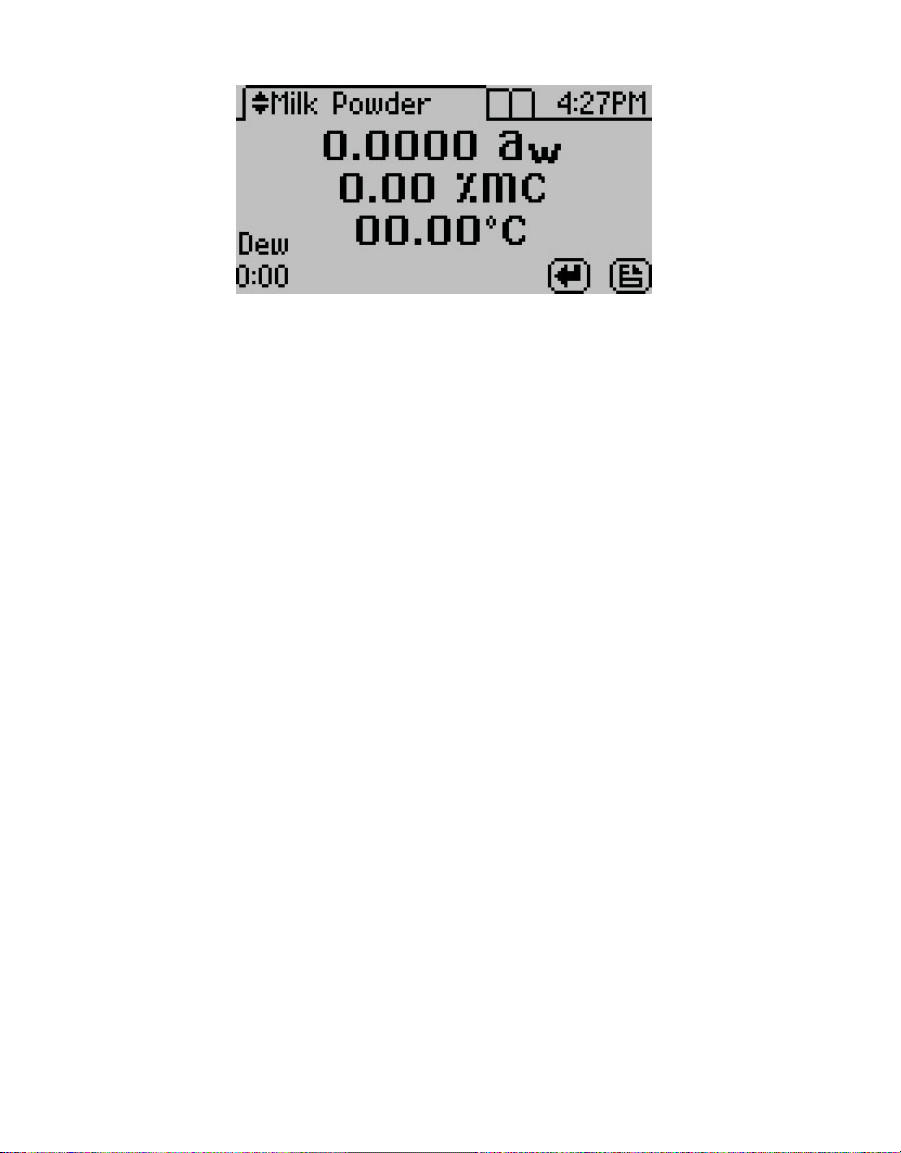

12. Select Start (Figure18).

16

OPERATION

Figure18 Start test

13. Place a sample in the sample chamber when prompted (Figure19).

Figure19 Prompt to place sample in chamber

14. Remove the lid from the sample cup prepared in step3 and place into the chamber.

15. Close and latch the lid.

16. Select OK to begin a reading.

Once the reading is complete, the measured water activity as well as the moisture

content based on the target model will display on the screen.

17. Adjust the moisture content value using UP and DOWN until it matches the average

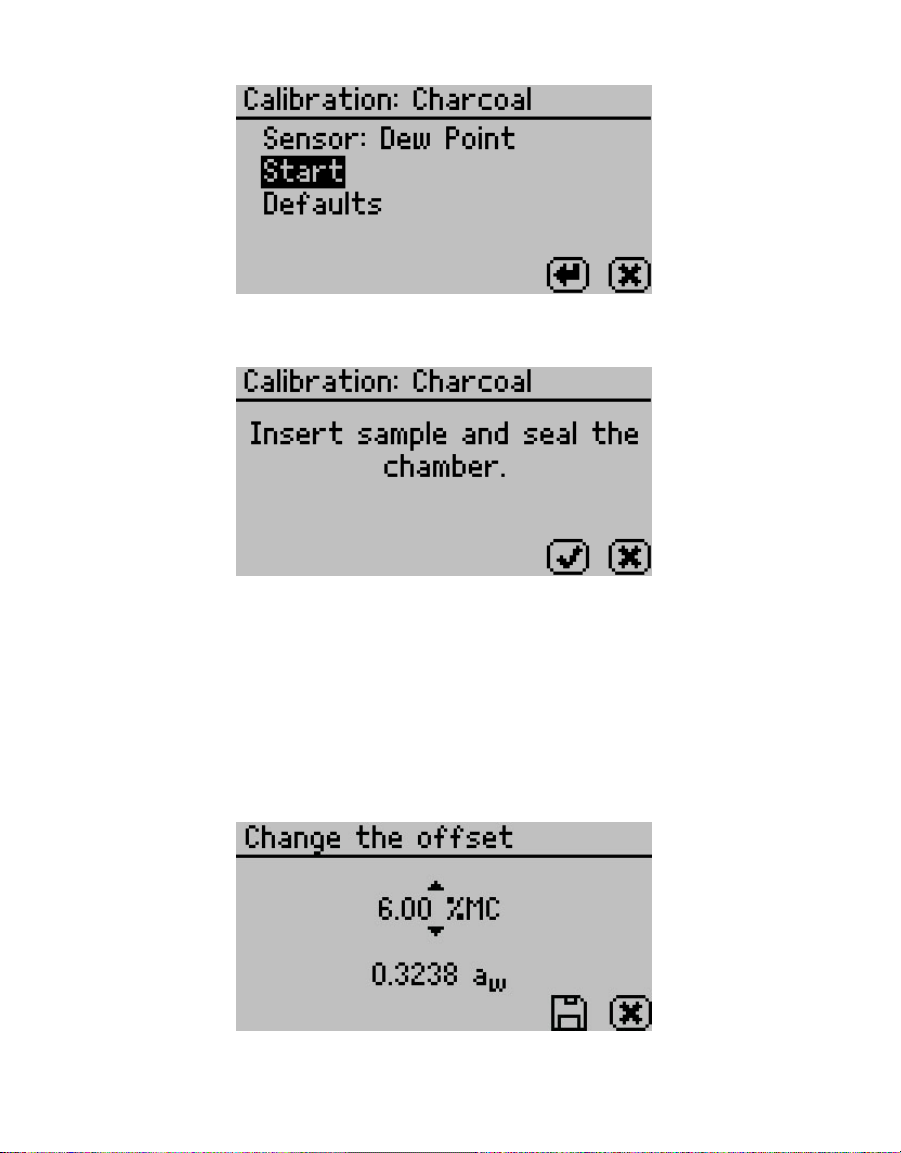

moisture content value obtained from the reference method in step5 (Figure20).

Figure20 Adjust the moisture content value to match the reference method

18. Select SAVE.

This manual suits for next models

3

Table of contents

Other METER GROUP Measuring Instrument manuals