Appleton • 1.800.621.1506 • www.appletonelec.com 305903 Rev. 6 07/29/19 • Page 1 of 4

The Appleton™ AEPGI Explosion-Proof Grounding Indicator

Installation and Operation Instructions

FOR PROPER AND SAFE INSTALLATION OF THIS PRODUCT, PLEASE READ THE FOLLOWING INSTRUCTIONS

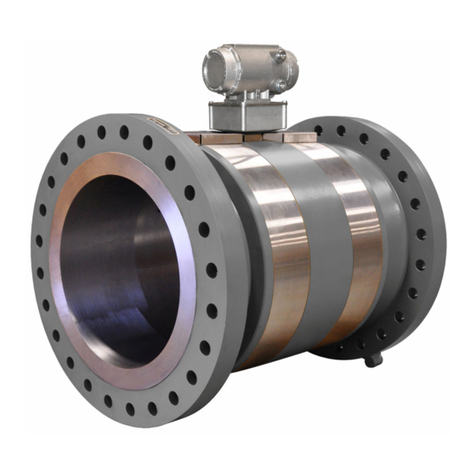

Appleton’s AEPGI Explosion-Proof Grounding Indicator provides a means to safely discharge an electrostatic charge to ground

in hazardous areas. The arc produced by a rapid discharge of accumulated static electricity to ground can ignite explosive fumes

causing damage to equipment and personnel. Therefore, before loading and unloading explosive uids, it is necessary to provide a

safe path that any electrostatic charge can be safely discharged to ground prior to connecting or disconnecting the uid transfer lines.

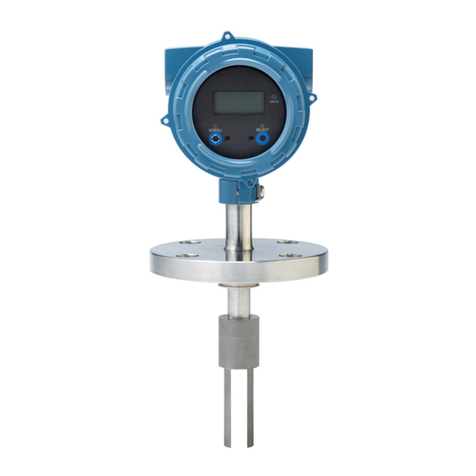

The AEPGI is equipped with a green and red indicator to show the status of ground continuity between the vessel and AEPGI. A green

indicator shows there is adequate ground continuity for uid transfer and red indicator shows there is a brake in ground continuity.

Control of the transfer equipment can also be controlled by a dry relay contact inside the AEPGI. When an adequate ground contact is

detected, a normally open contact will close, enabling the uid transfer equipment to activate. When the ground continuity is broken,

the contact will open, stopping the uid transfer equipment. Transfer operations should never be under taken when ground continuity

is broken, and not restarted until a satisfactory ground path is reestablished.

IT IS IMPORTANT TO READ, UNDERSTAND AND FOLLOW THESE INSTRUCTIONS FOR PROPER INSTALLATION

AND SAFE USE OF THIS PRODUCT. RETAIN THIS INSTRUCTIONS FOR FUTURE REFERENCE.

Signal Words Defined:

DANGER indicates a hazardous situation which, if not avoided will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided could result in death or serious injury

CAUTION indicates a hazardous situation which, if not avoided could result in minor or moderate injury.

NOTICE is used to address practices not related to physical injury.

Equipment shall be installed in accordance with all National and Local codes, acceptable to the Authority Having Jurisdiction.

Only qualied personnel should install, inspect, and perform regular maintenance on the equipment.

Refer to the product nameplate for important information regarding the hazardous location rating, enclosure environmental rating,

agency approval(s), and important safety information. Adhere to all warning and caution statements located on the exterior or interior

of the enclosure.

Class I, Division 1 locations require a conduit seal to be installed in each conduit run within the specied distance noted on the

product nameplate.

Unused conduit openings shall have a certied close-up plug installed that has the same hazardous location ratings as the

enclosure. The close-up plug must engage a minimum of ve full threads.

Always keep the cover bolts tight to prevent ignition of hazardous atmospheres and disconnect circuits before opening cover.

Only use the original cover screws provided with enclosure

Take extreme care not to damage the at-machined ange when opening the enclosure cover. Damaging the ange could affect

the enclosure’s integrity to protect the hazardous area.

Dirt, grease, and other foreign material must not accumulate on the at-machined ange surface of the body and cover. The cover

and body must fully mate against each other to provide the proper protection to the hazardous area.

Do not attempt to repair the cover gasket if damaged; contact factory for replacement. Remove damaged gasket and continue

to use the enclosure. The gasket does not affect the enclosure’s safety for use in the hazardous locations. However, the enclosure’s

environmental rating(s) will no longer be valid.

Install only an approved drain tting that has the same hazardous location ratings as the enclosure. Note, care must be taken

during hosedown operations. The enclosure may be watertight, but the drain may not be.

Since the conditions of use are outside of our control, the purchaser should determine the suitability of the equipment for the

intended use and assumes all risk and liability regarding the specic application.

305903 INSTRUCTION SHEET