METIS V2 User manual

Data Logger V2

Instruction Manual

Joe Holdsworth

7-29-2018

Data Logger V2 July 29, 2018

Page 1of 19

Contents

Revision History............................................................................................................................................2

Specifications................................................................................................................................................3

Power Limits..............................................................................................................................................3

Data Rates.................................................................................................................................................3

Other Specifications ..................................................................................................................................3

Pin Outs.........................................................................................................................................................4

AS218-35SN..............................................................................................................................................4

AS210-35SN..............................................................................................................................................6

Data Logger Layout.......................................................................................................................................7

Quick Start Guide..........................................................................................................................................8

Configuration Software..................................................................................................................................9

Application Notes ........................................................................................................................................10

Accelerometers........................................................................................................................................10

K-Type Thermocouples...........................................................................................................................10

Strain Gauges..........................................................................................................................................10

Appendix A –Strain Gauges.......................................................................................................................11

Data Logger V2 July 29, 2018

Page 2of 19

Revision History

Revision

Comment

Author

Date

1

Creation of Document and first issue

Joe Holdsworth

29/07/2018

2

Corrections

Joe Holdsworth

31/07/2018

Data Logger V2 July 29, 2018

Page 3of 19

Specifications

Power Limits

Parameter

Value

Note

External Voltage Supply Range

9-36VDC

Max reverse voltage protection

60V

This protection only applies to

the external power in pins –be

careful not to apply>3.3v to the

A to D pins

Internal Battery Capacity

2000mAh

Min time on battery

2.5hrs

This is with the 3 x 3.3 Precision

voltage regulators that supply

sensors and strain gauges

running at the max 200mA

Max Time on battery

8hrs

Underlying consumption of

electronics is 200mA, this value

assumes an additional 50mA for

sensors

Max current per A to D

200mA

3.3V_AD1, 3.3V_AD2 and

3.3V_AD3 are all capable of a

maximum of 200mA. These are

precision voltage regulators. Do

not put a bigger load on than

this!

Max A to D in voltage

3.3V

Min A to D in voltage

GND

Data Rates

Parameter

Value

Note

GPS update rate

1Hz

Max logging record rate

50Hz

Above 30Hz the time step

between logged measurements

becomes non deterministic

Other Specifications

GPS time

Time is UTC time

Accurate to 1ms

Data Logger V2 July 29, 2018

Page 4of 19

Pin Outs

AS218-35SN

Connector Name:

AIN

Connector Part No.

AS218-35SN

Connector Mating Part No.

AS618-35PX

Pin No.

Name

Notes

1

3.3V_AD1

2

GND_AD1

3

AD1_1+

4

AD1_1-

5

AD1_2+

6

AD1_2-

7

AD1_3+

8

AD1_3-

9

AD1_4+

10

AD1_4-

11

3.3V_AD1

12

GND_AD1

13

AD1_5+

14

AD1_5-

15

AD1_6+

16

AD1_6-

17

AD1_7+

18

AD1_7-

19

AD1_8+

20

AD1_8-

21

3.3V_AD2

22

GND_AD2

23

AD2_9+

24

AD2_9-

25

AD2_10+

26

AD2_10-

Data Logger V2 July 29, 2018

Page 5of 19

Pin No.

Name

Notes

27

AD2_11+

28

AD2_11-

29

AD2_12+

30

AD2_12-

31

3.3V_AD2

32

GND_AD2

33

AD2_13+

34

AD2_13-

35

AD2_14+

36

AD2_14-

37

AD2_15+

38

AD2_15-

39

AD2_16+

40

AD2_16-

41

3.3V_AD3

42

GND_AD3

43

AD3_17+

44

AD3_17-

45

AD3_18+

46

AD3_18-

47

AD3_19+

48

AD3_19-

49

AD3_20+

50

AD3_20-

51

3.3V_AD3

52

GND_AD3

53

AD3_21+

54

AD3_21-

55

AD3_22+

56

AD3_22-

57

AD3_23+

58

AD3_23-

59

AD3_24+

60

AD3_24-

61

5V

Max 25mA

62

GND

63

Not used

64

Not used

65

Not used

66

GND

Data Logger V2 July 29, 2018

Page 6of 19

AS210-35SN

Connector Name:

DIGITAL

Connector Part No.

AS218-35SN

Connector Mating Part

No.

AS618-35PX

Pin No.

Name

Notes

1

3.3V

2

GND

3

SDA

4

SCL

5

3.3V

6

GND

7

SDA

8

SCL

9

3.3V

10

GND

11

5V

12

GND

External power in -tive

13

9-36VIN

External power in +tive

Data Logger V2 July 29, 2018

Page 7of 19

Data Logger Layout

•Charging port –A micro USB connector to charge the devices battery, any 5v USB charging

device can be used to recharge this logger. Charge time is dependent on charger but maximum

charge rate is 500 milliamps, at this rate the unit will take just under 4 hours to fully charge.

•Spare Ethernet Port –This port is currently unused.

•Debug port –Micro USB Used to program and debug the data logger

•ON/Off Switch –turns the device power from battery on and off

•Charging Complete –This LED indicates that the battery is fully charged when on.

•Power On –This blue LED indicates the power is on when on.

•Battery Low –This LED indicates that the unit needs charging when on.

•GPS Status (not shown) –A solid red light means that the GPS receive is on but does NOT

have a lock, a blinking red light indicates a GPS lock.

•Unit Mode Select –The user presses and holds this button to select functionality

o1 Second Press (acknowledged with 1 audio beep) = Start new log, if one is already

running a new one will be started in a new file

o2 Second Press (acknowledged with 2 audio beeps) = Stop Logging

o3 second press (acknowledged with 3 audio beeps) = This requests that the unit sync

itself to GPS time when it is receiving the correct GPS data, even if the GPS light is

flashing it may take a while for this to happen. A long beep will occur when the unit is

sync’d.

•Unit Status –When a green LED is flashing the unit is logging, when a yellow LED is on it means

there is no Micro SD card detected.

•Micro SD Port –This is where the Micro SD card is inserted, the Micro SD card is where the

logger data is recorded to, it needs to be FAT32 and smaller than 32GB and have a ‘unit.cfg’file

created by the configuration GUI on it.

•GPS Antenna Connector –This is where the GPS antenna connect to the device.

Data Logger V2 July 29, 2018

Page 8of 19

Quick Start Guide

•Insert a Micro SD car into the slot on the bottom of the data logger.

•Turn On the Device.

•Check you do not have a low battery warning.

•If you want to have GPS data from the start (optional) of the test then you have to wait until the

red GPS light is flashing, the unit will log data without GPS information without any issues.

•When you want to start recording data press and hold the user input button for one second or

until you hear a single beep. When a new log is created the strain gauges are zero’d so it is

important that the seat post is unloaded at that point in time, i.e. no one is sitting on it.

•When you want the unit to stop logging press and hold the user input button for 2 seconds or until

you hear two beeps. Try and do this before you pull the micro SD card out or your data maybe

corrupted.

•A new file can be created without having to stop the old one first, this happens automatically.

•To sync the unit precisely to GPS time press and hold the user input button for three seconds, or

until you hear three beeps. The unit will then wait until it has received the appropriate GPS

message to sync the time, the sync completion will be indicated by a beep lasting a second in

duration, the time for this to happen can vary greatly on GPS signal quality. The accuracy of the

sync should in theory be within 1ms of GPS time.

•To read the data pull out the micro SD card and insert it into an SD card reader attached to a

computer, you should see something like this image:

•The data is contained in the ‘.csv file’, the other file, ‘unit.cfg’ is the configuration file for the unit

and needs to be kept there with that exact file name.

•Remember to turn off the unit and charge it, unit operation time from full charge is approx. 3 hrs.

Data Logger V2 July 29, 2018

Page 9of 19

Configuration Software

To configure the unit please visit www.metisengineering.com to download software. Go to the page where

you purchased the unit from and the latest software will be there.

Once the software is downloaded and installed please save the ‘unit.cfg’config file produced to the micro

USB stick that is going to be inserted into the unit. Do not rename this file.

Data Logger V2 July 29, 2018

Page 10 of 19

Application Notes

Accelerometers

When connecting an accelerometer please tie the negative side of the A to D channel to GND for the A to

D. For example if AD1_1+is connected to an accelerometer output, please make sure that AD1_1- is

connected to AD1_GND.

K-Type Thermocouples

If you select a channel as a K-Type thermocouple and don’t connected one this value will be the internal

box temperature.

Strain Gauges

Metis Engineering offer consultation and bridge completion modules for strain gauge installation.

National Instruments have a good page on the different strain gauge setups http://www.ni.com/white-

paper/3642/en/ Appendix A has the full article.

Data Logger V2 July 29, 2018

Page 11 of 19

Appendix A –Strain Gauges

What is strain?

In mechanical testing and measurement, you need to understand how an object reacts to various forces.

The amount of deformation a material experiences due to an applied force is called strain. Strain is

defined as the ratio of the change in length of a material to the original, unaffected length, as shown in

Figure 1. Strain can be positive (tensile), due to elongation, or negative (compressive), due to contraction.

When a material is compressed in one direction, the tendency to expand in the other two directions

perpendicular to this force is known as the Poisson effect. Poisson’s ratio (v), is the measure of this effect

and is defined as the negative ratio of strain in the transverse direction to the strain in the axial direction.

Although dimensionless, strain is sometimes expressed in units such as in./in. or mm/mm. In practice, the

magnitude of measured strain is very small, so it is often expressed as microstrain (µε), which is ε x 10-6.

Figure 1. Strain is the ratio of the change in length of a material to the original, unaffected length.

The four different types of strain are axial, bending, shear, and torsional. Axial and bending strain are the

most common (see Figure 2). Axial strain measures how a material stretches or compresses as a result

of a linear force in the horizontal direction. Bending strain measures a stretch on one side of a material

and the contraction on the opposite side due to the linear force applied in the vertical direction. Shear

strain measures the amount of deformation that occurs from a linear force with components in both the

horizontal and vertical directions. Torsional strain measures a circular force with components in both the

vertical and horizontal directions.

Data Logger V2 July 29, 2018

Page 12 of 19

Figure 2. Axial strain measures how a material stretches or pulls apart. Bending strain measures a stretch

on one side and a contraction on the other side.

How do you measure strain?

You can measure strain using several methods, but the most common is with a strain gage. A strain

gage’s electrical resistance varies in proportion to the amount of strain in the device. The most widely

used strain gage is the bonded metallic strain gage. The metallic strain gage consists of a very fine wire

or, more commonly, metallic foil arranged in a grid pattern. The grid pattern maximizes the amount of

metallic wire or foil subject to strain in the parallel direction. The grid is bonded to a thin backing called the

carrier, which is attached directly to the test specimen. Therefore, the strain experienced by the test

specimen is transferred directly to the strain gage, which responds with a linear change in electrical

resistance.

Data Logger V2 July 29, 2018

Page 13 of 19

Figure 3. The electrical resistance of metallic grid changes in proportion to the amount of strain

experienced by the test specimen.

A fundamental parameter of the strain gage is its sensitivity to strain, expressed quantitatively as the

gage factor (GF). GF is the ratio of the fractional change in electrical resistance to the fractional change in

length, or strain:

The GF for metallic strain gages is usually around 2. You can obtain the actual GF of a particular strain

gage from the sensor vendor or sensor documentation.

In practice, strain measurements rarely involve quantities larger than a few millistrain (e x 10-3).

Therefore, to measure the strain, you have to accurately measure very small changes in resistance. For

example, suppose a test specimen undergoes a strain of 500 me. A strain gage with a GF of 2 exhibits a

change in electrical resistance of only 2 (500 x 10-6) = 0.1%. For a 120 Ω gage, this is a change of only

0.12 Ω.

To measure such small changes in resistance, strain gage configurations are based on the concept of a

Wheatstone bridge. The general Wheatstone bridge, illustrated in Figure 4, is a network of four resistive

arms with an excitation voltage, VEX, that is applied across the bridge.

Data Logger V2 July 29, 2018

Page 14 of 19

Figure 4. Strain gages are configured in Wheatstone bridge circuits to detect small changes in resistance.

The Wheatstone bridge is the electrical equivalent of two parallel voltage divider circuits. R1 and

R2 compose one voltage divider circuit, and R4 and R3 compose the second voltage divider circuit. The

output of a Wheatstone bridge, Vo, is measured between the middle nodes of the two voltage dividers.

From this equation, you can see that when R1 /R2 = R4 /R3, the voltage output VO is zero. Under these

conditions, the bridge is said to be balanced. Any change in resistance in any arm of the bridge results in

a nonzero output voltage. Therefore, if you replace R4 in Figure 4 with an active strain gage, any changes

in the strain gage resistance unbalance the bridge and produce a nonzero output voltage that is a

function of strain.

Types of strain gages

The three types of strain gage configurations, quarter-, half-, and full-bridge, are determined by the

number of active elements in the Wheatstone bridge, the orientation of the strain gages, and the type of

strain being measured.

Quarter-Bridge Strain Gage

Configuration Type I

•Measures axial or bending strain

•Requires a passive quarter-bridge completion resistor known as a dummy resistor

•Requires half-bridge completion resistors to complete the Wheatstone bridge

•R4 is an active strain gage measuring the tensile strain (+ε)

Data Logger V2 July 29, 2018

Page 15 of 19

Figure 5. Quarter-Bridge Strain Gage Configurations

Configuration Type II

Ideally, the resistance of the strain gage should change only in response to applied strain. However,

strain gage material, as well as the specimen material to which the gage is applied, also responds to

changes in temperature. The quarter-bridge strain gage configuration type II helps further minimize the

effect of temperature by using two strain gages in the bridge. As shown in Figure 6, typically one strain

gage (R4) is active and a second strain gage(R3) is mounted in close thermal contact, but not bonded to

the specimen and placed transverse to the principal axis of strain. Therefore the strain has little effect on

this dummy gage, but any temperature changes affect both gages in the same way. Because the

temperature changes are identical in the two strain gages, the ratio of their resistance does not change,

the output voltage (Vo) does not change, and the effects of temperature are minimized.

Figure 6. Dummy strain gages eliminate effects of temperature on the strain measurement.

Half-Bridge Strain Gage

You can double the bridge’s sensitivity to strain by making both strain gages active in a half-bridge

configuration.

Data Logger V2 July 29, 2018

Page 16 of 19

Configuration I

Configuration II - Bending Strain

Only

Figure 7. Half-bridge strain gages are two times more sensitive than quarter-bridge strain gages.

Configuration Type I

•Measures axial or bending strain

•Requires half-bridge completion resistors to complete the Wheatstone bridge

•R4 is an active strain gage measuring the tensile strain (+ε)

•R3 is an active strain gage compensating for Poisson’s effect (-νε)

This configuration is commonly confused with the quarter-bridge type II configuration, but type I has an

active R3 element that is bonded to the strain specimen.

Configuration Type II

•Measures bending strain only

•Requires half-bridge completion resistors to complete the Wheatstone bridge

•R4 is an active strain gage measuring the tensile strain (+ε)

•R3 is an active strain gage measuring the compressive strain (-ε)

Full-Bridge Strain Gage

A full-bridge strain gage configuration has four active strain gages and is available in three different types.

Types 1 and 2 measure bending strain and type 3 measures axial strain. Only types 2 and 3 compensate

for the Poisson effect, but all three types minimize the effects of temperature.

Configuration I - Only Bending

Strain

Configuration II - Only Bending

strain

Configuration III - Only Axial

Strain

Data Logger V2 July 29, 2018

Page 17 of 19

Figure 8. Full-Bridge Strain Gage Configurations

Configuration Type I

•Highly sensitive to bending strain only

•R1 and R3 are active strain gages measuring compressive strain (–e)

•R2 and R4 are active strain gages measuring tensile strain (+e)

Configuration Type II

•Sensitive to bending strain only

•R1 is an active strain gage measuring the compressive Poisson effect (–νe)

•R2 is an active strain gage measuring the tensile Poisson effect (+νe)

•R3 is an active strain gage measuring the compressive strain (–e)

•R4 is an active strain gage measuring the tensile strain (+e)

Configuration Type III

•Measures axial strain

•R1 and R3 are active strain gages measuring the compressive Poisson effect (–νe)

•R2 and R4 are active strain gages measuring the tensile strain (+e)

How do I choose the right strain gage?

Once you have decided the type of strain you intend to measure (axial or bending), other considerations

include sensitivity, cost, and operating conditions. For the same strain gage, changing the bridge

configuration can improve its sensitivity to strain. For example, the full-bridge type I configuration is four

times more sensitive than the quarter-bridge type I configuration. However, full-bridge type I requires

three more strain gages than quarter-bridge type I. It also requires access to both sides of the gaged

structure. Additionally, full-bridge strain gages are significantly more expensive than half-bridge and

quarter-bridge gages. For a summary of the various types of strain gages, refer to the following table.

Data Logger V2 July 29, 2018

Page 18 of 19

Measurement Type

Quarter Bridge

Half-Bridge

Full-Bridge

Type I

Type II

Type I

Type II

Type I

Type II

Type III

Axial Strain

Yes

Yes

Yes

No

No

No

Yes

Bending Strain

Yes

Yes

Yes

Yes

Yes

Yes

No

Compensation

Transverse Sensitivity

No

No

Yes

No

No

Yes

Yes

Temperature

No

Yes

Yes

Yes

Yes

Yes

Yes

Sensitivity

Sensitivity at 1000 µε

~0.5

mV/V

~0.5

mV/V

~0.65

mV/V

~1.0 mV/V

~2.0 mV/V

~1.3 mV/V

~1.3 mV/V

Installation

Number of Bonded Gages

1

1*

2

2

4

4

4

Mounting Location

Single

Side

Single

Side

Single Side

Opposite

Sides

Opposite

Sides

Opposite

Sides

Opposite

Sides

Number of Wires

2 or 3

3

3

3

4

4

4

Bridge Completion

Resistors

3

2

2

2

0

0

0

*A second strain gage is placed in close thermal contact with structure but is not bonded.

Grid Width

Using a wider grid, if not limited by the installation site, improves heat dissipation and enhances strain

gage stability. However, if the test specimen has severe strain gradients perpendicular to the primary axis

of strain, consider using a narrow grid to minimize error from the effect of shear strain and Poisson strain.

Nominal Gage Resistance

Nominal gage resistance is the resistance of a strain gage in an unstrained position. You can obtain the

nominal gage resistance of a particular gage from the sensor vendor or sensor documentation. The most

common nominal resistance values of commercial strain gages are 120 Ω, 350 Ω, and 1,000 Ω. Consider

a higher nominal resistance to reduce the amount of heat generated by the excitation voltage. Higher

nominal resistance also helps reduce signal variations caused by lead-wire changes in resistance due to

temperature fluctuations.

Temperature Compensation

Ideally, strain gage resistance should change in response to strain only. However, a strain gage’s

resistivity and sensitivity also change with temperature, which leads to measurement errors. Strain gage

manufacturers attempt to minimize sensitivity to temperature by processing the gage material to

compensate for the thermal expansion of the specimen material for which the gage is intended. These

Data Logger V2 July 29, 2018

Page 19 of 19

temperature-compensated bridge configurations are more immune to temperature effects. Also consider

using a configuration type that helps compensate for the effects of temperature fluctuations.

Installation

Installing strain gages can take a significant amount of time and resources, and the amount varies greatly

depending on the bridge configuration. The number of bonded gages, number of wires, and mounting

location all can affect the level of effort required for installation. Certain bridge configurations even require

gage installation on opposite sides of a structure, which can be difficult or even impossible. Quarter-

bridge type I is the simplest because it requires only one gage installation and two or three wires.

Table of contents

Popular Data Logger manuals by other brands

Kilowatt Labs

Kilowatt Labs SIRIUS 1364-24-B-1C-TM-SD-A-G user manual

MadgeTech

MadgeTech Event101A Product user guide

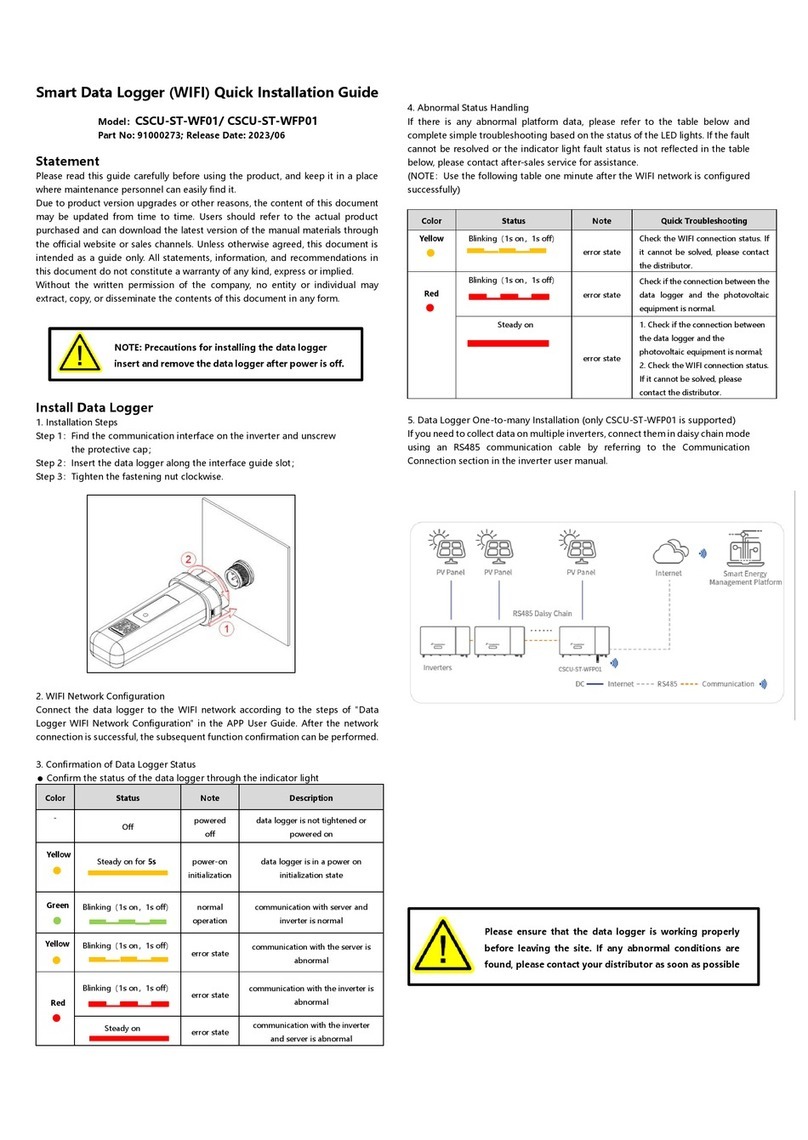

CSI

CSI CSCU-ST-WF01 Quick installation guide

Perfect Prime

Perfect Prime TC0309 instruction manual

ICP DAS USA

ICP DAS USA M-7026 user manual

CMA Dishmachines

CMA Dishmachines VINCILAB user guide