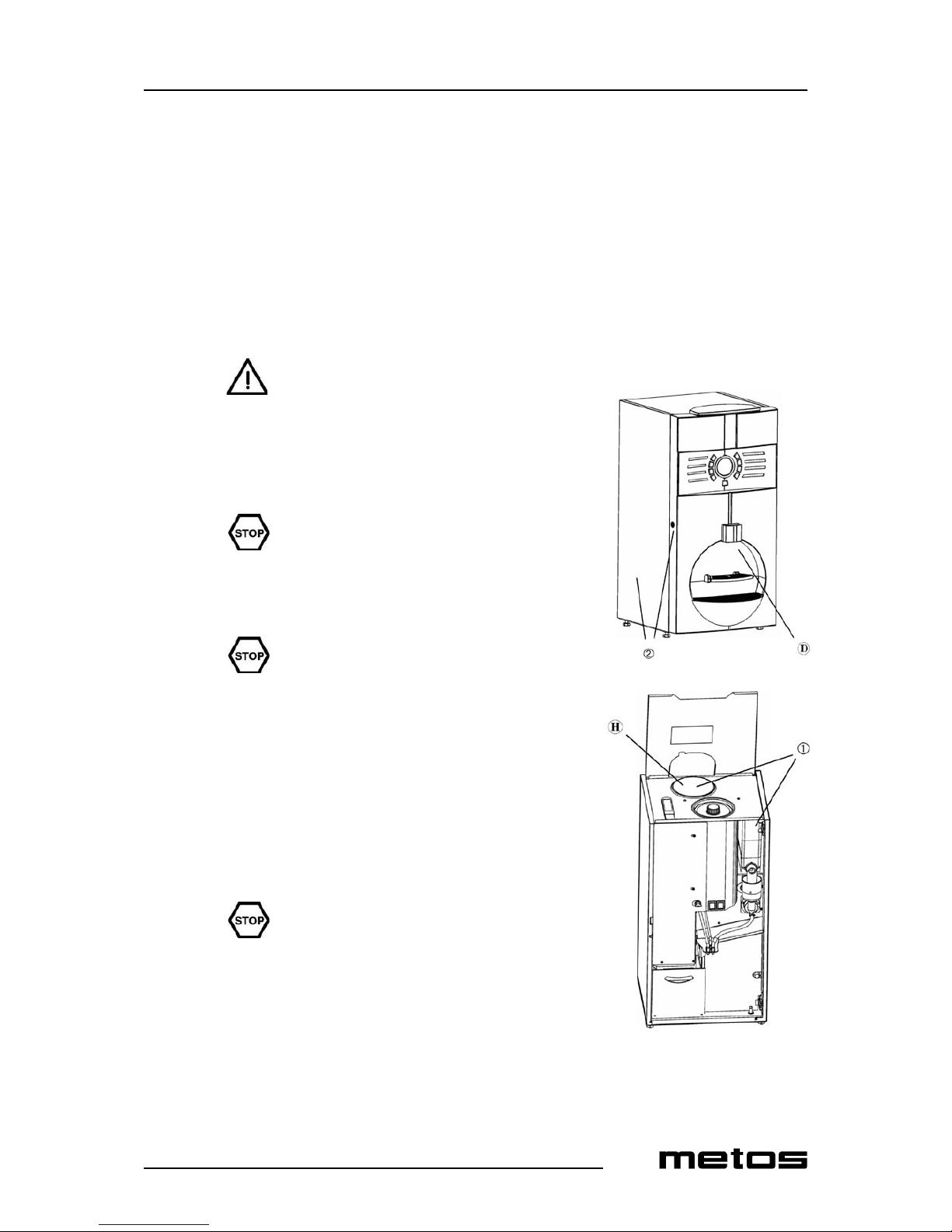

Never open any housing parts or covers unless instructed to do so. There are no

operating elements inside.

There can be a danger of electrocution or otherinjury from hot or moving parts.

Protect the machine from moisture! There can be a danger of electrocution if water

makes contact with any machine parts other than those expressly intended for this

purpose. In particular, you must not:

● operate the machine outdoors

● spray the machine with water

● spray the installation area, e.g. with a water pipe or high-pressure cleaner.

Do not continue to use the machine if damage is evident or recognizable mal-

functions occur. In such cases, important safety functions may be disturbed. First

have the machine inspected, and repaired where necessary, by our Technical

Service staff, e.g.

● if the housing is damaged or the door does not close properly,

● if the mains cable or mains plug is damaged or the electricity supply is

regularly interrupted by the fuse,

● ifwater leaks out of the machine,

● iferror messages appear on the display or the machine does not operate

as usual,

● if unusual smells are noticed or the machine housing becomes hot.

(During normal operation the housing is only warm to the touch).

In all the above cases, remove the plug from the power socket and turn the water

off. Then contact our Technical Service staff.

Observe all cleaning, inspection and maintenance intervals, as stated in the

manual.

● the machine´s safety concept can only work if all parts are kept clean and

parts subject to wear and tear are replaced early enough. Otherwise, the

safety, correct functioning and durability of the machine may be impaired.

All repair and maintenance work on the machine may only be carried out by our

Technical Service staff or a specialist authorized by the company.

The machine may only be programmed, cleaned and set up by the person installing

the machine or persons instructed in using the machine by the manufacturer.

The ground coffee used in this machine must be suitable for use in commercial

coffee machines.

The instant powder must be suited to use in automatic machines

The cleaning agent used for inserting into the storage urn and cleaning chute must

be suitable for use in Melitta coffee machines

Regular maintenance must be carried out as described in this manual.

After every (approx.) 80,000 cups, the machine must be serviced by our Technical

Service staff (at the owner´s expense).