Metrohm 872 User manual

872 Extension Module

Liquid handling – 2.872.0060

Manual

8.872.8003EN

Metrohm AG

CH-9101 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

www.metrohm.com

872 Extension Module

Liquid handling – 2.872.0060

Manual

8.872.8003EN 06. 2009 zst

Teachware

Metrohm AG

CH-9101 Herisau

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

■■■■■■■■■■■■■■■■■■■■■■ Table of contents

872 Extension Module – Liquid handling ■■■■■■■■ III

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Intended use ......................................................................... 2

1.3 About the documentation ................................................... 2

1.3.1 Content and scope .................................................................. 2

1.3.2 Symbols and conventions ........................................................ 2

1.4 Safety instructions ................................................................ 3

1.4.1 General notes on safety ........................................................... 3

1.4.2 Electrical safety ........................................................................ 3

1.4.3 Tubing and capillary connections ............................................. 4

1.4.4 Flammable solvents and chemicals ........................................... 4

1.4.5 Recycling and disposal ............................................................. 4

2 Overview of the instrument 5

2.1 Front ...................................................................................... 5

2.2 Rear ........................................................................................ 5

3 Functioning 6

3.1 10-port valve ......................................................................... 6

3.2 Transfer tubing ..................................................................... 8

3.3 Mixing vessel ......................................................................... 9

3.4 Peristaltic pump and injection valve ................................. 10

4 Assembly 12

4.1 General ................................................................................ 12

4.2 Mounting the extension module onto the IC instru-

ment ..................................................................................... 13

4.3 Mounting the extension module below the IC instru-

ment ..................................................................................... 16

4.4 Setting up the extension module next to the IC instru-

ment ..................................................................................... 19

4.5 Mounting the accessories .................................................. 23

5 Installation 26

5.1 About this chapter .............................................................. 26

5.2 Installation overview .......................................................... 26

5.3 Installation diagram .......................................................... 27

Table of contents ■■■■■■■■■■■■■■■■■■■■■■

IV ■■■■■■■■ 872 Extension Module – Liquid handling

5.4 10-port valve ....................................................................... 28

5.4.1 Connecting the 10-port valve ................................................ 28

5.5 Peristaltic pump .................................................................. 29

5.5.1 Principle of the peristaltic pump ............................................. 29

5.5.2 Installing the peristaltic pump ................................................ 30

5.6 Injection valve ..................................................................... 34

5.6.1 Connecting the injection valve ............................................... 34

5.6.2 Mode of operation of the injection valve ............................... 35

6 Start-up 37

7 Operation and maintenance 38

7.1 General information ........................................................... 38

7.1.1 Care ...................................................................................... 38

7.1.2 Maintenance by Metrohm Service .......................................... 38

7.1.3 Operation .............................................................................. 38

7.1.4 Shutting down ...................................................................... 39

7.2 Door ..................................................................................... 39

7.3 Peristaltic pump .................................................................. 39

7.3.1 Operation .............................................................................. 39

7.3.2 Maintenance ......................................................................... 40

7.4 Quality Management and validation with Metrohm ....... 42

8 Troubleshooting 43

8.1 Problems and their solutions ............................................. 43

9 Technical specifications 44

9.1 Reference conditions .......................................................... 44

9.2 Instrument ........................................................................... 44

9.3 Ambient conditions ............................................................ 44

9.4 Housing ............................................................................... 45

9.5 10-port valve ....................................................................... 45

9.6 Peristaltic pump .................................................................. 45

9.7 Injection valve ..................................................................... 46

9.8 Interfaces ............................................................................. 46

9.9 Safety specification ............................................................ 46

9.10 Electromagnetic compatibility (EMC) ................................ 46

9.11 Weight ................................................................................. 46

10 Conformity and warranty 47

10.1 Declaration of Conformity ................................................. 47

■■■■■■■■■■■■■■■■■■■■■■ Table of contents

872 Extension Module – Liquid handling ■■■■■■■■ V

10.2 Quality Management Principles ........................................ 48

10.3 Warranty (guarantee) ......................................................... 49

11 Accessories 50

11.1 Scope of delivery ................................................................ 50

11.2 Optional accessories ........................................................... 53

Index 56

Table of figures ■■■■■■■■■■■■■■■■■■■■■■

VI ■■■■■■■■ 872 Extension Module – Liquid handling

Table of figures

Figure 1 Front 872 Extension Module – Liquid handling .................................. 5

Figure 2 Rear 872 Extension Module – Liquid handling ................................... 5

Figure 3 10-port valve – positions ................................................................... 6

Figure 4 Valve switchover, normal and with secured position .......................... 7

Figure 5 6.1562.160 transfer tubing ............................................................... 8

Figure 6 6.2762.000 mixing vessel with cover ................................................. 9

Figure 7 Measuring volume – Filling the sample loop .................................... 10

Figure 8 Measuring volume – Aspirating sample segment ............................. 11

Figure 9 Setup versions ................................................................................. 13

Figure 10 Dismounting the bottle holder ......................................................... 14

Figure 11 Mounting the bottle holder ............................................................. 15

Figure 12 Removing the base tray ................................................................... 17

Figure 13 Mounting the base tray ................................................................... 18

Figure 14 Mounting the base tray ................................................................... 20

Figure 15 Mounting the bottle holder ............................................................. 21

Figure 16 Connecting the drainage tubings ..................................................... 22

Figure 17 Installation diagram ......................................................................... 27

Figure 18 Peristaltic pump ............................................................................... 29

Figure 19 Installing the pump tubing .............................................................. 30

Figure 20 Install pump tubing connection with filter ....................................... 31

Figure 21 Install pump tubing connection without filter .................................. 32

Figure 22 Injection valve - Measuring volume .................................................. 34

Figure 23 Injection valve – Positions ................................................................ 35

Figure 24 Pump tubing connection – Changing the filter ................................. 41

■■■■■■■■■■■■■■■■■■■■■■ 1 Introduction

872 Extension Module – Liquid handling ■■■■■■■■ 1

1 Introduction

1.1 Instrument description

Existing 850 Professional IC instruments can be expanded to include addi-

tional functions by means of extension modules. Every 850 Professional IC

instrument can be supplemented with up to 3 extension modules.

The 872 Extension Module – Liquid handling extends the possibilities

of inline sample preparation and liquid handling. Up to six auxiliary solu-

tions can be provided in the instrument. A mixing vessel that can be

mounted on the instrument allows the mixing of different solutions. The

872 Extension Module – Liquid handling makes guard column reactions

and pH adjustments possible - and much more.

The extension module is operated with MagIC Net software, just like the

IC instrument. When it is connected to an 850 Professional IC instrument,

MagIC Net recognizes the extension module automatically and checks its

functional capability. It controls and monitors the IC instrument as well as

the extension module, evaluates the measured data and administers it in a

database.

The 872 Extension Module – Liquid handling comprises the following

components:

10-port valve

The 10-port valve is utilized for sample preparation and serves as a switch-

over point between different liquids.

Peristaltic pump

The Peristaltic pump is used for pumping sample and auxiliary solutions. It

can rotate in both directions.

Injection valve

In Liquid Handling the injection valve is used for the measurement of pre-

cisely defined smaller volumes. The liquid is measured in the sample loop

and injected into the sample preparation process by means of valve

switchover.

1.2 Intended use ■■■■■■■■■■■■■■■■■■■■■■

2■■■■■■■■ 872 Extension Module – Liquid handling

1.2 Intended use

With the 872 Extension Module – Liquid handling, an 850 Profes-

sional IC instrument can be extended to include a broad range of addi-

tional sample preparation possibilities without having to modify the instru-

ment in between. For example calibration, ion exchange, guard column

reactions or a combination of several of them.

The present instrument is suitable for processing chemicals and flammable

samples. The usage of the 872 Extension Module therefore requires that

the user has basic knowledge and experience in the handling of toxic and

caustic substances. Knowledge with respect to the application of the fire

prevention measures prescribed for laboratories is also mandatory.

1.3 About the documentation

1.3.1 Content and scope

This document describes the 872 Extension Module – Liquid han-

dling, its assembly and connection to the IC instrument, as well as the

installation, operation and maintenance of the individual components.

Technical specifications, troubleshooting and information concerning

scope of delivery and optional accessories makes up the rest of the man-

ual.

This document does not on the other hand describe the functions of the

IC instrument - extension module unit, nor does it describe the capillary

connections that proceed from the extension module. For this purpose,

please refer to the manual for the IC instrument and that for the sample

processor.

Additional information concerning the configuration of MagIC Net can be

found on the online help for MagIC Net.

1.3.2 Symbols and conventions

The following symbols and styles are used in this documentation:

Cross-reference to figure legend

The first number refers to the figure number, the

second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

■■■■■■■■■■■■■■■■■■■■■■ 1 Introduction

872 Extension Module – Liquid handling ■■■■■■■■ 3

Warning

This symbol draws attention to a possible life hazard

or risk of injury.

Warning

This symbol draws attention to a possible hazard due

to electrical current.

Warning

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

Warning

This symbol draws attention to a possible biological

hazard.

Caution

This symbol draws attention to a possible damage of

instruments or instrument parts.

Note

This symbol marks additional information and tips.

1.4 Safety instructions

1.4.1 General notes on safety

WARNING

This instrument may only be operated in accordance with the specifica-

tions in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.4.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

WARNING

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

1.4 Safety instructions ■■■■■■■■■■■■■■■■■■■■■■

4■■■■■■■■ 872 Extension Module – Liquid handling

WARNING

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

1.4.3 Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are manda-

tory.

1.4.4 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■Set up the instrument in a well-ventilated location (e.g. laboratory

flue).

■Keep all sources of flame far from the workplace.

■Clean up spilled fluids and solids immediately.

■Follow the safety instructions of the chemical manufacturer.

1.4.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■■■■■■■■■■■■■■■ 2 Overview of the instrument

872 Extension Module – Liquid handling ■■■■■■■■ 5

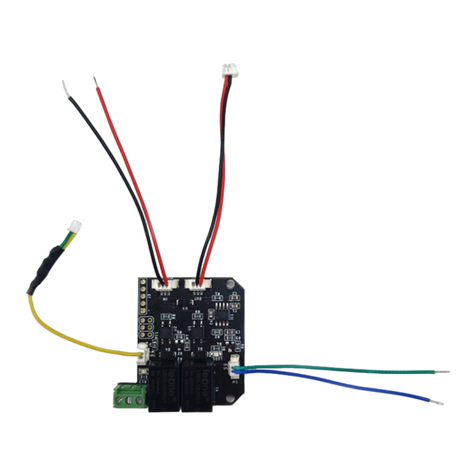

2 Overview of the instrument

2.1 Front

1 2 34

Figure 1 Front 872 Extension Module – Liquid handling

1Standby indicator 2Peristaltic pump

310-port valve 4Injection valve

2.2 Rear

In Out

Made by Metrohm Herisau Switzerland

12

Figure 2 Rear 872 Extension Module – Liquid handling

1Connector In

To connect the extension module to the IC

instrument or to another previously connec-

ted extension module.

2Connector Out

To connect an additional extension module.

3.1 10-port valve ■■■■■■■■■■■■■■■■■■■■■■

6■■■■■■■■ 872 Extension Module – Liquid handling

3 Functioning

3.1 10-port valve

The 10-port valve is used for sample preparation. For this, the central posi-

tion (3-11) can be connected to the 10 other positions, one after the

other, by means of the selector (3-13).

The transfer tubing is connected to the central position. Liquids can be

aspirated into the transfer tubing by one of the 10 positions with the aid

of a Dosino and then transported to any other position by reversing the

flow.

The following illustration shows a 10-port valve with a possible utilization

of the positions:

1

2

3

4

5

6

7

8

9

10

11

12

13

Figure 3 10-port valve – positions

1Position 1

Connector for the connection to e.g. the

injection valve in the extension module.

2Position 2

Connector for the connection to e.g. the

injection valve in the IC instrument.

3Position 3

Connector for the connection to e.g. the

mixing vessel.

4Position 4

Connector for the connection to an auxiliary

solution.

5Position 5

Connector for the connection to an auxiliary

solution.

6Position 6

Connector for the connection to an auxiliary

solution.

7Position 7

Connector for the connection to an auxiliary

solution.

8Position 8

Connector for the connection to e.g. the

waste container.

9Position 9

Connector for the connection to an auxiliary

solution.

10 Position 10

Connector for the connection to e.g. the ion

exchanger.

■■■■■■■■■■■■■■■■■■■■■■ 3 Functioning

872 Extension Module – Liquid handling ■■■■■■■■ 7

11 Central position

Connector connected with the transfer tub-

ing.

12 10-port valve

13 Selector

Can be rotated for selecting the active posi-

tion.

The selector can rotate in a clockwise or counterclockwise direction. Nor-

mally, the shortest path is selected when switching over to a new posi-

tion.

1

2

3

4

5

6

7

8

9

10

Secured positions

In order to avoid contaminations, any given position can be defined as

"secured". The secured position is moved to during switching only if it is

the goal of the switching procedure.

If the secured position lies along the shortest route during a valve switch-

over, then the longer path will automatically be selected.

Example: Switching from position 2 to position 5.

The shorter path travels via positions 3 and 4 (see illustration 4, left). If

however position 4 is defined as the secured position, then the 10-port

valve will automatically switch via the connectors 1 – 10 – 9 – 8 – 7 – 6

(see illustration 4, left).

X

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Figure 4 Valve switchover, normal and with secured position

3.2 Transfer tubing ■■■■■■■■■■■■■■■■■■■■■■

8■■■■■■■■ 872 Extension Module – Liquid handling

3.2 Transfer tubing

The transfer tubing – a long coiled tubing (V=15 mL) – is used both for

"storing" various liquids and in order not to contaminate the Dosino with

these liquids. These liquid segments can be separated from one another

with air bubbles or water. With its pedestal (5-3), the transfer tubing can

be placed in one of the recesses of the bottle holder.

1

2

3

Figure 5 6.1562.160 transfer tubing

1Connector to the Dosino 2Connector to the 10-port valve

3Pedestal

For placing into the 6.2057.200 bottle

holder.

The transfer tubing is connected by means of a connector (5-2) with the

central position of the 10-port valve and by means of another connector

(5-1) with a Dosino.

The Dosino is responsible for the transport and dosing of the liquids and is

filled with a transfer solution (usually water). It can move defined volumes

of liquids in two directions: aspirate and eject.

■During aspiration, the liquid is suctioned out of the active position of

the 10-port valve through the central position and into the transfer

tubing.

■During ejection, the liquid that has collected in the transfer tubing is

transported through the central position of the 10-port valve and from

there to the active position.

■■■■■■■■■■■■■■■■■■■■■■ 3 Functioning

872 Extension Module – Liquid handling ■■■■■■■■ 9

3.3 Mixing vessel

The mixing vessel is connected with the 10-port valve, e.g. through posi-

tion 3. Various liquids can be mixed in the mixing vessel. This takes place

either by means of rapid injection of the liquids to be mixed or by the

introduction of air bubbles. The homogenized liquid can be transported

onward through the 10-port valve.

1

2

3

Figure 6 6.2762.000 mixing vessel with cover

1Cover for the 6.2762.010 mixing vessel

With two connector openings.

26.2762.000 mixing vessel

Can be put on the 6.2057.200 bottle holder.

3Connector

For the 10-port valve.

Like the other Metrohm sample vessels, the mixing vessel is made of poly-

propylene PP. It has an extremely smooth surface which permits no drop

formation. The mixing vessel can be readily rinsed out and dried. It can be

used for anions as well as for cations.

3.4 Peristaltic pump and injection valve ■■■■■■■■■■■■■■■■■■■■■■

10 ■■■■■■■■ 872 Extension Module – Liquid handling

3.4 Peristaltic pump and injection valve

The peristaltic pump and the injection valve are utilized for the precise

measurement of small volumes.

The liquid to be dosed, e.g. sample (7-1), is pumped with the peristaltic

pump (7-2) through the sample loop (7-4) on the injection valve (7-3).

The desired volume is defined precisely by the size of the selected sample

loop.

1

2

3

4

5

6

9

10

7

8

123

4

Figure 7 Measuring volume – Filling the sample loop

1Sample 2Peristaltic pump

3Injection valve 4Sample loop

Following the switchover of the valve (8-2), the measured sample seg-

ment (8-5) is conveyed by aspiration with the Dosino (8-1) through the

10-port valve (8-4) into the transfer tubing (8-6), from where it can be

conveyed onward to a different outlet.

■■■■■■■■■■■■■■■■■■■■■■ 3 Functioning

872 Extension Module – Liquid handling ■■■■■■■■ 11

1

2

3

4

5

6

9

10

7

8

1

2

3

4

5

6

Figure 8 Measuring volume – Aspirating sample segment

1Dosino 2Injection valve

3Container with transfer solution 410-port valve

5Sample 6Transfer tubing

4.1 General ■■■■■■■■■■■■■■■■■■■■■■

12 ■■■■■■■■ 872 Extension Module – Liquid handling

4 Assembly

4.1 General

The extension modules are fitted directly to the 850 Professional IC instru-

ment and connected with it via 6.2156.060 connection cable. Extension

modules have no power supply of their own, but rather draw the electric-

ity they require from the instrument with which they are connected.

Up to three extension modules can be connected to an 850 Professional

IC instrument. The following restrictions are to be taken into account:

Restrictions The 850 Professional IC instruments and their extension modules must not

have more than 4 identical components in common, i.e.:

■a maximum of 4 high pressure pumps,

■a maximum of 4 peristaltic pumps,

■a maximum of 4 injection valves,

■a maximum of 4 suppressors (MSM, SPM incl.),

BUT

■only a maximum of 3 degassers

■and a maximum of 3 CO2 suppressors (MCS)

NOTE

If all 4 high pressure pumps are being used at once, then not all of

them are permitted to run at maximum flow for longer periods of time.

Extension modules can be mounted in the following setup versions:

■above, between instrument and bottle holder (9-A), or

■below, between instrument and base tray (9-B), or

■next to the instrument (9-C) with a separate 6.2061.110 base tray and

a 6.2061.100 bottle holder (to be ordered additionally). For this, the

longer 6.2156.070 connection cable (to be ordered additionally), is

necessary, too.

Other manuals for 872

3

This manual suits for next models

1

Table of contents

Other Metrohm Control Unit manuals