M20-EPS User Guide

Summary

I. TECHNICAL SPECIFICATIONS ................................................................................................................................... 7

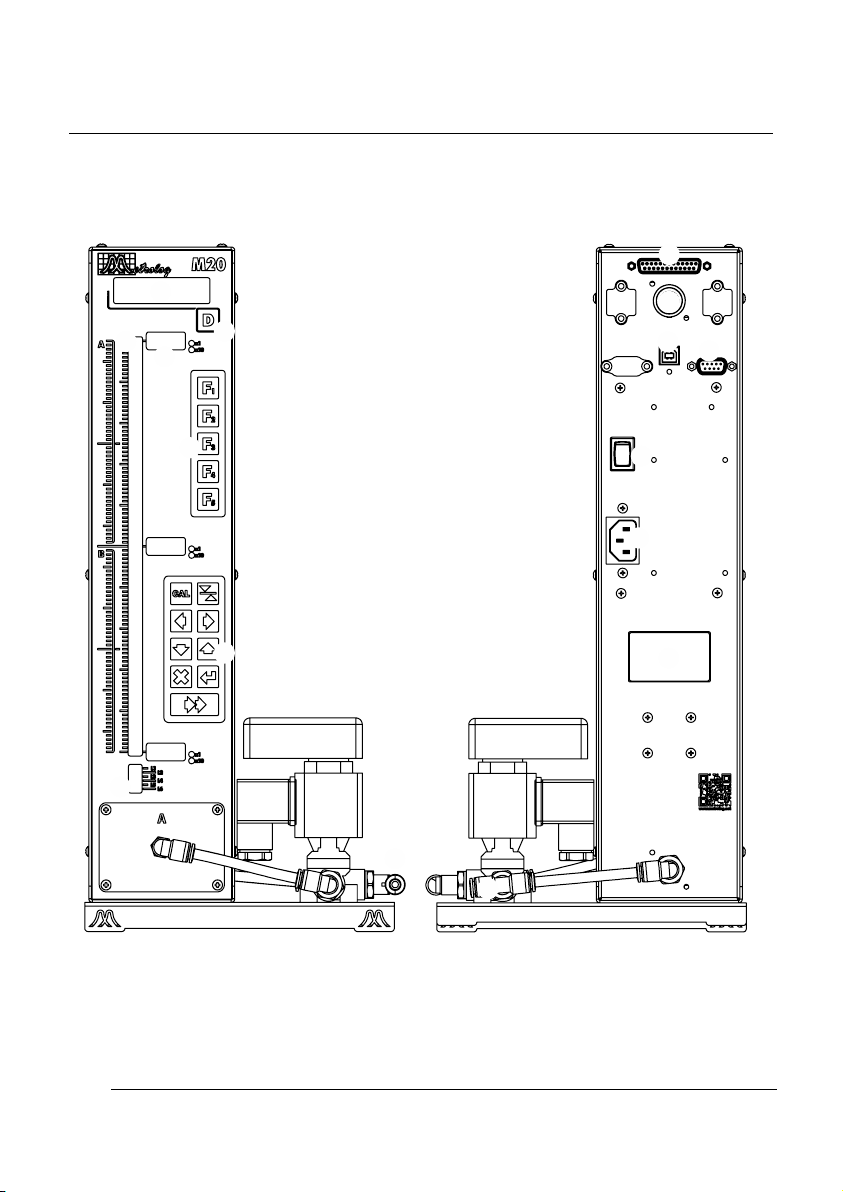

1. PANEL AND CONNECTORS....................................................................................................................................... 8

2. EQUIPMENT PLACEMENT AND SAFETY INFORMATION ................................................................................. 11

2.1 –INSTRUCTION AND SITE SELECTION ........................................................................................................................ 11

2.2 –COMPRESSED AIR SUPPLY ..................................................................................................................................... 12

2.3 –AG20 MEASUREMENT NEEDLE INSTALLATION ........................................................................................................ 13

2.4 –SAFETY GUIDELINES WHILE USING THE AG20........................................................................................................ 14

2.5 –REGULATIONS AND INJURIES PREVENTION ............................................................................................................. 15

3. BASIC MEASUREMENT PRINCIPLES .................................................................................................................... 18

3.1 –MEASUREMENT OF FUSION STRENGTH INDEX ........................................................................................................ 18

3.2 –CALIBRATION ROUTINE........................................................................................................................................... 19

3.3 –MEASUREMENT ROUTINE ....................................................................................................................................... 20

3.4 –DEEP MEASURING ................................................................................................................................................. 21

3.4.1 – Creation of guide holes.............................................................................................................................. 22

3.5 –STATISTICAL ANALYSIS........................................................................................................................................... 23

3.6 –TOLERANCE LIMITS ................................................................................................................................................ 24

3.7 –NEEDLE CLEAN UP AND AIR BLOCKAGE .................................................................................................................. 25

4 – DIGITAL I/O INTERFACES ...................................................................................................................................... 26

4.1 –USB/RS232 COMMUNICATION INTERFACE............................................................................................................. 26

4.1.1 – Connecting to a computer or data logger................................................................................................ 26

4.1.2 – Standard ASCII Protocol ........................................................................................................................... 27

4.1.3 – M20 Communication protocol ................................................................................................................... 28

4.2 –DIGITAL PARALLEL INTERFACE ............................................................................................................................... 30

4.2.1 – Digital interfaces working modes.............................................................................................................. 33

4.2.2 – PE-10 switch setup (optional component)............................................................................................... 36

5. DATA LOGGER ........................................................................................................................................................... 37

5.1 –INTEGRATED DATA LOGGER ................................................................................................................................... 37

5.2 –DATA LOGGER SETUP AND USE.............................................................................................................................. 38

5.2.1 – Sample acquisition ..................................................................................................................................... 38

5.2.2 – Transmission of acquired data ................................................................................................................. 38

6. SPECIAL PROCEDURES........................................................................................................................................... 40

6.1 –USER PARAMETERS FACTORY RESET..................................................................................................................... 40

6.2 –SECURITY RESTRICTIONS UNLOCK ......................................................................................................................... 41

6.3 –FIRMWARE UPDATE ................................................................................................................................................ 42

7. INTERNAL PARAMETERS AND ROUTINES REFERENCE................................................................................. 43