TQC AB6000 User manual

TQC Scrub Abrasion and

Washability Tester

(AB6000, AB6010)

Operating Instructions (V1.1 0118)

IMPORTANT! Before taking this instrument

in use we strongly advise you to read this

manual carefully.

3 |

TQC will grant a warranty for a period of 12 months for the TQC Scrub

Abrasion and Washability Tester and 12 months for all related equipment

from the date of delivery in respect of any evidence of faulty workmanship

and materials.

Should a delivered consignment prove to be contrary to contract upon

inspection, the customer shall grant TQC the opportunity hereunder of

removing the fault, or else the customer may demand replacement. Because

of size and weight of the instrument TQC will strive to give remote support.

Should the supply or delivery of any improvement or replacement not prove

possible, the customer may choose between having the purchase price

reduced or in demanding the contract of sale to be rescinded (conversion).

Damage resulting from natural wear and tear, mechanical or chemical

damage, an act of God or non compliance with the operating instructions

shall be excluded from the warranty as well as mechanical interference by

the customer or by third parties with TQC Scrub Abrasion and Washability

Tester and related equipment without TQC’s written permission. No liability

will be accepted for defects, damage or injury caused due to use not carried

out in accordance with the manufacturer’s user instructions.

To claim warranty, the rejected product has to be sent to TQC together with

the original invoice, any exchange before the product has been returned

to TQC is not possible. TQC reserve the right to repair, exchange or supply

an equivalent substitute. TQC is not liable for handling or transport costs.

Warranty on the purchase price is limited, all liability for consequential

damages or changes in technology is expelled.

This product complies to

- Machinery Directive 2006/42 / EC

- Low Voltage Directive 2006/95 / EC

- EMC Directive 2004/108 / EC

This product is RoHS 2 compliant (2011/65/EU)

WARRANTY

5 |

1 General

1.1 Importance of operating manual

1.2 User-responsibility

1.3 Responsibility of personnel

1.4 Dangers

1.5 Designated purpose

1.6 Copyright

1.7 Manufacturer’s/Supplier’s address

2 Safety Instructions

2.1 Meaning of Symbols

2.2 Availability of Safety Information

2.3 Dangers from Electrical Energy

2.4 Modifications to the Equipment

3 Transport and Storage

3.1 Packing

3.2 User: Check on Receipt

3.3 Reporting Transport Damage and

Documentation

3.4 Storage and Protective

Measures when not in use

4 Instrument Data

4.1 Name / Article

4.2 Scope of Supply

4.3 Technical Data

4.4 Dimensions and Weight

4.5 Basic Unit

5 Instrument Controls and Functions

5.1 Instrument Layout

5.2 Connecting a Mouse and Keyboard

6 Instrument Preperations

6.1 Installation

6.2 Tool Holders and Tools

6.3 Fluid Tubes

7 Navigation

7.1 Menu

7.2 Number Input

7.3 Text Input

8 Operation

8.1 Starting the Instrument

8.2 Run

8.2.1 Run

8.2.2 Manual Movement

8.3 Run Setup

8.3.1 Manual

8.3.2 Alarms

8.3.3 Pumps

8.3.4 Custom Presets

8.3.5 New Custom Preset

8.3.6 Standard Presets

8.3.7 Select Length

8.3.8 Test Positioning

8.3.9 Flush System (AB6000 only)

9 Instrument Setup

9.1 Instrument Setup Menu

9.2 Units

9.3 Alarms

9.4 Display Brightness

9.5 System Information

9.6 Reset

10 Mechanical

10.1 Test Beds

10.2 Sample Clamp Frames

10.3 Tool Holders

10.4 Tools

10.4.1 Small Sponge (AB5012)

10.4.2 Wild Boar Brush (AB5010)

10.4.3 Nylon Brush (AB5011)

10.4.4 Abrasive Pad Tool (AB5013)

10.4.5 Universal Material Clamp (AB5020)

10.4.6 MEK / Crockmeter Tool (AB5060)

10.4.7 Large Sponge Tool (AB5050)

10.4.8 TQC Cloth Holder (AB5055)

10.4.9 Metal Shim (AB5025)

10.4.10 Glass Bed (AB5180)

10.4.11 Heavy Weight Support Tool (AB5032)

10.4.12 Tubing (AB5115 and AB5113)

11 Care and Maintenance

11.1 Disposal of Materials

11.2 Customer Service

12 Disclaimer

Annex A Standards Conguration Table

Annex B Chemical Resistance

Annex C Operator Qualication List

Annex D Maintenance List

6 21/22

23/27

28

29

30/31

32/43

45

47

7

8

9

10/11

12

13

14/20

INDEX

| 6

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and

possible applications of the instrument. It contains important instructions

about how to use the instrument safely and economically; according to

the purpose designated. Following these instructions is not only essential

to avoid risks. It also reduces repair costs and down-time and increases the

products reliability and service-life.

Anyone who works with the instrument shall follow the instructions in this

manual, particularly the safety related instructions. Additionally local rules

and regulations relating to environmental safety and accident prevention

should be observed. It is mandatory that users have read and understand

this manual prior to first operation of the TQC Scrub Abrasion and

Washability Tester.

1.2 User-responsibility

The user should

a) Only allow persons to work with the instrument who are

familiar with the general instructions on how to work safely and

to prevent accidents. The use of the instrument should have been

instructed duly.

b) Regularly check the safety-awareness of personnel at work.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument

should pay attention to the general regulations relating to working safety

and accident prevention. The safety chapter and the warnings in this manual

should have been read and understood; acknowledged as evidenced by

their signature as can be placed in the Operator Qualification list Annex C.

1.4 Dangers

This instrument has been designed and constructed in accordance with

state-of-the-art technology and the acknowledged safety regulations.

Nevertheless, working with the instrument could cause danger to the

life and health of the operator or to others, or damage to the instrument

or other property. Therefore the instrument should only be used for its

designated purpose, and in a perfect technical condition. Any defect that

could have a negative effect on safety should be repaired and recorded.

1.5 Designated purpose

TQC Scrub Abrasion and Washability Tester is exclusively designed to

perform washability tests of painted and coated test panels as described

within the specifications. TQC will not be held liable for damage resulting

from improper use.

Designated purpose also includes properly observing all instructions in the

operation manual, and adherence to inspection and maintenance

schedules. TQC is entitled to request these form when warranty claims are

made and during inspections to ensure safe operation and evaluate correct

usage.

1.6 Copyright

The copyright of this operating manual remains with TQC. This operating

manual is intended solely for the user and his personnel. Its instructions

and guidelines may not be duplicated, circulated or otherwise passed on to

others, neither fully, nor partly. Infringement of these restrictions may lead

to legal action may be taken if this restrictions are infringed upon.

1.7 Manufacturer’s/Supplier’s address

TQC – Molenbaan 19

2908 LL Capelle aan den IJssel

The Netherlands

T +31(0)10 7900 100

F +31 (0)10 7900 129

1 GENERAL

7 |

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

2.2 Availability of Safety Information

The instruction manual should be kept in proximity to where the instrument

operates and should be visible and accessible at any time of operation.

In addition to the information contained in the instruction manual, general

and local regulations for accident prevention and environmental protection

shall be kept available and observed. Always ensure all guidelines in respect

of safety and dangers on the instrument are in readable condition.

In case of danger the instrument has to be switched off by means of the on /

off switch at the left back side of the instrument or by unplugging the mains

power, then the danger should be eliminated.

2.3 Dangers from Electrical Energy

• Work on the electrical supply may only be done by a qualified electrician.

• The electrical equipment of the instrument must be checked regularly.

Loose connections and cables damaged by heat must be corrected

immediately.

• Always make sure the instrument’s power is turned off while adjusting any

electrical component.

Make sure that no paint or other liquids are spilled on the

electronics

2.4 Modications to the Equipment

• Any modifications or additions or alterations to the instrument may solely

be made with permission from the manufacturer otherwise the warranty

will be void.

• Instruments which are not in fault-free condition must immediately be

switched off

• Only use replacement parts from the original supplier. Parts used from

other sources aren’t guaranteed to take the loading and meet the safety

requirements.

Possible immediate

danger to the life or

health of personnel.

If this guideline is not noted

it can lead to severe danger

to health, up to fatal injury.

A dangerous situation

could be caused.

Non observance of this

guideline can lead to injury

or to damage to equipment.

Special tips and

particular information.

Guidelines to make optimal

use of the instrument.

2 SAFETY INSTRUCTIONS

| 8

3.1 Packing

• Please take note of pictorial symbols on the packing.

• Check for transport damages. If the packaging is damaged only accept it

with a written approval of the transporter that the package was damaged.

3.2 User: Check on Receipt

• Check packing for damage

• After unpacking check complete supply.

3.3 Reporting Transport Damage and Documentation

• Any damage should be documented as accurately as possible (possibly

photographed) and reported to the relevant insurers or, in the case of sales

“delivered to customers works”, to the supplier.

3.4 Storage and Protective Measures when not in use

• The instrument must be stored in a dry place at a temperature

between 10 - 40˚C / 50 - 104˚F.

• If packing is damaged upon receipt immediately inform the forwarder and

make a note on the packing list and have it signed by the forwarder. Ideally

make some pictures of the damage as well.

• Store instrument in the original packing if possible.

3 TRANSPORT AND STORAGE

9 |

4 INSTRUMENT DATA

TQC Scrub Abrasion and

Washability Tester

24 V Adapter +

Power Cable

Manual Tubing Fluid Containers

Standard supplied Only supplied with AB6000

4.3 Technical Data

Traverse speed: 1 - 60 cycles per minute

Traverse speed accuracy: + / - 1% of set speed

Stroke length: 20 - 300 mm / 0.39 - 11.81 in

Stroke length accuracy: + / - 0.01 mm

Pump flow rate: 0.0 - 3.0 ml per minute / 0.0 - 0.79 GPH

Max. panel width: 70 mm

Max. panel length: 350 mm

Max. panel height: 35 mm

4.4 Dimensions and Weight

Depth: 490 mm / 19.3 in

Depth with pumps: 530 mm / 20.87 in

Width: 640 mm / 25.2 in

Height: 235 mm / 9.24 in

Weight: 30 - 35 kg / 66.14 - 77.16 lbs (depending on model)

4.5 Basic Unit

Power Supply: 24 VDC / 100 - 240 V / 50 - 60 Hz

Power consumption: max. 90 Watt

Display: 480 x 272 pixel TFT display

Control: 5-key navigation switch

(Mouse Keyboard optional)

Menu languages: English, Spanish, Chinese, Polish, German, French,

Italian, Japanese, Russian, Turkish

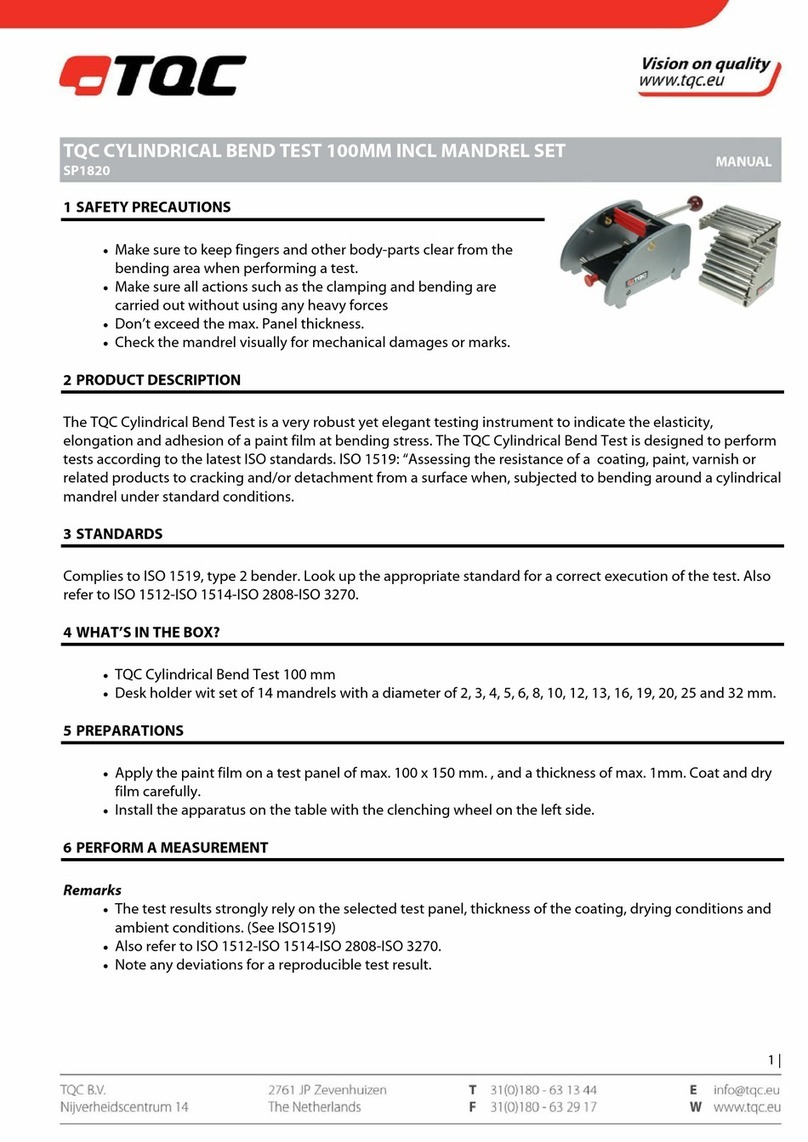

4.1 Name / Article

AB6000 TQC Scrub Abrasion and Washability Tester

AB6010 TQC Scrub Abrasion and Washability Tester Basic

4.2 Scope of Supply

TQC Scrub Abrasion and

| 10

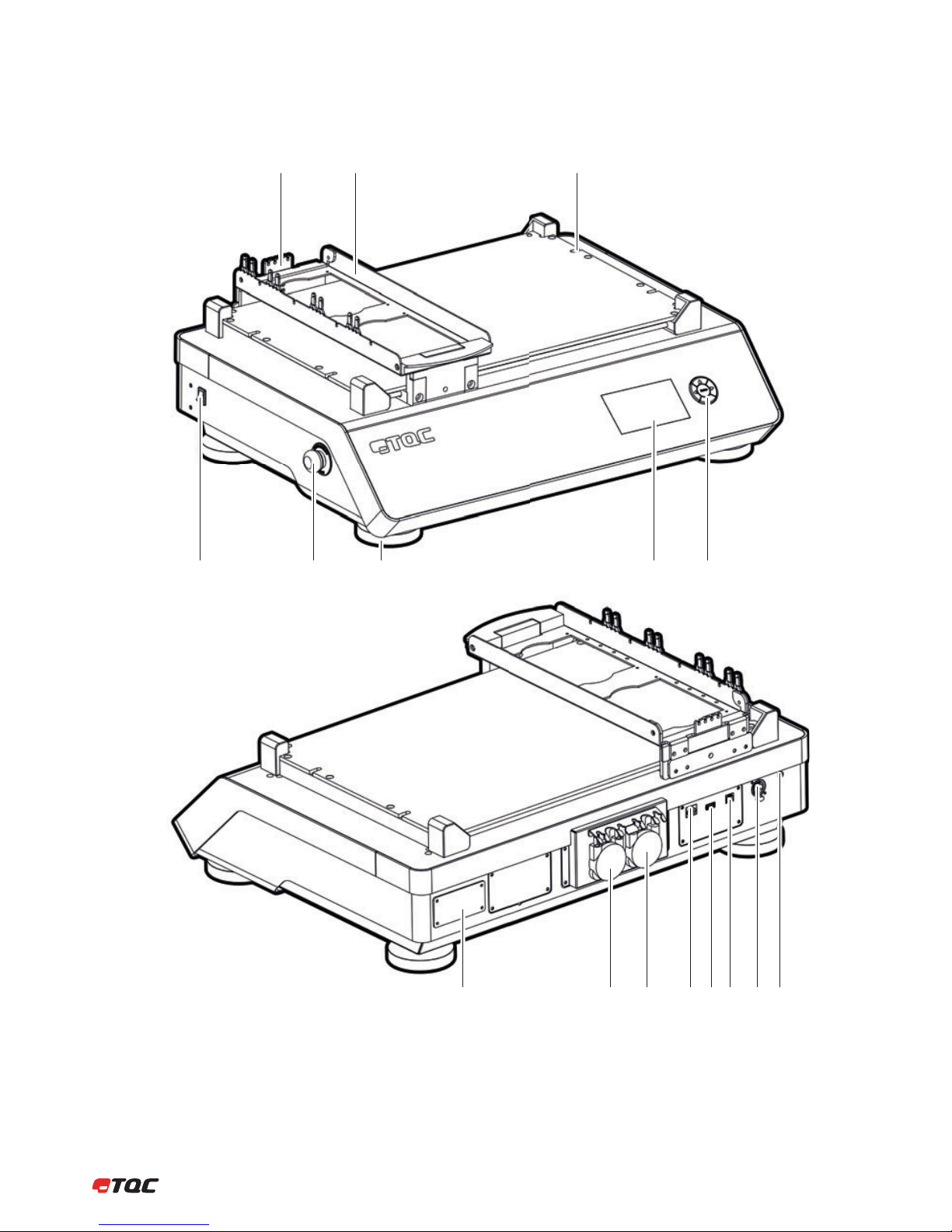

5 INSTRUMENT LAYOUT AND FUNCTIONS

Tube Holder

Tool Carrier

Fixture Screws

Power Switch

Emergency Button

Adjustable Feet

Full Color Display

5-key Navigation Switch

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

Machine ID-Tag

Pump AB

Pump CD

Ethernet

USB-A

USB-B

TQC Bus

Power Entry

45

910111213141516

678

12 3

5.1 Instrument Layout

11 |

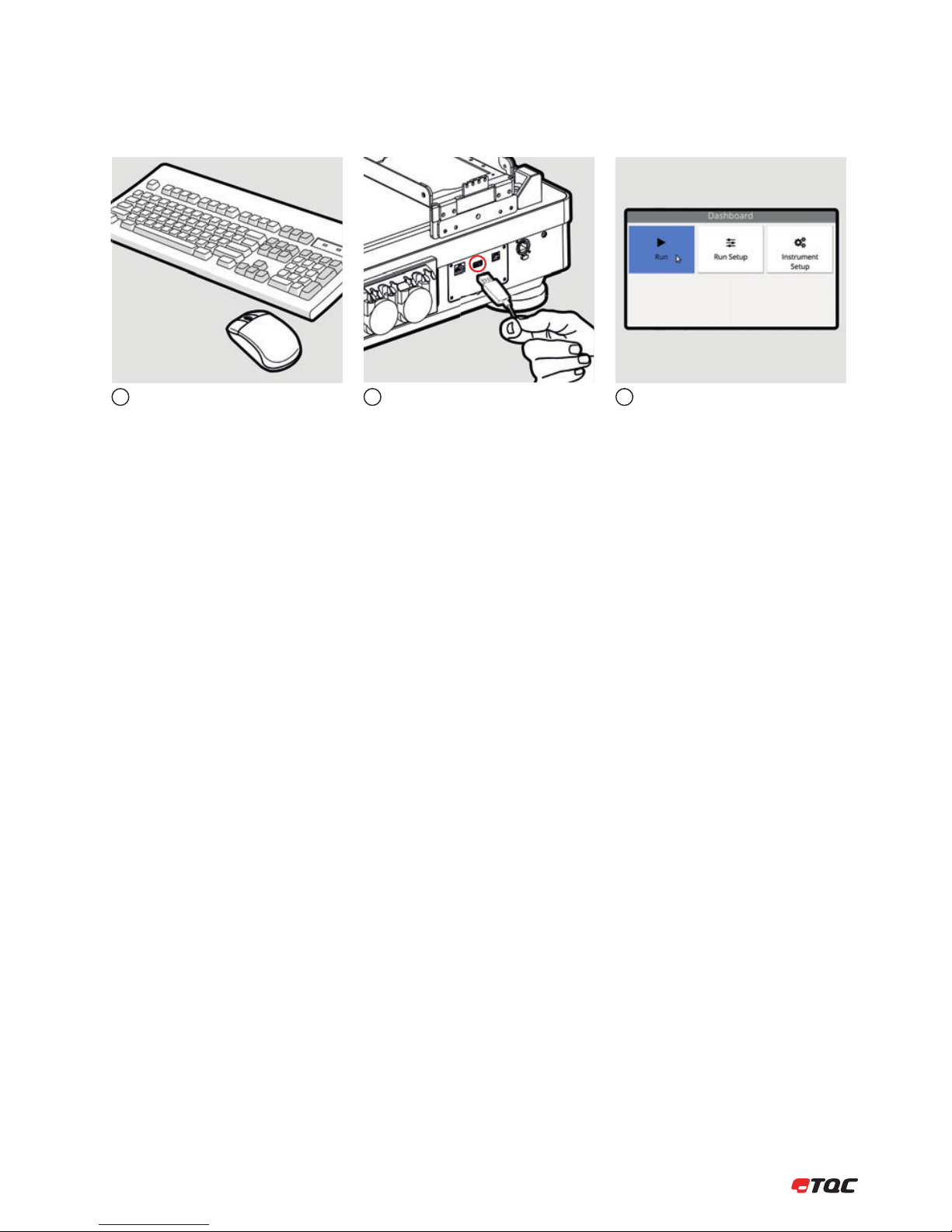

5.2 Connecting a Mouse and Keyboard

The instrument can also be controlled by a

mouse and/or keyboard.

Connect the mouse and/or keyboard to the

USB-A port at the back of the instrument.

Clicking the left mouse button behaves the

same as the OK button. (Not all input fields

can be controlled by a mouse.)

123

Clicking the left mouse button behaves the

3

| 12

6 INSTRUMENT PREPARATIONS

The instrument has to be installed on a

sturdy table or work area.

Lift the Tool Carrier.

Connect the power cable to the machine

and a wall socket.

Place the Test Beds and the Sample Clamp

Frames. Then close the Tool Carrier.

Place the Tool Holders first, then place the

Tools.

1

1

2

23

6.1 Installation

6.2 Tool Holders and Tools

6.3 Fluid Tubes

Mount the tubes in the bracket on the Tool

Carrier and place the correct tube at each

channel.

Connect the IN tubes from the pumps to

the fluid containers.

23

Connect the tubes to the fluid pumps. The

channels are marked on bracket.

1

13 |

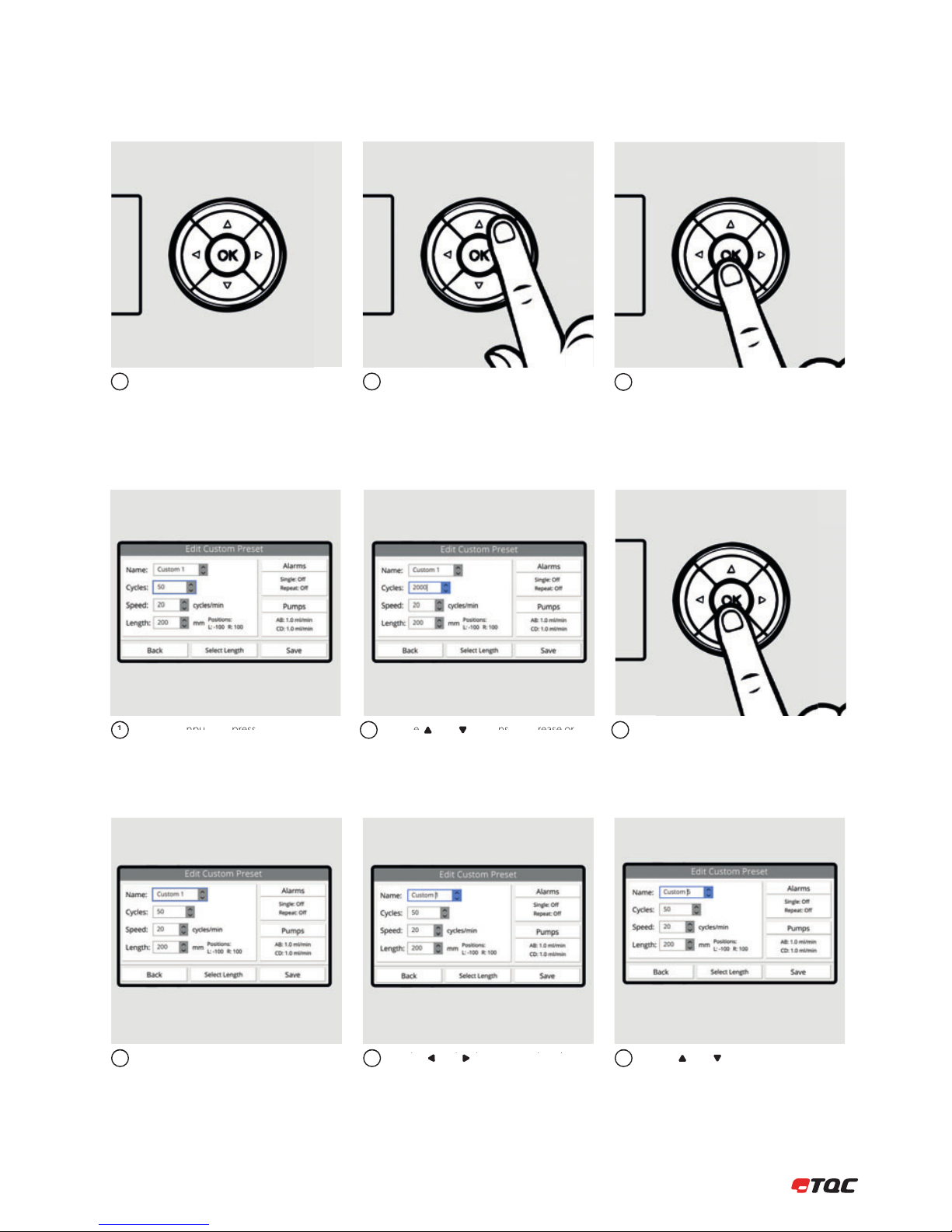

7 NAVIGATION

Use the 5-key button to navigate through

the interface. Red lights in the 5-key button

indicate possible actions for the selected

button.

You can change the selected button by

pressing the arrows on the 5-key button.

12 To confirm the selected button, press OK on

the 5-key button.

3

Select the input and press OK to edit the

value.

Use the and buttons to increase or

decrease the value. Hold the button to

increase or decrease in bigger steps.

Use the and buttons to select the

character.

Use the and buttons to change the

character.

Press OK to stop editing.

12

23

3

Select the input and press OK to edit the

value.

1

7.2 Number Input

7.1 Menu

7.3 Text Input

Sel

ect

th

ei

npu

ta

nd

pre

ss

OK

to

ed

it

the

K

1

Use th

e

and bu

tto

ns

to

inc

rea

se

or

2

h

db l h

| 14

8.1 Starting the Instrument

8 OPERATION

Press OK to initialize the instrument.This screen will be displayed after turning

on the instrument.

The instrument will check the system

for any errors and the Tool Carrier will be

calibrated.

12

Run

Click to start a new run.

Run Setup

Run related settings.

Instrument Setup

All instrument related settings.

3

Check fluids presence at tip of tubes.

(AB6000 only)

Follow the instructions on the display.

12 Place and secure tools.3

8.2 Run

8.2.1 Run

Follow the instructions on the display

2

15 |

Follow the instructions on the display.

A name or description can be given to the

marking. Click Conrm to save the marking.

The Tool Carrier will now move. Stay clear

from moving parts!

4

7

5

89

Click A, B,C,or D to mark a single channel

at current cycles/time. Click All to mark all

channels at current cycles/time. Click Pause

to temporarily stop the test.

Click Markings to view all markings of the

current run. Click Resume to continue the

run. Click Stop to stop the run.

Use the and buttons to scroll through

the list of markings. Click Clear to erase all

current markings.

6

Tools may be removed when the Tool

Carrier has stopped moving.

10

Follow the instructions on the displ

ay

4

Click

A

B

C

or D

to mark a single channel

6

An

ame

or

de

scr

ipt

ion

ca

nb

eg

ie

nt

ot

he

7

8

Click

Markings

to view all markings of the

| 16

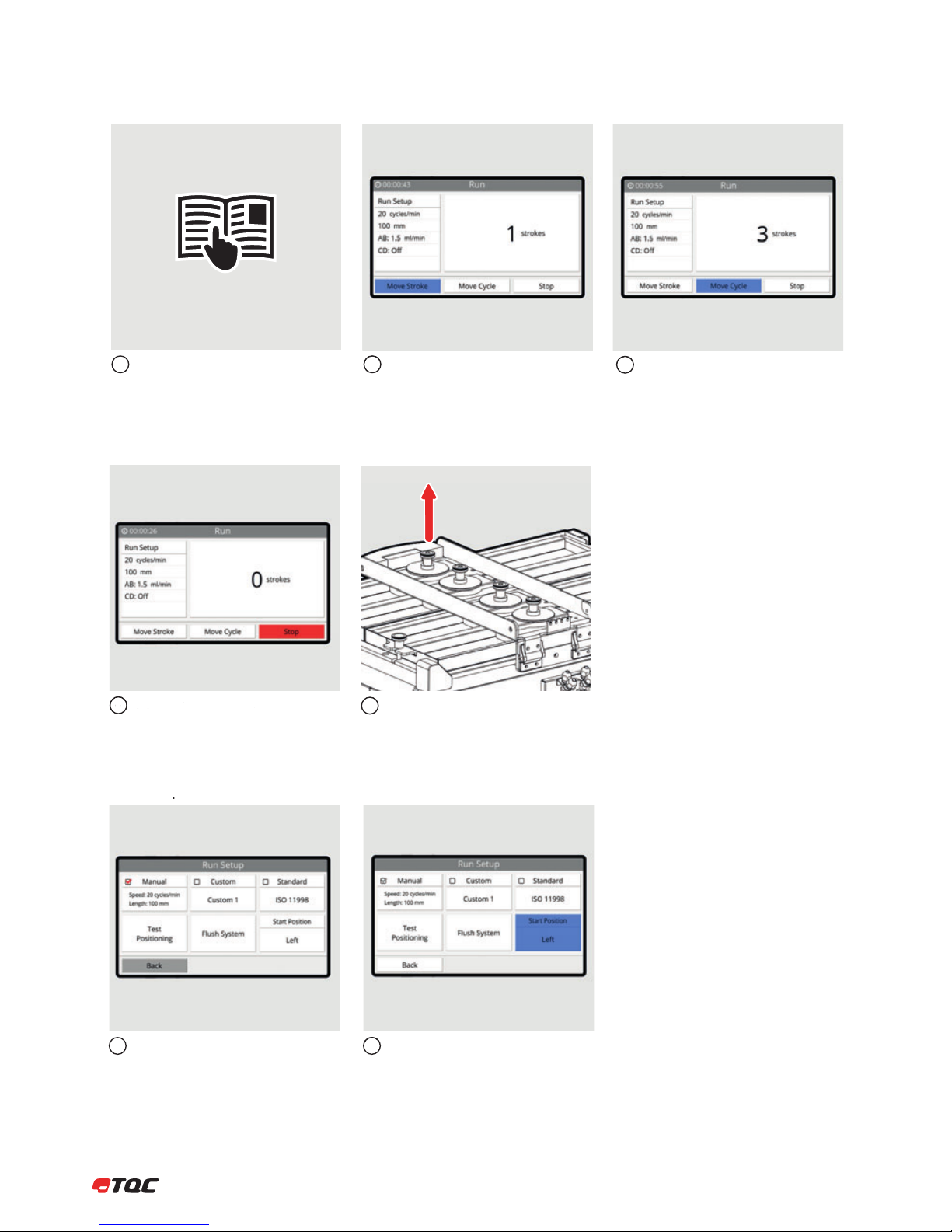

8.2.2 Manual Movement

See steps 1 – 4 from chapter 8.2.1.

8.2.1.

Click Move Stroke to move the Tool Carrier

a single stroke. (from Left to Right or Right

to Left, depending on set Start Position)

12 Click Move Cycle to move the Tool Carrier a

single cycle.

3

Click Stop to stop the run.

4Tools may be removed when the Tool

Carrier has stopped moving.

5

Run settings are set in Manual, Custom or

Standard. The red checkmark indicates the

active setup.

Click to set the movement start position to

Left or Right.

12

8.3 Run Setup

8.3

Run

Setup

Click

Move Stroke

to move the Tool Carrier

2

Click

Move Cycle

to move the Tool Carrier a

3

Click

St

op

k

to sto

p t

he run

.

4

Cli k t t th t t t iti t

2

17 |

Set the speed and length. Click Alarms to configure the alarms

settings. Click Pumps to configure the

pumps settings. (AB6000 only)

If uncertain about the left and right

position, use Select Length to determine

the positions. See 8.3.7.

123

8.3.1 Manual

Click Select to use the manual setup. Enable Manual Movement for manual

control of the Tool Carrier in a run.

45

8.3.1

Manual

Manual Movement

Instead of automatic movement, the user

can move the Tool Carrier a single stroke or

cycle by the click of a button. See 8.2.2 for

more information.

Single alarm will make a sound once at set

number of cycles. Enable Stop at alarm

to stop the Tool Carrier when an alarm is

triggered.

Repeat alarm will make a sound at set

interval.

Click Back to save the alarm settings.

123

8.3.2 Alarms

8.3

.2

Ala

rms

Cli k

Bk

t th l tti

3

| 18

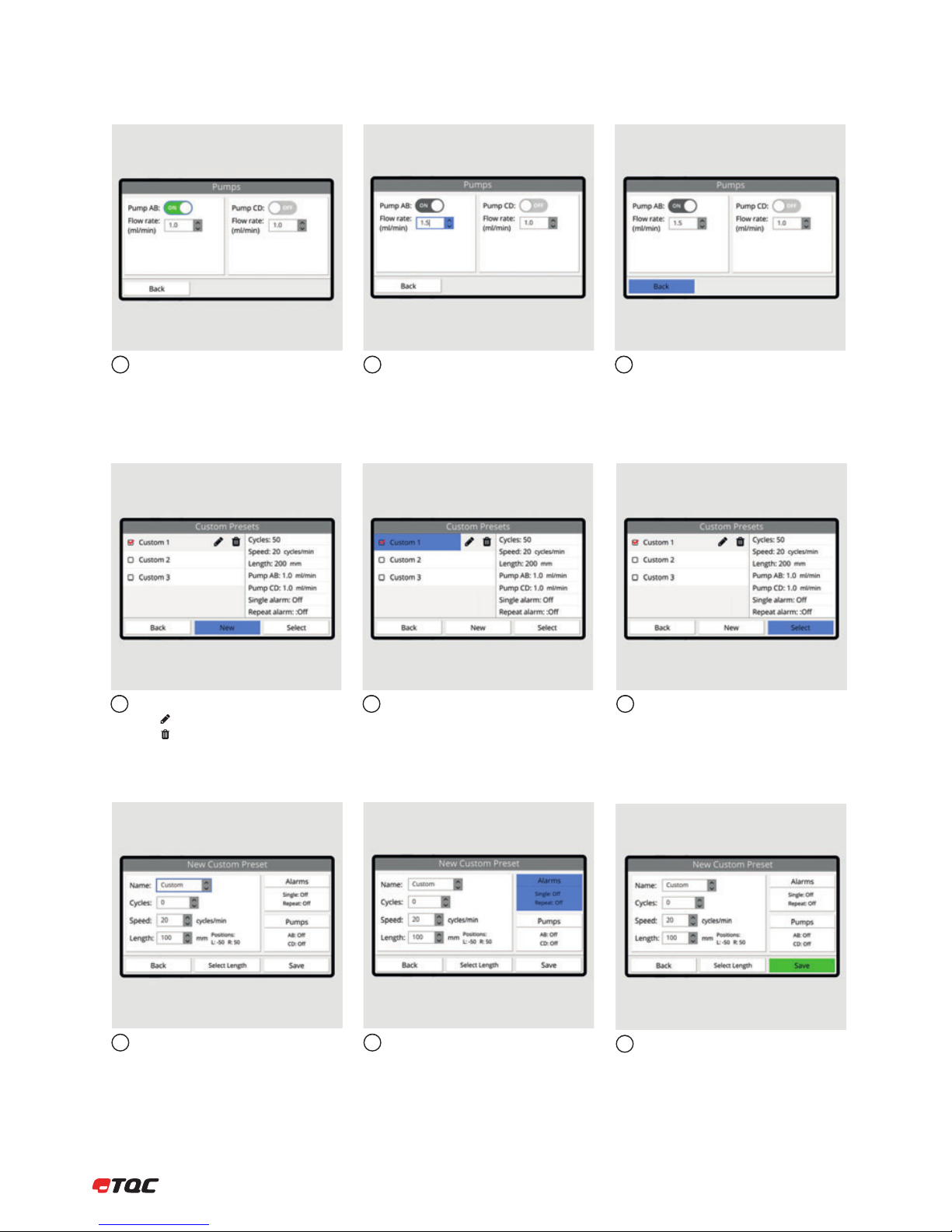

Enable or disable a pump. Set the flow rate speed. Click Back to save the pumps settings.

123

8.3.3 Pumps

Click New to create a new custom preset.

Click to edit the selected preset.

Click to delete the selected preset.

The selected preset’s settings are listed on

the right.

12 Click Select to use the selected custom

preset.

3

8.3.4 Custom Presets

Similar to Manual, set the A, B, C, and D.

A name can be given to the custom preset.

Click Alarms to configure the alarms

settings. Click Pumps to configure the

pumps settings. (AB6000 only)

12 Click Save to save the new custom preset.

The new preset will be listed in the Custom

Presets menu.

3

8.3.5 New Custom Preset

Click

Back

to save the pumps settings

3

19 |

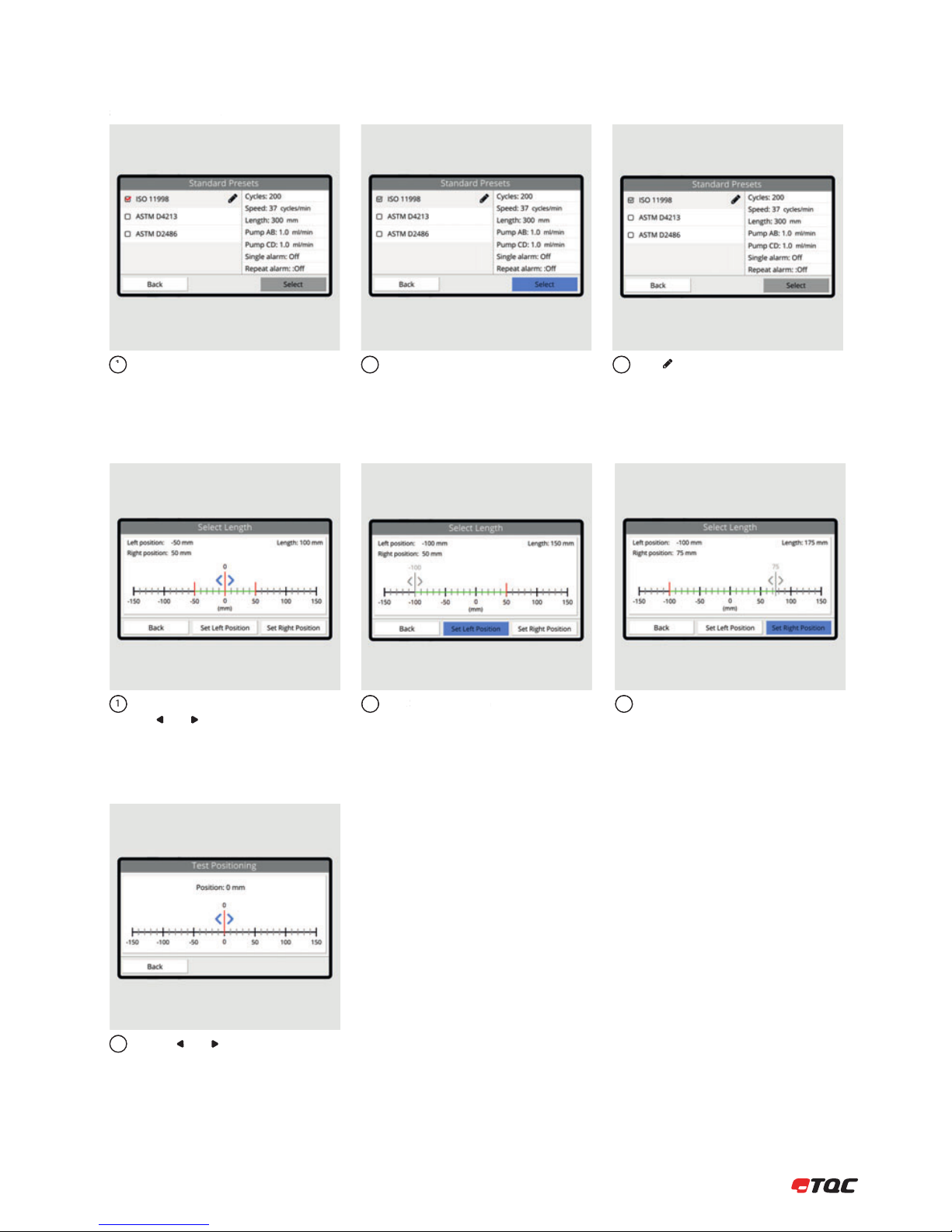

Predefined presets according several

standards.

Click Select to use the selected standard

preset.

Click to edit the number of cycles.

123

8.3.6 Standard Presets

Move the tool carrier by using

the and buttons. Make sure the Tool

Carrier can move freely.

Click Set Left Position to set the current

position as left position.

12 Click Set Right Position to set the current

position as right position.

3

8.3.7 Select Length

Move the tool carrier by using

1

Click

Set Left Position

to set the current

2

Click

Set Right Posit

ion

to set the current

3

Use the and buttons to move the

Tool Carrier. Left and Right position for

irregular test objects can be determined.

1

8.3.8 Test Positioning

Predefined presets according se eral

1

8.3.6

St

a

n

da

r

d

Preset

s

Click

Select

to use the selected standard

2

Click to edit the number of cycles

3

| 20

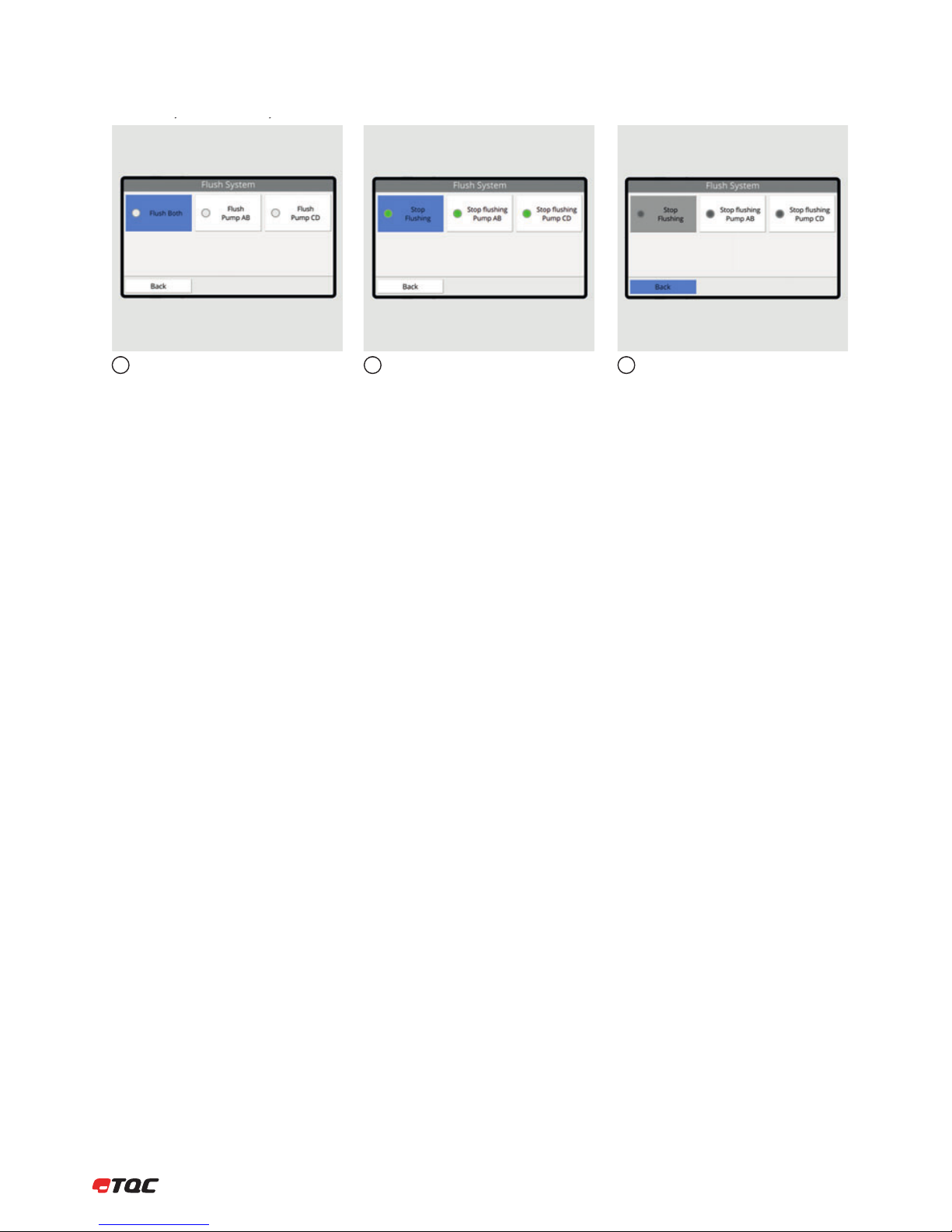

Click Flush Both to start both fluid pumps. Click Flush Pump AB or Flush Pump CD to

start one of the pumps.

12 Click Back to return to the Run Setup menu.

Active pumps will be stopped.

3

8.3.9 Flush System (AB6000 only)

yy

This manual suits for next models

1

Table of contents

Other TQC Test Equipment manuals