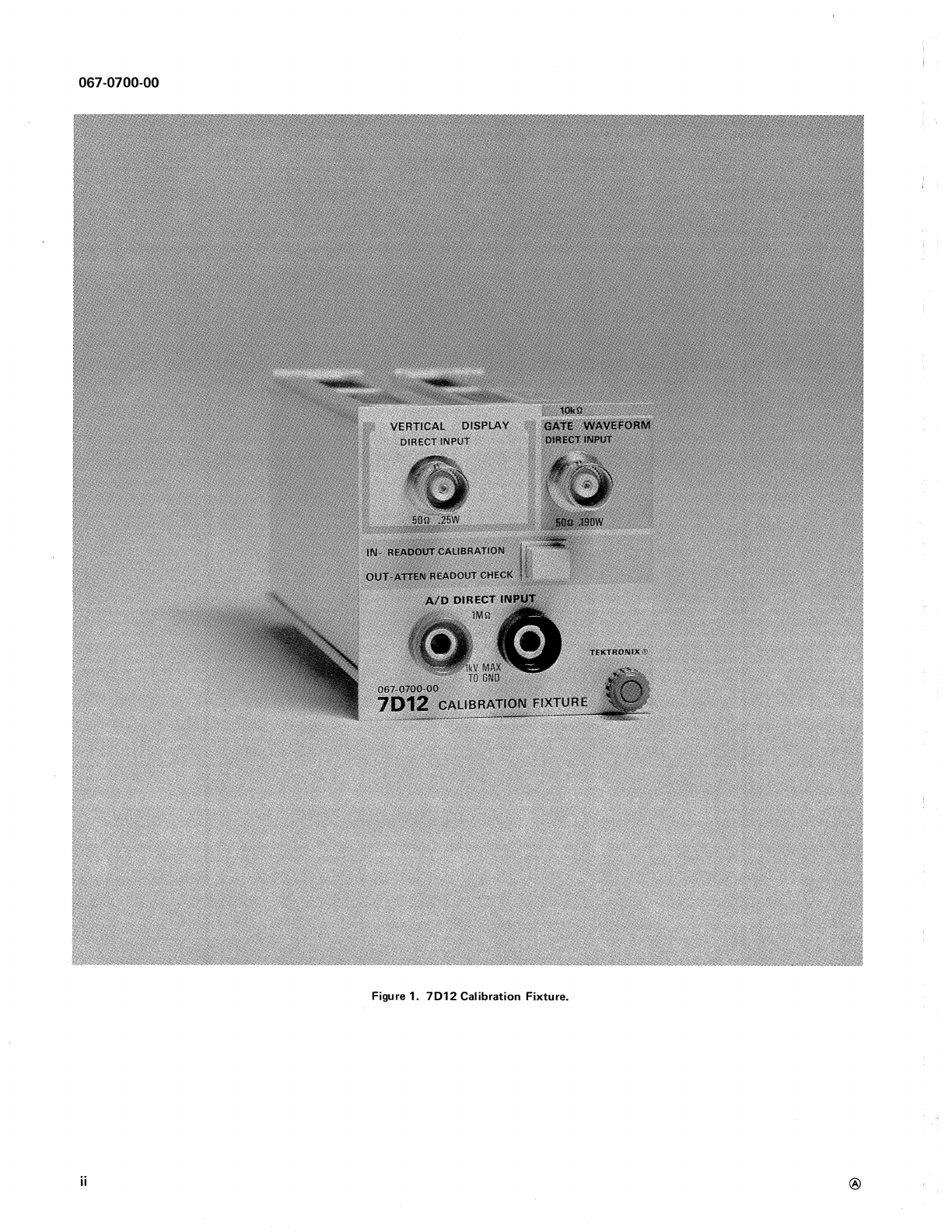

Tektronix 067-0700-00 User manual

Other Tektronix Test Equipment manuals

Tektronix

Tektronix 545 Use and care manual

Tektronix

Tektronix 2252 User manual

Tektronix

Tektronix TAS 465 User manual

Tektronix

Tektronix TDS5000B Series Use and care manual

Tektronix

Tektronix 7603 Operating instructions

Tektronix

Tektronix 3 Series User manual

Tektronix

Tektronix 2205 User manual

Tektronix

Tektronix MSO4104B User manual

Tektronix

Tektronix TDS 510A User manual

Tektronix

Tektronix 2213 Assembly instructions

Tektronix

Tektronix A6312 User manual

Tektronix

Tektronix MDO3000 Series User manual

Tektronix

Tektronix MDO4104C Installation and maintenance instructions

Tektronix

Tektronix TBS2000 Series User manual

Tektronix

Tektronix 2445 User manual

Tektronix

Tektronix TDS 310 User manual

Tektronix

Tektronix THS3024 User manual

Tektronix

Tektronix CTRL7100 Series User manual

Tektronix

Tektronix TBS2000B Series Setup guide

Tektronix

Tektronix TBS2000 Series Setup guide