3

2. Closeinlet andoutlet valves toOB 2000PT and

open bypass line to clean the system. Be sure to

close bypass line after cleaning the system.

Duringblow down, make sure that the

temperature does not rise higher than the limit of

the capillary unit, otherwise damage to capillary

may occur.

3. Loosen lock nut (16) on the temperature pilot and

turnthe adjusting screw (15) and align the needle

withthe required temperatureposition on thedial.

See Table 2-1. Note that the number on the dial

willgive anapproximate temperature valuewith

thecorrespondingtemperature range.

4. Loosen lock nut (28) on the pressure pilot and

turnadjusting screw (27)counterclockwise

removingall tensionfrom adjustingspring (24).

5. Openvalve onoutlet ofOB 2000PT and also on

controlpipe.

6. Openinlet valveto OB2000PT– SLOWLY.

7. Turnthe adjustingscrew (27) onpressure pilot

valve clockwise until the heater output is 5°F

abovethe desiredtemperature setting.If

temperature adjustment in step 3 limits this

operation,adjust temperature pilot adjusting

screwaccordingly. Make sureall valvesbetween

theOB 2000PT and equipment areopen and

equipment is calling for steam.

8. Turnadjusting screw(15) ontemperature pilot

counterclockwise,lowering to thedesired

temperature.

9. Allow system to stabilize and adjust temperature

accordingly.

10. Tightenlock nut (16)on the temperaturepilot and

lock nut (28) on pressure pilot.

11. If adjustments are made at partial load the

temperaturewill sagunder heavierloads. When

maximum load occurs increase pressure setting

enoughto maintaindesired temperature.

Note: Make sure the set pressure temperature does

not exceed the temperature limit of the capillary.

Capillarycan withstand amaximum of 68°Fabove the

ratedrange.

Example –Capillary range of 131-201°F will

withstandtemperature of 269°F.

E. Maintenance Inspection

1. TroubleshootingHints –many of the problems

thatoccur withpressure/temperature regulators

aredue to dirtholding the mainor pilot valveopen.

Additionally make sure that the thermometer

sensingthe fluid temperatureis operating

correctly.

2. Check that the bellows follower was installed.

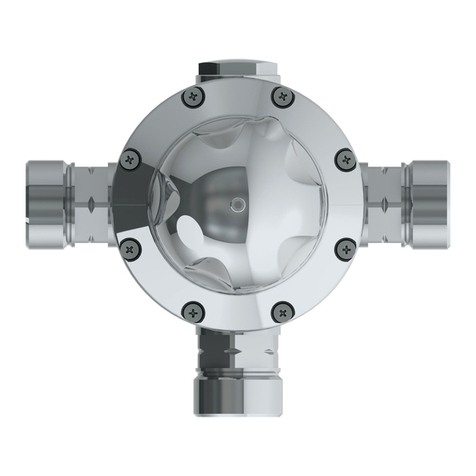

Disassembly

Before disassembly, make sure the inlet and outlet valves

to the regulator are closed and the pressure has been

relieved.

A. Disassembly of Temperature Pilot Valve

(See Figure 4-1 on Page 4)

1. Loosencapillary ringunion (22)and temperature

sensor bellows (35). Make sure not to lose

bellowsfollower(10).

2. Loosen lock nut (16) and turn adjusting screw (15)

counterclockwise (left), freeingup adjusting

spring(14).

3. Removefour hexagonalbolts (17)from the spring

housing(2) andremove adjustingspring (14).

4. Removetop bellowsplate (6) andtop seal bellows

(5).

5. Loosenthe guide(7) and remove the bottom

bellows plate (8) and the bottom bellows seal (5)

fromthe bottom halfof temperature pilot.

6. Removepilot valve andstem (3).

7. Forassembly procedure,followreverse order.

B. Disassembly of Pressure Pilot Valve

(See Figure 5-1 on Page 5)

1. Loosen the lock nut (28) and the adjusting

screw(27) counterclockwise (left)and turn

until the pressure is relieved from set point

adjustingspring (24).

2. Removefour hexhead bolts and take out

adjustingspring (24), bottom spring plate (26), top

springplate (25), andtwo pilot diaphragms (23).

3. Removepilot valveassembly (17,18, 19, 20,21)

at the center of the pilot body (2).

4. Pilotbody canbe removedfrom main valve by

disconnectingfitting (30A)and removingfour hex

bolts(38). Careshould be taken when removing

pilotfrom mainvalve. The main valve isheld bya

spring which is compressed.

C. Disassembly of Main Valve

(See Figure 5-1 on page 5)

1. Disconnect the copper tubing on the side of the

valve(See Fittings 30A, 30B, 30C).