Meunier Technologies DICE DS User manual

© Meunier Technologies Inc. 2021 - All rights reserved 1

DICETM Dosing Module

Model: DS & DM

Installation, Operation and Maintenance Manual

Date: 2022-02-04

Version: V10E

Meunier Technologies Inc.

meuniertechnologie.com

© Meunier Technologies Inc. 2021 - All rights reserved 2

Table of Contents

Safety .................................................................................................................................. 4

General............................................................................................................................ 4

Unpacking and Storage....................................................................................................... 5

Unpacking........................................................................................................................ 5

Storage and Handling...................................................................................................... 5

Technical Specifications...................................................................................................... 7

Components.................................................................................................................... 7

Technical Specifications .................................................................................................. 8

Dimensions...................................................................................................................... 8

Model Number................................................................................................................ 9

Connection reference numbers................................................................................... 9

Model Number nomenclature................................................................................... 10

Connectors................................................................................................................. 11

Parts List ........................................................................................................................ 13

Installation ........................................................................................................................ 14

Mounting....................................................................................................................... 14

Connections................................................................................................................... 16

Typical Installation ........................................................................................................ 17

Operation.......................................................................................................................... 18

Start-up.......................................................................................................................... 18

Setup and adjustment ............................................................................................... 18

Normal Operation ......................................................................................................... 24

Typical operating modes............................................................................................... 25

Injecting (normal operation) ..................................................................................... 25

Pump calibration........................................................................................................ 25

Depressurizing the DICE™module ........................................................................... 26

Pressure relief (Preventing overpressure condition) ................................................ 27

Ball Valves...................................................................................................................... 28

Lockout.......................................................................................................................... 29

DICETM module depressurizing...................................................................................... 30

Maintenance..................................................................................................................... 31

© Meunier Technologies Inc. 2021 - All rights reserved 3

Disassembly and Assembly ........................................................................................... 31

Ball valve.................................................................................................................... 31

Pressure relief and back pressure valve.................................................................... 33

Bleed Valve ................................................................................................................ 35

Pressure indicator and isolator.................................................................................. 36

Periodic Maintenance ................................................................................................... 37

Inspection .................................................................................................................. 37

Cleaning ..................................................................................................................... 37

Ball valve.................................................................................................................... 37

Pressure relief and back pressure valve.................................................................... 37

Pressure indicator and isolator.................................................................................. 37

Spare Parts .................................................................................................................... 38

Troubleshooting ............................................................................................................ 39

© Meunier Technologies Inc. 2021 - All rights reserved 4

Safety

General

Carefully read this manual before installing, starting up and servicing the DICETM dosing

module.

Warning notes must be strictly followed in order to

avoid injuries and damages.

The module is internally pressurized and can

cause injuries if not handled correctly.

The fluids* used in the dosing module or in the

cleaning process may be hazardous.

The following minimum personal protective

equipment should be used near the dosing module:

protective gloves, glasses and clothing.

Always refer to the MSDS for all safety

instructions related to the fluids* used.

Turn off electrical power, depressurize system,

release both regulating valves (back pressure valve and

pressure relief valve), and vent fluids* to a safe area

before servicing the DICETM dosing module.

Always flush all fluids* prior to module

maintenance.

Refer to technical specifications for the maximum

operating flow, pressure and operating temperature.

Modifying the DICETM module, installing non-factory parts or not following the

maintenance procedure listed in the present manual may cause injuries, affect product

performance, be hazardous and void existing limited warranties.

*Note: Fluids include: chemicals, polymer solutions, cleaning solutions, water, etc.

© Meunier Technologies Inc. 2021 - All rights reserved 5

Unpacking and Storage

Unpacking

When unpacking the product, ensure that it is defect-free and according to the purchase

order. Please notify Meunier Technologies Inc. or your supplier if there are any

irregularities.

Avoid any changes to the back pressure valve and pressure relief valve as they may be

factory set. Factory set valves are labelled with the desired pressure at each valve.

The box should contain one (1) DICETM dosing module, one (1) IOM (Installation,

Operation and Maintenance) manual and the purchased spare parts.

Storage and Handling

The DICETM dosing module ball valves should be stored in a fully closed

position. Storing the DICETM dosing module with partially open ball valves

could cause permanent damage to the ball valve seats, which could lead to ball

valve leakage.

The DICETM dosing module must be stored indoors, inside its cardboard box, at a

temperature of between 5 °C to 40 °C and with a relative humidity level under

80%.

The DICETM dosing module must be stored without any pre-set pressure on the

back pressure valve and pressure relief valve.

Excessive stacking of packages may cause damage to the product. Never stack

more than five (5) DICETM dosing modules.

© Meunier Technologies Inc. 2021 - All rights reserved 6

Do not store the DICETM dosing module in a corrosive environment or directly

exposed to sunlight.

Handle the DICETM dosing module with care. Never throw the dosing module,

even when it is in its cardboard box. The product is not designed to sustain

impact.

When transporting the DICETM dosing module, do not carry it by the ball valve

handle or the connectors.

© Meunier Technologies Inc. 2021 - All rights reserved 7

Technical Specifications

Components

DICETM DS

DICETM DM

© Meunier Technologies Inc. 2021 - All rights reserved 8

Technical Specifications

Maximum pressure (psi)

DIXX1

DIXX2

150

250

Ambient operating temperature (°C)

5 @ 40

Liquid operating temperature (°C)

5 @ 40

Storage Temperature (°C)

5 @ 40

The dosing module should not be used with fluid containing slurry or fluid which could

crystallize or which may have already crystallized.

Dimensions

DIMENSIONS mm (in)

Size

A

B

C

D

E

F

G

1/2''

DS

DIS2X

201,8 (7,94)

280,8 (11.05)

193,4 (7.61)

168,9 (6.65)

228,6 (9.00)

146,9 (5.78)

113,9 (4.48)

DM

DIM2X

218,6 (8,61)

312,5 (12.30)

193,4 (7.61)

181,6 (7.15)

260,3 (10.25)

159,6 (6.28)

145,7 (5.73)

1''

DM

DIM4X

269,0 (10.59)

376,0 (14.80)

232,7 (9.16)

223,0 (8.78)

296,0 (11.65)

194,0 (7.64)

150,0 (5.90)

© Meunier Technologies Inc. 2021 - All rights reserved 9

Model Number

The model number (as purchased) and serial number are engraved on the top of the

right side surface of the module.

Connection reference numbers

Note: The DICETM DS is only available in the 1/2'' version and the DICETM DM is

available in both the 1/2'' and the 1'' version.

© Meunier Technologies Inc. 2021 - All rights reserved 10

Model Number nomenclature

Example:

DICETM DS (Only available in 1/2''):DIS21-MVII-3333444Z

DICETM DM (Available in 1/2'' & 1''):DIM21-MVII-3333444Z4

Other standard materials:

Ball valve handle: ABS or HDPE plastic

Ball valve Seat: Virgin PTFE

Bolts, nuts, washers, set screws: 18-8 stainless steel

Note:

Vented ball valves offered as an option.

Other materials can be supplied upon request.

Options will be listed at the end of the Model Number in the option section.

#1 #2 #3 #4 #5 #6 #7 #8 #9

- - 3 3 3 3 4 4 4 Z 4 - XXX

DICE DI Configuration

DS S

DM MSize (in)

1/2 2

1 4 Pressure

150 psi 1

250 psi 2

PVC V

Connections

PMMA M Size 1/2''

PVDF D PVC V 0

CPVC C

PVDF D

O-ring Material 1/2'' FNPT 2

VITON I

EPDM E Diaph Material

VITON I 4

EPDM E

6

7

Z

Size 1''

0

1'' FNPT 2

3

CAP 4

6

Z

W

Option

Isolator & Pressure

1

M

V

I

I

Flare connector for 1/2''

OD PFA Tubing

Socket for 32mm OD

Rigid Piping

Mushroom Nut Only

CAP

1'' Socket; For SCH 80

Rigid Piping

1/2'' Socket; For SCH 80

Rigid Piping

G5/8 & Fits Grundfos

Tubing Ferrule Adaptor

3

5

Family

DI

S

Socket for 20mm OD

Rigid Piping

Isolator & Pressure

No Connector & No

Mushroom Nut

2

Block

Material

Wetted

Parts

Material

1/2'' MNPT & Fits LMI

Tubing Ferrule Adaptor

1

Mushroom Nut Only

© Meunier Technologies Inc. 2021 - All rights reserved 11

Connectors

As per numbers in Model Number Nomenclature

Mushroom Nut Only

Connector code: 0

1/2'' MNPT & Fits LMI Tubing

Ferrule Adaptor

*LMI Ferrule Kit included;

Refer to LMI tubing connection system information sheet

Connector code: 1

FNPT

Connector code: 2

Socket for SCH 80 Rigid Piping

Connector code: 3

© Meunier Technologies Inc. 2021 - All rights reserved 12

CAP

Connector code: 4

G5/8 & Fits Grundfos Tubing

Ferrule Adaptor

*Grundfos Ferrule Kit not included; sold separately

Connector code: 5

Socket for Metric Rigid Piping

Connector code: 6

Flare connector for PFA Tubing

*Connection nut not included; sold separately

Connector code: 7

Isolator & Pressure Gauge

Connector code: Z

No Connector &

No Mushroom Nut

Connector code: W

© Meunier Technologies Inc. 2021 - All rights reserved 13

Parts List

PART

NO.

DESCRIPTION

1

MONO BLOCK

2

CARRIER

3

STEM

4

BALL

5

STEM NUT

6

SEAT

7

O-RING –CARRIER

8

O-RING –SEAT

9

O-RING –STEM

10

O-RING –STEM NUT

11

VALVE HANDLE

12

HANDLE SET SCREW

13

BP/PR TOP BODY

14

SPRING BOTTOM SEAT

15

SPRING TOP SEAT

16

DIAPHRAGM

17

SPRING

18

SOCKET HEAD SCREW

19

ADJUSTMENT SCREW

20

HEX NUT

21

PR/BP WASHER

22

SLEEVE CONE ADAPTER

23

O-RING –SLEEVE CONE ADAPTER

24

ISOLATOR AND PRESSURE GAUGE

25

MUSHROOM NUT

26

CONNECTOR SOCKET

27

CONNECTOR NPT

28

CONNECTOR HOSE

29

CAP

30

O-RING - CONNECTOR

31

MOUNTING WASHER

32

BLEED VALVE

33

O-RING -BLEED VALVE

Refer to the figures in the Installation and Disassembly and Assembly sections for PART

NO.

Note: 25, 26 and 27 are exemplary connectors. All the connector configurations can be found in

the Model Number nomenclature of the IOM (Installation, Operation and Maintenance Manual).

© Meunier Technologies Inc. 2021 - All rights reserved 14

Installation

Warning! Always use the proper tool for each step of the installation.

Mounting

The DICETM dosing module is designed to be mounted on a planar surface using the

three (3) mounting holes. The DICETM should always be mounted so that the injection

port is facing upwards as shown in the following figure. To avoid accumulation and

trapped air, the DICETM should always be levelled.

© Meunier Technologies Inc. 2021 - All rights reserved 15

To avoid mechanical stress on the DICETM body, put the three (3) washers (31) provided

between each of the mounting holes (rear face) and the mounting surface. It is

important to make sure that no corner is touching the mounting surface. Only the

washers should touch the mounting surface. See the following figure for this type of

mounting. Mounting holes can accommodate both M6 and ¼ size socket head screws.

Each screw should be torqued to 35 in-lb.

When installing the DICETM dosing module, remember to factor in sufficient space for

module maintenance.

© Meunier Technologies Inc. 2021 - All rights reserved 16

Connections

In order to suit all application needs, a variety of connections are

available. All connections (NPT, Socket, Hose, etc.) are assembled on

the block using the mushroom nut (25). This type of assembly allows

for simple disassembly of connections, thereby avoiding the need to

cut any pipe when doing maintenance.

In order to assemble the pipe with the chosen connection type, slide the mushroom nut

(25) onto the connector (26/27/28). Insert the pipe or flexible hose into the connector

according to state-of-the-art rules so that the two parts are securely fastened to each

other.

The pipes and tubing should be perfectly aligned with the dosing module connections to

prevent mechanical stress. Excessive stress can cause part failure.

Once the assembly is completed, fasten it to the desired port on the block. When

tightening the mushroom nut (25), verify that the o-ring (30) is well positioned in the

connector groove (26/27/28). The mushroom nut (25) should be hand tightened only;

no tools should be used for this. Ensure that the o-ring is properly squeezed.

Connectors: Socket (26), NPT (27), Hose (28), Cap (29)

If an accessory is connected to the accessory port (ex: pulsation damper), it must be

equipped with its own support. The dosing module is not designed to support the

accessory weight.

Note: 25, 26 and 27 are exemplary connectors. All the connector configurations can be

found in the Model Number nomenclature of the IOM (Installation, Operation and

Maintenance Manual).

© Meunier Technologies Inc. 2021 - All rights reserved 17

Typical Installation

The following figures can be used as a typical installation of the DICETM dosing module in

a dosing system.

Note: Never use a pipe wrench for dosing module installation.

© Meunier Technologies Inc. 2021 - All rights reserved 18

Operation

Start-up

Prior to system start-up, the responsible individuals should be informed of the safety

instructions to be followed. This manual should be available at all times.

Setup and adjustment

The pressure relief and back pressure valve needs to be adjusted prior to system

operation.

Note: If requested upon purchase, the back pressure and pressure relief valve can be

factory preset. If so, no adjustment is required prior to system operation.

© Meunier Technologies Inc. 2021 - All rights reserved 19

Pump priming assistance

In order to assist and optimise initial pump

priming, a bleed valve (32) has been integrated

on the left side of the DICE Module. The valve

allows evacuating potential trapped gas between

the pump outlet and the back pressure valve that

could be preventing the pump from priming.

In order to assist pump priming, slightly open the

bleed valve (32) by unscrewing it while the pump

is cycling until fluid starts passing through. Only

partial unscrewing is required. The Bleed valve

does not need to be (and should not be) fully

unscrewed to assist pump priming.

Then simply close the bleed valve and carry on with either the DICETM set-up and

adjustment or the system normal operation.

Note: The bleed valve can also assist with pump priming if the pump loses prime during

normal operation.

© Meunier Technologies Inc. 2021 - All rights reserved 20

Pressure relief valve adjustment

In order to adjust the set point of the Pressure Relief valve, the module’s three ball

valves must be in the closed position.

Start by screwing completely the back pressure adjustment screw (19').

Start the pump and wait until fluid passes through the pressure relief valve into the

evacuation port. Use the adjustment screw (19) to obtain the desired pressure set point.

Once the desired set-pressure is obtained, tighten the counter nut (20), stop the pump

and slowly open the evacuation valve to release the system pressure.

Proceed with the back pressure valve adjustment.

Notes:

The maximum torque to be applied on the adjustment screw (19 & 19') and

counter nut (20 & 20') is 35 in-lb.

Turning the screw clockwise increases the set pressure.

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Nice

Nice MC424L instructions

Honeywell

Honeywell VR4611VA1007 instruction sheet

Telit Wireless Solutions

Telit Wireless Solutions LE51-868S DemoUnit user guide

Velleman-Kit

Velleman-Kit K8030 quick start guide

Comeval

Comeval UNIFLOW DP Series Installation, operating and maintenance manual

AES Corporation

AES Corporation IntelliPro Fire 7794A installation manual

Murphy

Murphy Autostart AS705S Communications guide

Hypro

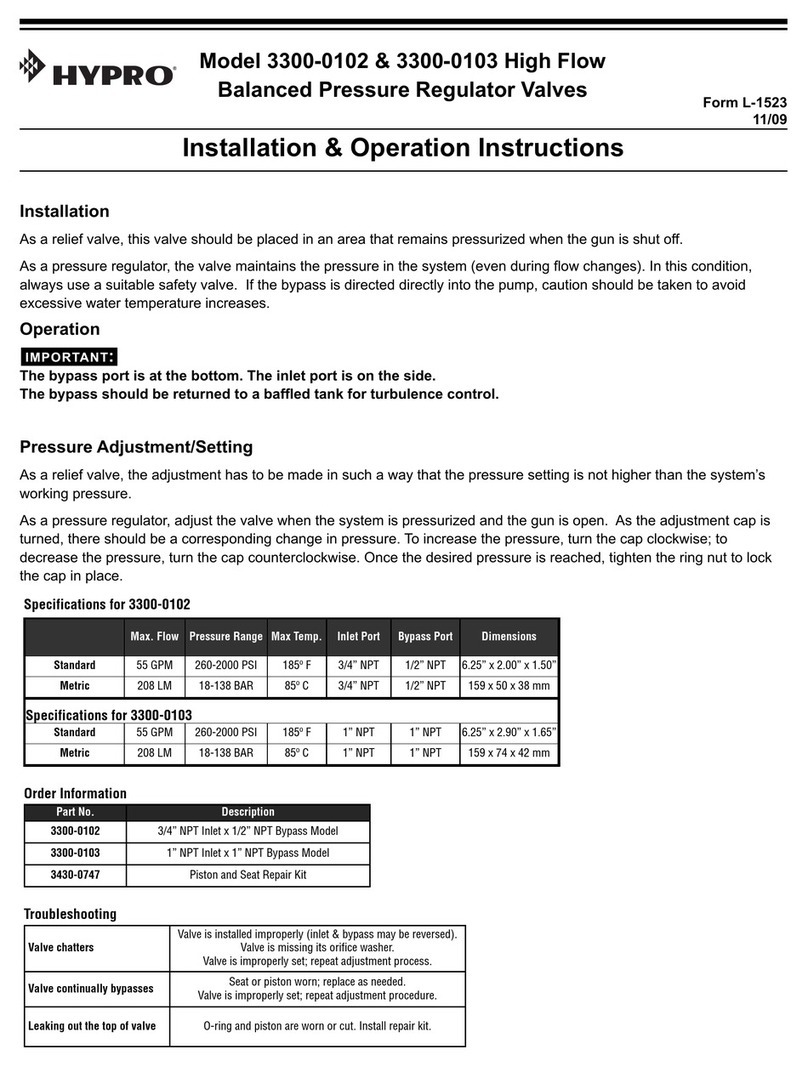

Hypro 3300-0102 Installation & operation instructions

STOLLMAN

STOLLMAN BlueMod+C11/G2 Hardware reference

Allen-Bradley

Allen-Bradley DF1 Installation and programming manual

A1 Security Cameras

A1 Security Cameras LINQ2 Installation and programming manual

Plugwise

Plugwise TOM quick start