Meynell V8/3 User manual

1

V8/3

THERMOSTATIC

MIXING VALVE

PRODUCT MANUAL

IMPORTANT

Installer: This Manual is the property of the customer

and must be retained with the product for

maintenance and operational purposes.

2

CONTENTS

Safety : Warnings ....................................................................................3

Advice.......................................................................................................3

Description...............................................................................................4

Pack Contents ......................................................................................... 5

Dimensions ..............................................................................................7

Specications ..........................................................................................8

Installation Requirements .................................................................... 10

Installation .............................................................................................12

General............................................................................................... 12

Reverse Outlet Connector .................................................................13

1. Exposed Models ............................................................................14

2. Built-in Models................................................................................15

Commissioning .....................................................................................17

Exercising the Thermostat..................................................................17

Commissioning Checks......................................................................17

Maximum Temperature.......................................................................18

Maximum Temperature Setting ..........................................................18

Operation ...............................................................................................19

Fault Diagnosis......................................................................................20

Maintenance...........................................................................................21

General............................................................................................... 21

Planned Maintenance............................................................................22

Healthcare..........................................................................................22

Frequency of In-service Tests ...........................................................22

Checkvalves and Filters .....................................................................23

Type 2 and Type 3 Valves...................................................................... 25

Application..........................................................................................25

Installation Conditions ........................................................................ 26

Commissioning...................................................................................26

Maintenance.......................................................................................27

Spare Parts ............................................................................................ 28

Notes ......................................................................................................30

Customer Care.........................................................................Back Page

3

The function of a thermostatic mixing valve is to deliver water consistently at a safe

temperature. This requires that:

1. It is installed, commissioned, operated and maintained in accordance with the

recommendations given in this manual.

2. Type 2 and 3 valves are only used for applications covered by their approved

designations.

3. Periodic attention is given, as necessary, to maintain the product in good functional

order. Recommended guidelines are given in section: ‘Maintenance’.

4. Continueduseofthisproductinconditionsoutsidethespecicationlimitsgiven

in this Manual can present potential risk to users.

SAFETY : WARNINGS

ADVICE

The use of the word ‘failsafe’ to describe the function of a thermostatic mixing valve

is both incorrect and misleading. In keeping with every other mechanism it cannot

be considered as being functionally infallible.

Provided that the thermostatic mixing valve is installed, commissioned, operated

withinthespecicationlimitsandmaintainedaccordingtothisManual,theriskof

malfunction, if not eliminated, is considerably reduced.

Malfunction of thermostatic mixing valves is almost always progressive in nature

and will be detected by the use of proper temperature checking and maintenance

routines.

Certain types of system can result in the thermostatic mixing valve having excessive

‘dead-legs’ of pipework. Others allow an auxiliary cold water supply to be added

to the mixed water from the mixing valve. Such systems can disguise the onset of

thermostatic mixing valve malfunction.

Ultimately, the user or attendant must exercise due diligence to ensure that the

delivery of warm water is at a stable, safe temperature. This is particularly important

in such healthcare procedures as supervised bathing of patients unable to respond

immediately to unsafe temperatures.

IfyouexperienceanydifcultywiththeinstallationoroperationofyournewMixing

Valve, then please refer to “Fault Diagnosis”, before contacting Kohler Mira Ltd.

Our telephone and fax numbers can be found on the back cover of this guide.

4

INTRODUCTION

The Meynell V8/3 is a Thermostatic Mixing Valve specied to meet the highest

standards of safety, and reliability as demanded by today’s users. All Meynell products

are designed, manufactured and supported in accordance with accredited BS EN

ISO 9001: 2000 Quality Systems.

This Manual covers all Meynell V8/3 Thermostatic Mixing Valves manufactured from

June 1997.

Thesufx‘3’indicatesthatthismixerhasbeencertiedforuseinUKHealthcare

premises as a Type 3 valve under the BUILDCERT TMV3 scheme. For Healthcare

installation refer to section: ‘Type 2 and Type 3 Valves’. In this case this product

hasalsobeencertiedasaType2valveundertheBUILDCERTTMV2scheme.This

productalsocomplieswiththeWaterSupply(waterttings)Regulations1999.

A point of use Thermostatic Mixing Valve designed to supply temperature controlled

hot water to both single and multi-point installations.

Meynell V8/3:

Exposedorbuilt-inmodelwithstublever,allchromenish,swivelelbowsexcept

rising, falling or rear entry supplies. 15 mm compression inlet, 1/2” BSP or 15 mm

outlet connections.

Meynell V8/3 L:

Exposedorbuilt-inmodelwithlongleverfordisableduse,allchromenish,15mm

compression inlet, 1/2” BSP or 15 mm outlet connections.

Meynell V8/3 K:

Exposedmodelwithlocked(non-adjustable)controlknob,allchromenish,15mm

compression inlet, 1/2” BSP or 15 mm compression outlet connections.

DESCRIPTION

5

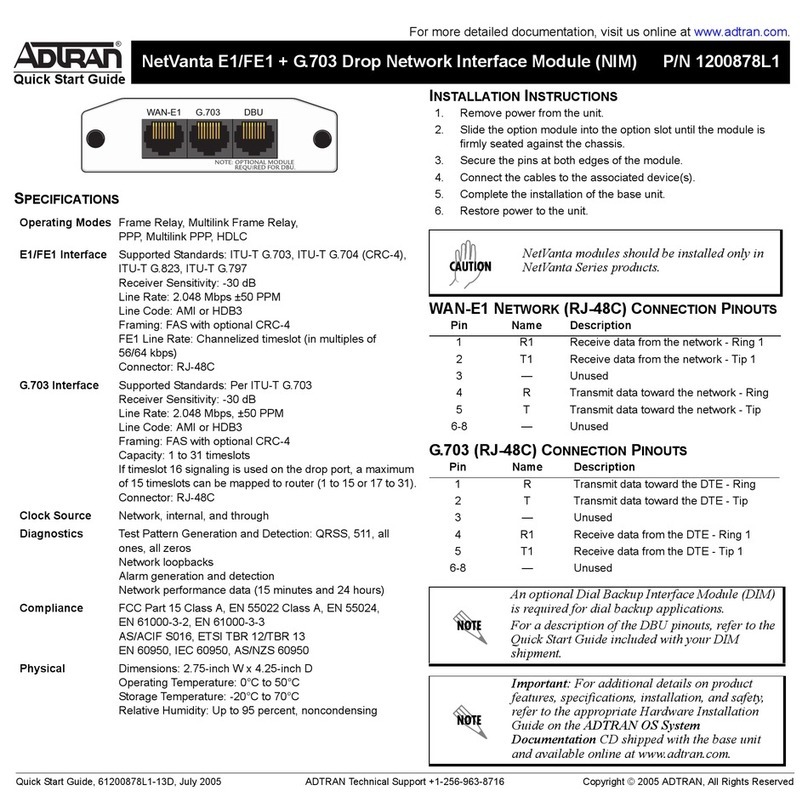

PACK CONTENTS

Exposed Models

Tick the appropriate boxes to familiarize yourself with the part names and to

conrmthatthepartsareincluded.

Documentation

1 x NHS Requirements Booklet

1 x V8/3

1 x V8/3 L

1 x V8/3 K

1 x Hexagonal Key

3 x Fixing Screws

1 x Olive

1 x Compression Nut

Or

Or

6

Built-in Models

1 x Hexagonal Key

3 x Fixing Screws

Documentation

1 x NHS Requirements Booklet

1 x V8/3 B

1 x V8/3 BL

1 x Foam Seal

1 x Rubber Grommet

1 x Concealing Plate

7

DIMENSIONS

Exposed Model

Built-in Model

160 mm

130 mm Centres

122.5 mm

65 mm

35 mm

161 mm

124 mm

55 mm MAX

35 mm MIN

122.5 mm

35 mm

8

Normal Operating Conditions are considered as:

inlet maintained pressures are nominally balanced

daily usage 1-6 hours

installation and usage environment not subject to extremes of temperature,

unauthorised tampering or wilful abuse.

Operating Parameters

ForType2and3valvesthesupplyconditionsspeciedinsection:‘Type 2 and

Type 3 Valves, Application’ take precedence over the operating parameters which

follow.

Pressures And Flow Rates

For optimum performance, maintained supply pressures should be nominally

equal.

Maximum Pressure Loss Ratio: 10:1

Minimum Maintained Pressure: 0.1 bar (= 1 metre head from underside of cold tank

tooutletofshowertting)

Maximum Static Pressure: 10 bar

•

•

•

SPECIFICATIONS

0.1 0.2 0.3 0.4 0.5 1.0 2.0

0

5

10

15

20

25

30

35

40

45

PressureLoss(bar)

FlowRate(L/Min)

Thermostatic Mixing Valve

9

Temperature Control

Minimum temperature differential between hot and outlet temperature: 10°C

Optimum temperature control range: 35 - 45°C

Maximum hot water temperature: 85°C (for safety, a recommended hot water storage

temperature maintained below 85°C and for ablutionary installations at between

60 to 65°C).

The performance specification outlined below is achieved with outlet blend

temperature set between 35 - 45°C and supplies of 15°C cold and 65°C hot with

nominally equal pressures.

Outlet blend temperature is maintained within 2°C with a 10°C change in hot

or cold supply.

Thermostatic shut down to seepage within 2 seconds if cold supply fails. This is

achieved only if the hot supply temperature is 10°C above the set outlet blend

temperature.

Connections

Inlet connectors are 15 mm compression

Outlet connector is 1/2” BSP Male or 15 mm compression

Hot(H)andCold(C)inletsareclearlymarkedandmustbeconnectedthisway.

•

•

10

INSTALLATION REQUIREMENTS

Isolating Valve

Mixing Valve

OverowIndicator

Pressure Reducing Valve

Float Valve Twin Impeller Pump

Single Impeller Pump

Tempering Valve

Mini Expansion Vessel

Key to Symbols

The Meynell V8/3 Thermostatic Mixing Valve is compatible with the following

systems:

Gravity fed system

The Mixing Valve MUST be fed from a

cold water cistern and hot water cylinder

providing nominally equal pressure.

Gas heated system

The Mixing Valve MUST be installed with

a gas water heater or combination boiler

of a fully modulating design.

11

Unvented mains pressure system

The Mixing Valve can be installed with a

unvented, stored hot water cylinder.

Mains pressurised instantaneous hot

water system (thermal store)

The Mixing Valve can be installed with

systems of this type with balanced

pressures.

Pumped system

The Mixing Valve can be installed with an

inletpump(twinimpeller).Thepumpmust

be installed on the oor next to the hot

water cylinder.

Air Separation

30°-60°

90°

12

INSTALLATION

General

Installation must be carried out in accordance with these instructions, and must be

conductedbydesignated,qualiedandcompetentpersonnel.

1. Before commencing, make sure that the installation conditions comply with the

information given in section: ‘Specications’. For Type 2 and 3 valves see also

Installation conditions in section: ‘Type 2 and Type 3 Valves’.

2. Care must be taken during installation to prevent any risk of injury or

damage.

3. The mixing valve should be positioned for easy access during use and

maintenance. All routine maintenance procedures can be conducted with the

mixingvalvebodyinplace(exceptforstrainerandcheckvalveaccess).Forall

models, allow a minimum 80 mm clearance in front of the temperature control

to enable removal of the serviceable parts during maintenance. Conveniently

situated isolating valves must be provided for maintenance.

4. The use of supply-line or zone strainers will reduce the need to remove debris at

each mixing valve point. The recommended maximum mesh aperture dimension

for such strainers is 0.5 mm. Inlet pressure tappings which allow measurement

of inlet pressure to the mixing valve under operating conditions are particularly

recommended for healthcare with Type 2 and 3 valves.

5. Pipework must be rigidly supported.

6. Pipework dead-legs should be kept to a minimum. The mixed water outlet piping

should not exceed 2 m and the overall length from the hot water circuit to the

discharge point should not exceed 5 m.

7. Supply pipework layout should be arranged to minimise the effect of other outlet

usage upon the dynamic pressures at the mixing valve inlets.

8. Inlet and outlet threaded joint connections should be made with PTFE tape or

liquid sealant. Do not use oil-based, non-setting jointing compounds.

9. Toeliminatepipedebrisitisessentialthatsupplypipesarethoroughlyushed

through before connection to the mixing valve.

13

25 mm

Spill Over

Level

Hose Retaining Ring

10. Decide on a suitable position for the

Mixing Valve. The position of the

Mixing Valve and the Shower Fittings

must provide a minimum gap of

25 mm between the spill-over level of

the shower tray/bath and the handset.

This is to prevent back-siphonage. For

further information on the installation

of your shower ttings, refer to the

Fittings Installation and User Guide.

Note! Only use shower fittings

recommended by the manufacturer

or supplier.

Reverse Outlet Connector

IftheShowerOutletneedstobereversed(e.g.bottomoutlettotopoutlet):

1. RemovetheBlankingCap(iftted).

2. Using a 1/2” hexagonal key remove the Sealing Plug from the top and the Outlet

Connector from the bottom of the Thermostatic Mixing Valve.

3. Swaparoundandret,ifchangingfromatconnectortocompressionmake

sure that the ‘O’ Seal is changed around.

4. Retinreverseorder.

Coned End

Coned End

Flat End

Blanking Cap

Sealing Plug

‘O’ Seal

Outlet

Connector

Olive

Compression

Nut

‘O’ Seal

‘O’ Seal

14

1. Exposed Models

1.1 Decide on a suitable position for the

Thermostatic Mixing Valve where all

users can operate it.

1.2 Remove the Wall Bracket from the rear

of the Mixer Valve Body by loosening

the Wall Bracket Grubscrew with a

2.5mmhexagonalkey(supplied).

1.3 Use the Wall Bracket to mark 3 hole

positions. Drill wall and insert suitable

Wall Plugs (not supplied) for No.10

FixingScrews(supplied).

1.4 The Thermostatic Mixing Valve is

supplied for rising supplies.

For Falling or Rear Entry supplies

loosen the Elbow Grubscrew and

rotate the Elbow to the required

position. Then secure with the

Grubscrew.

1.5 Fit the supply pipework (Hot - Left,

Cold-Right).

Caution! It is essential at this point

that the supply pipework is thoroughly

ushed through before connection

to the Thermostatic Mixing Valve.

Failure to do so may result in product

malfunction.

1.6 Locate the Thermostatic Mixing Valve

onto the pipework and secure to the

Wall Bracket with the Grubscrew.

1.7 Tighten the Compression Nuts and

Olives using a suitable spanner.

1.8 Install the Shower Fittings, refer to

your Shower Fittings Installation and

User Guide.

1.9 Turn on the hot and cold water

supplies and check for leaks.

Hexagonal Key

Elbow

Inlet Pipework

Fixing Screws

Wall Bracket

Wall Plugs

(notsupplied)

Inlet Pipework

(rearsupplies)

35 mm

35 mm

15

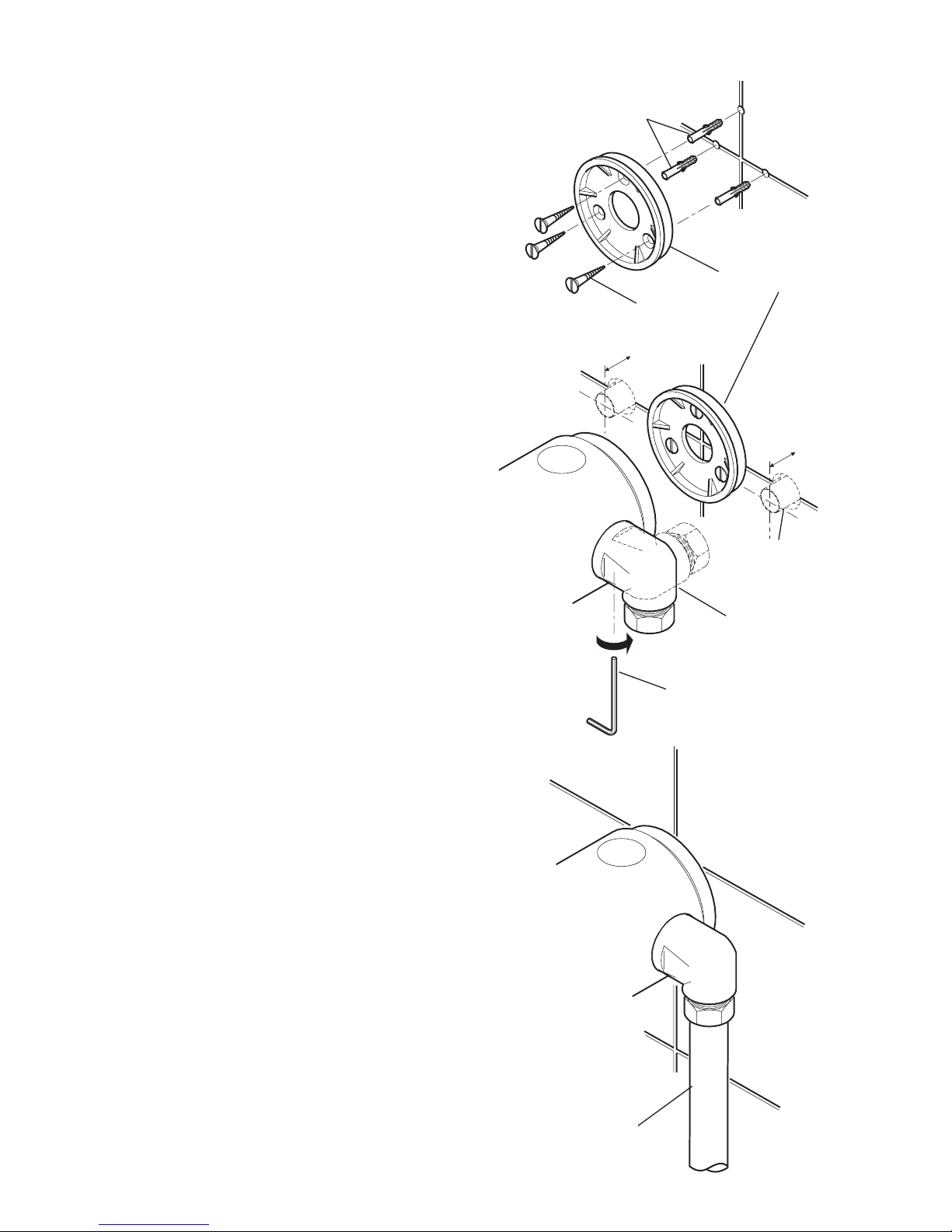

2. Built-in Models

2.1 Decide on a suitable position for the

Thermostatic Mixing Valve where all

users can operate it.

2.2 Determine the routes of the incoming

hot and cold supply pipework. They

can be rising or falling supplies.

2.3 Determine the route for the outlet

pipework. When connecting the

Shower Fittings to the outlet they

should be to the side and above the

Thermostatic Mixing Valve to make

sure that the Flexible Hose hangs

correctly and does not obstruct the

Shower Control. The outlet can be

sited on the right or on the left, as site

dictates.

2.4 Mark suitable routes for inlet and

outlet pipework.

2.5 Cut away plasterboard and brick

work to a depth of between 60 mm

to 80 mm. Depth should be 67 mm

min/87mmmaxincludingnishwall

thickness(tilesorfaciaboard).

2.6 Fit the supply pipework

(Hot-Left,Cold-Right).

Caution! It is essential at this point

that the supply pipework is thoroughly

ushed through before connection

to the Thermostatic Mixing Valve.

Failure to do so may result in product

malfunction.

2.7 Fix the Thermostatic Mixing Valve

to the wall or timber noggin (refer to

section: ‘1. Exposed Models’ and

followinstructions1.2and1.3).

2.8 Make the connections to the inlets

and outlet of the Thermostatic Mixing

Valve as shown

2.9 Tighten the Compression Nuts and

Olives using a suitable spanner.

2.10Turn on the hot and cold water

supplies and check for leaks.

ColdHot

Outlet

Shower

Outlet

Alternative

Routes

16

2.11Plaster and tile up to the Thermostatic

Mixing Valve, leaving a maximum

diameter hole around the Mixing Valve

of 125 mm.

2.12Fit the Sealing Grommet to the inner

diameter of the Concealing Plate.

Remove the protective backing from

onesideoftheFoamWasherandx

to rear of the Concealing Plate.

2.13Unscrew the Control Knob Grubscrew

and remove the Control Knob.

2.14Check that the Concealing Plate will

cover the installation hole.

2.15Peel the second protective backing

from the Foam Washer and t over

the Thermostatic Mixing Valve.

Push evenly on the Concealing

Plate to make sure that the adhesive

backingprovidesasufcientseal.

2.16RetandsecuretheControlKnob.

Sealing Grommet

Concealing

Plate

Foam Seal

Control Knob

Concealing Plate

(apply pressure

evenly)

17

COMMISSIONING

Commissioning must be carried out in accordance with these instructions, and must

beconductedbydesignated,qualiedandcompetentpersonnel.

Exercising the Thermostat

Thermostatic Mixing Valves are inclined to lose their responsiveness if not used.

Valves which have been in storage, installed but not commissioned, or simply not

used for some time should be exercised before setting the maximum temperature

or carrying out any tests.

A simple way to provide this exercise is:

(a) makesurethatthehotandcoldwaterareavailableatthevalveinlets,

and the outlet is open.

(b) movethetemperaturecontrolrapidlyfromcoldtohotandhotbackto

cold several times, pausing at each extreme.

Commissioning Checks

(Temperatures should always be recorded using a thermometer with proven

accuracy)

1. Check the inlet pipework temperature for correct function of the checkvalves.

2. Operate the Meynell V8/3 and check:

Flowrateissufcientforpurpose

Temperature obtainable is acceptable

All connections are watertight.

3. It is advisable to establish a performance check at this time, which should

be noted for future reference as part of a Planned Maintenance Program (a

MaintenanceRecordCardhasbeenprovidedwiththisManual).

The procedure should be chosen to imitate both typical and difcult operating

conditions,suchasanysupplypressureuctuationsthatmaybelikely.Anideal

method is to locate another outlet on the common cold water supply close to the

Thermostatic Mixing Valve (operating this outlet should cause a drop in supply

pressure),andnotethesubsequenteffectonblendtemperature.Thisshouldbeno

morethan2°Cchange).

Note! Causing thermal shutdown of the Meynell V8/3 by full closure of the cold

supply may not adequately indicate the practical capability of the Meynell V8/3, nor

its service condition. Consequently this is not a recommended performance check,

and repeated such testing may ultimately affect service life.

•

•

•

18

1. Turn on the Thermostatic Mixing Valve

to its maximum setting, (for Lockshield

models turn on the separate outlet

device tted eg. stopvalve). Let the

temperature stabilise.

2. Unscrew the Control Knob Grubscrew

and remove the Control Knob or

Lockshield.

3. Insert the 2.5 mm hexagon key into

the centre of Mixing Valve Head.

4. Turn the hexagon key anticlockwise

to increase the temperature, or

clockwise to decrease temperature.

5. Refit and secure the Control

Knob or Lockshield and turn off

the Thermostatic Mixing Valve (on

lockshield models turn off the outlet

device).

Note! The Control Knob should be

ttedwiththe‘brand’horizontal.

Note! For Lockshield models make

sure that the anti-rotation slots

are engaged on the Lug on the

Mixing Valve Body (refer to arrow on

illustration).

Maximum Temperature

The maximum blend temperature obtainable by the user should be limited, to prevent

accidental selection of a temperature that is too hot.

The Meynell V8/3 is fully performance tested, and the maximum temperature is preset

to approximately 42°C under ideal installation conditions at the factory.

Site conditions and personal preference may dictate that the maximum temperature

has to be reset following installation.

Maximum Temperature Setting

Make sure that an adequate supply of hot water is available at the hot inlet of the

Meynell V8/3 and that both inlet isolating valves are fully open.

The minimum temperature of the hot water must be at least 10°C above the desired

blend, however during resetting this should be close to the typical storage maximum

tooffsetthepossibilityofanyblendshiftduetouctuatingsupplytemperatures.

Cooler

Warmer

Lockshield Model

19

Temperature selection (not lockshield model).

The mixer has one control to set temperature and works in a sequence:

Off→Cold→Tepid→Pre-setMaximum

OPERATION

Preset Maximum

Temperature

Off

20

FAULT DIAGNOSIS

Symptom Cause/Rectication

1. Only hot or cold

water from mixer

outlet.

a. Inletsuppliesreversed(hotsupplytocoldsupply).

b. No hot water reaching mixer.

c. Checkstrainersandinlet/outletttingsforblockage.

d. Installation conditions continuously outside operating

parameters, refer to section: ‘Specications’ and 2.e

below.

2. Fluctuating or

r e d u c e d f l o w

rate.

Normal function of the thermostatic control when operating

conditions are unsatisfactory.

a. Checkstrainersandinlet/outletttingsforblockage.

b. Makesureminimumowrateissufcientforsupply

conditions.

c. Make sure the maintained inlet pressures are

nominallybalancedandsufcient.

d. Make sure the inlet temperatures differentials are

sufcient.

e. (Subsequent to rectication of supply conditions)

Check thermostatic performance; renew Piston

Assembly if necessary.

3. Noowratefrom

mixer outlet.

a. Checkstrainersandinlet/outletttingsforblockage.

b. Hot or cold supply failure.

4. Blend temperature

drift.

Indicates operating conditions changed.

a. Refer to symptom 2. above.

b. Hotsupplytemperatureuctuation.

c. Supplypressuresuctuating.

d. Seal damage or wear. Renew seals.

5. Maximum blend

temperature

setting too hot or

too cold.

a. Indicates incorrect maximum temperature setting;

refer to section: ‘Commissioning’.

b. As symptom 4. above.

6. Water leaking

from mixer body.

Seal wear or damage.

a. Obtain Seal Kit, renew all seals.

7. Flow rate too high

or too low.

a. (Toolow)Refertosymptom2.a-e. above.

b. (Toolow)Insufcientsupplypressures.

c. (Toohigh)Supplypressuretoohigh.

d. (Toohigh)Refertosymptom2.a-e. above.

Table of contents

Popular Control Unit manuals by other brands

IMI Hydronic

IMI Hydronic IMI TA TA-MIX quick start guide

Rohde & Schwarz

Rohde & Schwarz R&S OSP-B157W8 user manual

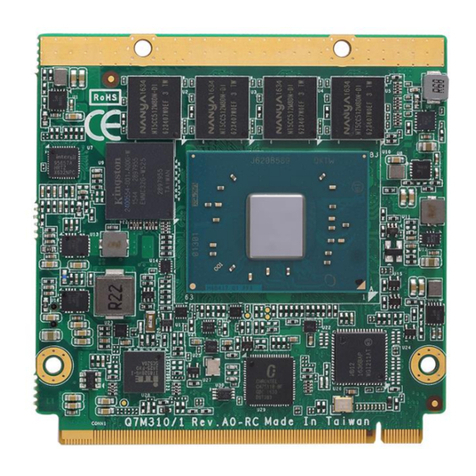

AXIOMTEK

AXIOMTEK Q7M310 user manual

Pentair

Pentair F251 Installation & maintenance instructions

Edwards

Edwards SCU-800 instruction manual

Texas Instruments

Texas Instruments DAC7731 user guide