MFJ-1795W Vertical Antenna Instruction Manual

INTRODUCTION

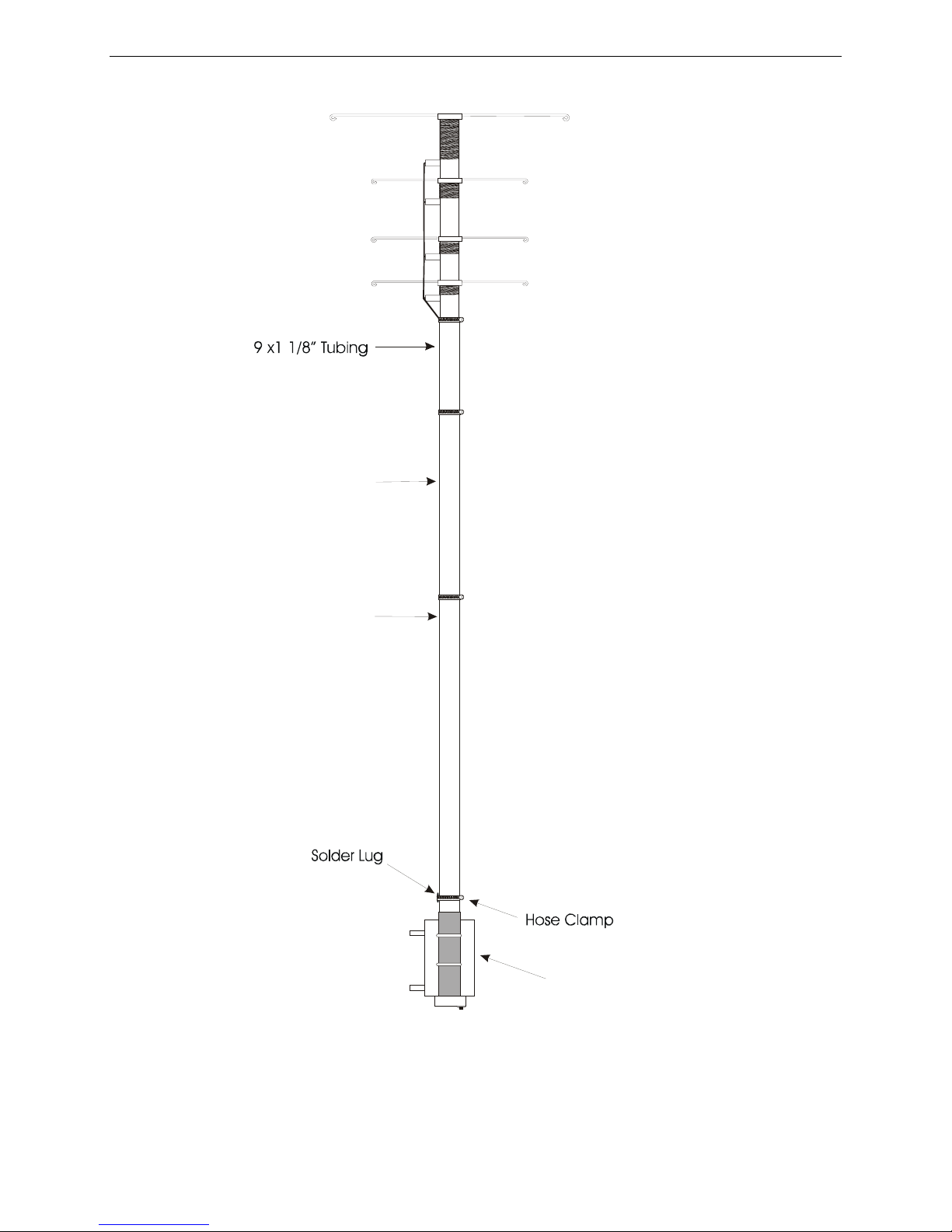

The MFJ-1795W HF antenna was designed to provide portable or permanent WARC Band

operation from restricted locations. When combined with the MFJ Ground-Coupled™ Portable

Antenna Base or other suitable grounding system, such as radial system, the result is a small

vertical antenna under 10 feet in height.

The reduction in size is accomplished by adding separate loading coils and capacitance hats for

each band at the top of the antenna. The efficient end loading coils are wound on fiberglass

forms. The high quality materials and construction of the HF loading system allows a maximum

power rating of 1500 watts SSB PEP on 60, 30, 17 and 12 meters.

The power rating of this antenna varies from band to band. The PEP ratings are primarily

determined by the voltage breakdown of the components, while the CW ratings are generally

determined by the components heating.

The following chart lists the power rating and the 2:1 VSWR bandwidth of this antenna:

Band (Meters) Power (Watts) Bandwidth (KHz)

CW SSB RTTY

60m 700 1500 500 100

30m 1250 1500 750 300

17m 1250 1500 1000 1000

12m 1250 1500 750 2000

The weight and wind load of this antenna are 10 pounds and approximately two square feet

respectively.

WARNING: Improper installation and assembly can be hazardous! Read

these instructions thoroughly before attempting to assemble, install, or

operate this product! High power transmitting devices produce voltages that

can cause severe burns or other injuries.

CHOOSING A LOCATION FOR THE ANTENNA

The best performance on receiving and transmitting will be obtained by mounting the antenna in

a clear location above or away from buildings, towers, feed-lines, utility wires, and other

antennas. While your own ingenuity and particular circumstances will determine the final

mounting method, we will pass along a few ideas for both permanent and portable installation.

WARNING: Always mount this antenna so that it is out of the reach of adults as well as

children. The capacitance elements can cause injury and or severe RF burns.

2