MFZ Ovitor CS 110 User manual

Operating Instructions for CS 110 Door Controls EN

CS 110 Door Controls / Rev. A 05 – 1

2 – CS 110 Door Controls / Rev. A 05

1. Contents

1. Contents 2

2. Information in this document 2

3. General safety instructions 3

4. Product overview 4

5. Initial operation 6

6. Initialisation 11

7. Changing the direction of rotation 11

8. Setting the travel limits 11

9. Programming using the LCD Monitor 13

10. Navigator (only with the LCD monitor) 14

11. Input mode (LCD monitor) 15

12. Error indication and elimination 16

13. Door cycle counter 17

14. Technical data 17

15. EC Declaration of Incorporation 18

Original Operating Instructions

−Protected by copyright.

−No part of this manual may be reproduced without our

prior approval.

−Subject to alterations in the interest of technical progress.

−All dimensions are given in millimetres.

−The illustrations are not true to scale.

Meaning of symbols

DANGER!

Safety notice indicating a danger that will directly result in

death or severe injury.

WARNING!

Safety notice indicating a danger that can result in death or

severe injury.

CAUTION!

Safety notice indicating a danger that can result in slight or

moderate injuries.

NOTICE

Safety notice indicating a danger that can result in damage

to property or in irreparable damage to the product

CHECK

Reference to a check that needs to be carried out

REFERENCE

Reference to separate documents that must be observed

Instruction requiring action

−List, itemisation

ÔReference to other sections of this document

2. Information in this document

EN

CS 110 Door Controls / Rev. A 05 – 3

3. General safety instructions

DANGER!

Failure to comply with the documentation could

result in life-threatening danger!

Be sure to follow all the safety instructions in this docu-

ment.

Warranty

The warranty with regard to function and safety is only valid

if the warnings and safety instructions in these operating

instructions are observed.

MFZ Antriebe GmbH + Co. KG accepts no liability for personal

injury or material damage arising from failure to observe the

warnings and safety instructions.

MFZ shall not provide a warranty and does not accept any

liability for damage arising from the use of non-approved

replacement parts or accessories.

Use for the intended purpose

The CS 110 control unit is intended exclusively for the

purpose of controlling door systems that have mechanical or

electronic (AVE) travel limit systems.

Keep remote control units out of the reach of children and

do not allow children to play with xed regulating or control

devices.

Target group

Only qualied and trained specialist tters are allowed to

install the door operator and carry out mechanical servicing

work.

Qualied and trained specialist tters must have the follow-

ing:

− - Knowledge of the general and specic safety and

accident-prevention regulations

−- Knowledge of all the relevant regulations

−Training in the use and care of appropriate safety equip-

ment

−The ability to recognise the risks associated with the instal-

lation work

Only qualied and trained electricians are allowed to connect

up the door operator to the power supply and to carry out

electrical servicing work.

Qualied and trained electricians must have the following:

− Knowledge of the general and specic safety and accident-

prevention regulations

−Knowledge of the relevant electrotechnical regulations

−Training in the use and care of appropriate safety equip-

ment

−The ability to recognise the risks associated with electricity

Instructions relating to installation and connection

−Before commencing electrical works, the system must be

disconnected from the power supply. Measures must be

taken to ensure that the power supply remains switched off

for the duration of the works.

−The local safety regulations must be observed.

−Power cables must be laid separately from control cables.

Regulations and test specications

The following regulations must be complied with when

connecting, programming or servicing the unit. (The list is not

exhaustive.)

Construction product standards

− EN 13241-1 (Products without re resistance or smoke

control characteristics)

−EN 12445 (Safety in use of power operated doors - Test

methods)

−EN 12453 (Safety in use of power operated doors - Requi-

rements)

−– EN 12635 (Garage doors and gates - Installation and

use)

−EN 12978 (Safety devices for power operated doors and

gates - Requirements and test methods)

4 – CS 110 Door Controls / Rev. A 05

EMC

−EN 55014-1 (Electromagnetic compatibility - Requirements

for household appliances)

−EN 61000-3-2 (Limits for harmonic current emissions)

− EN 61000-3-3 (Limitation of voltage changes, voltage uc-

tuations and icker in public low-voltage supply systems)

−EN 61000-6-2 (Electromagnetic compatibility (EMC) - Part

6-2: Generic standards - Immunity for industrial environ-

ments)

−EN 61000-6-3 (Electromagnetic compatibility (EMC) - Part

6-3: Generic standards - Emission standard for residential,

commercial and light-industrial environments)

Machinery standards

−EN 60204-1 (Safety of machinery - Electrical equipment of

machines, Part 1: General requirements)

−EN 12100-1 (Safety of machinery - Basic concepts, general

principles for design, Part 1: Basic terminology, methodo-

logy)

Low-voltage electricity

−EN 60335-1 (Household and similar electrical appliances -

Safety)

−EN 60335-2-103 (Particular requirements for drives for

gates, doors and windows)

Committee for Workplaces (Ausschuss für Arbeitsstätten -

ASTA)

−ASR A1.7 (Technical Regulations for workplaces - Doors

and gates)

4. Product overview

4.1 Models available

The following models of the CS 110 control unit can be

supplied:

−CS 110 control unit integrated in the operator

−CS 110 control unit in CS Mini housing

−CS 110 control unit in CS Standard housing -

All of these models can be tted with a plug-in radio receiver.

The following housing models can be supplied:

−Housing unit with 3-button input unit CS

−Housing unit with 3-button input unit KDT

−Housing with ON/OFF key switch

−Housing with mains switch

−Housing with emergency stop button

The operating instructions describe the connection options

and programming procedures for the following models:

−CS 110 control unit with CSI buttons

−CS 110 control unit with LCD display board CS 250 / 110

General safety instructions

EN

CS 110 Door Controls / Rev. A 05 – 5

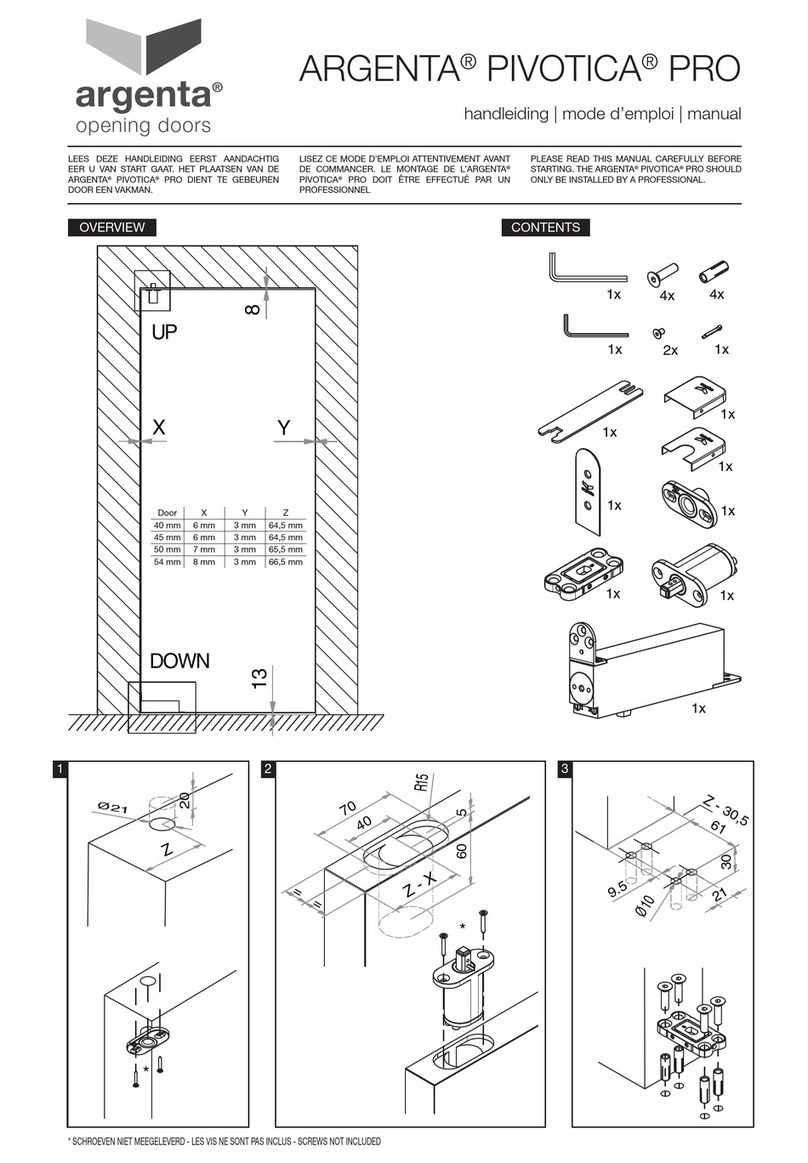

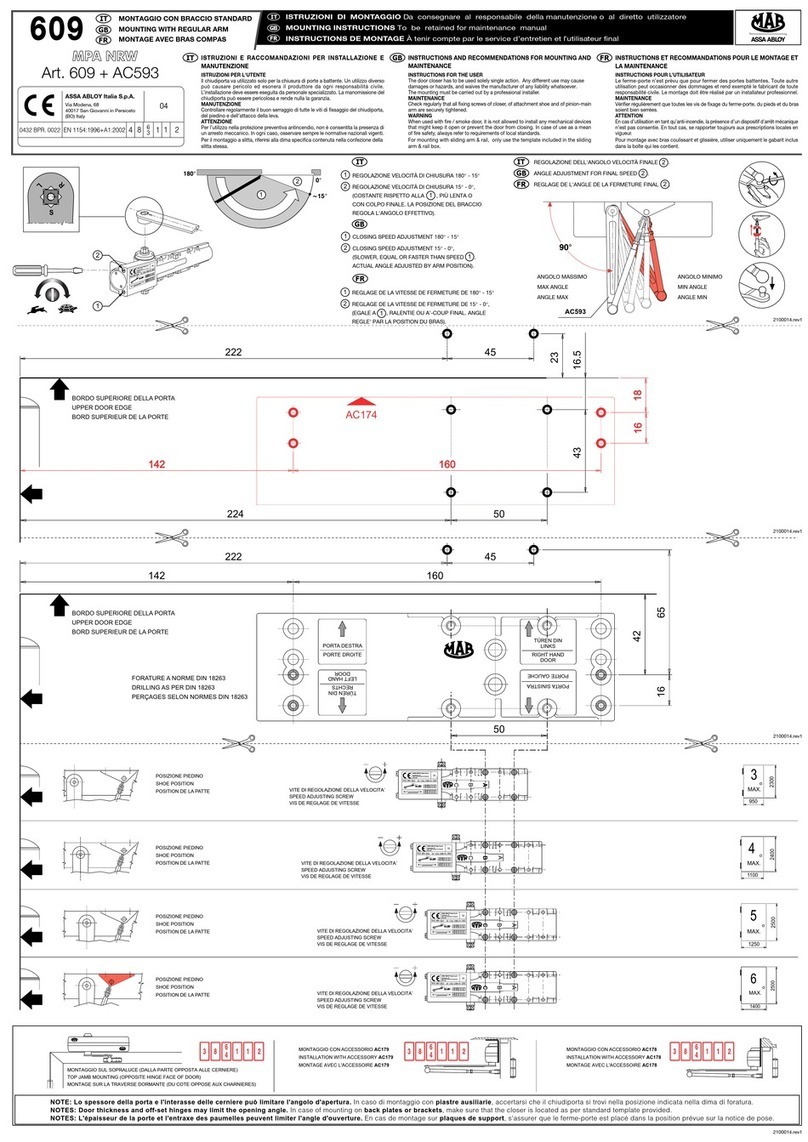

4.2 Main circuit board of the CS 110

L1

F1 = 250 mA

400V

230V

PE

- + P

F1

X16X15

X21

X18 X19

X17

X14

X1

X2

L2 L3 L1

U V WX2

X3

X13

K1

X11

X10

X9X8X7X6

X5X4

K3

X12

Key:

PE: Protective earth terminal block

X1: Mains power supply terminal

block

X2: Motor terminal block

X3: Network selection terminal block

X5: Relay terminal block

X8: Emergency stop terminal block

X9: 3-button input unit terminal

block

X11: Mechanical limit switch terminal

block

X12: Connector for RS485 devices

X14: Operating mode terminal block

X15/X16: Circuit card terminal block

X17: Radio terminal block

X18: Terminal block for buttons on

housing

X19: Terminal block for additional

shut-off system

X21: AVE RS485

K1: Relay

K3: Reversing contactor

F1: 250 mA fuse

6 – CS 110 Door Controls / Rev. A 05

5.1 General

WARNING!

To ensure that the system functions properly, the following

conditions must apply:

−The door is installed and functions properly.

−The MFZ geared motor is installed and ready for opera-

tion.

−The command and safety devices are installed and

function properly.

−The control unit housing with the CS 110 control unit is

installed.

NOTICE

The door, the MFZ geared motor and the command and

safety devices must be installed in accordance with the

relevant manufacturer’s instructions.

WARNING!

To ensure that the control unit functions properly, the

following conditions must apply:

−The supply voltage must correspond to the voltage

shown on the type plate.

−The supply voltage must correspond to the voltage of the

door operator.

−With a three-phase current supply, a clockwise rotating

eld must be ensured.

−If a permanent connection is to be made, an all-pole

mains switch must be installed.

−With a three-phase current supply, only three-pole circuit

breakers (10 A) may be used.

WARNING!

Before switching on the control unit for the rst time,

check to ensure that the cabling works are complete and

that all the motor connections are secure at both the

motor and the control unit. All control voltage inputs are

separated galvanically from the mains power supply.

5. Initial operation

5.2 Connection to the mains power supply

Detailed circuit diagram showing mains power connec-

tion (400 V / 230 V / 3-phase)

X3

230 V

X3

400 V

L3

L2

L1

400V 3~/PE

230V 3~/PE

PE

PE

PE

X1

Detailed circuit diagram showing mains power con-

nection (230 V / 1-phase)

L2

L3

L1

230V 1~/N/PE

PE

PE

PE

X1

X3

230 V

L

N

NOTICE

If the bridge is placed in the wrong position at X3, perma-

nent damage to the controls may be caused!

REFERENCE

See page 17 for technical data.

EN

CS 110 Door Controls / Rev. A 05 – 7

NOTICE

Changing the direction of rotation:

After the door operator has been connected, press the

OPEN and CLOSE buttons to check that the direction of

rotation is correct.

If the movement of the door does not correspond to the

buttons pressed, the connections at terminals U and V (or

OPEN/CLOSE) must be swapped over.

NOTICE

Safety switches of the door operator:

If the AVE Standard electronic limit switch is used, the

safety switches of the operator will be connected via the

AVE connector, which means that a bridge must be inserted

at X2:1/2.

5.3 Connection of the door operator

3-phase operator

1-phase operator

M

PE

PE

U

V

W

1

2

ab

a = Thermo switch

b = Emergency release / emergency hand chain /

emergency hand crank

X2

M

PE

PE

N

OPEN

CLOSE

1

2

ab

X2

a = Thermo switch

b = Emergency release / emergency hand chain /

emergency hand crank

8 – CS 110 Door Controls / Rev. A 05

Initial operation

5.4 Connection of limit switches

NOTICE

The limit switch settings are programmed automatically

during initial operation.

The type of limit switch used can be entered in the Input

menu.

a) Mechanical limit switches

X11

1 = Limit switch,

OPEN

2 = Limit switch,

CLOSE

3 = Pre-limit switch,

CLOSE

b) Electronic limit switch RS485

CS 110 in housing

X21

The numbers on the connector are

also the numbers of the leads:

4: Safety circuit input

5: RS 485 B

6: GROUND

7: RS 485 A

8: Safety circuit output

9: 12VDC

NOTICE

If no limit switch is connected at RS885, then the

safety circuit (4/8) must be bridged.

c) Electronic limit switches

CS 110 control unit integrated in the operator

X22 (on the plug-in circuit board)

The numbers on the connector are

also the numbers of the leads:

1: 5VDC

2: Signal 1

3: Signal 2

4: GROUND

5.5 Connection of safety devices

X8

1: Emergency stop

or door safety circuit

NOTICE

If no emergency stop is connected, the input must be

bridged.

EN

CS 110 Door Controls / Rev. A 05 – 9

3-button input unit - external button (KDT)

X9

External key switch

X9

NOTICE

If no stop system is connected at X9, then the input must be

bridged.

5.7 Connection for relay output

X5

STOP

OPEN

CLOSE

STOP

OPEN

CLOSE

5.6 Connection of command devices

CSI 3-button input unit

X12

4: Safety circuit input

5: RS 485 B

6: GROUND

7: RS 485 A

8: Safety circuit output

9: 12VDC

NOTICE

If no CSI button input unit is connected, then the

safety circuit (4/8) must be bridged.

CS 3-button input unit

X18

STOP

OPEN

CLOSE

10 – CS 110 Door Controls / Rev. A 05

Initial operation

5.8 Plug-in module

X15

X16

LED 1

LED 2

X15 X16

X22

LED 2 LED 1

NOTICE

Operation is not possible without the plug-in module.

5.9 Operating mode selector switch

X14

J1 Mode of operation for closing

direction:

Open: deadman mode

Closed: press-and-release

J2 Mode of operation for opening

direction:

Open: deadman mode

Closed: press-and-release

NOTICE

Operation with the press-and-release mode is allowed only

if the safety devices required by the regulations are in place.

5.10 Options

5.10.1 Radio receiver - CS plug-in radio system

X17

Program the transmission code:

1. Give the programming button of the receiver a short

press (holding for less than 1.6 seconds). The

programming mode will be activated. The LED of the

receiver ashes.

2. Press the channel button of your transmitter. When

the radio control system has saved the transmission

code, the LED of the receiver will light up and remain

lit for approximately 4 seconds.

5.10.2 Module - additional shut-off system

X19

EN

CS 110 Door Controls / Rev. A 05 – 11

6. Initialisation

During initial operation (when the power supply is switched

on), the controls automatically program the following compo-

nents:

−Limit switch system

−CSI buttons

−Display

During the automatic programming process, the red LED

on the CPU board lights up. Operation of the system is not

possible.

NOTICE

Before initialising the system:

The components must be installed before initial operation.

If these components are altered or added at a later date,

they can be automatically programmed via the CS compact

display or by initialising the system again.

Initialisation mode: The control unit can be switched to ini-

tialisation mode by pressing the “-” and “P” buttons on the

circuit board at the same time and keeping them pressed as

you switch on the power. Keep the buttons pressed until the

green LED lights up.

The saved travel limit settings will then be deleted and all

the parameters will be reset to the factory settings.

NOTICE

7. Changing the direction of rotation

During initial operation, the directional rotation of the door

operator must be checked and, if necessary, changed.

Switch to adjustment mode.

Press the OPEN button (if possible) The door should move

in the open direction. If the door moves in the close direc-

tion, you must change the direction of rotation.

Continue by setting the travel limits.

NOTICE

Changing the direction of rotation

Switch to adjustment mode.

Press the + and - buttons on the circuit board at the same

time and hold pressed for 5 seconds.

The red LED will ash rapidly.

Alternatively, two of the phases of the door operator can be

swapped with each other.

8. Setting the travel limits

8.1 Setting the electronic travel limits using

the adjusting buttons on the circuit board

Switch to ADJUSTMENT mode by pressing the P button and

holding for approximately 5 seconds. The red LED will ash

slowly.

Setting the travel limit in the OPEN direction

−Press the OPEN/CLOSE button to drive the door to the

desired travel limit position in the OPEN direction.

−Then save the travel limit position by pressing the P

button and the OPEN button at the same time.

The red LED will ash quickly for approximately 1

second.

Setting the travel limit in the CLOSE direction

−Press the OPEN/CLOSE button to drive the door to the

desired travel limit position in the CLOSE direction.

−Then save the travel limit position by pressing the P

button and the CLOSE button at the same time.

The red LED will ash quickly for approximately 1

second.

The adjustment mode will then end automatically. The red

LED will switch off.

NOTICE

−The adjustment mode will end automatically after 10

seconds if no key is pressed.

− When setting the travel limits for the rst time, both

travel limit positions must be set; otherwise, normal

operation will not be possible.

−If one of the travel limit positions needs to be readjusted,

you can press the “P” button to leave the Adjustment

menu after resetting the travel limit in question.

12 – CS 110 Door Controls / Rev. A 05

Setting the travel limits

8.3 Setting the electronic travel limits using

the LCD display

Switch to ADJUSTMENT mode.

−Press the “P” button until “Adjustment” appears in the

display.

Setting the travel limit in the OPEN direction

−Press the “+” button to drive the door to the desired

travel limit position in the OPEN direction.

−Then save the travel limit position by pressing the “P”

button and the “+” button at the same time.

Setting the travel limit in the CLOSE direction

−Press the “-” button to drive the door to the desired

travel limit position in the CLOSE direction.

−Then save the travel limit position by pressing the “P”

button and the “-” button at the same time.

Press the “P” button to leave adjustment mode.

NOTICE

− When setting the travel limits for the rst time, both

travel limit positions must be set; otherwise, normal

operation will not be possible.

−If one of the travel limit positions needs to be readjusted,

you can press the “Stop” button or “P” button to leave

the Adjustment menu after resetting the travel limit in

question.

8.4 Setting the mechanical travel limits

Switch to ADJUSTMENT mode.

Set the travel limits as described in the instruction manual

supplied with the mechanical limit switches.

Press the “P” button to leave adjustment mode.

NOTICE

−The adjustment mode will not end automatically. In order

to return to normal operating mode, you must leave

adjustment mode by pressing the “P” button.

8.2 Setting the electronic travel limits using

the CSI 3-button input unit

Switch to ADJUSTMENT mode.

−Press the STOP button for approximately 5 seconds. The

red LED will ash rapidly.

−Release the STOP button. The red LED will light up for

2 seconds.

−Press the STOP button within this 2-second period and

hold it pressed for approximately 5 seconds. The red

LED will ash slowly. Release the STOP button.

Setting the travel limit in the OPEN direction

−Press the OPEN/CLOSE button to drive the door to the

desired travel limit position in the OPEN direction.

−Then save the travel limit position by pressing the STOP

button and the OPEN button at the same time.

The red LED will ash quickly for approximately 1

second.

Setting the travel limit in the CLOSE direction

−Press the OPEN/CLOSE button to drive the door to the

desired travel limit position in the CLOSE direction.

−Then save the travel limit position by pressing the STOP

button and the CLOSE button at the same time.

The red LED will ash quickly for approximately 1

second.

The adjustment mode will then end automatically. The red

LED will switch off.

NOTICE

−The adjustment mode will end automatically after 10

seconds if no key is pressed.

− When setting the travel limits for the rst time, both

travel limit positions must be set; otherwise, normal

operation will not be possible.

−If one of the travel limit positions needs to be readjusted,

you can press the “P” button to leave the Adjustment

menu after resetting the travel limit in question.

EN

CS 110 Door Controls / Rev. A 05 – 13

9. Programming using the LCD Monitor

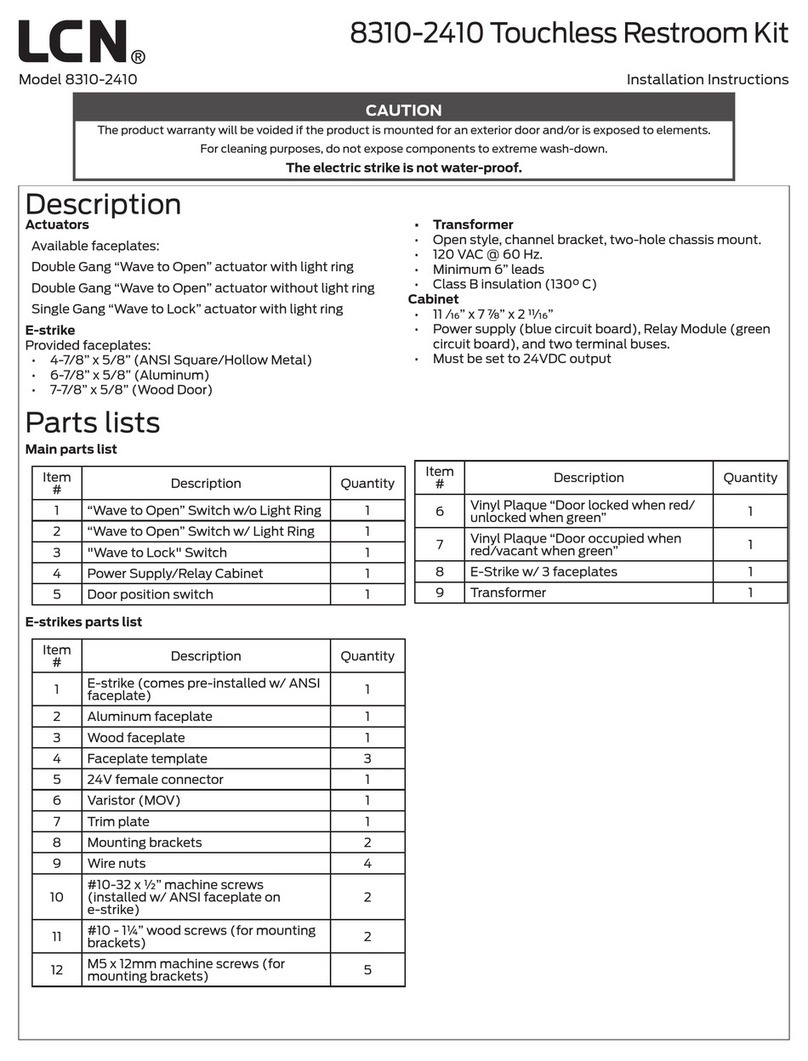

9.1 Overview of the LCD monitor

AUTOMATIC O

RESTING

A

B

C D E

F

G

H

Key:

A: Mode of operation / Diagnostics info

B: Parameters / Diagnostics info

C: (+) button

D: (-) button

E: (P) button

F: Value / Status

G: Value / Status

H: Jumper

9.2 Modes of operation of the LCD monitor

CAUTION!

The mains power supply must be switched off before con-

necting the display unit. Only a display unit manufactured

by MFZ (article number 1700004793) may be used.

In combination with the LCD monitor, the control unit has

four modes of operation:

1. AUTOMATIC

2: ADJUSTMENT

3: INPUT

4: DIAGNOSTICS

If the Jumper H is pulled out, the “+”, “-” and “P” buttons

will have no effect. The display will continue to function.

Operating mode 1: AUTOMATIC

The AUTOMATIC mode is used for operating the door.

Display:

−Displays the action being carried out

−Displays any errors

If the jumper at J1/J2 is used to set the operating mode to

deadman operation, then MANUAL will be shown in the

display instead of AUTOMATIC.

Operating mode 2: ADJUSTMENT

The ADJUSTMENT mode is used for setting the travel limits

for the OPEN and CLOSE directions. Fine adjustments can be

made in the INPUT operating mode.

Display:

−Displays the travel limit value

NOTICE

When in ADJUSTMENT mode, the door will not stop

automatically when it reaches the travel limit position.

Driving the door beyond the travel limit position could cause

damage to the door.

Operating mode 3: INPUT

In the INPUT mode, the values of various parameters can be

altered.

Display:

−Displays the selected parameter

−Displays the current value or status

Operating mode 4: DIAGNOSTICS

In the DIAGNOSTICS mode, door-specic monitoring can be

carried out.

Display:

−Displays the monitored function

−Displays the status of the function

14 – CS 110 Door Controls / Rev. A 05

AUTOMATIC

RESTING

P

> 1 second

ADJUSTMENT

RESTING

+

-> Position, DOOR OPEN ADJUSTMENT

MANUAL OPEN

Save door position:

P

hold and

+

> 1 sec

-

-> Position DOOR CLOSED ADJUSTMENT

MANUAL CLOSE

Save door position:

P

hold and

-

> 1 sec

P

> 1 sec

INPUT

+

and

-

> 2 sec INPUT

DEUTSCH :

Scroll up in menu:

+

> 2 sec

Scroll down in menu:

-

> 2 sec

Select value:

P

> 1 sec

Increase the value:

+

Decrease the value:

-

Save the value:

P

Return to mode: INPUT:

+

and

-

> 1 sec

INPUT

FINE OPEN : 0

INPUT

FINE CLOSE : 0

INPUT

ROT.FIELD : MOD1

INPUT

LIMIT SWITCH : MOD1

INPUT

RELAY 1 : MOD14

DIAGNOSTICS Scroll up in menu:

+

> 2 sec

Scroll down in menu:

-

> 2 sec

Return to mode -AUTOMATIC:

P

Only data requests are possible

TOP ES : ON

BOTTOM ES : OFF

OPEN BUTTON : OFF

CLOSE BUTTON : OFF

STOP CIRCUIT : ON

DOOR CYCLES : 0000

AVE : XXXX

10. Navigator (only with the LCD monitor)

EN

CS 110 Door Controls / Rev. A 05 – 15

Function Description Possible settings Factory settings

Language Select the menu language D, GB, F, NL D

RELAY 1

MOD1: Red warning light ashes as warning before door movement and

lights up during movement

MOD2: Red warning light ashes as warning before door movement and

ashes during movement

MOD3: Red warning light lights up as warning before door movement and

lights up during movement

These 3 modes are affected by the parameter M1-3 RESTING

MOD4: Impulse when OPEN command is given

MOD5: Error message

MOD6: Travel limit in OPEN direction

MOD7: Travel limit in CLOSE direction

MOD8: Travel limit in OPEN direction negated

MOD9: Travel limit in CLOSE direction negated

MOD10: Pre-limit position in OPEN direction

MOD11: Pre-limit position in CLOSE direction

MOD12: Pre-limit position in CLOSE direction to travel limit in CLOSE

direction

MOD13: Magnetic lock function

MOD14: Brake

MOD1 – MOD14 Relay 1: MOD14

FINE

OPEN

Fine adjustment of the travel limit in the OPEN direction, in relation to the

saved travel limit position in the OPEN direction -250 to +250 0

FINE

CLOSE

Fine adjustment of the travel limit in the CLOSE direction, in relation to the

saved travel limit position in the CLOSE direction -250 to +250 0

ROT.FIELD MOD 1: Clockwise rotating drive

MOD 2: Anticlockwise rotating drive MOD1, MOD2 MOD1

LIMIT

SWITCH

MOD 1: AVE

MOD 2: mechanical limit switches MOD1, MOD2 MOD2

NOTICE

The parameters FINE CLOSE, FINE OPEN and ROT.FIELD can be used only in conjunction with the AVE limit switch.

11. Input mode (LCD monitor)

16 – CS 110 Door Controls / Rev. A 05

12. Error indication and elimination

LED 1, green (circuit card or CSI button)

Error Indicator Comments

No operating voltage present Off No voltage supply present

LED 2, red (circuit card or CSI button)

LCD display

Error Indicator Comments

Error STOP 1x ash Stop circuit must be closed; door movement then possible

Error RS485 2x ash System stopped; error in transmission protocol.Acknowledge the error by

pressing Stop; restart is possible by pressing button.

Error Travel Limit 3x ash System stopped and no door movement possible. Disconnect control unit from

power supply; reprogram the travel limit positions.

Error Rotational eld 4x ash System stopped and no door movement possible. Switch the rotational direc-

tion; disconnect control unit from power supply.

Error Power 5x ash System stopped. Acknowledge the error by pressing Stop; restart is possible by

pressing button.

Error Running time 6x ash System stopped. Acknowledge the error by pressing Stop; restart is possible by

pressing button.

NOTICE

After the cause of the error has been remedied, the control unit must be disconnected from the power supply and then recon-

nected.

EN

CS 110 Door Controls / Rev. A 05 – 17

Dimensions of

housing:

165 x 220 x 110 mm

Installation: install vertically on a wall; minimum installation

height: 1,100 mm

Power supply via

L1, L2, L3, N, PE:

400 V 3~, 230 V 3~ or 230V 1~50 / 60Hz;

Power input:

max. 2200 W with 400V 3-phase supply

max. 1500 W with 230V 3-phase supply

max. 1100 W with 230V 1-phase supply

60% duty cycle with a maximum running time

of 120 s

Fuse protection: Type K 8A fuse, to be tted by the customer

on site

Power consumption

of controls alone:

max. 250 mA

Control voltage: 24 V DC; maximum of 250 mA; protected by

a self-resetting fuse for external sensors. All

control voltage inputs are separated galvanically

from the mains power supply.

Control inputs: 24 V DC, all inputs must be connected such that

they are potential-free.

Minimum signal duration for input control

commands > 100 ms

Control outputs: 24 V DC, maximum of 150 mA

Relay outputs If inductive loads are connected (e.g. additional

relays or brakes), these must be equipped with

suitable interference suppression (recovery

diode, varistors, RC circuits).

Normally-open potential-free contact; minimum

of 10 mA; maximum of 230 V AC / 4 A

Once contacts have been used in power circuits

they can no longer be used for low currents.

Safety circuit / Emer-

gency off function:

It is essential that all inputs are connected such

that they are potential free; if the safety circuit

is interrupted, no further door operator move-

ment is possible, not even in deadman mode.

Temperature range: In operation: -10 °C ... +45 °C

In storage: -25 °C ... +70 °C

Air humidity: Up to 80% with no condensation

Vibration: Low-vibration mounting, e.g. on a masonry wall

Protection class IP 65

Weight Approx. 1.8 kg

13. Door cycle counter 14. Technical data

The number of cycles can be shown by pressing the buttons

on the circuit board. The red LED will indicate the number of

cycles by ashing.

−Drive the door to the travel limit in the OPEN direction.

−Press the OPEN button and then the P button immediately

afterwards, keeping both buttons pressed for approximately

5 seconds.

−The number of cycles will then be shown by a series of

ashes E__Z__H__T__ZT__HT

(whereby a zero is indicated by two short ashes).

− The break between digits is indicated by the ashing of the

green LED.

Example: 10408 cycles (* long ash / * short ash)

Green LED *****

Red LED *_*_*_*_*_*_*_* ** *_*_*_* ** * **

Value 8 0 4 0 1 0

18 – CS 110 Door Controls / Rev. A 05

15. EC Declaration of Incorporation

We hereby declare that the following product:

CS 110 Door Controls

complies with the basic requirements of Machinery Directive

(2006/42/EC):

This partly completed machinery complies with all the regula-

tions of the EC Construction Products Directive (89/106/EEC),

EC Electromagnetic Compatibility Directive (2004/108/EEC)

and the EC Low Voltage Directive (2006/95/EC).

The following standards were applied:

EN 60204-1

Safety of machinery - Electrical equipment of machines, Part

1: General requirements

EN 12100-1

Safety of machinery - Basic concepts, general principles for

design, Part 1: Basic terminology, methodology

EN 12453

Safety in use of power operated doors - Requirements

EN 12604

Doors and gates - Mechanical aspects - Requirements

EN 61000-6-2

Electromagnetic compatibility (EMC) - Part 6-2: Generic stan-

dards - Immunity for industrial environments

EN 61000-6-3

Electromagnetic compatibility (EMC) - Part 6-3: Generic

standards - Emission standard for residential, commercial and

light-industrial environments

EN 60335-1

Household and similar electrical appliances - Safety

EN 60335-2-103

Particular requirements for drives for gates, doors and win-

dows

Manufacturer and manager of documentation

MFZ Antriebe GmbH & Co. KG, Neue Mühle 4, 48739 Legden,

Germany

The special technical documents were prepared in accordance

with Annex VII, Part B of EC Machinery Directive 2006/42/

EC. We undertake to supply these documents, in electronic

form and within a reasonable period, in response to a duly

reasoned request from the market surveillance authorities.

The partly completed machine may not be set in operation

until it has been ascertained that the machine in which the

partly completed machine is to be installed complies with all

the requirements of Machinery Directive (2006/42/EC).

Place and date

Legden, den 18 January 2012

Manufacturer’s signature

Hans-Joachim Molterer

Job description of the signatory

Executive Director

EN

CS 110 Door Controls / Rev. A 05 – 19

#1700012038

#103730

Table of contents

Popular Door Opening System manuals by other brands

LCN

LCN 8310-2410 installation instructions

Assa Abloy

Assa Abloy Corbin Russwin DC6200 Series installation instructions

Assa Abloy

Assa Abloy Norton 5630 Series Installation and instruction manual

Open Sesame Door Systems

Open Sesame Door Systems 133 owner's manual

Assa Abloy

Assa Abloy Norton 1600 quick start guide

WebDoor

WebDoor CADET PRO Installation and instruction manual