3 Set-up

LNOTE: The red dip switches (power supply dip switches) need to be set for 24V.

- Dip switch SW1 should be set to OFF

- Dip switch SW2 should be set to ON

All applications

Selecting a Mode

The restroom kit has two Restroom applications built in

(Modes M 7 & M 8). The default mode for the restroom kit

is Mode M 7 (Fail Safe).

Determining which mode is correct for you will be based on

whether the e-strike is set to Fail Safe (Mode M 7) or Fail

Secure (Mode M 8).

There are three LED displays that will allow you to see

what mode you have selected when advancing through the

modes.

To change the mode of the restroom kit, simply press the

MENU button once and use the UP button to advance to the

desired mode.

Editing the Settings for a Mode

Typical times are pre-set for lock release and door operator

activation and is ready to use without changing any

parameters. If you need to change the timing or delay for an

output, it can be done by pressing the “MENU” button within

the mode you selected.

Once the option is selected you can use the “UP or DOWN”

buttons to select the timing needed. The first option (H & 1

flashing) will be how long relay 1 will be activated for (0-50

seconds).

The second option (d & 1 flashing) will be how long to wait

before activating relay 2 (0-15 seconds).

The third option (H & 2 flashing) will be how long relay 2 will

be activated for (0-50 seconds).

The fourth option (d & 2 flashing) will be how long to wait

before activating relay 3 (0-15 seconds).

The fih option (H & 3 flashing) will be how long relay 3 will

be activated for (0-50 seconds). See chart below.

Factory Reset (Defaulting the Relay Module)

To return the relay module back to its factory default settings

you will need to remove power, then hold down the “MENU”

button while powering up the relay module.

Once started you will see the firmware version listed then

a number “1” will be displayed. Reconnect your power and

press the “MENU” button once then use the “UP” or “DOWN”

button to advance to the desired mode.

Fully test the operation of the restroom kit for proper

functionality.

Display (M) Description (Mode you are in) Parameters (1-15)

H, then 1 Relay 1 hold time 0.0 to 50 seconds

d, then 1 Relay 2 delay time 0.0 to 15 seconds

H, then 2 Relay 2 hold time 0.0 to 50 seconds

d, then 2 Relay 3 delay time Depends on mode

H, then 3 Relay 3 hold time 0.0 to 50 seconds

d Sets the display ON or OFF during operating mode ON or OFF

AInput delay on Activate. If other than 0.0 is selected, the input must be held

in for the time period chosen before the relay module will activate. 0.0 to 10 seconds

1 Set Dry Input 1 to activate on normally open or normally closed contact. N/O or N/C

2 Set Dry Input 2 to activate on normally open or normally closed contact. N/O or N/C

3 Set Dry Input 3 to activate on normally open or normally closed contact. N/O or N/C

4 Set Dry Input 4 to activate on normally open or normally closed contact. N/O or N/C

5 Not used. Not used

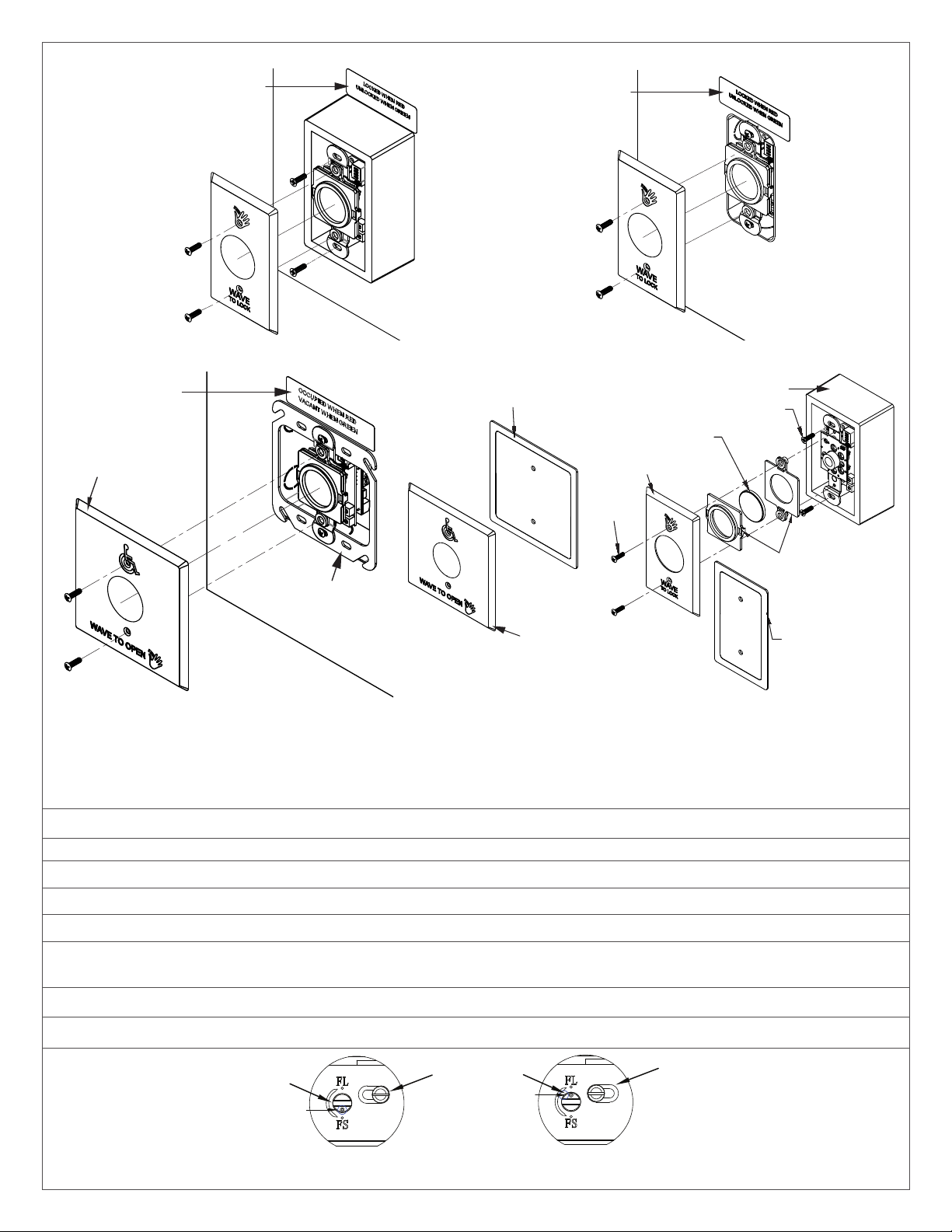

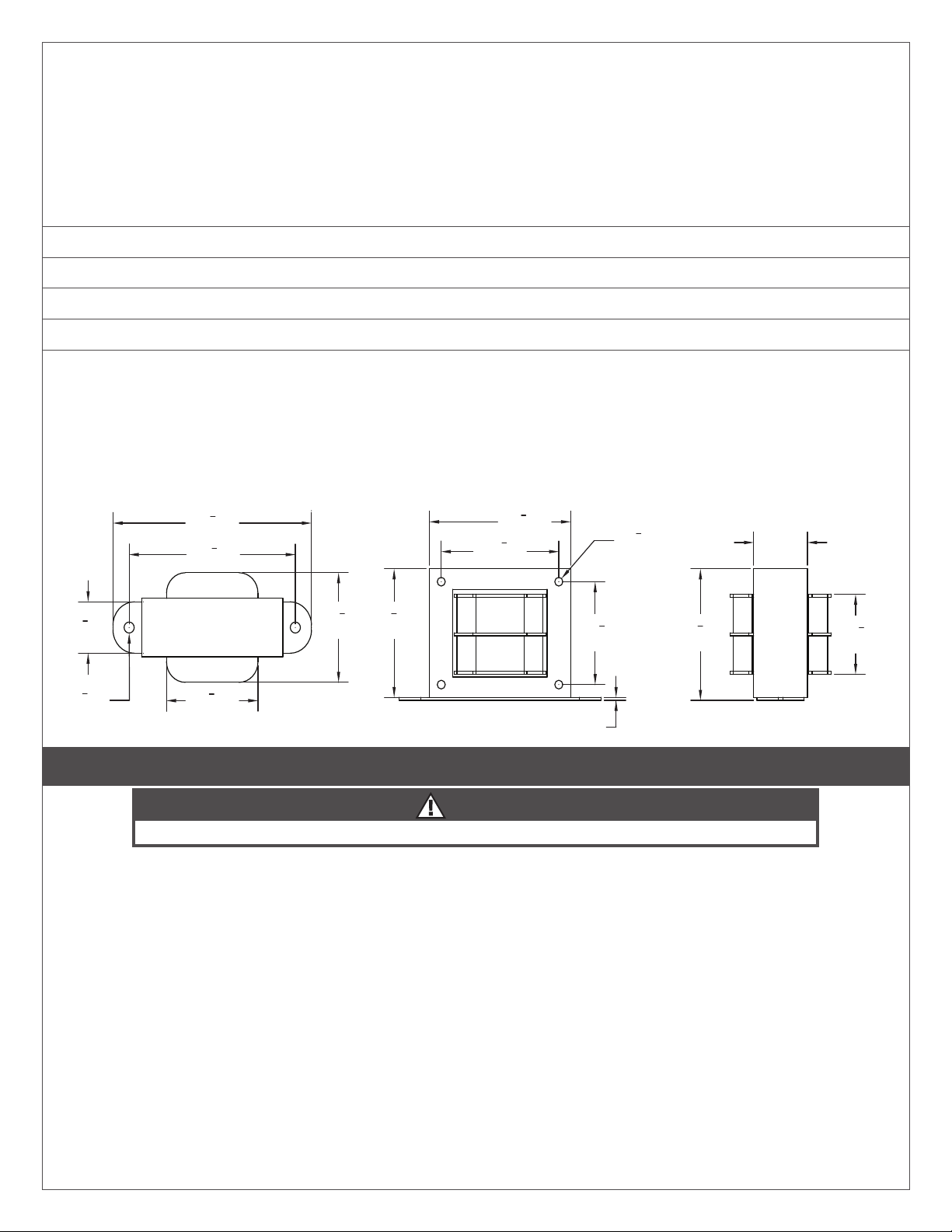

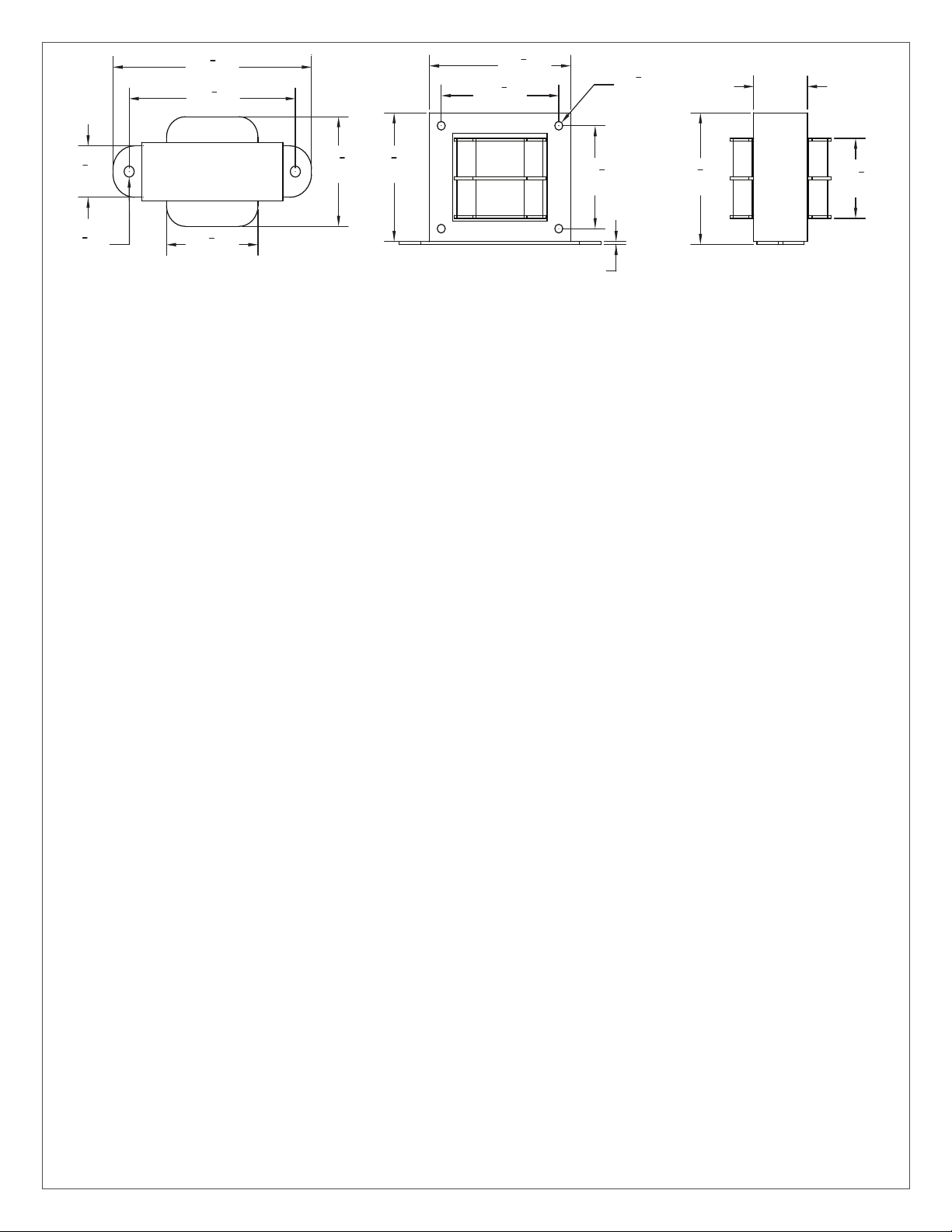

Actuators

The Outside Wave to Open/Wave to Lock with light ring actuators

LCAUTION: Do not apply power to the unit until all secondary wiring is complete and dip switches have been set.

Power — TB6

The actuators is powered by 24VDC. Connect the power to pins 1 and 2 on TB6. This is a non-polarized connection. Connect

VDC +/- from right terminal bus of Control Box to screw terminals on TB6 (not polarity sensitive).

Inputs

The actuators provide inputs for door contacts, Request to Exit and remote control of the LED light ring. These inputs are

found on TB2. All inputs require a dry contact closure to operate.