MG ANODI De Stefani ACES User manual

CGR

srl

MG ANODI

INTERNATIONAL AD

Velikotarnovsko Shosse 1

5400 Sevlievo – Bulgaria

Mobile: +39 345 8412837

Web: www. g-anodi.co

E-mail:

aces@ g-anodi.co

via V. Bottego n.41

41126 Modena - Italia

tel.- fax +39 059822673

WEB: www.cgr-aces.it

EMAIL: info@cgr-aces.it

MG ANODI INTERNATIONAL AD

Velikotarnovsko Shosse 1

5400 Sevlievo - Bulgaria

Mobile: +39 345 8412837

Web: www. g-anodi.co

E-mail: aces@ g-anodi.co

ENGLISH from page 1 to page 12 (rev. 02)

DICHIARAZIONE DI CONFORMITA’/

DECLARATION OF CONFORMITY

Fabbricante/Manufacturer:

MG ANODI INTERNATIONAL AD

Velikotarnovsko Shosse 1

5400 Sevlievo – Bulgaria

Descrizione del prodotto/

Product(s) description: Dispostivo elettronico anticorrosione per

bollitori/Electronic devices for boilers and

water-heaters corrosion prevention:

Modello (i)/Model(s): A C E S Serie H

A C E S G 2

Si certifica sotto la nostra esclusiva responsabilità che i prodotti a cui si riferisce la

presente dichiarazione sono conformi alle seguenti Direttive europee/

We hereby certify under our sole responsability, that the product(s) to which this

declaration relates is/are in conformity with the requirements of the following

European Directives:

Council Directive 89/336/EEC Directive (Electromagnetic Compatibility),

Council Directive73/23EEC Directive (Low Voltage Equipement Safety)

Council Directive 2001/95/EC Directive (General Product Safety).

E alle seguenti norme armonizzate / and with the following European Standards

CONTENTS

1 Using the manual 1

2 Symbols 2

3 Description of the product

3.1 Permissible/improper use

3

4 Supply specifications 4

5 Installation and startup 5

5.1 Electronic device installation

5

5.2 Anode installation

5

5.3 Device installation

5.4 Startup

6

6 Troubleshooting 8

7 Maintenance 8

8 Spare parts 8

9 Warranty 9

10 Instructions regarding disposal 9

ACES - ACES G2 technical card 10-11

Manufacturer’s declaration of conformity 12

English

EN 60065 (2004):Audio, video and similair electronic apparatus Safety

requirements

EN 55011 (2011) CISPR 11/A1:2010-03 ;

EN 61000-4-3 (2007)- radiated immunity (10V/m,80-1000MHz, AM 80%)

EN 61000-4-6 (2011) - conducted RF immunity (10Vrms,0.15-80MHz,AM80%)

EN 61000-4-2 (2011) - electrostatic discharge (8 KV air, 4 KV contact)

EN 61000-4-4/A1 (2010) - BURST (2 KV, 5 kHz)

EN 61000-3-2/A1/A2 (2011) - harmonic current emissions

Sevlievo, 01/07/2016

Luca De Stefani, General Manager

Introduction

These operating instructions apply

to the products called ACES and

ACES G2.

The ACES device is an impressed

current cathodic protection system

for enamelled/vitrified or stainless

steel boilers of up to 5,000 litres

capacity.

The ACES G2 device is also an

impressed current cathodic

protection system for enamelled/

vitrified boilers of up to 1,000 litres

capacity.

This instruction handbook always comes

with the product, and is placed inside

the packing.

The last page of this handbook contains

the manufacturer’s declaration of

conformity, which must be kept by the

user together with the handbook and

shown to the competent supervisory

authority on the occasion of any checks

or inspections.

1

1. USING THE INSTRUCTIONS

This handbook must be consulted by

the customer for correct installation

and use of the product.

The user must strictly comply with the

safety instructions given in it.

The manufacturer declines any liability

for injury or damage due to improper

use (§ 3) of the product and/or failure

to apply the rules for safe operation

described in this handbook.

Keeping the handbook

This handbook must be kept carefully

and in good condition by the user.

If it is lost, the user can request a new

copy from the manufacturer on

payment.

Given below are the symbols present

in this publication, together with their

respective meanings.

READ THE MANUAL CAREFULLY

indicates cases or situations

where the user must refer to

the instructions present in the

manual in order to carry out a

given operation correctly and

safely.

WARNING

The warning messages

indicate the risk of accident

or danger during operation or

maintenance work, if the procedures

and conditions described are not

carefully observed.

ATTENTION

The attention messages

indicate risk of damage to

the equipment during operation or

maintenance work, if the procedures

and conditions described are not

carefully observed.

NOTE: The notes bring the

user’s attention to important

information regarding the matter,

application or procedure.

The ACES device is an impressed

current cathodic protection electronic

system for boilers and water heaters.

Its purpose is to annul the corrosive

effect that the water would have on

the tank lining.

It is also extremely effective against

the presence of microorganisms

harmful to health, such as legionella

pneumophila. There are two product

types: ACES and ACES G2, which

differ for the type of application.

ACES is installed on enamelled and

vitrified boilers of up to 5,000 litres

capacity.

ACES G2 is always installed on the

same types of boilers, with capacities

of up to 1,000 litres. In case of

unfavourable conditions or containers

holding more than 5,000 litres, the

use of two or more generators is

provided for. The ACES system

provides cathodic protection against

corrosion, obtained by ensuring the

potential of the electrolyte by means

of an impressed current produced by

the device.

ACES G2 TECHNICAL CARD

For stainless steel, MG ANODI INTERNATIONAL will prepare a

design according to the

characteristics and capacity of the boiler.

2

3. DESCRIPTION OF PRODUCT

PERMISSIBLE/

IMPROPER USE

2. SYMBOLS

Description of the product:

an impressed current electronic

device for cathodic protection against corrosion in enamelled /

vitrified boilers of up to 1,000 litres capacity.

Electrical characteristics:

Power supply

Voltage:

230 ± 10% Volt

Frequency:

50/60 Hz

max. output voltage: 16VDC

max. output current: 0.13 A

protection rating: IP 55

max. input: 3.2 W

Generator dimensions:

nominal external dimensions of generator: 60x52x35.5 mm.

weight:

approx. 0.26 kg

cable with flat plug: length 1900 mm

low tension cable: length 1900 mm

TITANIUM ELECTRODE (ACES AND ACES G2)

Description of the product:

a current delivery and

measurement device with coating in noble metal

Size of electrodes:

various lengths depending on the

characteristics of the tanks to be protected

size of treated part: 3 mm

This handbook must be consulted by

the customer for correct installation

and use of the product.

The user must strictly comply with the

safety instructions given in it.

The manufacturer declines any liability

for injury or damage due to improper

use (§ 3) of the product and/or failure

to apply the rules for safe operation

described in this handbook.

Keeping the handbook

This handbook must be kept carefully

and in good condition by the user.

If it is lost, the user can request a new

copy from the manufacturer on

payment.

Given below are the symbols present

in this publication, together with their

respective meanings.

READ THE MANUAL CAREFULLY

indicates cases or situations

where the user must refer to

the instructions present in the

manual in order to carry out a

given operation correctly and

safely.

WARNING

The warning messages

indicate the risk of accident

or danger during operation or

maintenance work, if the procedures

and conditions described are not

carefully observed.

ATTENTION

The attention messages

indicate risk of damage to

the equipment during operation or

maintenance work, if the procedures

and conditions described are not

carefully observed.

NOTE: The notes bring the

user’s attention to important

information regarding the matter,

application or procedure.

The ACES device is an impressed

current cathodic protection electronic

system for boilers and water heaters.

Its purpose is to annul the corrosive

effect that the water would have on

the tank lining.

It is also extremely effective against

the presence of microorganisms

harmful to health, such as legionella

pneumophila. There are two product

types: ACES and ACES G2, which

differ for the type of application.

ACES is installed on enamelled and

vitrified boilers of up to 5,000 litres

capacity.

ACES G2 is always installed on the

same types of boilers, with capacities

of up to 1,000 litres. In case of

unfavourable conditions or containers

holding more than 5,000 litres, the

use of two or more generators is

provided for. The ACES system

provides cathodic protection against

corrosion, obtained by ensuring the

potential of the electrolyte by means

of an impressed current produced by

the device.

ACES G2 TECHNICAL CARD

For stainless steel, MG ANODI INTERNATIONAL will prepare a

design according to the

characteristics and capacity of the boiler.

2

3. DESCRIPTION OF PRODUCT

PERMISSIBLE/

IMPROPER USE

2. SYMBOLS

Description of the product:

an impressed current electronic

device for cathodic protection against corrosion in enamelled /

vitrified boilers of up to 1,000 litres capacity.

Electrical characteristics:

Power supply

Voltage:

230 ± 10% Volt

Frequency:

50/60 Hz

max. output voltage: 16VDC

max. output current: 0.13 A

protection rating: IP 55

max. input: 3.2 W

Generator dimensions:

nominal external dimensions of generator: 60x52x35.5 mm.

weight:

approx. 0.26 kg

cable with flat plug: length 1900 mm

low tension cable: length 1900 mm

TITANIUM ELECTRODE (ACES AND ACES G2)

Description of the product:

a current delivery and

measurement device with coating in noble metal

Size of electrodes:

various lengths depending on the

characteristics of the tanks to be protected

size of treated part: 3 mm

ACES TECHNICAL CARD

Generator dimensions:

an impressed current electronic device

for cathodic

protection against corrosion

in

enamelled /

vitrified

boilers of up to 5,000 litres capacity.

Technical characteristics:

Power supply

Voltage:

230 Volt ± 10%

Frequency:

50/60 Hz

max. output voltage: 13VDC

max. output current: 0.25 A

protection rating: IP 55

max. input: 4.5 W

operating temperature from 0 to 50°

double electrical insulation

Generator dimensions:

nominal external dimensions of generator: 60x52x45 mm.

weight:

approx. 0.40 kg

cable with flat plug: length 1900 mm

low tension cable: length 1900 mm

TITANIUM ELECTRODE (ACES AND ACES G2)

Description of the product:

a current delivery and

measurement device with coating in noble metal.

Size of electrodes:

various sizes depending on the

characteristics of the tanks to be protected

size of treated part: 3 mm

For stainless steel, MG ANODI INTERNATIONAL will prepare a

design according to the

characteristics and capacity of the boiler.

Maintaining of the potential is

guaranteed through constant

periodical measurement of the

difference in potential between the

boiler and the titanium anode.

According to measurement results, the

electronic device of the equipment

adjusts the current potential the

titanium anode must deliver in order to

guarantee optimum protection against

corrosion.

The anode consists of a 3 mm

diameter titanium rod (figure 1 on next

page).

One of the two ends of the anode is

treated by means of an

electrochemical activation process

<6> and the other non-activated end

is equipped with a threaded cap in

special plastic material of diameter

1/2”, conical gas <5>.

Only the terminal end of the anode

(whose length can vary) is

electrochemically activated and able to

impress current, whereas the other

part of the anode does not undergo the

above-mentioned treatment and its

purpose is to convey the current near

the activated area. The electronic

device is housed in a plastic container

resistant to high temperatures <1>.

Correct operation of the device is

monitored by a special sensor and

indicated by a LED located in the front

of the equipment <8>.

If the LED lights up green it

means that the device is

working properly; if it lights up

red, the LED signals an operation

fault.

The correct polarity of the

cables

must

be

strictly

respected during

the

installation stage: the wire

ending with the faston contact

(positive polarity) must be connected

to the anode; the wire ending with the

eyelet (negative polarity) must be

connected to the tank earth.

Failure to comply with this instruction

implies improper use and invalidates

the warranty.

Also, the earth (eyelet) must be

secured to the tank.

The earth (eyelet) MUST NEVER be

connected to the pipes entering or

leaving the tank.

3.1 Permissible/improper use

The device in question must only be

used as an anticorrosion device for

enamelled/vitrified boilers or boilers in

stainless steel. It cannot be used for

different types of boilers and must be

installed and used according to the

instructions given in this handbook.

Any use different from that for which

the product is intended and any non-

compliance with the instructions given

in this handbook implies non-

compliance with the product’s

intended use.

The manufacturer declines

any liability for damage or

injury caused by improper

and non-conforming use of

the product.

3

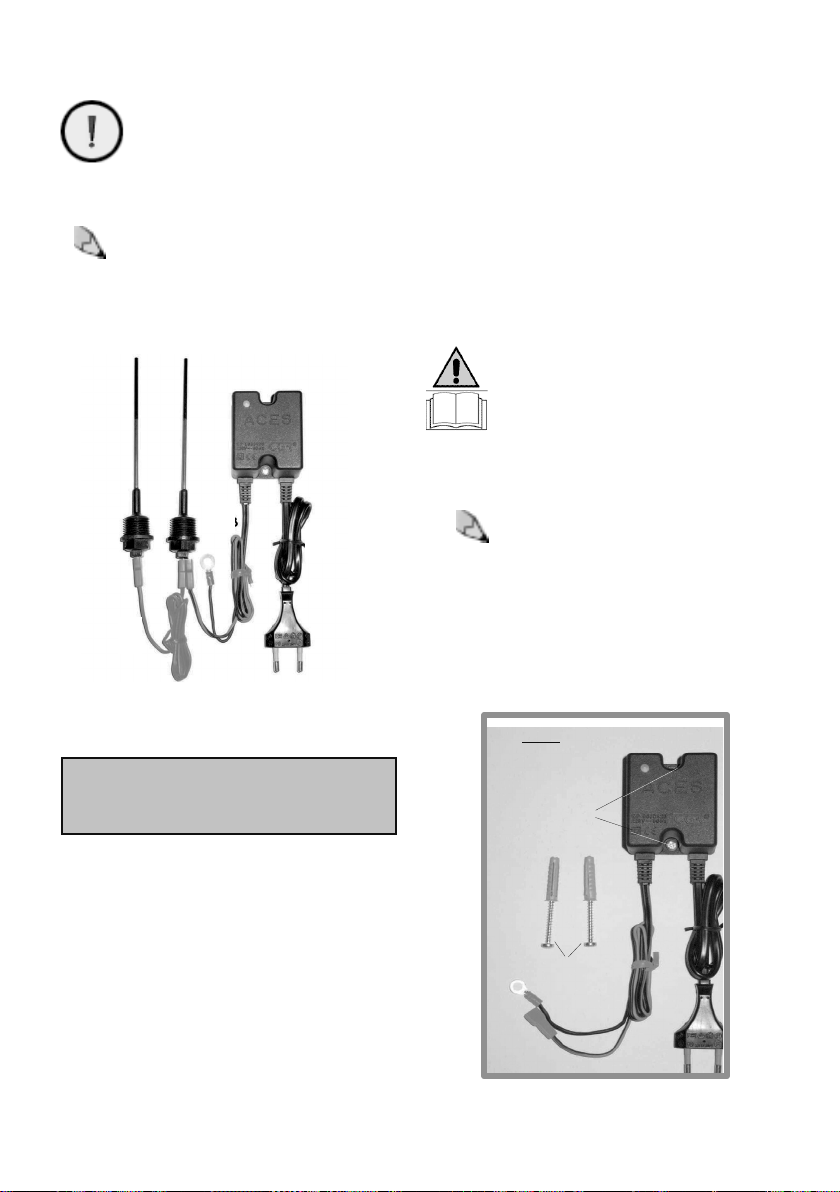

1

generator

2

power

cable

3

low

tension cable

4

earth

5

anode

holder

cap

6

anode

7

female

faston

8

operation

green

-

red

LED

9

cable

glands

10

eyelets

for

assembly

At the time of shipment the products

are packed inside special cardboard

containers.

The integrity of the contents during

transport is obtained by placing

protection material such as

polystyrene inside the packing.

The weight of the load to be handled

is always specified on the outside of

the packing.

With large supplies, the weight of the

load may exceed 30 kg.

In this case the loads must

not be handled manually.

Carry out these activities

using special lifting tools.

During manual handling (in case of

loads of less than 30 kg to be

handled) the personnel engaged in

this activity must wear safety shoes

and protective gloves.

The supply consists of:

- anodes (in the quantity required by

the customer and in the types

agreed on according to customer

needs)

- generator

- power cable

- low tension cable

- earth

- cap holder

- anode holder cap

- female faston

- operation LED (green and red)

- possible single-core cable for

2nd anode (if requested by

customer)

- cable glands and eyelet for

installation (present only in the

ACES device) (figure 2 on next

page).

9.1 WARRANTY SERVICES

ACES line products are covered for the

period envisaged for the European

guarantee (2 years) starting from the

purchase invoice date . The warranty

entitles the purchaser to replacement

of the product or its repair (if feasible)

in case of any operation defects

occurring within 2 years of the date of

purchase.

9.2 WARRANTY PROVISIONS

If the validity of the warranty rights is

ascertained, the product will be

returned at the manufacturer’s

expense.

Replacement of the product is not

envisaged whenever the fault depends

on:

- incorrect or improper use;

- fraudulent tampering or behaviour by

the user contrary to the

manufacturer’s instructions referred

to in this manual;

- connection not complying with the

technical and safety regulations in

the user’s country;

- if the product was open or repaired

by the customer himself or by

unauthorised personnel.

If, on checking the device, it is

found that the present damage is

not covered by the warranty, the

cost incurred by such checking

shall be borne by the customer.

Products not covered by warranty

will only be repaired at the

customer’s expense.

If the lack of right to the warranty

is ascertained, MG ANODI will get

the opinion of the customer who

shall inform MG ANODI regarding

what to do

(if to proceed or not

with repair or

replacement at his

own expense).

Equipment used in the domestic

environment

According to the current European

regulations, electrical and electronic

equipment must be disposed of

differently from domestic waste.

Private individuals residing in

EU member countries have free access

to the special electrical/electronic

waste collection areas.

For more information contact the

authority in charge of disposal

operations for such products in your

country.

In some EU countries, when

purchasing a new product the local

dealer is obliged to collect the old

product. Contact the dealer for further

information.

Equipment used in workplaces

Even in case of equipment used in the

workplace, it must be disposed of in

compliance with the current

regulations in the country.

Current European regulations require

such types of waste to be disposed of

according to specific procedures.

Before carrying out disposal, contact

the dealer to find out if there are

specific collection programmes.

4

9

4. SUPPLY SPECIFICATIONS

6

8

10

1

3

9

4

5

2

7

figure 1

key

9. WARRANTY 10. INFORMATION

REGARDING DISPOSAL

1

generator

2

power

cable

3

low

tension cable

4

earth

5

anode

holder

cap

6

anode

7

female

faston

8

operation

green

-

red

LED

9

cable

glands

10

eyelets

for

assembly

At the time of shipment the products

are packed inside special cardboard

containers.

The integrity of the contents during

transport is obtained by placing

protection material such as

polystyrene inside the packing.

The weight of the load to be handled

is always specified on the outside of

the packing.

With large supplies, the weight of the

load may exceed 30 kg.

In this case the loads must

not be handled manually.

Carry out these activities

using special lifting tools.

During manual handling (in case of

loads of less than 30 kg to be

handled) the personnel engaged in

this activity must wear safety shoes

and protective gloves.

The supply consists of:

- anodes (in the quantity required by

the customer and in the types

agreed on according to customer

needs)

- generator

- power cable

- low tension cable

- earth

- cap holder

- anode holder cap

- female faston

- operation LED (green and red)

- possible single-core cable for

2nd anode (if requested by

customer)

- cable glands and eyelet for

installation (present only in the

ACES device) (figure 2 on next

page).

9.1 WARRANTY SERVICES

ACES line products are covered for the

period envisaged for the European

guarantee (2 years) starting from the

purchase invoice date . The warranty

entitles the purchaser to replacement

of the product or its repair (if feasible)

in case of any operation defects

occurring within 2 years of the date of

purchase.

9.2 WARRANTY PROVISIONS

If the validity of the warranty rights is

ascertained, the product will be

returned at the manufacturer’s

expense.

Replacement of the product is not

envisaged whenever the fault depends

on:

- incorrect or improper use;

- fraudulent tampering or behaviour by

the user contrary to the

manufacturer’s instructions referred

to in this manual;

- connection not complying with the

technical and safety regulations in

the user’s country;

- if the product was open or repaired

by the customer himself or by

unauthorised personnel.

If, on checking the device, it is

found that the present damage is

not covered by the warranty, the

cost incurred by such checking

shall be borne by the customer.

Products not covered by warranty

will only be repaired at the

customer’s expense.

If the lack of right to the warranty

is ascertained, MG ANODI will get

the opinion of the customer who

shall inform MG ANODI regarding

what to do

(if to proceed or not

with repair or

replacement at his

own expense).

Equipment used in the domestic

environment

According to the current European

regulations, electrical and electronic

equipment must be disposed of

differently from domestic waste.

Private individuals residing in

EU member countries have free access

to the special electrical/electronic

waste collection areas.

For more information contact the

authority in charge of disposal

operations for such products in your

country.

In some EU countries, when

purchasing a new product the local

dealer is obliged to collect the old

product. Contact the dealer for further

information.

Equipment used in workplaces

Even in case of equipment used in the

workplace, it must be disposed of in

compliance with the current

regulations in the country.

Current European regulations require

such types of waste to be disposed of

according to specific procedures.

Before carrying out disposal, contact

the dealer to find out if there are

specific collection programmes.

4

9

4. SUPPLY SPECIFICATIONS

6

8

10

1

3

9

4

5

2

7

figure 1

key

9. WARRANTY 10. INFORMATION

REGARDING DISPOSAL

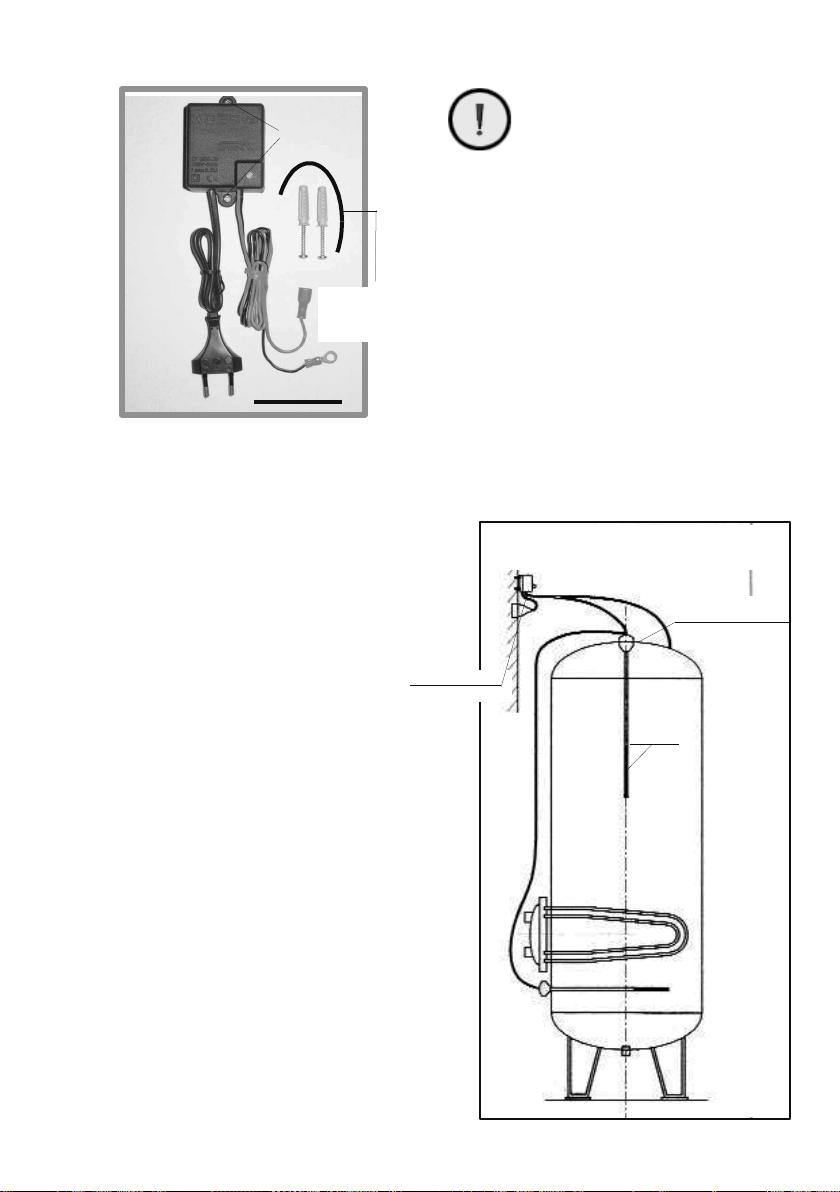

ACES

FIXING

HOLES

PLASTIC PLUGS

SCREWS

figure

3.1

Non-compliance with these

instructions and therefore

inverting polarities annuls the

anticorrosive power of the

equipment.

Connect the power outlet after

making sure the mains current

matches the data given on the rating

plate of the device (Volt 230

±

10,

Hz. 50/60) and that the mains voltage

is applied continuously.

The power outlet is also used as a

disconnecting device.

Therefore it must be easily

accessible to the user.

For safety reasons, the tank

for heating the water must

not work for long periods

without water being drawn.

The power outlet cannot be

disconnected when the

heating tank is full,

otherwise the anticorrosion

protection is annulled.

As already illustrated, the ACES device

is equipped with a fault diagnosis

system with the LED on the box of the

device lighting up.

When started, if everything works

properly the LED of the device

lights up green.

If the LED lights up red, it means

there is a fault.

In this case, the user must:

- make sure there is water in the tank;

- make sure the power plug is

connected and that there is current;

- make sure the earth of the device’s

circuit is properly connected,

otherwise the circuit does not close

and the device cannot work.

8

If all the above checks gave

negative results and no faults

explaining lighting up of the red

LED were found, avoid carrying

out any activity and contact the

manufacturer

The above-mentioned device does not

require any kind of maintenance work.

In normal conditions and with correct

use it will work for decades.

MG ANODI INTERNATIONAL does

not provide for the supply of

spare

parts, because in normal conditions

and with correct use of the

device

none of its parts should wear

out to

the point of requiring replacement.

In case of specific requests by the

user, MG ANODI INTERNATIONAL can

supply any additional anodes with

respective single-core

cable.

The user must check the

contents of the supply upon

delivery.

In case of errors or

omissions, contact the manufactu-

rer.

Note:

The size of the anodes depends on the

capacity of the tank, with reference to

the DIN 4753 table.

figure 2: ACES device with double anode

5.1 Electronic device installation

The ACES device can be fixed to the

wall or ceiling (the method is the same

both for ACES and ACES G2).

In both cases, proceed as follows (see

figures 3.1 and 3.2):

- make two holes (in the wall or

ceiling) for inserting the fixing

screws.

- Insert plastic plugs, suitable for

fixing screws, in the two holes.

5

- Position the device, matching the

holes in the device with those obtained

in the wall or ceiling.

- Insert the fixing screws (of length

according to the depth of the holes

made and the type of product; ACES

requires larger screws, ACES G2

requires smaller screws).

- fix the screws and check the solidity

and tightness of the fixing.

5.2 Anode installation

To fit the anode on the tank, the

tank must be arranged to receive

the anode support, i.e. the tank

must be provided with a special

hole whose diameter must not be

less that 1/2”-conical gas for inserting

the anode.

Note:

If the diameter of the hole for the

anode is more than 1/2”, the anode

must be equipped with a special

reduction adapter to ensure its perfect

insertion inside the tank. The user must

procure the suitable galvanised

reduction adapter.

5. INSTALLATION AND

STARTUP

8. SPARE PARTS

7. MAINTENANCE

6. TROUBLESHOOTING

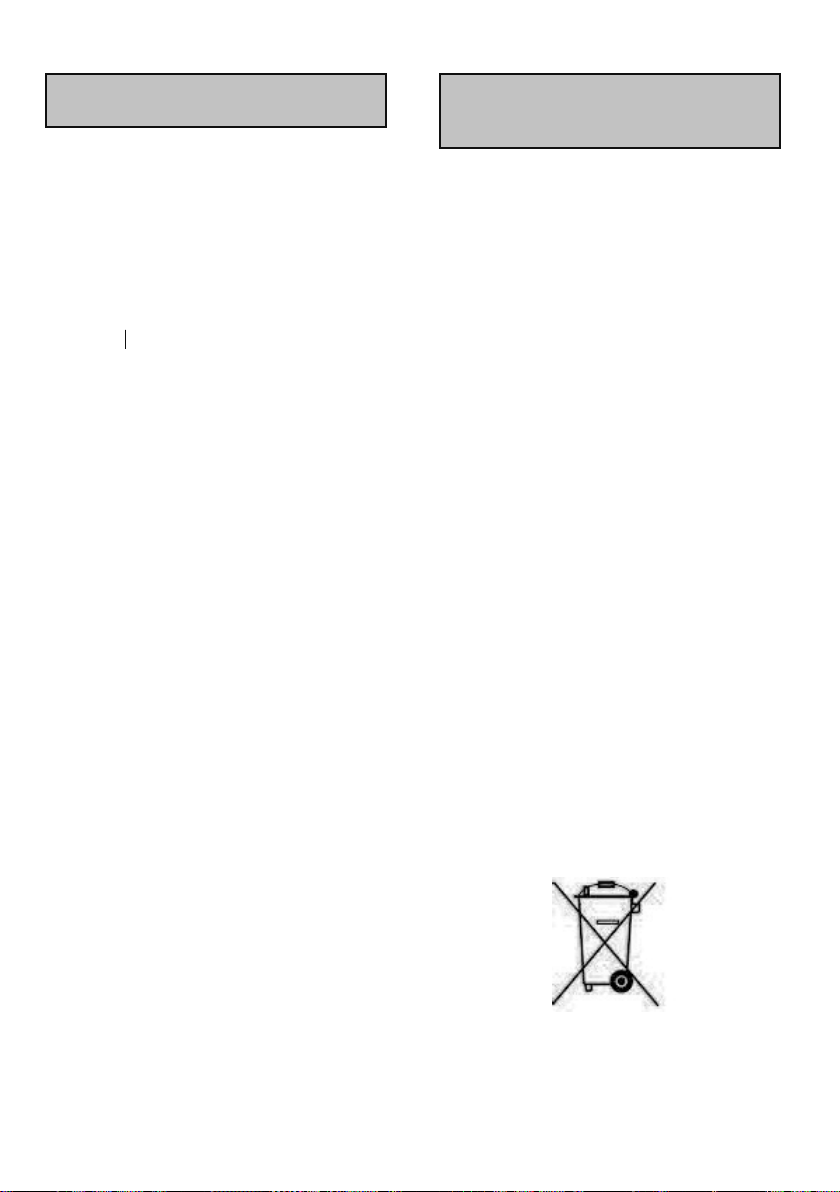

figure

4.1:

example

of

assembly

on boiler - exchanger

inlet hole

anode support

wall-mounted

generator

anode

anode

6

anode support inlet hole

anode

wall-mounted

generator

wall-mounted

generator

anode

anode support inlet hole

figure 3.2

FIXING

HOLES

PLASTIC

PLUGS AND

SCREWS

ACES G2

The anode is supplied protected

by a plastic protection. Remove

the protection before installing

the anode. The user must not

operate in any way on the activated part

of the anode (terminal end), to clean it or

other, since similar activities could

damage the anode, neutralising its

anticorrosive effectiveness.

5.4 Startup

After carrying out the steps described

above (the first two steps can also be

carried out in reverse order to that

described):

-1- Insert the anode inside the hole

arranged on the tank (with the aid of

figure 4.2: example of assembly in water

heater-horizontal anode

figure 4.2: example of assembly in

water heater-vertical anode

5.3 Device installation

For tanks up to 1000 l. a single

anode can be fitted.

The anode holder cap must be

inserted inside the tank hole (figures

4.1, 4.2, 4.3) directly or using a

special reduction adapter as

described above.

For the ACES device to correctly

carry out its anticorrosive function, it

must be fitted in the geometric

centre of the tank (whether fitted

vertically or horizontally).

In case of large tanks holding more

than 1,000 litres, two anodes must

be installed and, regarding the

surface to be protected, the tank is

virtually divided into 3 parts (see

fig. 4.1)

In this case the two anodes must be

positioned so that the distance

between anode and tank walls is the

same, in order to obtain total

anticorrosive coverage of all the area

involved.

a special reduction adapter in case of

a larger hole);

-2- fix the anode by screwing it on the

hole in the tank;

-3- insert the low tension cable (positive

polarity), called faston, on the

anode;

-4- connect the cable with eyelet

(negative polarity) to the tank earth.

Connection to the tank earth is carried

out by inserting the eyelet of the cable

with negative polarity inside a special

screw on the tank casing

Every tank has a screw for the earth

connection (it may be in different places

on the tank casing, depending on the

boiler manufacturer).

At the end of the operations

described, carry out the following

checks:

- make sure the tank is full of water

(the pressure must be regular; check

with a manometer); in case of lack of

water, suitably fill;

- ensure correct polarity of the cables:

the wire ending with the faston

contact (positive polarity) must be

connected to the anode; the wire

ending with the eyelet (negative

polarity) must be connected to the

tank earth.

figure 4.3: example of assembly on

7

boiler

with

coil

anode support inlet hole

wall

-

mounted

generator

anode

figure

4.1:

example

of

assembly

on boiler - exchanger

inlet hole

anode support

wall-mounted

generator

anode

anode

6

anode support inlet hole

anode

wall-mounted

generator

wall-mounted

generator

anode

anode support inlet hole

figure 3.2

FIXING

HOLES

PLASTIC

PLUGS AND

SCREWS

ACES G2

The anode is supplied protected

by a plastic protection. Remove

the protection before installing

the anode. The user must not

operate in any way on the activated part

of the anode (terminal end), to clean it or

other, since similar activities could

damage the anode, neutralising its

anticorrosive effectiveness.

5.4 Startup

After carrying out the steps described

above (the first two steps can also be

carried out in reverse order to that

described):

-1- Insert the anode inside the hole

arranged on the tank (with the aid of

figure 4.2: example of assembly in water

heater-horizontal anode

figure 4.2: example of assembly in

water heater-vertical anode

5.3 Device installation

For tanks up to 1000 l. a single

anode can be fitted.

The anode holder cap must be

inserted inside the tank hole (figures

4.1, 4.2, 4.3) directly or using a

special reduction adapter as

described above.

For the ACES device to correctly

carry out its anticorrosive function, it

must be fitted in the geometric

centre of the tank (whether fitted

vertically or horizontally).

In case of large tanks holding more

than 1,000 litres, two anodes must

be installed and, regarding the

surface to be protected, the tank is

virtually divided into 3 parts (see

fig. 4.1)

In this case the two anodes must be

positioned so that the distance

between anode and tank walls is the

same, in order to obtain total

anticorrosive coverage of all the area

involved.

a special reduction adapter in case of

a larger hole);

-2- fix the anode by screwing it on the

hole in the tank;

-3- insert the low tension cable (positive

polarity), called faston, on the

anode;

-4- connect the cable with eyelet

(negative polarity) to the tank earth.

Connection to the tank earth is carried

out by inserting the eyelet of the cable

with negative polarity inside a special

screw on the tank casing

Every tank has a screw for the earth

connection (it may be in different places

on the tank casing, depending on the

boiler manufacturer).

At the end of the operations

described, carry out the following

checks:

- make sure the tank is full of water

(the pressure must be regular; check

with a manometer); in case of lack of

water, suitably fill;

- ensure correct polarity of the cables:

the wire ending with the faston

contact (positive polarity) must be

connected to the anode; the wire

ending with the eyelet (negative

polarity) must be connected to the

tank earth.

figure 4.3: example of assembly on

7

boiler

with

coil

anode support inlet hole

wall

-

mounted

generator

anode

ACES

FIXING

HOLES

PLASTIC PLUGS

SCREWS

figure

3.1

Non-compliance with these

instructions and therefore

inverting polarities annuls the

anticorrosive power of the

equipment.

Connect the power outlet after

making sure the mains current

matches the data given on the rating

plate of the device (Volt 230

±

10,

Hz. 50/60) and that the mains voltage

is applied continuously.

The power outlet is also used as a

disconnecting device.

Therefore it must be easily

accessible to the user.

For safety reasons, the tank

for heating the water must

not work for long periods

without water being drawn.

The power outlet cannot be

disconnected when the

heating tank is full,

otherwise the anticorrosion

protection is annulled.

As already illustrated, the ACES device

is equipped with a fault diagnosis

system with the LED on the box of the

device lighting up.

When started, if everything works

properly the LED of the device

lights up green.

If the LED lights up red, it means

there is a fault.

In this case, the user must:

- make sure there is water in the tank;

- make sure the power plug is

connected and that there is current;

- make sure the earth of the device’s

circuit is properly connected,

otherwise the circuit does not close

and the device cannot work.

8

If all the above checks gave

negative results and no faults

explaining lighting up of the red

LED were found, avoid carrying

out any activity and contact the

manufacturer

The above-mentioned device does not

require any kind of maintenance work.

In normal conditions and with correct

use it will work for decades.

MG ANODI INTERNATIONAL does

not provide for the supply of

spare

parts, because in normal conditions

and with correct use of the

device

none of its parts should wear

out to

the point of requiring replacement.

In case of specific requests by the

user, MG ANODI INTERNATIONAL can

supply any additional anodes with

respective single-core

cable.

The user must check the

contents of the supply upon

delivery.

In case of errors or

omissions, contact the manufactu-

rer.

Note:

The size of the anodes depends on the

capacity of the tank, with reference to

the DIN 4753 table.

figure 2: ACES device with double anode

5.1 Electronic device installation

The ACES device can be fixed to the

wall or ceiling (the method is the same

both for ACES and ACES G2).

In both cases, proceed as follows (see

figures 3.1 and 3.2):

- make two holes (in the wall or

ceiling) for inserting the fixing

screws.

- Insert plastic plugs, suitable for

fixing screws, in the two holes.

5

- Position the device, matching the

holes in the device with those obtained

in the wall or ceiling.

- Insert the fixing screws (of length

according to the depth of the holes

made and the type of product; ACES

requires larger screws, ACES G2

requires smaller screws).

- fix the screws and check the solidity

and tightness of the fixing.

5.2 Anode installation

To fit the anode on the tank, the

tank must be arranged to receive

the anode support, i.e. the tank

must be provided with a special

hole whose diameter must not be

less that 1/2”-conical gas for inserting

the anode.

Note:

If the diameter of the hole for the

anode is more than 1/2”, the anode

must be equipped with a special

reduction adapter to ensure its perfect

insertion inside the tank. The user must

procure the suitable galvanised

reduction adapter.

5. INSTALLATION AND

STARTUP

8. SPARE PARTS

7. MAINTENANCE

6. TROUBLESHOOTING

1

generator

2

power

cable

3

low

tension cable

4

earth

5

anode

holder

cap

6

anode

7

female

faston

8

operation

green

-

red

LED

9

cable

glands

10

eyelets

for

assembly

At the time of shipment the products

are packed inside special cardboard

containers.

The integrity of the contents during

transport is obtained by placing

protection material such as

polystyrene inside the packing.

The weight of the load to be handled

is always specified on the outside of

the packing.

With large supplies, the weight of the

load may exceed 30 kg.

In this case the loads must

not be handled manually.

Carry out these activities

using special lifting tools.

During manual handling (in case of

loads of less than 30 kg to be

handled) the personnel engaged in

this activity must wear safety shoes

and protective gloves.

The supply consists of:

- anodes (in the quantity required by

the customer and in the types

agreed on according to customer

needs)

- generator

- power cable

- low tension cable

- earth

- cap holder

- anode holder cap

- female faston

- operation LED (green and red)

- possible single-core cable for

2nd anode (if requested by

customer)

- cable glands and eyelet for

installation (present only in the

ACES device) (figure 2 on next

page).

9.1 WARRANTY SERVICES

ACES line products are covered for the

period envisaged for the European

guarantee (2 years) starting from the

purchase invoice date . The warranty

entitles the purchaser to replacement

of the product or its repair (if feasible)

in case of any operation defects

occurring within 2 years of the date of

purchase.

9.2 WARRANTY PROVISIONS

If the validity of the warranty rights is

ascertained, the product will be

returned at the manufacturer’s

expense.

Replacement of the product is not

envisaged whenever the fault depends

on:

- incorrect or improper use;

- fraudulent tampering or behaviour by

the user contrary to the

manufacturer’s instructions referred

to in this manual;

- connection not complying with the

technical and safety regulations in

the user’s country;

- if the product was open or repaired

by the customer himself or by

unauthorised personnel.

If, on checking the device, it is

found that the present damage is

not covered by the warranty, the

cost incurred by such checking

shall be borne by the customer.

Products not covered by warranty

will only be repaired at the

customer’s expense.

If the lack of right to the warranty

is ascertained, MG ANODI will get

the opinion of the customer who

shall inform MG ANODI regarding

what to do

(if to proceed or not

with repair or

replacement at his

own expense).

Equipment used in the domestic

environment

According to the current European

regulations, electrical and electronic

equipment must be disposed of

differently from domestic waste.

Private individuals residing in

EU member countries have free access

to the special electrical/electronic

waste collection areas.

For more information contact the

authority in charge of disposal

operations for such products in your

country.

In some EU countries, when

purchasing a new product the local

dealer is obliged to collect the old

product. Contact the dealer for further

information.

Equipment used in workplaces

Even in case of equipment used in the

workplace, it must be disposed of in

compliance with the current

regulations in the country.

Current European regulations require

such types of waste to be disposed of

according to specific procedures.

Before carrying out disposal, contact

the dealer to find out if there are

specific collection programmes.

4

9

4. SUPPLY SPECIFICATIONS

6

8

10

1

3

9

4

5

2

7

figure 1

key

9. WARRANTY 10. INFORMATION

REGARDING DISPOSAL

ACES

FIXING

HOLES

PLASTIC PLUGS

SCREWS

figure

3.1

Non-compliance with these

instructions and therefore

inverting polarities annuls the

anticorrosive power of the

equipment.

Connect the power outlet after

making sure the mains current

matches the data given on the rating

plate of the device (Volt 230

±

10,

Hz. 50/60) and that the mains voltage

is applied continuously.

The power outlet is also used as a

disconnecting device.

Therefore it must be easily

accessible to the user.

For safety reasons, the tank

for heating the water must

not work for long periods

without water being drawn.

The power outlet cannot be

disconnected when the

heating tank is full,

otherwise the anticorrosion

protection is annulled.

As already illustrated, the ACES device

is equipped with a fault diagnosis

system with the LED on the box of the

device lighting up.

When started, if everything works

properly the LED of the device

lights up green.

If the LED lights up red, it means

there is a fault.

In this case, the user must:

- make sure there is water in the tank;

- make sure the power plug is

connected and that there is current;

- make sure the earth of the device’s

circuit is properly connected,

otherwise the circuit does not close

and the device cannot work.

8

If all the above checks gave

negative results and no faults

explaining lighting up of the red

LED were found, avoid carrying

out any activity and contact the

manufacturer

The above-mentioned device does not

require any kind of maintenance work.

In normal conditions and with correct

use it will work for decades.

MG ANODI INTERNATIONAL does

not provide for the supply of

spare

parts, because in normal conditions

and with correct use of the

device

none of its parts should wear

out to

the point of requiring replacement.

In case of specific requests by the

user, MG ANODI INTERNATIONAL can

supply any additional anodes with

respective single-core

cable.

The user must check the

contents of the supply upon

delivery.

In case of errors or

omissions, contact the manufactu-

rer.

Note:

The size of the anodes depends on the

capacity of the tank, with reference to

the DIN 4753 table.

figure 2: ACES device with double anode

5.1 Electronic device installation

The ACES device can be fixed to the

wall or ceiling (the method is the same

both for ACES and ACES G2).

In both cases, proceed as follows (see

figures 3.1 and 3.2):

- make two holes (in the wall or

ceiling) for inserting the fixing

screws.

- Insert plastic plugs, suitable for

fixing screws, in the two holes.

5

- Position the device, matching the

holes in the device with those obtained

in the wall or ceiling.

- Insert the fixing screws (of length

according to the depth of the holes

made and the type of product; ACES

requires larger screws, ACES G2

requires smaller screws).

- fix the screws and check the solidity

and tightness of the fixing.

5.2 Anode installation

To fit the anode on the tank, the

tank must be arranged to receive

the anode support, i.e. the tank

must be provided with a special

hole whose diameter must not be

less that 1/2”-conical gas for inserting

the anode.

Note:

If the diameter of the hole for the

anode is more than 1/2”, the anode

must be equipped with a special

reduction adapter to ensure its perfect

insertion inside the tank. The user must

procure the suitable galvanised

reduction adapter.

5. INSTALLATION AND

STARTUP

8. SPARE PARTS

7. MAINTENANCE

6. TROUBLESHOOTING

ACES TECHNICAL CARD

Generator dimensions:

an impressed current electronic device

for cathodic

protection against corrosion

in

enamelled /

vitrified

boilers of up to 5,000 litres capacity.

Technical characteristics:

Power supply

Voltage:

230 Volt ± 10%

Frequency:

50/60 Hz

max. output voltage: 13VDC

max. output current: 0.25 A

protection rating: IP 55

max. input: 4.5 W

operating temperature from 0 to 50°

double electrical insulation

Generator dimensions:

nominal external dimensions of generator: 60x52x45 mm.

weight:

approx. 0.40 kg

cable with flat plug: length 1900 mm

low tension cable: length 1900 mm

TITANIUM ELECTRODE (ACES AND ACES G2)

Description of the product:

a current delivery and

measurement device with coating in noble metal.

Size of electrodes:

various sizes depending on the

characteristics of the tanks to be protected

size of treated part: 3 mm

For stainless steel, MG ANODI INTERNATIONAL will prepare a

design according to the

characteristics and capacity of the boiler.

Maintaining of the potential is

guaranteed through constant

periodical measurement of the

difference in potential between the

boiler and the titanium anode.

According to measurement results, the

electronic device of the equipment

adjusts the current potential the

titanium anode must deliver in order to

guarantee optimum protection against

corrosion.

The anode consists of a 3 mm

diameter titanium rod (figure 1 on next

page).

One of the two ends of the anode is

treated by means of an

electrochemical activation process

<6> and the other non-activated end

is equipped with a threaded cap in

special plastic material of diameter

1/2”, conical gas <5>.

Only the terminal end of the anode

(whose length can vary) is

electrochemically activated and able to

impress current, whereas the other

part of the anode does not undergo the

above-mentioned treatment and its

purpose is to convey the current near

the activated area. The electronic

device is housed in a plastic container

resistant to high temperatures <1>.

Correct operation of the device is

monitored by a special sensor and

indicated by a LED located in the front

of the equipment <8>.

If the LED lights up green it

means that the device is

working properly; if it lights up

red, the LED signals an operation

fault.

The correct polarity of the

cables

must

be

strictly

respected during

the

installation stage: the wire

ending with the faston contact

(positive polarity) must be connected

to the anode; the wire ending with the

eyelet (negative polarity) must be

connected to the tank earth.

Failure to comply with this instruction

implies improper use and invalidates

the warranty.

Also, the earth (eyelet) must be

secured to the tank.

The earth (eyelet) MUST NEVER be

connected to the pipes entering or

leaving the tank.

3.1 Permissible/improper use

The device in question must only be

used as an anticorrosion device for

enamelled/vitrified boilers or boilers in

stainless steel. It cannot be used for

different types of boilers and must be

installed and used according to the

instructions given in this handbook.

Any use different from that for which

the product is intended and any non-

compliance with the instructions given

in this handbook implies non-

compliance with the product’s

intended use.

The manufacturer declines

any liability for damage or

injury caused by improper

and non-conforming use of

the product.

3

This handbook must be consulted by

the customer for correct installation

and use of the product.

The user must strictly comply with the

safety instructions given in it.

The manufacturer declines any liability

for injury or damage due to improper

use (§ 3) of the product and/or failure

to apply the rules for safe operation

described in this handbook.

Keeping the handbook

This handbook must be kept carefully

and in good condition by the user.

If it is lost, the user can request a new

copy from the manufacturer on

payment.

Given below are the symbols present

in this publication, together with their

respective meanings.

READ THE MANUAL CAREFULLY

indicates cases or situations

where the user must refer to

the instructions present in the

manual in order to carry out a

given operation correctly and

safely.

WARNING

The warning messages

indicate the risk of accident

or danger during operation or

maintenance work, if the procedures

and conditions described are not

carefully observed.

ATTENTION

The attention messages

indicate risk of damage to

the equipment during operation or

maintenance work, if the procedures

and conditions described are not

carefully observed.

NOTE: The notes bring the

user’s attention to important

information regarding the matter,

application or procedure.

The ACES device is an impressed

current cathodic protection electronic

system for boilers and water heaters.

Its purpose is to annul the corrosive

effect that the water would have on

the tank lining.

It is also extremely effective against

the presence of microorganisms

harmful to health, such as legionella

pneumophila. There are two product

types: ACES and ACES G2, which

differ for the type of application.

ACES is installed on enamelled and

vitrified boilers of up to 5,000 litres

capacity.

ACES G2 is always installed on the

same types of boilers, with capacities

of up to 1,000 litres. In case of

unfavourable conditions or containers

holding more than 5,000 litres, the

use of two or more generators is

provided for. The ACES system

provides cathodic protection against

corrosion, obtained by ensuring the

potential of the electrolyte by means

of an impressed current produced by

the device.

ACES G2 TECHNICAL CARD

For stainless steel, MG ANODI INTERNATIONAL will prepare a

design according to the

characteristics and capacity of the boiler.

2

3. DESCRIPTION OF PRODUCT

PERMISSIBLE/

IMPROPER USE

2. SYMBOLS

Description of the product:

an impressed current electronic

device for cathodic protection against corrosion in enamelled /

vitrified boilers of up to 1,000 litres capacity.

Electrical characteristics:

Power supply

Voltage:

230 ± 10% Volt

Frequency:

50/60 Hz

max. output voltage: 16VDC

max. output current: 0.13 A

protection rating: IP 55

max. input: 3.2 W

Generator dimensions:

nominal external dimensions of generator: 60x52x35.5 mm.

weight:

approx. 0.26 kg

cable with flat plug: length 1900 mm

low tension cable: length 1900 mm

TITANIUM ELECTRODE (ACES AND ACES G2)

Description of the product:

a current delivery and

measurement device with coating in noble metal

Size of electrodes:

various lengths depending on the

characteristics of the tanks to be protected

size of treated part: 3 mm

ACES TECHNICAL CARD

Generator dimensions:

an impressed current electronic device

for cathodic

protection against corrosion

in

enamelled /

vitrified

boilers of up to 5,000 litres capacity.

Technical characteristics:

Power supply

Voltage:

230 Volt ± 10%

Frequency:

50/60 Hz

max. output voltage: 13VDC

max. output current: 0.25 A

protection rating: IP 55

max. input: 4.5 W

operating temperature from 0 to 50°

double electrical insulation

Generator dimensions:

nominal external dimensions of generator: 60x52x45 mm.

weight:

approx. 0.40 kg

cable with flat plug: length 1900 mm

low tension cable: length 1900 mm

TITANIUM ELECTRODE (ACES AND ACES G2)

Description of the product:

a current delivery and

measurement device with coating in noble metal.

Size of electrodes:

various sizes depending on the

characteristics of the tanks to be protected

size of treated part: 3 mm

For stainless steel, MG ANODI INTERNATIONAL will prepare a

design according to the

characteristics and capacity of the boiler.

Maintaining of the potential is

guaranteed through constant

periodical measurement of the

difference in potential between the

boiler and the titanium anode.

According to measurement results, the

electronic device of the equipment

adjusts the current potential the

titanium anode must deliver in order to

guarantee optimum protection against

corrosion.

The anode consists of a 3 mm

diameter titanium rod (figure 1 on next

page).

One of the two ends of the anode is

treated by means of an

electrochemical activation process

<6> and the other non-activated end

is equipped with a threaded cap in

special plastic material of diameter

1/2”, conical gas <5>.

Only the terminal end of the anode

(whose length can vary) is

electrochemically activated and able to

impress current, whereas the other

part of the anode does not undergo the

above-mentioned treatment and its

purpose is to convey the current near

the activated area. The electronic

device is housed in a plastic container

resistant to high temperatures <1>.

Correct operation of the device is

monitored by a special sensor and

indicated by a LED located in the front

of the equipment <8>.

If the LED lights up green it

means that the device is

working properly; if it lights up

red, the LED signals an operation

fault.

The correct polarity of the

cables

must

be

strictly

respected during

the

installation stage: the wire

ending with the faston contact

(positive polarity) must be connected

to the anode; the wire ending with the

eyelet (negative polarity) must be

connected to the tank earth.

Failure to comply with this instruction

implies improper use and invalidates

the warranty.

Also, the earth (eyelet) must be

secured to the tank.

The earth (eyelet) MUST NEVER be

connected to the pipes entering or

leaving the tank.

3.1 Permissible/improper use

The device in question must only be

used as an anticorrosion device for

enamelled/vitrified boilers or boilers in

stainless steel. It cannot be used for

different types of boilers and must be

installed and used according to the

instructions given in this handbook.

Any use different from that for which

the product is intended and any non-

compliance with the instructions given

in this handbook implies non-

compliance with the product’s

intended use.

The manufacturer declines

any liability for damage or

injury caused by improper

and non-conforming use of

the product.

3

DICHIARAZIONE DI CONFORMITA’/

DECLARATION OF CONFORMITY

Fabbricante/Manufacturer:

MG ANODI INTERNATIONAL AD

Velikotarnovsko Shosse 1

5400 Sevlievo – Bulgaria

Descrizione del prodotto/

Product(s) description: Dispostivo elettronico anticorrosione per

bollitori/Electronic devices for boilers and

water-heaters corrosion prevention:

Modello (i)/Model(s): A C E S Serie H

A C E S G 2

Si certifica sotto la nostra esclusiva responsabilità che i prodotti a cui si riferisce la

presente dichiarazione sono conformi alle seguenti Direttive europee/

We hereby certify under our sole responsability, that the product(s) to which this

declaration relates is/are in conformity with the requirements of the following

European Directives:

Council Directive 89/336/EEC Directive (Electromagnetic Compatibility),

Council Directive73/23EEC Directive (Low Voltage Equipement Safety)

Council Directive 2001/95/EC Directive (General Product Safety).

E alle seguenti norme armonizzate / and with the following European Standards

CONTENTS

1 Using the manual 1

2 Symbols 2

3 Description of the product

3.1 Permissible/improper use

3

4 Supply specifications 4

5 Installation and startup 5

5.1 Electronic device installation

5

5.2 Anode installation

5

5.3 Device installation

5.4 Startup

6

6 Troubleshooting 8

7 Maintenance 8

8 Spare parts 8

9 Warranty 9

10 Instructions regarding disposal 9

ACES - ACES G2 technical card 10-11

Manufacturer’s declaration of conformity 12

English

EN 60065 (2004):Audio, video and similair electronic apparatus Safety

requirements

EN 55011 (2011) CISPR 11/A1:2010-03 ;

EN 61000-4-3 (2007)- radiated immunity (10V/m,80-1000MHz, AM 80%)

EN 61000-4-6 (2011) - conducted RF immunity (10Vrms,0.15-80MHz,AM80%)

EN 61000-4-2 (2011) - electrostatic discharge (8 KV air, 4 KV contact)

EN 61000-4-4/A1 (2010) - BURST (2 KV, 5 kHz)

EN 61000-3-2/A1/A2 (2011) - harmonic current emissions

Sevlievo, 01/07/2016

Luca De Stefani, General Manager

Introduction

These operating instructions apply

to the products called ACES and

ACES G2.

The ACES device is an impressed

current cathodic protection system

for enamelled/vitrified or stainless

steel boilers of up to 5,000 litres

capacity.

The ACES G2 device is also an

impressed current cathodic

protection system for enamelled/

vitrified boilers of up to 1,000 litres

capacity.

This instruction handbook always comes

with the product, and is placed inside

the packing.

The last page of this handbook contains

the manufacturer’s declaration of

conformity, which must be kept by the

user together with the handbook and

shown to the competent supervisory

authority on the occasion of any checks

or inspections.

1

1. USING THE INSTRUCTIONS

This manual suits for next models

1

Table of contents