EM-9502-A Rev.7 P. 1 / 5

MG CO., LTD. www.mgco.jp

5-2-55 Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

INSTRUCTION MANUAL

DC INPUT DIGITAL PANEL METER

(4 1/2 digit, LED display type) MODEL 47LV

BEFORE USE ....

Thank you for choosing us. Before use, please check con-

tents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact our sales office or representatives.

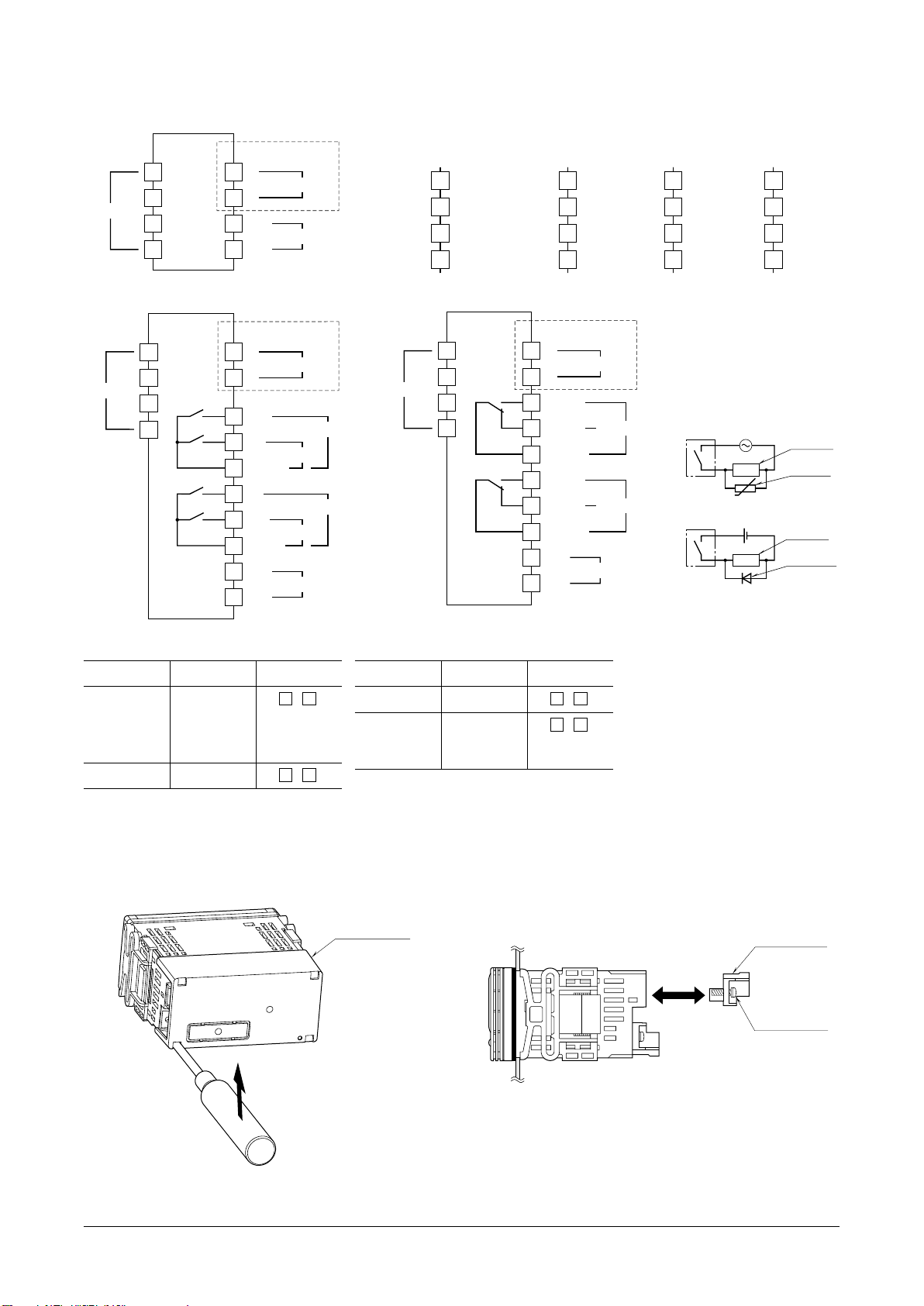

■PACKAGE INCLUDES:

Digital panel meter

(body + mounting bracket × 2 + watertight packing)........(1)

Engineering unit sticker label sheet..................................(1)

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

For detailed explanations to operate and program the mod-

ule, please refer to Model 47LV Operating Manual (EM-

9502-B), downloadable at our web site.

2.00 marked parameters are usable with the product ver-

sion 2.00 or higher.

POINTS OF CAUTION

■CONFORMITY WITH EU DIRECTIVES

• This equipment is suitable for Pollution Degree 2, Meas-

urement category II (alarm output, transient voltage

2500V) and Installation Category II (transient voltage

2500V). Reinforced insulation (input or DC output to

alarm output to power: 300V) and basic insulation (input

to DC output: 300V) are maintained. Prior to installation,

check that the insulation class of this unit satisfies the

system requirements.

• Altitude up to 2000 meters.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to con-

form to CE requirements. Failure to observe these re-

quirements may invalidate the CE conformance.

• The actual installation environments such as panel con-

figurations, connected devices, connected wires, may af-

fect the protection level of this unit when it is integrated

in a panel system. The user may have to review the CE

requirements in regard to the whole system and employ

additional protective measures to ensure the CE conform-

ity.

• In order to enable the operator to turn off the power in-

put immediately, install a switch or a circuit breaker ac-

cording to the relevant requirements in IEC 60947-2 and

properly indicate it.

■POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

100 – 240V AC rating: 85 – 264V, 50/60 Hz, approx. 6.5VA

24V DC rating: 24V ±10%, approx. 3W

110V DC rating: 85 – 150V, approx. 3W

■GENERAL PRECAUTIONS

• Before you remove the unit or mount it, turn off the power

supply and input signal for safety.

• Be sure to put the terminal cover on while the power is

supplied.

■ENVIRONMENT

• Indoor use.

• When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -10 to +55°C

(14 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

• Be sure that the ventilation slits are not covered with ca-

bles, etc.

■REQUIREMENTS TO ENSURE IP66

• Observe the designated panel cutout size (W92 ×H45

mm).

• The watertight packing included in the product package

must be placed behind the front cover.

• Both mounting brackets must be fastened tightly until

they hit the panel.

• Confirm visually that the packing is not contorted or ex-

cessively run off the edge after installation.

■WIRING

• Make sure for safety that only qualified personnel per-

form the wiring.

• Do not install cables close to noise sources (high frequen-

cy line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■EX-FACTORY SETTING (/SET)

• Activating “initialization” of Lockout Setting Mode, Ex-

factory settings or user’s specified parameters will be

deleted and overwritten with the factory default values.

Notice that after this, Ex-factory settings will be irrecov-

erable.

■AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.