MGF 120 Series User manual

mgf co.uk

UNDERSLUNG

LIFTING BEAM

CREATING SAFE WORKING ENVIRONMENTS

MODELS: 120 SERIES AND S80

With over 40 years of experience, MGF is a privately-owned company whose focus is the provision

of fully engineered excavation and structural support solutions and complimentary lifting and

safety equipment to the construction industry. We combine technical expertise and operational

performance to ensure the highest levels of customer service. With a focus on developing and

promoting industry best practice in excavation safety we aim to assist our customers in creating

safe working environments for their employees.

CUSTOMER SERVICE AND SUPPORT

The hire and sale of our products is fully supported by our team of qualified engineers,

experienced Technical Sales Representatives, hire desk and operational staff. Our hire centres

provide the focal point for service delivery where our hire desk team will be pleased to receive

your enquiry.

DELIVERY CAPABILITIES

Our dedicated fleet of vehicles offer a flexible solution to quickly meet our customers delivery

needs throughout the UK. We partner with several global shipping companies to ensure we can

quickly deliver our products on a global scale.

CREATING SAFE

WORKING ENVIRONMENTS

CONTENTS

SECTION 1: 120 SERIES UNDERSLUNG LIFTING BEAM

INTRODUCTION 4

SECTION 2: 120 SERIES UNDERSLUNG LIFTING BEAM

ASSEMBLY PROCEDURE 5

SECTION 3: S80 UNDERSLUNG LIFITNG BEAM INTRODUCTION 6

SECTION 4: S80 UNDERSLUNG LIFTING BEAM LOADING

OPTIONS 7

SECTION 5: S80 UNDERSLUNG LIFTING BEAM ASSEMBLY

PROCEDURE 9

SECTION 6: SAFE USE WARNINGS

PRE-LIFT CHECKS 10

ISSUE 1

MGF-GN36-r2-04/22-AW

MGF 120 Series Underslung Lifting Beams are available in two lengths of 3.5m and 4.25m,

each beam has a WLL of 2000kg making a pair capable of lifting 4000kg.

One of the intended applications for this product is handling static caravans. A pair of

beams achieve weight category D in accordance with NCC Code of Practice 501.

The 3.5m beam (product ID 2.9135) is suitable for 10ft wide caravans.

The 4.25m beam (product ID 2.9142) is suitable for 12ft wide caravans.

The system is provided as a rigid beam (A) with two 3.25t safety bow shackles (B).

It is recommended that the Underslung Lifting Beams are used in combination with either

MGF F55 Spreader Frames or S80 Spreader Beams above the caravan to prevent any

crushing effects.

PRODUCT

ID

HEIGHT WIDTH LENGTH WEIGHT

WLL* PER

LIFT POINT

WLL*

PER BEAM

SAFE LIFT

ZONE

NO LIFT

ZONE

(mm) (mm) (mm) (kg) (kg) (kg) (mm) (mm)

2.9135 200 132 3500 60 1,000 2,000 1260 980

2.9142 200 132 4250 70 1,000 2,000 1260 1730

*Working Load Limit

SPAN / CAPACITY CHART

UNDERSLUNG LIFTING BEAM TYPICAL SETUP

= Sling to vertical angle

B

A

SAFE LIFT ZONESAFE LIFT ZONE

SPAN

Figure 1: Typical beam setup

120 SERIES UNDERSLUNG

LIFTING BEAM

INTRODUCTION

NO LIFT ZONE

USER GUIDE SECTION 1

4

120 SERIES UNDERSLUNG LIFTING BEAM

120 SERIES UNDERSLUNG LIFTING BEAM - CARAVAN

HANDLING OVERVIEW

• Each beam has a WLL of 2,000kg

• 12ft caravans should be lifted with the 4.25m beams

• 10ft caravans should be lifted with the 3.50m beams

• Slings must be vertical [β] within 3° or less

• The designated caravan support points MUST be seated within the safe lift zone painted

yellow on the beam

• The caravan centre of gravity must be seated centrally on the beam to ensure a safe and

even lift, ensuring that lift points are not overloaded

• Prior to lifting, perform a test lift slightly above the ground to ensure that the load is

balanced

• Check the ID details on each component to ensure the correct lengths are used

• Connect suitable vertical slings (min. 1t WLL) to the lower shackles on either MGF

S80 Spreader Beams or F55 Spreader Frames, ensure lengths allow for clearance of

guttering etc.

• When using these beams with caravans position the Underslung Lifting Beams under

the caravan support points ensuring that they make contact within the ‘Safe Lift Zone’

• When using these lifting beams in other applications it is essential that the supports of

the item being lifted are within the ‘Safe Lift Zone’

• Connect the vertical slings to the 3.25t safety bow shackles [B] at each end of the lifting

beams

120 SERIES UNDERSLUNG

LIFTING BEAM ASSEMBLY

PROCEDURE

USER GUIDE SECTION 1 & 2

5

120 SERIES UNDERSLUNG LIFTING BEAM

S80 5m Spreader Extensions can be used as an underslung lifting beam in conjunction with

two end attachments in the configuration as shown below :

S80 UNDERSLUNG LIFTING

BEAM INTRODUCTION

PART REF DESCRIPTION PRODUCT ID WEIGHT/ITEM

(KG)

A85t Shackle 62

BDrop Link 2.9203 38

C55t Shackle 40

DEnd Attachment 2.9201 82

E5.0m Strut 2.9250 267

FTotal 16no. M20 x 65, grade 8.8 HT bolts, nuts and washers

Total Weight 711

A

B

C

DE

F

USER GUIDE SECTION 3

6

S80 UNDERSLUNG LIFTING BEAM

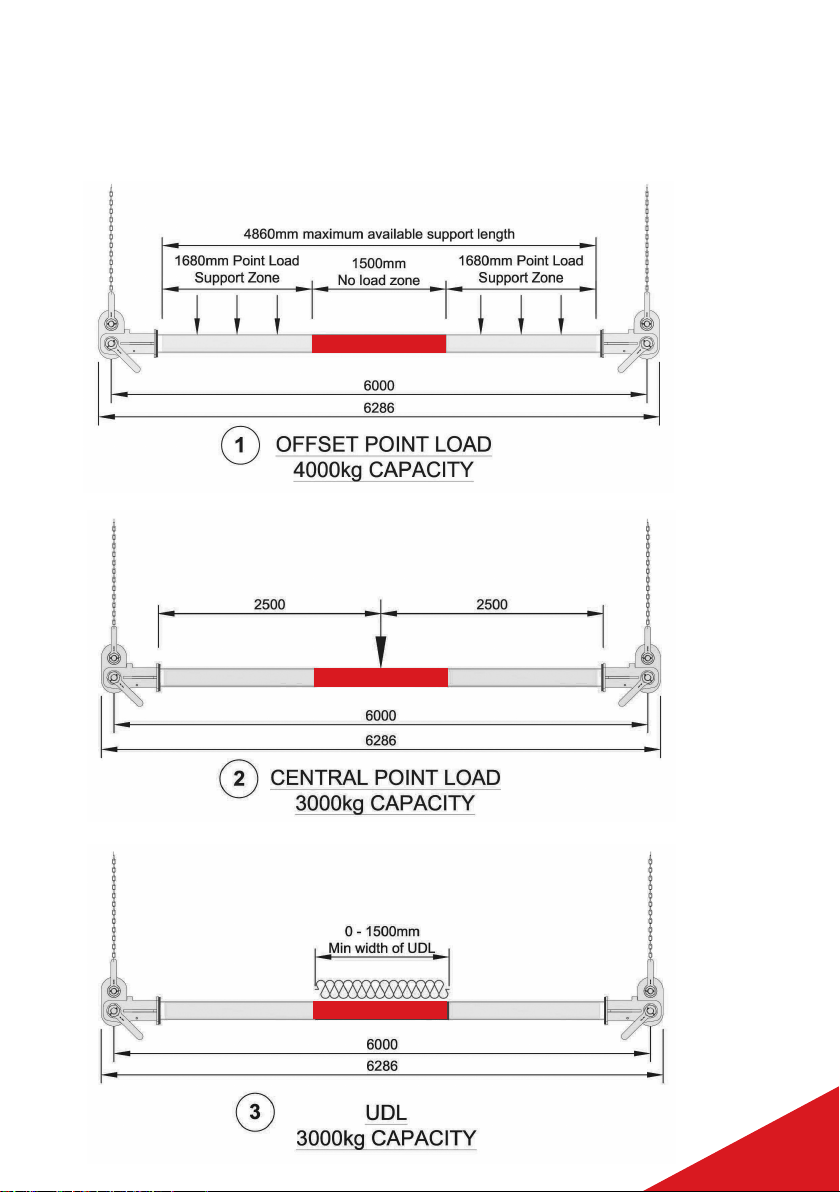

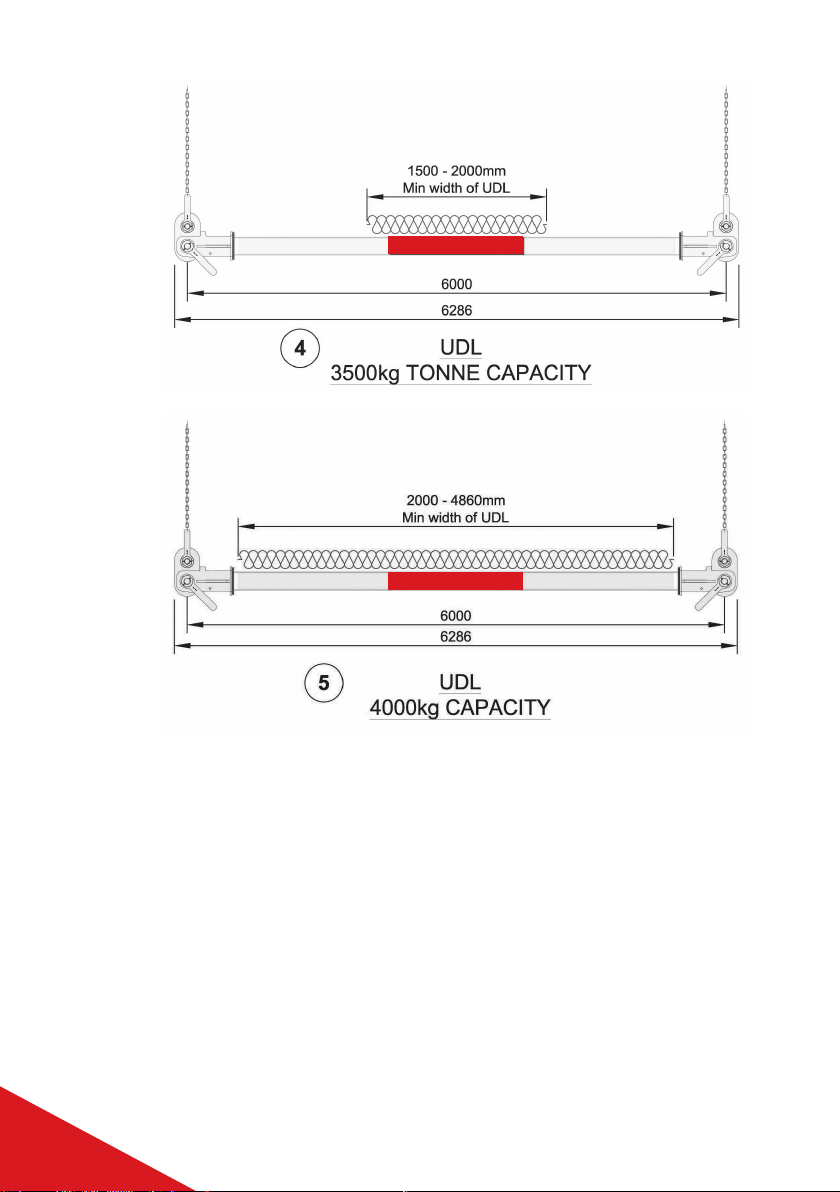

S80 UNDERSLUNG LIFTING

BEAM LOADING OPTIONS

USER GUIDE SECTION 4

7

S80 UNDERSLUNG LIFTING BEAM

1. The beam has a WLL of 4,000kg when point loads are applied as long as the 1.5m

central span is not loaded.

2. The beam has a WLL of 3,000kg when point loads are concentrated to the 1.5m central

portion of the beam.

3. The beam has a WLL of 3,000kg when load is applied as a UDL (universally distributed

load) over a span from 0 to 1.50m.

4. The beam has a WLL of 3,500kg when load is applied as a UDL (universally distributed

load) over a span from 1.5m to 2.0m.

5. The beam has a WLL of 4,000kg when load is applied as a UDL (universally distributed

load) over a span from 2.0 to 4.86m.

USER GUIDE SECTION 4

8

S80 UNDERSLUNG LIFTING BEAM

S80 UNDERSLUNG LIFTING

BEAM INTRODUCTION

• Check the ID details on each component to ensure the correct lengths are used

• Connect end attachments [D] to 5.0m S80 strut [E] with 8no. M20 x 65, grade 8.8 HT

bolts, nuts and washers [F] at each end. Tighten all bolts to a minimum torque of

240Nm, 2 threads minimum must be visible beyond the nut. Bolts should be re-

tightened before every lifting operation

• Ensure that the handling points [G] on the S80 strut point sidewards leaving a clear

space on the top face for positioning the load

G

• Connect drop link [B] to end attachment [D] with bow shackle [A]

• Connect suitable vertical slings (min. 2t WLL) to upper shackle [C] and secure onto

drop link [B]

• Ensure that there is adequate clearance between the load being lifted and the vertical

slings to avoid snagging

• It is recommended that S80 spreader beams or F55 spreader frames are used above to

support the underslung lifting beams below

• Vertical slings must be vertical [β] within 3° or less

• The load must be rigid and secured in such a way that the underslung lifting beams

cannot slide apart or together when in use

• The load must be seated in such a way that it cannot cause the S80 to rotate about its

axis

• The centre of gravity must be seated centrally on the beam to ensure a safe and even

lift, ensuring that lift points are not overloaded

• Prior to lifting, perform a test lift slightly above the ground to ensure that the load is

balanced

USER GUIDE SECTION 5

9

S80 UNDERSLUNG LIFTING BEAM

It is the hirer’s responsibility to inspect the beams and all fittings prior to any lifting

operations being undertaken. Consult an MGF representative before lifting if there is any

doubt over the quality of the equipment or if you are unsure about any aspect of these rules.

Equipment to be used in accordance with MGF’s terms and conditions of hire.

All operations must be carried out to approved method statements and risk assessments.

PRE-LIFT CHECKS

Before lifting there are several checks which should be done:

Must ensure that the slings are not twisted or tangled

Confirm that correct lifting points are being used

Keep the loaded beams clear of obstacles – any contact could cause unsafe

release of load or beam failure

Ensure that the sling lengths and rating are suitable, and the beam does not tilt

Ensure that the centre of gravity of the caravan is positioned centrally on the

beams to ensure an even lift

Each component needs to be checked prior to each lift

Prior to first use of a new assembly, carry out a trial lift just above ground level to

ensure that straightness is maintained under its own self-weight

Ensure that the lifting beams cannot slip on the support points during the lift.

Clamps may be required

SAFE USE WARNINGS

Before operatives use the equipment, they should read and understand

these warnings:

• Do not exceed stated WLL for all of the components

• Do not rig the vertical slings more than 3 degrees from vertical.

• When moving or positioning use tag lines to control movement.

• Individual components can be heavy and care must be taken if manual handling.

• The equipment must be used in accordance with the procedures from ‘Lifting

Operations and Lifting Equipment Regulations 1998’ (LOLER).

• Operatives using this system should be suitably trained, competent and have a

clear understanding of Safe Slinging procedures.

• Never lift over or near people, ensure an exclusion zone is in place during any

lifting operations.

• Do not use on uneven ground or during high winds.

• All loads being lifted should be rigid and additional safety measures may be

required to prevent the beams from moving or twisting during the lift.

USER GUIDE SECTION 6

10

UNDERSLUNG LIFTING BEAM

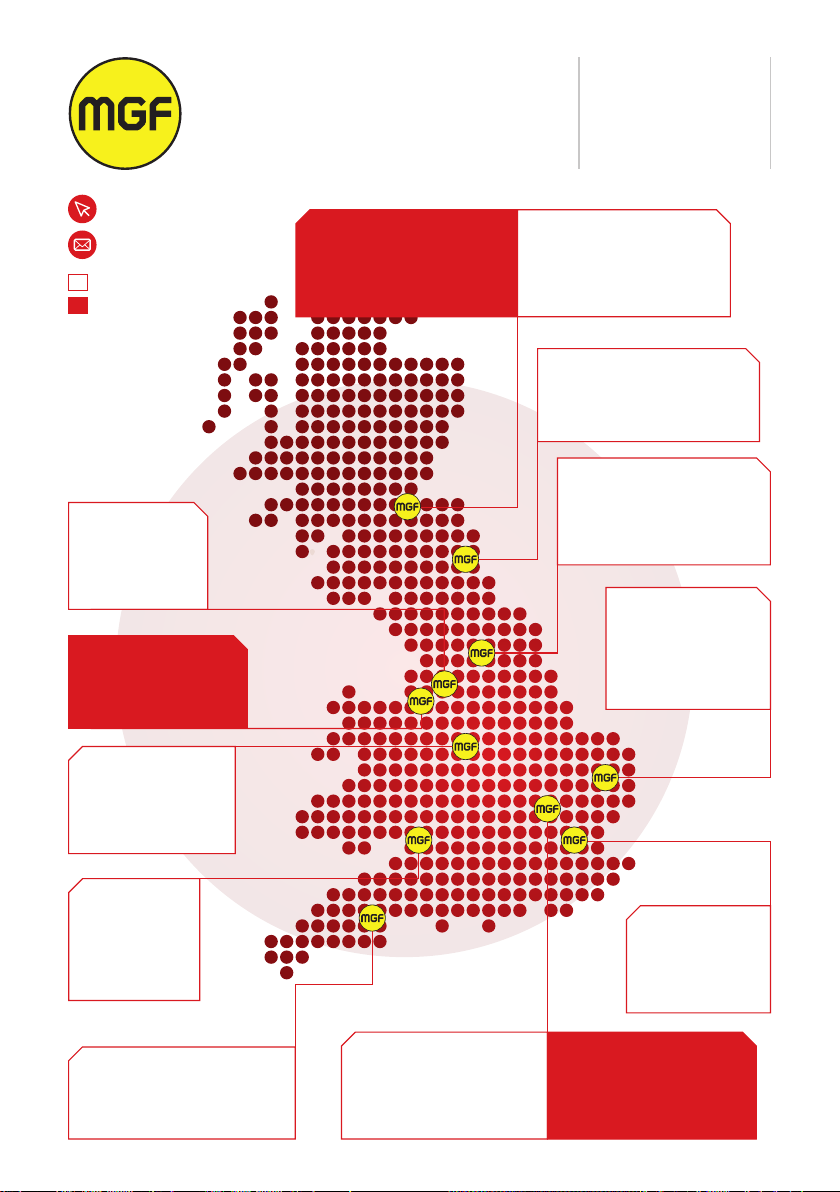

NORTH EAST – DURHAM DEPOT

Thistle Road, Littleburn Ind. Est.

Langley Moor, County Durham

DH7 8HJ

T: 01913 782100

YORKSHIRE –

CASTLEFORD DEPOT

Allerton Bywater Business Park

Newton Lane, Castleford

WF10 2AL

T: 01977 521930

EAST ANGLIA –

STANTON DEPOT

Unit 5, O’Brien Ind. Est.

Grove Lane, Stanton

Bury St. Edmunds

Suffolk, IP31 2AR

T: 01359 252204

LONDON –

DARTFORD DEPOT

Ray Lamb Way

Manor Road

Erith, Kent, DA8 2LB

T: 01322 344520

SOUTH WEST – EXETER DEPOT

Unit 58, Greendale Business Park

Woodbury Salterton, Exeter

EX5 1EW

T: 01395 233194

SOUTH WEST –

BRISTOL DEPOT

Severn Road

Chittening

Avonmouth

Bristol, BS11 0YL

T: 01179 820706

MIDLANDS –

RUGELEY DEPOT

Redbrook Lane

Brereton, Rugeley

Staffordshire, WS15 1QU

T: 01889 574777

NORTH WEST –

WARRINGTON DEPOT

Clayton Road, Birchwood

Warrington, WA3 6RP

T: 01925 598537

NORTH WEST –

ASTLEY DEPOT

Wallwork Road

Astley, Manchester

M29 7JT

T: 01942 896282

HEAD OFFICE

GRANT HOUSE

LOCKETT ROAD

ASHTON IN

MAKERFIELD

WIGAN, WN4 8DE

T: 01942 402700

ENGINEERING

CENTRE

FOUNDATION HOUSE

WALLWORK ROAD

ASTLEY, MANCHESTER

M29 7JT

T: 01942 402704

SOUTH EAST – TRING DEPOT

Units 21 & 22, Airfield Ind. Est.

Cheddington Lane

Long Marston, Tring

Hertfordshire, HP23 4QR

T: 01296 663250

SOUTH EAST – TRING DEPOT

Units 22a, Airfield Ind. Est.

Cheddington Lane

Long Marston, Tring

Hertfordshire, HP23 4QR

T: 01925 598537

WEST LOTHIAN –

LIVINGSTON DEPOT

Letham Road, Houstoun Ind. Est.

Livingston, West Lothian

EH54 5BY

T: 01506 535556

WEST LOTHIAN –

LIVINGSTON DEPOT

Letham Road, Houstoun Ind. Est.

Livingston, West Lothian

EH54 5BY

T: 01925 598537

mgf.co.uk

enquiries@mgf.co.uk

EXCAVATION SAFETY

STRUCTURAL

SUPPORT

enquiries@mgf.co.uk

Astley |Bristol |Castleford |Dartford |Durham |Exeter |Livingston |Rugeley |Stanton |Tring

Warrington |Wigan

MGF.CO.UK

This manual suits for next models

1

Table of contents

Other MGF Industrial Equipment manuals