MHS Boilers CRUZ belt Instruction manual

INSTALLATION,OPERATION,MAINTENANCE

MANUAL

CRUZ®belt

CRUZbelt

2

E0032544Rev090710

CRUZbelt

3

E0032544Rev090710

CRUZbelt INDEX

Purpose .................................................................................................................................. 4

Equipment Warranty............................................................................................................... 5

Warning and Safety Instructions............................................................................................. 6

Introduction............................................................................................................................. 8

Receiving and Unpacking....................................................................................................... 8

Site Preparation.................................... .................................................................................. 8

Floor Support Information..................... .................................................................................. 8

Floor Support Installation........................................................................................................ 9

Ceiling Hanger Installation...................................................................................................... 9

Ceiling Hanger Sway Bracing................ ................................................................................. 9

Anchoring Ceiling Hangers.................... ............................................................................... 10

Conveyor Set-up................................................................................................................... 11

Electrical ............................................................................................................................... 12

Belt Tracking......................................................................................................................... 14

Commissioning of Equipment ............................................................................................... 16

Preventive Maintenance ........................................................................................................17

Maintenance Schedule.......................................................................................................... 18

Troubleshooting – Belt.......................................................................................................... 19

Troubleshooting – Gearmotor............................................................................................... 21

Troubleshooting – Chain and Sprocket................................................................................. 23

Troubleshooting – Bearings.................................................................................................. 24

Replacement Parts ............................................................................................................... 25

Mission.................................................................................................................................. 46

CRUZbelt

4

E0032544Rev090710

PURPOSE

It is the intent of MHS Conveyor, through

this manual, to provide information that acts as a

guide in the installation, operation and

maintenance of MHS Conveyor CRUZbelt

conveyors.

This manual describes basic installation

practices, assembly arrangements, preventive

maintenance and assists in replacement parts

identification.

This service manual is intended for use

by personnel who are knowledgeable of

installation and safe working practices on

conveyor systems.

Not all applications and conditions can be

covered; therefore, this manual is to be used

ONLY as a guide.

If additional copies of this manual are needed or if

you have any question concerning the

conveyor please contact your Business

Partner or MHS Conveyor' Customer Support

at 231-798-4547 or Fax 231-798-4146.

CRUZbelt

5

EQUIPMENT WARRANTY

MHS Conveyor warrants that the material and workmanship entering into its equipment is

merchantable and will be furnished in accordance with the specifications stated.

MHS Conveyor agrees to furnish the purchaser without charge any part proved defective within 2

years from date of shipment or before the equipment has forty-one hundred (4100) hours of

running use, whichever period is shorter, provided the purchaser gives MHS Conveyor immediate

notice in writing and examination proves the claim that such materials or parts were defective when

furnished. For drive components specific to XenoROL® (i.e. Xeno belts, slave Xeno belts, drive

spools, standard and speed-up, and spacers), this warranty shall be extended to five years or ten

thousand (10,000) hours of running use, whichever period is shorter, provided the conveyors are

applied, installed and maintained in accordance with MHS Conveyor published standards. Other

than the above, there are no warranties which extend beyond the description on the face hereof.

Consequential damages of any sort are wholly excluded.

The liability of MHS Conveyor will be limited to the replacement cost of any defective part. All

freight and installation costs relative to any warranted part will be at the expense of the purchaser.

Any liability of MHS Conveyor under the warranties specified above is conditioned upon the

equipment being installed, handled, operated, and maintained in accordance with the written

instructions provided or approved in writing by MHS Conveyor.

The warranties specified above do not cover, and MHS Conveyor makes no warranties which

extend to, damage to the equipment due to deterioration or wear occasioned by chemicals,

abrasion, corrosion or erosion; Purchaser's misapplication, abuse, alteration, operation or

maintenance; abnormal conditions of temperature or dirt; or operation of the equipment above rated

capacities or in an otherwise improper manner.

All equipment and components not manufactured by MHS Conveyor carry only such warranty as

given by the manufacturer thereof, which warranty MHS Conveyor will assign or otherwise make

available to Purchaser without recourse to MHS Conveyor, provided that such warranty is

assignable or may be made available.

IMPORTANT

For service on motors, reduction units, electrical components, controls, air or hydraulic cylinders,

contact the local authorized sales and service representative of respective manufacturer. If none is

available in your locality, contact the MHS Conveyor representative. MHS Conveyor will not be

responsible for units that have been tampered with or disassembled by anyone other than the

authorized representative of the respective manufacturer.

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

EXTENDING BEYOND THOSE SET FORTH IN THIS STATEMENT OF WARRANTY.

Rev 04/08/2009

E0032544Rev090710

CRUZbelt

6

E0032544Rev090710

WARNINGS AND SAFETY INSTRUCTION

MHS Conveyor CRUZbelt conveyor is shipped

with safety equipment installed. This

equipment includes guarding, warning labels,

and pop-out rollers. All safety equipment

must be in place before running any conveyor.

Read and obey all warning labels. Any labels

damaged during the life of the conveyor will be

replaced free of charge.

Walking on or riding moving conveyor

is prohibited. Lock out power before removing

any guarding. Loose clothing and long hair

must be kept away from moving equipment.

Special attention must be paid to the

following areas of this manual:

WARNING

This is a notice which, if not followed, could result

in serious injury or death.

CAUTION

This is a notice which, if not followed, could result

in damage to equipment.

NOTE

This is where you will be notified of helpful

information.

CRUZbelt

7

E0032544Rev090710

CRUZbelt

8

E0032544Rev090710

INTRODUCTION

This manual provides information for

installing, operating, and maintaining your

MHS Conveyor CRUZbelt conveyor. A complete

parts list has been provided, along with a list of

recommended spare parts. Important safety

information is included throughout this manual.

MHS Conveyor CRUZbelt is considerably

different than other belt conveyor. An

understanding of this manual will help you take

advantage of the many unique features of

CRUZbelt.

Some features of interest:

•CRUZ®channel side frames have integrated

cable trays.

•Side frames allow optional shrouds for a

sleek appearance.

•Slider bed frames are interchangeable with

roller bed frames.

•All intermediate bed sections can be made

into end beds.

•End pulleys, snubbers, and take-up pulleys

are adjusted with cams. By eliminating the

usual threaded rods, adjustments are made

in seconds.

•Innovative tube spanners eliminate bed

squaring.

•Alignment sight holes allow all pulleys to be

easily squared before startup.

•Motor mounting allows chain adjustment

without affecting sprocket alignment.

This manual is arranged in the suggested order of

installation.

RECEIVING AND UNPACKING

Check items received against the bill of lading or

packing list. Inspect all equipment for damage.

Claims for damaged equipment must be made

against the carrier immediately.

All units have an identification tag on them.

Important information on the tag includes model

description, item number, and tag number. The tag

number matches the tag number on the layout

drawing, if applicable.

SITE PREPARATION

1. Establish building baselines from the layout

drawings.

2. Lay out centerline and end points of each

unit using the building baselines.

3. Check the installation path for interferences.

FLOOR SUPPORT INFORMATION

All supports are intended to be used at a conveyor

splice or the end of a unit. If a splice cannot

be supported contact your MHS Conveyor

distributor for other options. Support CRUZbelt at

each end and at every splice as shown below.

Leg elevations are shown on the elevation drawings.

Leg elevation can also be set by subtracting 6-3/8”

from the desired top of belt elevation.

NOTE

Top of Belt – 6 3/8”= Top of Support

If knee braces are required, they are installed on

approximately 30’ centers as shown below.

BRACE

KNEE

BRACE

STRAP

SUPPORT

FLOW DOWNSTREAM

CENTER

DRIVE

Note brace direction. Near a drive the brace should

be on the upstream side of the support. Elsewhere

the brace should be downstream of the support. For

maximum effect the angle between the brace and

the side frame must be between 30 and 45 degrees.

Supports over 48” use a double knee brace. To

make a double knee brace, bolt two straps together

with a minimum 8” overlap.

WARNING

Leg uprights must be vertical.

Adjust stand head to compensate for slope.

SPLICE SPLICE

LAST LEG 6" FROM END

CRUZbelt

9

E0032544Rev090710

FLOOR SUPPORT INSTALLATION

1. Set all supports for unit to proper height.

2. Attach supports to both sides of drive.

3. On intermediate and end beds, attach one

support on the end furthest from the drive.

CEILING HANGER INSTALLATION

WARNING

Consult the building architect or structural engineer

regarding ceiling loading and structural limitations of

the building.

WARNING

Consult your distributor or a structural engineer to

determine hanger and header steel sizes.

Install ceiling hangers at conveyor splices as shown

below.

HANGER

UPRIGHT

(MIN. 1-1/2" X 1-1/2" X 3/16" ANGLE)

SPLICE

DROP ROD

WELD NUT

(WELD AFTER LEVELING)

STOP

NUT

JAM

NUT

V-BRACKET

FLAT STRAP CONNECTOR

CROSS PIPE

EXTENSION NUT

(WELDED TO HANGER)

HANGER

Cross pipes, v-brackets, flat strap connectors, and

related hardware are provided standard. Drop rods

and hardware are optional.

CEILING HANGER SWAY BRACING

•Sway bracing should be a minimum of 1-1/2”

x 1-1/2” x 3/16” angle.

•Secure sway bracing to the hanger upright

near the conveyor and extend upward at an

angle between 30 and 45 degrees.

•Brace horizontally to building structure

where possible.

•Hanger uprights over 12’-0” long must have

a horizontal bridge as shown.

•Sway bracing should be installed on every

third hanger or 30’-0”, whichever is less.

•Install x-bracing as shown if bracing cannot

be installed outside uprights.

•Additional bracing should be used before

and after curves, at drives, and at product

divert points.

BUILDING STRUCTURE.

WHERE POSSIBLE TO

HORIZONTAL BRACE

SWAY BRACES OVER 12' LONG

AT BRACE MIDPOINT TO

ADD HORIZONTAL MEMBER

SWAY

BRACE

COLUMN

HEADER

STEEL

UPRIGHT

HANGER

SWAYBRACE

X-BRACING

(1) BRACE EVERY SET OF HANGERS

ALTERNATE AS SHOWN

NOTE

Check for product clearance before

adding X-bracing.

CRUZbelt

10

E0032544Rev090710

ANCHORING CEILING HANGERS

Open building steel:

The following references are from the American

Institute for Steel Construction manual (AISC).

•Welding of auxiliary

steel (stringers or

headers) to building steel is prohibited.

•Drilling and bolting to building steel is not

recommended and will be done only with the

customer’s written permission.

•Clamping of stringers or headers to building

trusses will normally be done only at panel

points. Specific customer permission and

load calculations by a qualified engineer are

necessary to clamp between panel points.

•Headers when used for short spans, such as

between roof purlins, will be securely

clamped to building steel. Stringers when

used between headers may be welded or

bolted to the headers directly or with suitable

angle clips.

Concrete ceilings:

•Anchor by drilling into concrete ceiling and

inserting suitable bolt anchors. Follow bolt

manufacturer’s recommendations for hole

diameter and depth.

•Anchor each hanger with four bolts (two per

upright) minimum ½” diameter.

•Heavier loads like drives or areas of

vibration require 5/8” diameter through bolts

with backup plates or multiple anchor bolts.

Wood joists/beams:

•Hangers may be attached directly to the

joists providing the load rating of the building

will permit. Attach each hanger to the

vertical side of the joist in two places, one

above the other. Drill through the joist in the

upper position and secure with a ½”

diameter through bolt with backup plate or

heavy washer. A ½” diameter lag bolt may

be used in the lower position.

•When a header is required to support the

load, it must bridge across two or more

joists. Attach as described above. Hanger

uprights may then be secured to the header.

Concrete or masonry walls:

•Support equipment by drilling into the wall

and inserting suitable bolt anchors.

•Use a ½” diameter through bolt with backing

plate should the load or wall conditions

warrant.

WARNING

Consult a structural engineer to determine which

anchoring method will support your load.

CRUZbelt

11

E0032544Rev090710

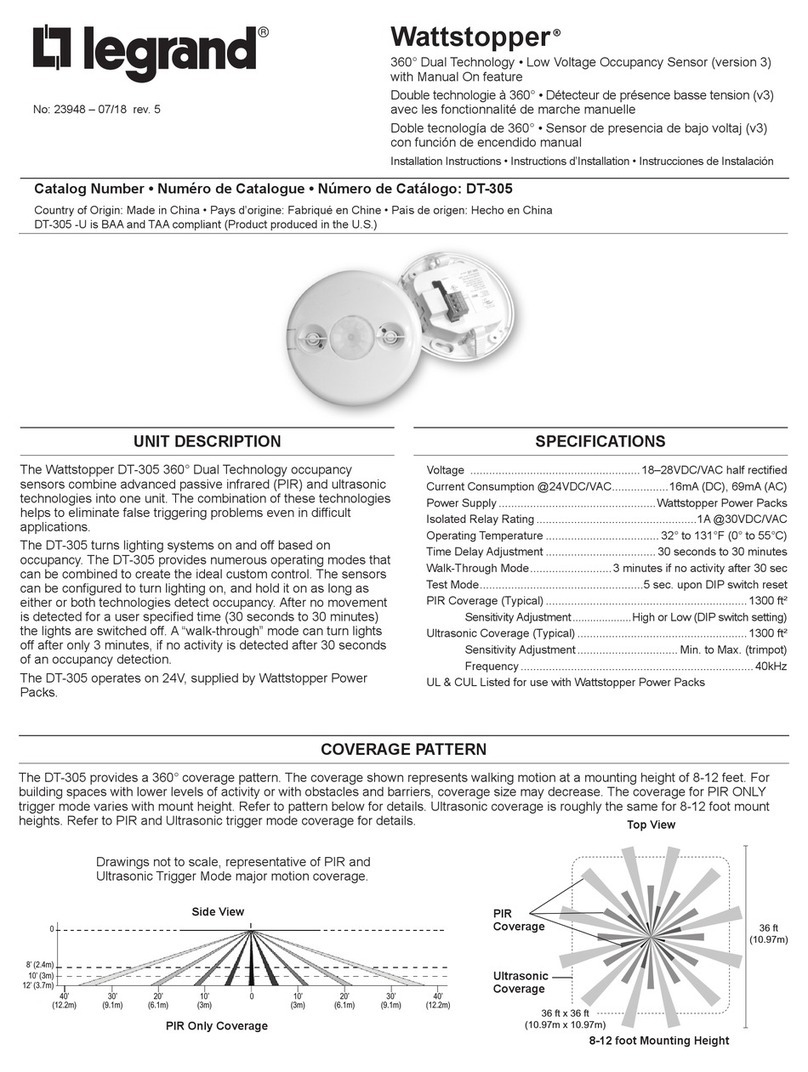

CONVEYOR SET UP

1. Place each bed in position per layout

drawing.

2. Splice beds together as shown below:

CRUZBELT SPLICE

3. Set final elevation and level unit. Conveyor

must be level side-to-side as shown:

CONVEYOR MUST BE LEVEL

LEVEL

4. Tighten support bolts and anchor to floor.

5. Install any required guard rail as shown:

LOWER BRACKET

ARM

UPPER BRACKET

SPLICE

GUARD RAIL

GUARDRAIL

6. Square end pulleys and snubbers using

alignment holes. Move cam or snubber

bracket until the 3/8” square alignment hole

is in line with the 3/8” square in the bed

frame. A 3/8” key stock can be inserted into

the holes for quick alignment.

ALIGNMENT

HOLES

ALIGNMENT

I

7. Locate drive. Remove both black plastic

drive shrouds and quick-release pins. Use a

3/8” ratchet extension in the square hole of

one football bracket to roll the take-up as

shown. (NOTE: no sockets are needed, just

the 3/8” extension)

TAKEUP

PIN

3/8" RATCHET

W/EXTENSION

FOOTBALL

BRACKET

8. Thread belt through conveyor. Labels on

drive beds and end beds show specific

threading. A general belt path is shown

below:

DRIVE PULLEY

RETURN

IDLER

SNUBBER

END PULLEY

TAKE-UP PULLEY

THREADING

END BED DRIVE BED END BED

9. Pull belt ends together and insert lacing pin.

A belt puller may be needed to draw the

ends together.

10. Tension belt by rolling a football bracket

away from the motor. A standard 3/8” drive

ratchet will provide correct belt tension with

ease. Do not over tension the belt by using

a “cheater bar” on the ratchet. Belt should

be just tight enough to drive the product.

11. Replace quick-release pins into both football

brackets. One bracket may need to be

aligned slightly to insert the pin. Replace

drive shrouds.

CAUTION

Do not run the conveyor without replacing

both quick release pins.

CRUZbelt

12

E0032544Rev090710

ELECTRICAL

WARNING

All electrical controls must be installed, wired, and

connected by a licensed electrician.

All motor controls and wiring must conform to

the National Electrical Code as published by the

National Fire Protection Association and

approved by the American National Standards

Institute, Inc. In addition, since specific

electrical codes vary from one area to another,

be sure to check with the proper authorities

before starting the electrical wiring.

The voltage of the motor will be stamped on the

name plate. This voltage must match available

voltage. Consult the wiring diagram on the motor for

proper connections. If the motor on a single

direction conveyor runs the wrong direction, the

leads must be switched to reverse rotation.

WARNING

Motor must be connected to the voltage

listed on the name plate.

Consult the wiring diagram of the inside cover of the

starter and pushbutton for the proper electrical

connections.

Three phase drives require transformers to reduce

the pushbutton and control circuit to 115 volts. If

primary voltage is changed, the transformer must be

changed according to the wiring diagram found on

the transformer.

NOTE

All controls equipment is covered by the original

manufacturer’s warranty.

NEMA enclosure ratings are as follows:

•NEMA 1- Indoor use, provides protection

against contact with internal components.

Suitable for use in warehouse and

distribution environments.

•Gasketed NEMA 1- Same use as NEMA 1,

but with additional protection against dirt and

dust.

•NEMA 3- Outdoor use, designed to keep out

rain and dust.

•NEMA 4- Indoor and outdoor use, designed

to keep out rain and dust.

•NEMA 12- Indoor use, provides protection

against dust, dirt, oil seepage, and dripping

of non-corrosive liquids. Suitable for use in

industrial environments.

•NEMA 13- Indoor use, provides protection

against dust, dirt, sprayed oil and non-

corrosive liquids.

CONTROLS – SAFETY GUIDELINES

The following are basic conveyor control safety

guidelines for common controls equipment.

WARNING

All safety devices, including wiring of electrical safety

devices, shall be arranged to operate in a “fail safe”

manner. If power failure or failure of the device

occurs a hazardous condition must not result.

START-UP WARNING HORN:

Ideally, all conveyors should be within sight of the

conveyor start button. This allows the operator to

verify no one will be in danger when the conveyor

starts.

An audible warning device is required if all conveyor

cannot be seen from the start button location. It

could be a horn, buzzer, or bell unique to that

conveyor for that location. It must be loud enough to

be head at any point of the conveyor being started.

It should sound for five seconds after the start button

is pushed, prior to the conveyor starting. Any

auxiliary equipment such as vertical lifts, turntables,

etc. must be included in the warning circuitry.

All conveyors that start and stop automatically

should be marked with the appropriate labels.

Adding a warning horn to conveyors that start

unexpectedly is recommended.

START PUSHBUTTONS:

Start pushbuttons should be the flush type or

guarded to prevent accidental activation. They

should be provided with a legend plate defining

which conveyors will be started.

STOP PUSHBUTTONS:

Stop pushbuttons should be the extended type so

that any contact will result in activation. They should

have a legend plate defining which conveyors will be

stopped.

CRUZbelt

13

E0032544Rev090710

OPERATOR CONTROLS:

Additional operator controls should be designed into

the system with the same guidelines that go into

start and stop pushbuttons. Devices which are

repeated on multiple control stations, such as

emergency stops, should be located at the same

relative location on each station. All operator

controls shall be clearly marked or labeled to

indicate the function controlled.

EMERGENCY STOPS:

All locations where an operator must work directly at

the conveyor should be protected by an emergency

stop. Operators should not have to leave their

position to actuate the emergency stop.

Conveyor in areas of high pedestrian traffic should

also be protected by emergency stop devices.

Emergency stops should be located throughout a

system. Their location will depend on likely

observation points and areas with special devices or

interfaces between equipment.

Emergency stops can be a pushbutton or cable

operated switch. The pushbutton should be

mushroom-style and red. The pushbutton must

require resetting after actuation. Cable operated

switches should trip by pulling the cable and require

resetting at the switch.

An emergency stop should normally stop all

conveyors in the system. Very large systems may

involve dividing the system into zones of control.

Actuating an emergency stop must drop out the start

circuit and require restarting the system using the

start pushbutton.

WARNING

Before restarting a conveyor which has been

stopped because of an emergency, an inspection of

the conveyor shall be made and the cause of the

stoppage determined. The starting device shall be

locked out before any attempt is made to correct the

cause of the stoppage.

CONTROLS LOGIC:

Solid state controls logic devices, such as

programmable controllers, are used extensively for

conveyor control. They are very reliable, but a

hardware failure or software bug could cause an

output to malfunction. For this reason, start circuits,

warning horn circuits, and emergency stops should

usually be configured using conventional relay logic.

SAFETY SWITCHES:

All conveyor control cabinets and motors should be

provided with safety (or disconnect) switches.

These switches must have provisions for padlocking.

As required for maintenance, equipment should be

locked in the OFF position.

SPECIAL DEVICES:

Special devices and equipment such as vertical lifts,

turntables, high speed conveyors etc. all have

unique design and safety requirements and should

be evaluated individually.

CRUZbelt

14

E0032544Rev090710

BELT TRACKING

WARNING

Only qualified personnel should be allowed to track

the belt. Use caution since conveyor must be run

during the tracking procedure.

ALL PULLEYS AND SNUBBERS MUST BE

SQUARE and conveyor must be level prior to

tracking the belt. Align the 3/8” square in the cam

and snubber bracket with the corresponding square

in the bed frame. (See “Conveyor Set-up” section).

Conveyor must be wired to run the correct direction.

Belt should be tensioned tight enough to drive the

heaviest product.

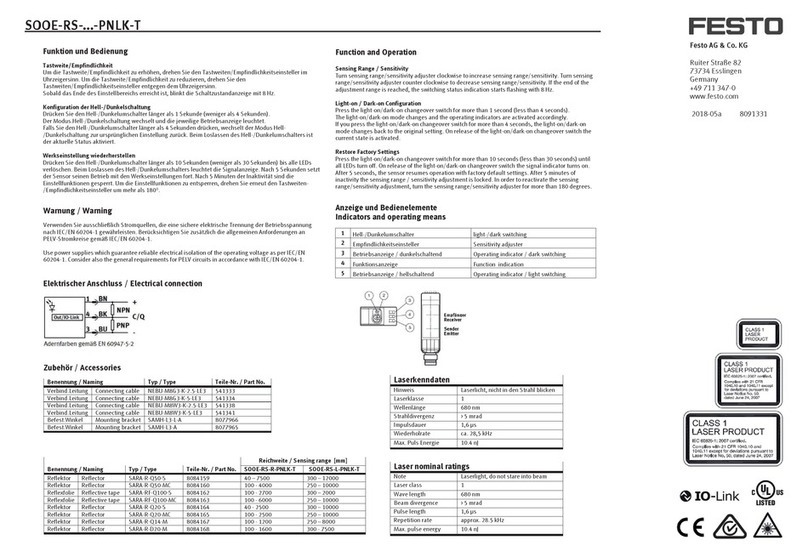

Belt tracking is accomplished using either the

tracking cams or snubber tracking brackets.

I

TRACKINGBRKTS

TRACKING CAM

SNUBBER TRACKING BRACKET

ALIGNMENT

HOLES

Snubber tracking brackets are located near the end

of the conveyor on the return belt snubber and near

the middle of noseovers. Tracking cams are located

on the end pulleys, the drive snubber, and near the

middle of noseunders.

CAM

BRKT

CAM

BRKT

CAM

DRIVE

NOSE

UNDERNOSE

OVER

BRKTLOCATION

Turn the tracking cam with a 3/8” ratchet as shown:

TURNCAM

3/8" RATCHET

3/8" EXTENSION

NO SOCKET

Tracking scenarios:

(Note: “FLOW” refers to belt flow direction, not

necessarily product flow)

FLOW

BELTTRAVEL

BELTTRAVEL

FLOW

FLOW

FLOW

BELTTRAVEL

BELTTRAVEL

FLOW

BELTTRAVEL

FLOW

BELTTRAVEL

END PULLEY,

NOSEUNDER SNUBBER

NOSEUNDER SNUBBER

END PULLEY,

DRIVE

SNUBBER

SNUBBER

DRIVE

RETURN SNUBBER,

NOSEOVER SNUBBER

NOSEOVER SNUBBER

RETURN SNUBBER,

TRACKING

NOTE

Belt moves toward the end of the pulley

that it contacts first.

CRUZbelt

15

E0032544Rev090710

CRUZbelt is slightly different to track than other

conveyor. Since the belt is only 7/16” narrower than

the between frame dimension, some belt contact

with the side frame is expected. However, the belt

must not be allowed to contact the frame near any

end pulley or snubber.

CAUTION

Belt must not be allowed to contact the side frame

near an end pulley or a snubber.

Some basic tracking information:

•The belt moves TOWARD the end of a

pulley it contacts first.

•Use snubber tracking brackets before using

tracking cams. End pulley tracking is used

as a last resort.

•Tracking brackets and cams only affect belt

DOWNSTREAM of the device. Find the

nearest bracket or cam upstream from the

problem area and adjust as shown.

•Adjust bracket or cam slightly and watch belt

for several revolutions before continuing.

CAUTION

CRUZbelt conveyor must be used with

mono-filament belting. Use of any other belting

will damage conveyor. Consult your MHS

Conveyor distributor for belt specifications.

CRUZbelt

16

E0032544Rev090710

COMMISSIONING OF EQUIPMENT

GENERAL

Commissioning of the equipment can best be

defined as the final adjustments and test of the

installed equipment required for its proper operation.

The need for commissioning is inherent, since the

individual components of equipment are brought

together at the installation site to operate as a

system.

Mechanical and electrical commissioning is most

often carried out simultaneously. Commissioning

must simulate the actual operation of the system as

close as possible to demonstrate the ability to

perform reliably at the specified rate in the

prescribed operational sequence.

During the Commissioning Phase, it is necessary to

load the equipment with product to be conveyed,

which provides the means of detecting those areas

requiring adjustment. Personnel will be required to

support operational functions. This may serve as

part of operator training and familiarity with the

system. During the commissioning activity, special

attention should be directed toward personnel

safety. No unnecessary risks should be taken that

would endanger the safety of any personnel. All

personnel must familiarize themselves with all safety

features of the system such as emergency stops

and motor disconnects.

MECHANICAL STATIC CHECKOUT

(No power to the conveyor.)

1. Follow the belt path through the entire conveyor.

2. Visually inspect the installation. Is the conveyor

straight? Is the conveyor reasonably level from

side to side? From end to end?

3. Check guard rail clearance to product.

4. Eliminate all catch points.

5. Check conveyor elevations.

6. All bolts and set screws tight.

7. Check product clearance to overhead structures.

8. Simulate all operational functions with actual

product.

9. All guards in place with proper clearance.

10. All OSHA required guards in place on walkways,

catwalks, ladder-ways, floor openings, etc.

11. All labels and warning signs in proper place,

unobstructed.

MECHANICAL DYNAMIC CHECKOUT

(Power to the conveyor, but no product on it.)

1. Turn the motor ON. With the belt moving make

sure each belt has proper tension.

2. Check the belt tracking.

CRUZbelt

17

E0032544Rev090710

PREVENTIVE MAINTENANCE

GENERAL:

Preventive maintenance includes lubrication,

adjustment of equipment, and replacing or repairing

parts before failure.

All maintenance should be recorded in a log. This

should show what was serviced and when. The log

can then be used to trouble-shoot any systemic

problems.

WARNING

Do not perform any maintenance until the conveyor

power is locked out and cannot be turned on by any

person other than the one performing the

maintenance. If more than one person is working on

the conveyor, each person must have a lock on the

power. Any air lines in the work area should also be

turned off.

Make sure personnel are clear of the conveyor

before starting. All guards must be in place before

starting.

GEARMOTOR:

The drive unit should be checked monthly. Check

the motor gear case for leaking seals. Check fluid

level and fill with ISO VG220 mineral oil if necessary.

Check breather on the gear case.

CHAINS AND SPROCKETS:

Chains and sprockets should be checked monthly.

If either the sprockets or the chain are worn, both

should be replaced. Sprockets must be checked for

alignment with a straight edge. Clean the chain with

a non-flammable solvent and lubricate with 30W

synthetic oil. A brush is recommended for oil

application.

Check chain tension after initial run-in and then

monthly. Tension should be slightly slack, as

shown:

3/16"-1/4"

CHAIN

3/16"-1/4"

ALLOWABLE CHAIN SLACK

ROLLERS:

Inspect rollers periodically for debris build-up.

BELTS:

Belts normally need very little care. Clean monthly

with compressed air or a stiff brush. Clean bi-

annually with water and detergent.

CAUTION

Do not use petroleum-based products

to clean the belt.

REGREASABLE BEARINGS:

The drive unit and power take-off have regreasable

bearings. These bearings should be lubricated

every six months.

CRUZbelt

18

E0032544Rev090710

MAINTENANCE SCHEDULE

Maintenance intervals will vary site by site.

Establish short intervals at first, then lengthen if

possible. The following is based on 8 hours per day,

5 days per week under normal conditions:

DAILY

•Listen for unusual noises

•Inspect conveyor for debris

•Check belting for build up or debris

•Verify all pulleys and rollers turn free

•Verify all guarding is in place

•Check for oil leakage

•Check for unusual vibration

•Check for loose bolts or parts

WEEKLY

•Inspect belt for proper tracking and tension

•Inspect belt lacing

•Inspect belt edges for fraying

•Inspect bearings and gear motor for

excessive heat or noise

•Clean breather vent on gear motor

•Check operation of all electrical controls

•Inspect motor mounting bolts

MONTHLY

•Clean chains and sprockets. Lubricate with

synthetic 30 weight oil.

•Check chain tension and alignment

•Clean belt with compressed air or stiff brush

•Check gear motor oil level

•Check pulley lagging for signs of wear

SEMI-YEARLY

•Clean belt and all surfaces with detergent

and water

•Grease drive pulley and power take-off

bearings.

YEARLY

•Inspect bolts for tightness

•Check for plumb and level.

•Touch up paint

TWO YEARS OR 10,000 HOURS

•Drain and fill gearmotor with ISO VG220

mineral based oil.

CAUTION

Verify all tools and foreign objects have been

removed from conveyor. Check that all guards have

been replaced and bolts have been retightened.

CRUZbelt

19

E0032544Rev090710

TROUBLESHOOTING GUIDE - BELT

Problem Belt Possible Cause Remedy

1. Belt stopped or moving

slower than normal,

reducer output shaft is

turning properly and all

electrical components

are operating normally.

Chain is loose and is skipping

sprocket teeth Tension chain. Check sprocket

alignment, check for worn teeth.

Belt has separated Replace the entire belt or cut out

damaged portion and add new

piece with extra lacings.

Bearings have failed Locate and replace the bearings

Belt slipping on drive pulley See #2 below

Belt lacing pulled out See #3 below

Improper belt tension Re-tension take-up pulley

Drive sprocket loose on shaft Re-tighten sprocket and check for

shaft wear

Belt jammed due to obstruction Check belt path and remove any

obstruction

Belt mistracked on return side Reference Belt Tracking procedure.

2. Belt slipping on drive

pulley Take-up pulley not adjusted

properly Adjust take-up cam in small

increments. Do not over-tighten.

Drive pulley lagging or pulley side of

belt is slippery

Replace pulley if lagging worn

smooth. If slipping is caused by

foreign substances in the lagging or

bottom of belt, clean by scraping or

wire brushing. Do not use solvents

on belt or pulley lagging.

New belt has stretched Normal. Re-adjusted take-up.

Seized end pulley or snubber roller

bearings Check and replace as required

Load too heavy Remove as required. Re-analyze

needs.

Belt threaded improperly Check belt path per this manual

3. Belt lacing pulling out Tension too high Reduce belt tension at take-up

pulley

Obstruction Remove obstruction

Lacing worn out Replace lacing with Clipper #36SP

CRUZbelt

20

E0032544Rev090710

TROUBLESHOOTING GUIDE - BELT

Problem Belt Possible Cause Remedy

4. Belt runs to one side Rollers preceding and at trouble

point are not square

Check alignment of pulleys and

rollers. Adjust pulleys and rollers as

required. See Belt Tracking section

of this manual.

Build-up of foreign material on

rollers and pulleys Clean rollers and pulleys. Do not

use solvents.

Conveyor not level Level conveyor bed

Bowed belt If belt is new, load tension may

straighten it. Otherwise, replace.

Pulley bearing set screws loose

allowing pulleys to walk to one side

Loosen belt and reposition the

pulley centered in the frame.

Retighten the set screws and center

the belt on the pulley.

Worn bearings Check and replace.

Belt not joined securely at lacing Re-cut belt ends square and re-

lace.

Off center loading Correct loading conditions.

5. Rips at or near edge of

belting Obstruction Remove obstruction

Belt running against conveyor frame See Belt Tracking section of this

manual.

Loose lacing Check lacing for tightness and

general condition. Check if belt is

chamfered on corners.

6. Conveyor belt jerks

during operation Too much slack in drive chain which

is jumping the sprocket Adjust chain tension, check for worn

sprockets.

Chain climbing the sprocket See “Chains & Sprockets” #8

7. Gouging of top cover Obstruction Locate and remove obstruction

Damaged return idler or snubber

pulley

Verify return idlers and snubber

pulleys are spinning freely and have

no material build-up.

8. Severe wear on drive

pulley side of belting Belt slipping on drive pulley See #2 above

Frozen or sticking rollers or pulleys Replace bad pulleys or rollers

Slider bed damage or misalignment Check slider bed for smoothness

and alignment at joints

9. Excessive belt

stretching Tension too great Reduce belt tension by take-up

adjustment

Table of contents

Other MHS Boilers Accessories manuals