MHZ nova-02 User manual

Installation instructions

Edition 10.2020

nova_02 tube awning

2

Page

Subject to technical changes, Edition 10.2020

Table of contents

Safety Instructions for the Installation 3 to 7

Installation Instructions 9 to 17

Adjustment instructions for Sun Top drives 19

Adjustment instructions for OREA RTS radio-controlled drives 20

Adjustment instructions for Sunea io radio-controlled drives 21

nova_02 tube awning installation instructions

3

Subject to technical changes - Edition 10.2020

1. Reading the installation and operating instructions

The operating instructions must be read prior to

installation. Any failure to do so absolves the manufacturer

of any duty of liability

1.1. Safety notes and warnings relating to installation

instructions

Safety notes can be found throughout the text. They are

marked with a symbol and a note:

Important safety information:

Notes that are important for the functioning of the product

and can result in serious injury or death in the event of

improper use are marked with this warning triangle.

Important safety information:

This warning triangle indicates notes that are important

for the functioning of the product and that if not followed

represent a risk of electrocution that can result in serious

injury or death.

1.2. Qualification

These installation instructions are aimed exclusively at quali-

fied fitters with sound knowledge in the following areas:

Health and safety at work and accident

prevention regulations

Handling of ladders and scaffolding

Handling and transport of long, heavy

components

Working with tools and machines

Attaching fasteners Assessing the fabric of

buildings Commissioning and operating

the product

In the absence of any of these qualifications, a

specialist fitting company must be employed to install

the product.

Electrical work:

The permanent electrical installation must be carried

out by a qualified electrician in accordance with the national

regulations. Installation instructions are enclosed with the

electrical appliances supplied with the awning. These must

be followed.

1.3. Goods acceptance

The delivery must be inspected immediately upon receipt for

any damage sustained in transit. In addition, the contents of

the shipment must be checked against the delivery note.

1.4. Transport

The permitted axle load and permitted total weight of

the transport vehicle may not be exceeded. Loading can

effect the vehicle's handling.

The goods being transported are to be tied down and

properly secured. The shade system packaging is to be

protected against moisture. Any soaked packaging may

disintegrate and result in accidents. Packaging opened for

the purpose of goods receipt inspection must be properly

taped up for further transportation.

After the awning is unloaded, it is to be transported to the

installation site the right way up and in the proper installation

position so that it does not have to be manoeuvred through

tight spaces.

The note on the position and side information on the awning

box is to be adhered to.

1.5. Pulling up with ropes

If the awning system needs to be pulled up to a higher

position with the help of ropes, the awning is to be

taken out of the packaging,

fastened to the hoisting ropes in such a wa

that they cannot slip off, and

pulled up smoothly in a vertical position.

The same applies to taking down the awning.

1.6. Mounting brackets

Before starting installation, check

that the type and number of fitting brackets supplied

match the order

that the details given with the order about the

substructure to which the awning is to be fixed match

the actual substructure found at the installation site.

If any variances that impair safety are identified, the installation

may not be carried out.

Important safety instructions for the installation

nova_02 tube awning installation instructions

!

!

!

!

!

!

4

NB:

Supplied without installation materials (available as accesso

ries). Installation materials need to be matched by the fitter to

the given installation substructure.

Where fastening materials ordered with the system are used

we do not simultaneously assume liability for proficient

installation. The installer is exclusively liable for determining if

the fastening materials for the respective masonry are suitable

and for the installation being performed properly. The wall

plug manufacturers' respective fitting guides must be followe

1.7. Fasteners

The awning fulfils the requirements of the wind resistance

category specified in the CE conformity mark (see operating

instructions). In installed condition, this requirement is only

met if:

the awning is installed using the type and number

of brackets recommended by the manufacturer

(see point 1.17 on page 6+7)

the awning is installed taking account of the wall

plug extraction forces specified by the manufacturer

(see point 1.17 on page 6+7)

that during installation attention has been paid to the

guidance of the manufacturer of the wall plugs used.

1.8. Climbing aids

Climbing aids may not be attached to or leant against

the awning. They must be steady and provide adequate grip.

Only use ladders that are certified for the proper load

bearing weight.

1.9. Fall protection equipment

There is a risk of falling when working at any significant

height. The appropriate fall protection equipment is to be

used to guard against falls

1.10. Electrical connection

The awning may only be connected if the electric motor's

specifications match the electricity source (see operating

instructions). The electrical component installation notes

supplied with the unit must be followed.

The unit is to be protected with an upstream FI circuit

breaker in accordance with VDE regulations.

Only cables and connectors with a protection class of a

minimum of IP 54 may be used to supply power.

1.11. Partially assembled awnings

Where awnings are partially assembled at the factory,

e.g. linked systems with no fabric, the spring-loaded parts

(see marking on the product) are secured against inadvertent

opening. The securing device must not be removed until the

blind has been completely installed.

These marked, spring-loaded blind components present

a high risk of injury!

1.12. Intended use

Awnings may be used only for the purpose defined for

them in the operating instructions. Changes, such as attach

ments and modifications not intended by the manufacturer

may only be carried out with the manufacturer's written

consent.

Additional loading of the awnings by attaching objects or by

cable tensioning or the like can result in damage to the

awning or to it falling down; this is not permitted.

Important safety instructions for the installation

nova_02 tube awning installation instructions

Subject to technical changes - Edition 10.2020

!

!

!

!

!

!

!

!

1

2

3

4

MHZ Hachtel GmbH & Co. KG

Sindelfinger Straße 21

D-70771 Leinfelden-Echterdingen

Germany

2018

LE-001

EN 13561:2015

art_01, art_02, VEGAS, nova_02

CLASSIC, CLASSIC MAXIMA

Use on the outside of buildings

and other structures

Resistance to wind loads: Class 1

Total energy transmittance g : NPD

tot

*

* For awnings mounted on wooden substructures and/or to

rafters, and for awnings in special sizes or finishes, it is not

possible to state wind resistance classes (class 0).

Example of a CE Conformity Mark in the accompanying document:

1

2

3

4

CE conformity mark, consisting of the

CE mark defined in Directive 93/68/EEC.

Name or identification code and the registered

address of the manufacturer.

The year that the CE mark was issued.

Declaration of performance reference number.

Number of the European standard applied,

as given in the EU's Official Journal.

Product type's unique identifying code.

Product's intended purpose, as

specified in the European norm.

Level and class of the stated power output.

5

Subject to technical changes - Edition 10.2020

1.13. Unsupervised operation

When working in the extension area of the awning, the

automatic controller must be turned off. There is a risk of

crushing or falling.

In addition, ensure that the system cannot be unintentionally

manually operated. For this purpose, the power is to be cut,

e.g. take out the fuse or disconnect the plug. Furthermore, in

the case of manual operating systems the operating crank

must be removed and securely stored.

If the awning is used by several users, a priority locking

system (controlled external electricity turn-off switch) must

be used, which makes the retraction and extension of the

awning impossible during cleaning and maintenance work.

1.14. Trial run

The first time the system is extended, no one is permit-

ted in the extension area of or under the awning.

A visual check must be made of the fasteners and brackets

after the first trial run.

During trial runs the automatic control or switch may not be

used if the awning is out of the operator's sight (there is a risk

of unintended extension/retraction). The use of a test cable

to turn on the motor is recommended.

The installation and adjustment instructions included with

the awning from the manufacturers of the motor, switch and

controller must be followed.

1.15. Crush and shear zones

There are crush and shear zones between drop bar

and tube/cassette and/or covers near the joint arm and

moving sections. Clothing i.e. body parts can be pulled

into the system!

If the awning is being installed at a height of less than

2.5 metres above accessible thoroughfares, it may be turned

on only by a push button switch from which there is a view of

the moving parts. Electrical controllers, radio drives with

latching function, latching switches, etc. are not permissible

in this case.

The push-button switch must be fitted within sight of the

drop bar but away from the moving parts. Ideally it should

be fitted at a height of 1.3 metres (national regulations

relating to the disabled must be observed).

1.16. Handover

All operating instructions as well as the installation

and adjustment instructions issued by the motor, switch and

controller manufacturers are to be handed over to the user

with an induction session. The user is to be instructed

comprehensively on safety and on use of the awning.

Failure to follow the instructions or any incorrect operation

can cause accidents and damage to the awning.

All instructions are to be kept by the customer for future

reference and must be passed on to the new owner if the

awning is sold.

Based on knowledge of the particular circumstances at the

site and the finished installation, the installation firm will

tell the user whether the wind resistance class specified by

the manufacturer has been achieved in the installed conditi

on. If not, the installation company must document the wind

resistance class actually attained.

Recommendation:

If you are the fitter, have the awning’s correct installation

and set-up, the time of installation and details of the accep

tance meeting, including that you explained the safety

information, confirmed in writing.

Important safety instructions for the installation

nova_02 tube awning installation instructions

!

!

!

!

HF 8

WK6

HI

WK8

KS

HK

KU

12

WK10

WK11

DK3

14

8

HH 12

4xø15

20

150

203 mm

175 mm

20

4xø15

22,2

4xø17

22,2

20

150

230 mm

25 150

200 mm

340 mm

20 300

50 280

350 mm

12

6xø17

203 mm

175 mm

175

20 135

135

20

203 mm

175 mm

140

22,5 95

135

20

135

KF

KH

8

12

130 mm

65

50 280

350 mm

12

2xø17

KT

KV

12

DK7

!

1

1

1

Subject to technical changes - Edition 10.2020

6

Important safety instructions for the installation

nova_02 tube awning installation instructions

B-set = bracket set; WK = wall bracket; DK = ceiling bracket

*1 Galvanised, powder-coated in frame colour

*2 Bracket set in combination with roof rafter bracket

Note: Brackets must be installed on the arm bracket.

Pay attention to the centre-to-centre distance.

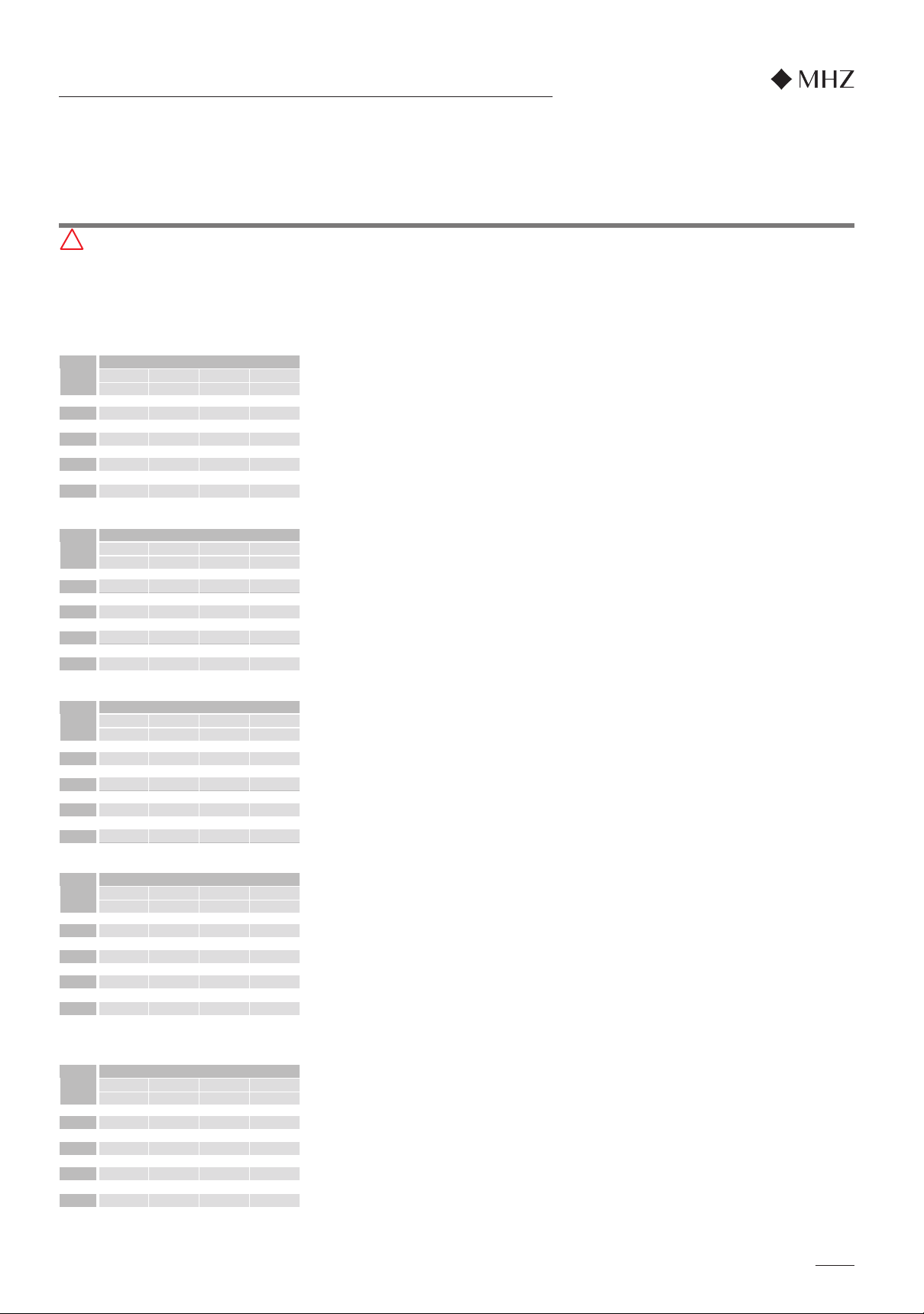

1.17. Bracket arrangement and extraction forces

Be sure to take note of all key installation information!

All brackets supplied with the product must be used and they must be fitted using all fixing points.

Pay attention to the extraction forces (see p. 7).

Standard wall bracket set

consisting of 2-off WK6

B-set Description Bracket arrangement Illustration

Fixing

points

Wall bracket set

consisting of 2-off WK8

for installation on difficult substructures

Wall bracket set

consisting of 2-off WK10

(1 each of WK6 and steel plate *)

for fixing to critical substructures

Ceiling bracket set

consisting of 2-off DK3

Standard wall bracket set

consisting of 3-off WK6

Wall bracket set

consisting of 3-off WK8

for installation on difficult substructures

Wall bracket set

consisting of 2-off WK10

(1 each of WK6 and steel plate *)

and 1-off WK11 (1 each of WK6 and steel

plate *) for fixing to critical substructures

Roof rafter bracket set *

consisting of 2-off DK7

2

Ceiling bracket set

consisting of 3-off DK3

Roof rafter bracket set *

consisting of 3-off DK7

2

7

250 359 HF 556 HF

300 413 HF 639 HF 911 HF

350 467 HF 723 HF 1.029 HF 1.391 HF

400 521 HF 806 HF 1.148 HF 1.550 HF

450 575 HF 890 HF 1.267 HF 1.710 HF

500 629 HH 973 HH 1.385 HH 1.869 HH

550 683 HH 1.057 HH 1.504 HH 2.272 HH

600 737 HH 1.140 HH 1.622 HH 2.454 HH

250 491 KS 727 KS

300 568 KS 839 KS 1.164 KS

350 646 KS 952 KS 1.318 KS 1.751 KS

400 723 KS 1.064 KS 1.473 KS 1.954 KS

450 800 KS 1.176 KS 1.627 KS 2.157 KS

500 877 KT 1.289 KT 1.781 KT 2.360 KT

550 954 KT 1.401 KT 1.936 KT 2.854 KT

600 1.031 KT 1.514 KT 2.090 KT 3.085 KT

250 307 KF 476 KF

300 354 KF 548 KF 782 KF

350 401 KF 621 KF 884 KF 1.196 KF

400 447 KF 693 KF 987 KF 554 HI

450 494 KF 765 KF 1.090 KF 611 HI

500 541 KH 838 KH 1.193 KH 669 HK

550 588 KH 910 KH 535 HK 813 HK

600 635 KH 983 KH 581 HK 879 HK

150 200 250 300

250 307 KF 476 KF

300 354 KF 548 KF 782 KF

350 401 KF 621 KF 884 KF 1.196 KF

400 447 KF 693 KF 987 KF 554 HI

450 494 KF 765 KF 1.090 KF 611 HI

500 541 KH 838 KH 1.193 KH 669 HK

550 588 KH 910 KH 539 HK 813 HK

600 635 KH 983 KH 581 HK 879 HK

150 200 250 300

250 307 KF 476 KF

300 354 KF 548 KF 782 KF

350 401 KF 621 KF 884 KF 497 HI

400 447 KF 693 KF 987 KF 554 HI

450 494 KF 765 KF 453 HI 611 HI

500 541 KH 838 KH 496 HK 669 HK

550 588 KH 910 KH 539 HK 813 HK

600 635 KH 983 KH 581 HK 879 HK

150 200 250 300

!

WALL installation on brick MZ 12

Projection in cm

Width

in cm

N B-Set N B-Set N B-Set N B-Set

WALL installation on hollow brick HLZ 12

Projection in cm

Width

in cm

N B-Set N B-Set N B-Set N B-Set

WALL installation on cellular concrete PB2

Projection in cm

Width

in cm

N B-Set N B-Set N B-Set N B-Set

Subject to technical changes - Edition 10.2020

WALL installation on concrete (C20/25)

Projection in cm

Width

in cm

N B-Set N B-Set N B-Set N B-Set

150 200 250 300

CEILING installation on concrete (C20/25)

Projection in cm

Width

in cm

N B-Set N B-Set N B-Set N B-Set

150 200 250 300

N = extraction force in Newtons (N) per fastening screw; K set = specified bracket set (see overview on page 6)

Important safety instructions for the installation

nova_02 tube awning installation instructions

So that the wind resistance class specified by us is valid, the fasteners must be matched to the existing substructure by the fitter.

Where orders are received without specification of the installation substructure, you will receive mounting brackets for mounting on concrete C 20/25. Please note that these

brackets may not be suitable for installation on other substructures. In order to satisfy DIN EN 13561, it is necessary to fit the type and number of brackets recommended for each

product. It is essential to observe the defined wall plug extraction forces as well as the mounting and installation instructions given by the manufacturer of the fasteners (including

the edge and hole distances). Precise extraction forces in relation to the thickness of the insulating plaster and the desired bracket set as well as to installation on other substructures

on request.

Coupled systems are counted as two individual systems (system width = 1/2 total width). The bracket set (K set) is required twice.

EXTRACTION FORCES AND BRACKET SETS for wind resistance class 1

Extraction forces in Newton (N) per fastening screw

9

4

6

18

2

3

10

7

9

5

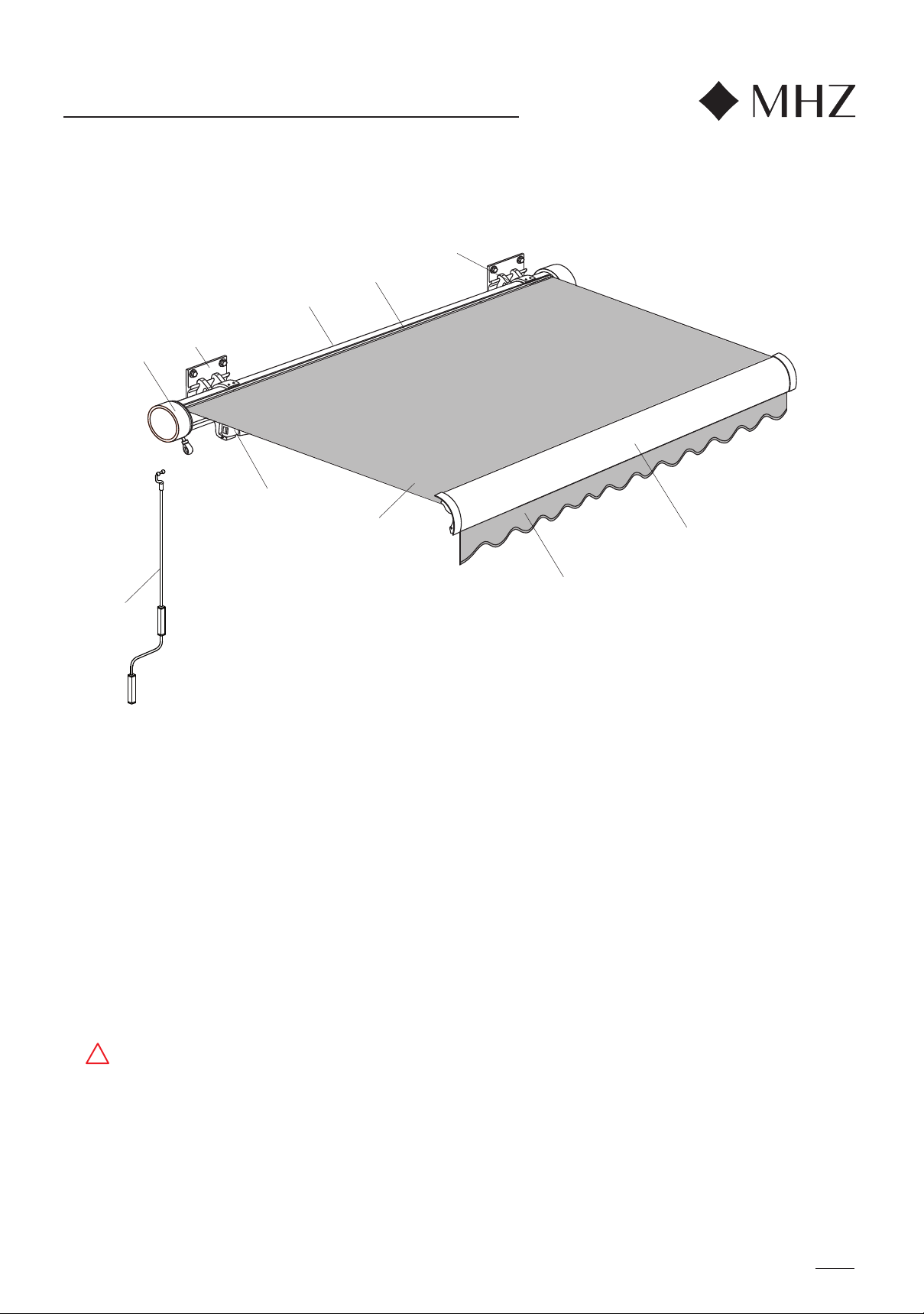

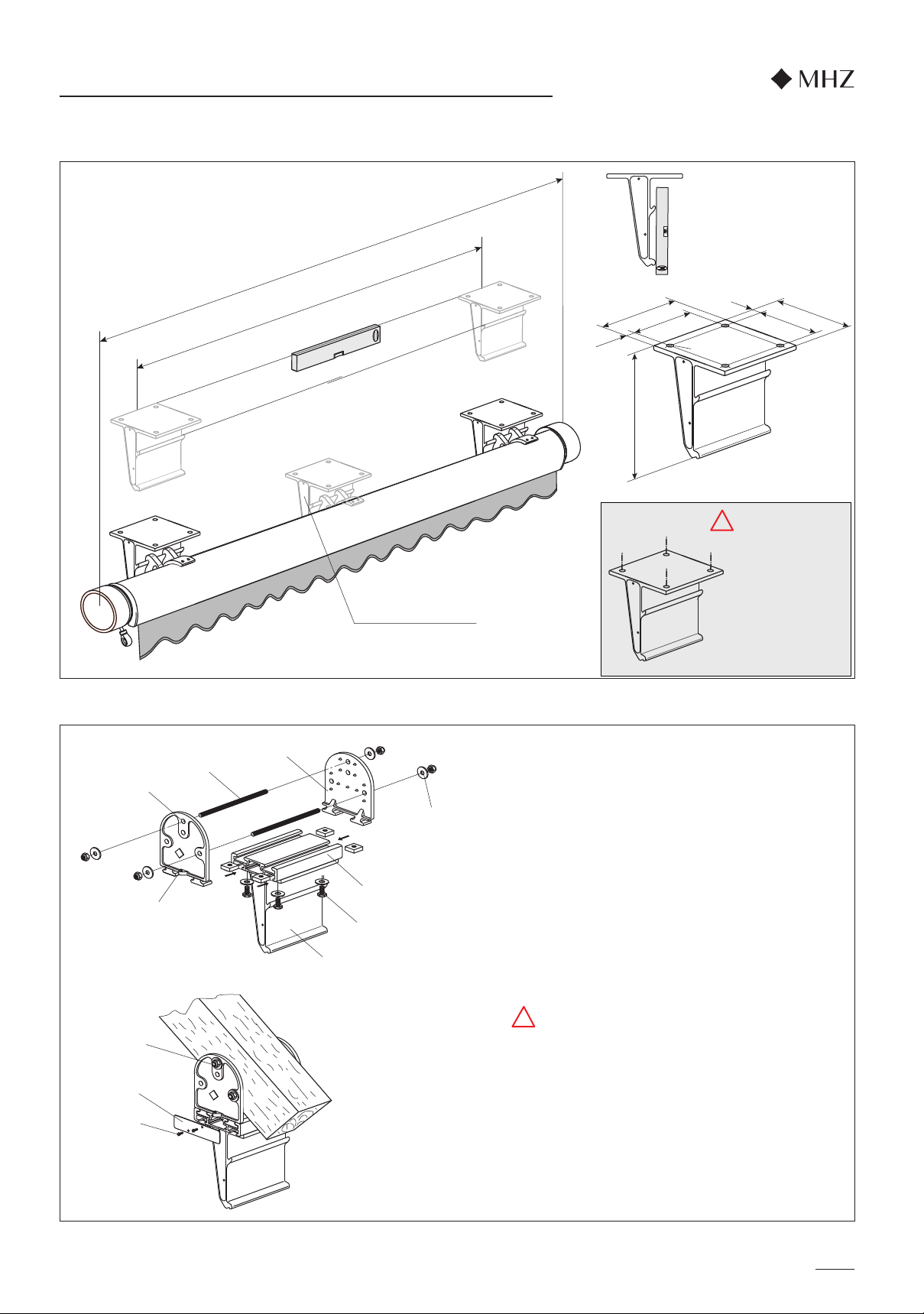

INSTALLATION INSTRUCTIONS

1. Awning fabric

2. Side cap

3. Wall bracket

4. Tube

5. Fabric tube

6. Arm bracket

7. Joint arm

8. Drop bar with end caps

9. Valance with binding

10. Crank handle

nova_02 tube awning

Check delivery at once for any

damage caused in transit.

The contents of the shipment must

be checked against the delivery

note.

Caution:

Supplied without

fastening materials.

The fasteners must be matched by

the fitter to the given installation

substructure.

Important:

The extraction forces for the

fastening screws must be defined

on the basis of 70N/m² related to

the awning fabric surface area.

Operating note:

An awning is a sunshade, not a shield

from all forms of weather.

In the event of wind, storms, snow or

rain, it must be retracted. If the awning

is equipped with an automatic

controller (e.g. wind and sun sensor),

this must be switched off over the

winter (danger of icing up).

Give the user of the awning the

accompanying operating instructions

and explain to them in detail all the

guidance on awning use and safety.

MHZ awnings require in the main no

maintenance. If any faults do arise, notify

your specialist retailer.

Required tools:

- Phillips screwdriver size2

- Allen wrench SW 2, 3, 4 + 6

- Box spanner SW 17

- SW8 socket wrench or SW8 socket

spanner with flexible shaft

- Spirit level

If electrically operated:

1 adjustment cable for SunTop drives

(prod. no. 99-1085) or

1 adjustment cable for RTS or io wireless

drives (prod. no. 99-4196) Adjustment

cables can be used only for the

installation!

Caution: For motor settings please follow

the setting instructions for electric drives,

p.19, 20 + 21.

Subject to technical changes - Edition 10.2020

!

175

20

20

150

203

22

4xø15

10

*

!

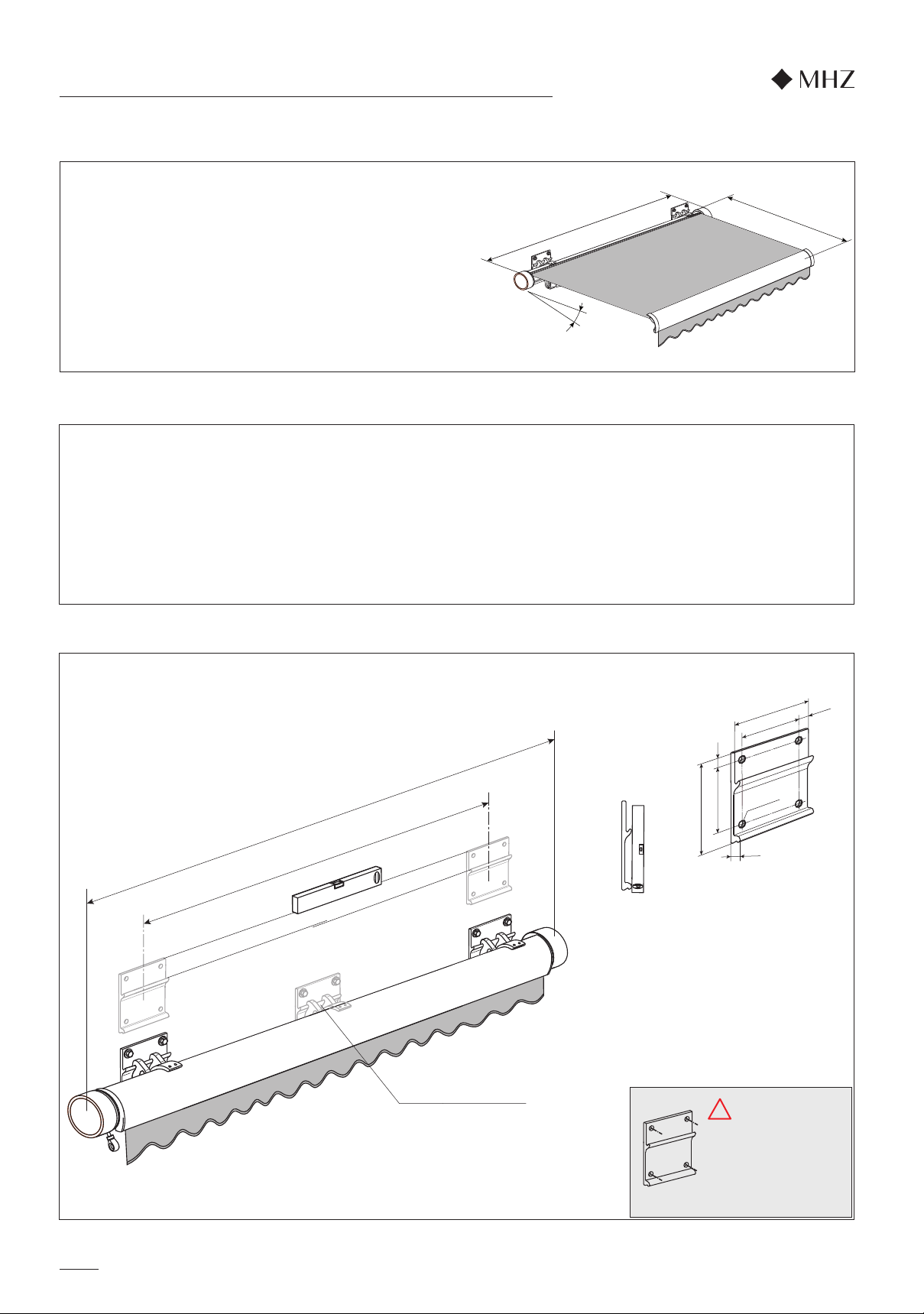

II

Subject to technical changes - Edition 10.2020

Unit width

Projection

* Pitch

Mark out the full awning width (unit width) on the wall or ceiling.

Specify the alignment with the guide (horizontal).

Measure the awning's centre-to-centre distance, i.e. the measurement from the centre of the arm bracket to the centre of

the arm bracket, and transfer to the awning width marked on the wall or ceiling. Align the brackets on the wall or ceiling

and attach with screws.

Caution: The brackets must always be aligned vertically and horizontally.

The fittings must be

suitable for the existing

installation substructure!

4 Fixing points

Technical data

Unit width: from 190 cm to 600 cm

coupled from 601 cm to 1200 cm

Projection: 150 / 200 / 250 / 300 cm

Arm bracket: pitch adjustable from 5° bis 28°

Type of installation: wall / ceiling / rafter

from unit width of 451 cm: Central support bracket

1. Attaching the brackets

1.1. Wall installation

nova_02 tube awning installation instruction

Arm bracket centre-to-centre distance

Unit width

A support bracket is

installed in the centre

of units with a width

of 451 cm and above.

11

15

16

17

A

MHZ

12

13

14

213

4x ø15

20 135

175

20 135

175

MHZ

A

18

19

11

!

!

II

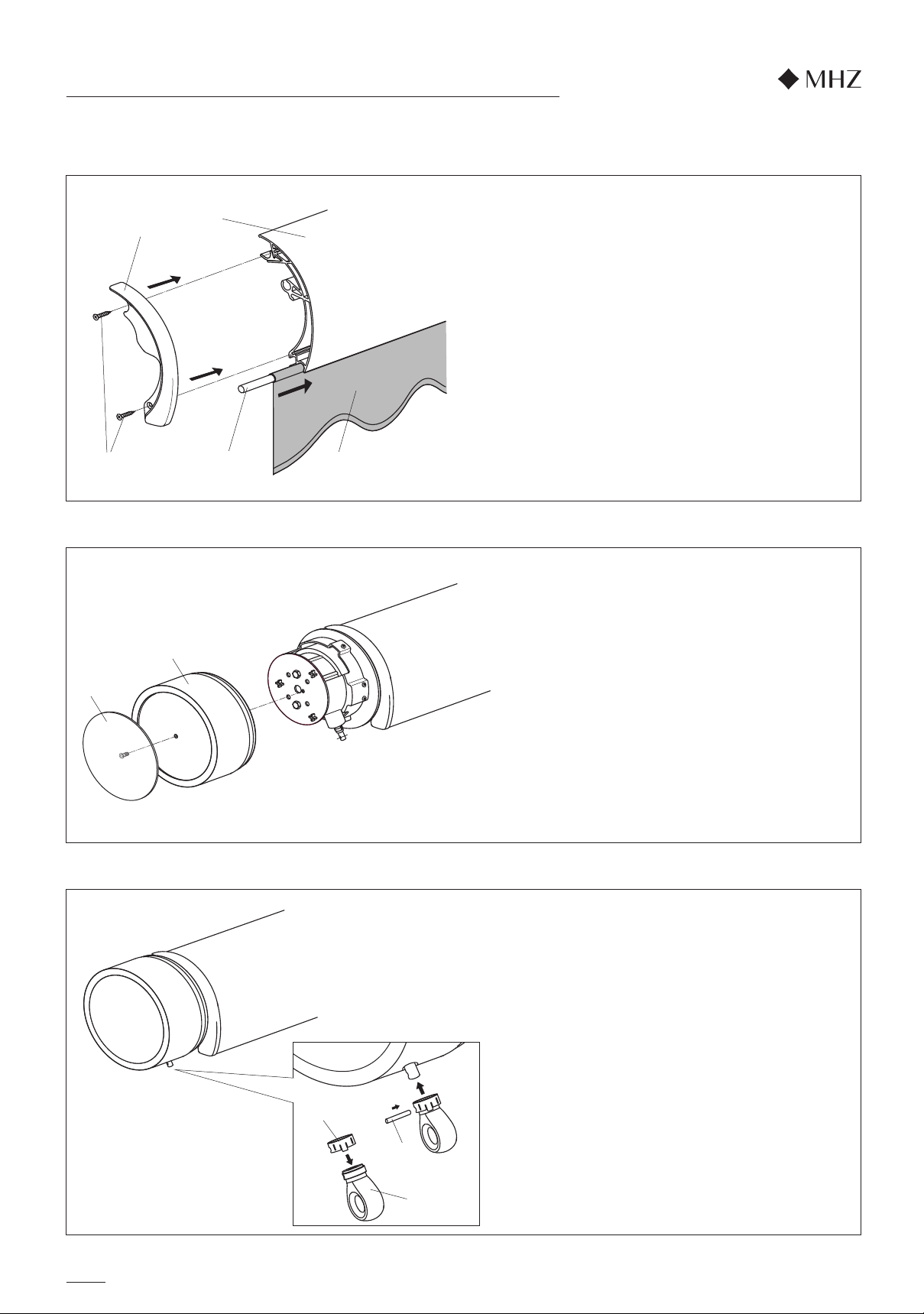

1.2. Ceiling installation

1.3. Roof rafter installation (accessory)

The fittings must be

suitable for the existing

installation substructure!

4 Fixing points

Using sliding block, hexagon head screw M10x25,

U-washer (12) and box spanner SW17, fix support

rail (11) to roof rafter bracket (13).

Push both plates (14) into the upper grooves of the

support rail (11). Mark top drill hole (A) on the rafter

and drill through using a ø12 mm drill bit.

Push through threaded rod (15) and screw in place at

both ends with washers and M10 nuts (16).

As shown at 1.2. Ceiling installation, align rafter

brackets with each other.

Drill second hole appropriate to the two plates and

screw in place. Then tighten threaded pin (17).

Then fix side panels (18) of the support rail in place

using 2, 4.2x16 slotted pan head screws (19) for each.

nova_02 tube awning installation instructions

Subject to technical changes - Edition 10.2020

Arm bracket centre-to-centre distance

Unit width

A support bracket is

installed in the centre

of units with a width

of 451 cm and above.

12

20

21

3

22

6

23

24

Subject to technical changes - Edition 10.2020

Horizontal

setting

Step 1

Step 2

nova_02 tube awning installation instructions

3. Dropping in the awning

4a. Setting the awning arms to be horizontal

Mount the awning in the bracket (3) using the arm

brackets (6) and attach to the brackets with the two

M8x25 threaded pins (22) (SW4 Allen key).

Note:

Always tighten the two outer threaded pins (22) on the

brackets first and then the inner ones.

If with the awning retracted the arms are not horizontal,

proceed as follows:

Extend the awning approx. 20 cm.

Loosen the M6x16 threaded pin (23) pointing towards

the centre of the awning in the arm bracket arm slot

(SW3 Allen key).

Move the arm into a horizontal position by tightening or

loosening the opposite outer threaded pin (24) in the

arm bracket.

Note: - Tightening the threaded pin:

Arm moves up

- Loosening the threaded pin:

Arm moves down

After adjusting the arms, both threaded pins (23, 24)

must be tightened again.

Extend and retract the awning and check the setting.

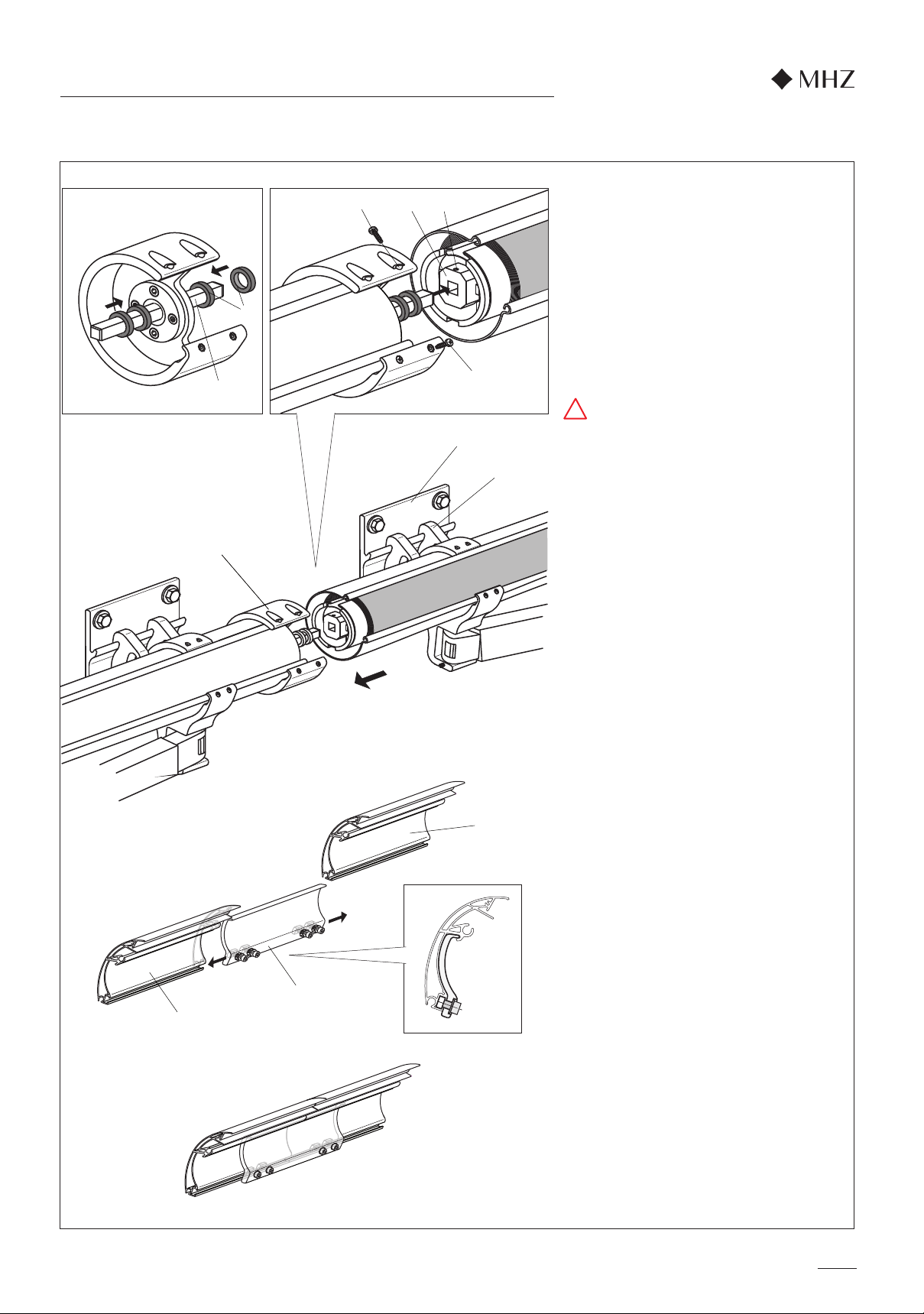

2. Installing the gear eyelet extension

Before mounting the awning in the brackets, the

extension for the connecting rod eyelet must be

installed.

Place the extension (20) in the bevel gear support

and secure with the locking bolt (21).

25

13

SW 2

29

28

2726

nova_02 tube awning installation instructions

If the arms tilt out towards the wall when the awning is

retracted (axial setting), proceed as follows:

Extend the awning approx. 10 cm.

To be able to centre the awning fabric in the drop bar,

loosen the threaded pin on the left and right of the

piping clip (25) (SW2). Loosen the cylinder head

screws (26) on the left and right of the suspension

bracket (27) using a SW6 Allen key.

Almost close the awning.

Centre the drop bar and awning fabric. Align the left

and right arm axially (place arm on the front arm

stop).

Mark the new left and right position of the suspension

bracket on the drop bar with a pencil.

Extend the awning approx. 10 cm.

Secure the cylinder head screws (26) in the new

position on the left and right of the suspension

bracket (27). Secure the awning fabric on the left and

right again using the piping clips (25).

Extend and retract the awning and check the settings.

Subject to technical changes - Edition 10.2020

4b. Aligning the awning arms by their axis

5. Pitch adjustment

Extend awning fully.

Use the SW8 Allen key (29) provided to twist the

spindle (28) until the desired incline is achieved.

Horizontally align the drop bar.

Tip: For easier adjustment of the pitch slightly

raise arms

Turning right = steeper pitch

Turning left = shallower pitch

Adjustment range of 5° - 28°

Installation tip:

SW8 socket spanner with flexible shaft

Axial

setting

14

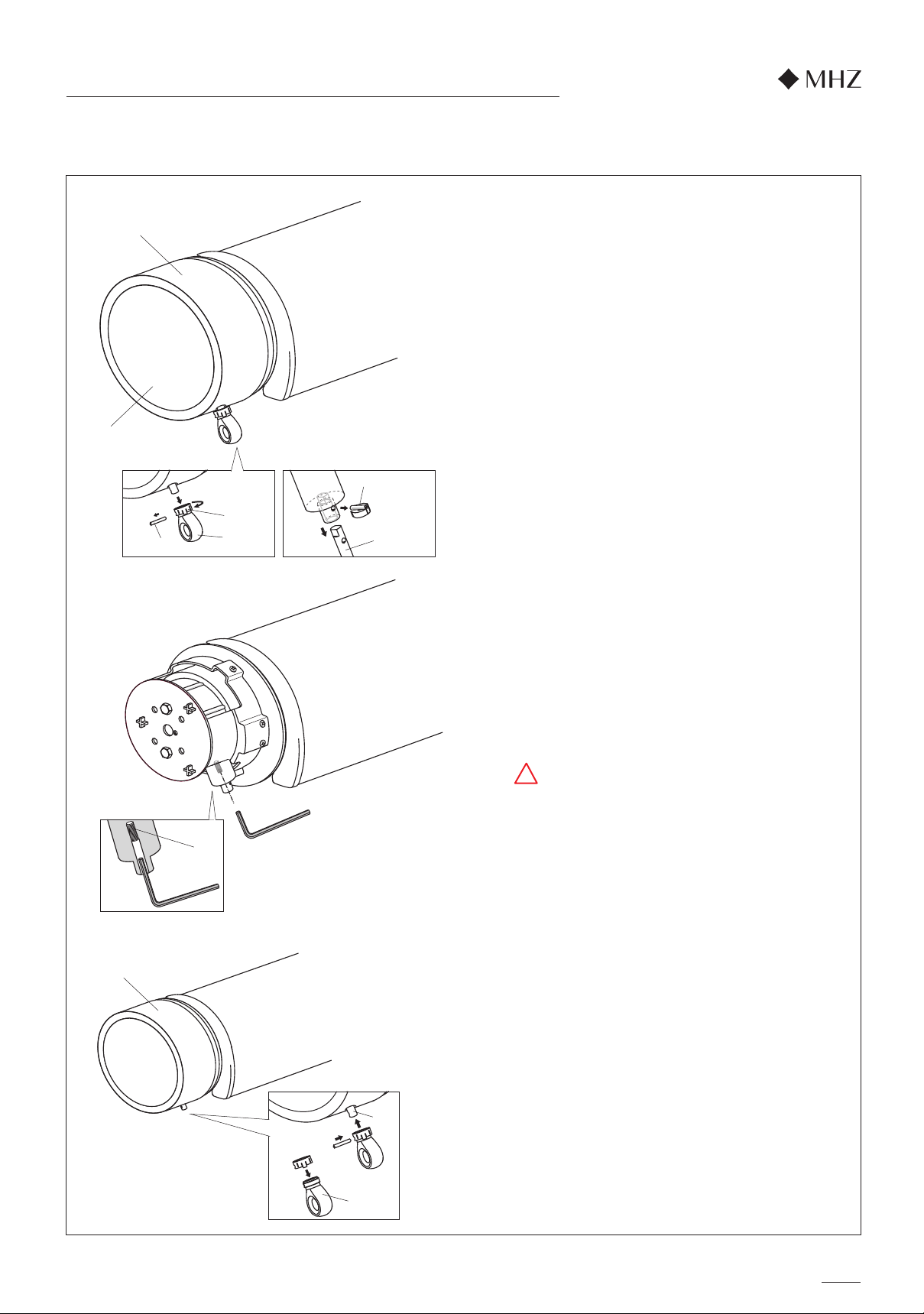

9

30

32

31 8

33

2

35

34

36

Step 1

Step 2

Step 3

nova_02 tube awning installation instructions

7. Side cap installation

Subject to technical changes - Edition 10.2020

8. Gear eyelet installation

Attach the side cap (2) and screw on to the tube ring

with the cover (33).

Push the retaining ring (34) on to the connecting rod

eyelet (35) and slide both on to the extension. Turn

the retaining ring and connecting rod eyelet into

position until the cylindrical pin (36) for securing the

eyelet on the extension can be inserted.

Remove the round piping from the drop bar. Insert

the round piping (30) into the valance (9). Always

push the valance into the groove on the drop bar (8)

from the right. Push the end cap (31) onto the drop

bar and secure with 3.5x19 countersunk screws (32)

and a size2 Phillips screwdriver.

Tip: To store the valance safely in the winter, loosen

the end cap and pull the valance out of the

drop bar. Then attach the end cap back on the

drop bar.

6. Valance

15

35

36 20

21

2

33

SW 4

37

35

2

20

34

!

nova_02 tube awning installation instructions

9. Gear adjustment

The gear's end setting is set at the factory. If you do,

nevertheless, want to change the end setting, proceed

as follows:

Extend awning until the free-wheel clutch activates

(clear 'click' sound). Then retract awning c. 1 to 2 cm.

Twist the retaining ring (34) on the connecting rod

eyelet (35) until the cylindrical pin (36) for removing the

connecting rod eyelet is visible. Remove the cylindrical

pin. Remove the side cap (2) after unscrewing the

cover(33).

To set the gearing, take off extension (20). Remove

bolt lock (21) and pull extension (20) out of the bevel

gear's mount.

Gear adjustment:

Using an SW 4 Allen key, loosen the internal securing

screw (37) by three rotations. Fit extension (20) and

plastic eyelet (35) again.

When adjusting the end stop outwards (projection

becomes greater):

Using the crank handle, slightly wind the awning in

(c. 1 cm) in order to take pressure off the end stop.

Then wind out to the desired end position.

This short movement prevents any damage to

the adjustment cogging.

When adjusting the end stop inwards (projection

becomes smaller):

Using the crank handle, wind the awning in to the

desired end position.

Take off eyelet and extension and tighten securing

screw (37) again.

Then fit extension (20), plastic eyelet (35) and

side cap (2) again.

Check setting by retracting by c. 50 cm and then

extending until the free-wheel clutch activates (clear

'click' sound).

Note:

Wind in UP direction (wall direction)

= projection gets smaller

Wind in DOWN direction (projection direction)

= projection gets bigger

Subject to technical changes - Edition 10.2020

Step 1

Step 2

Step 1

Step 2

39

40

41

42

43

38

39

40

41

42

38

44

38

16

nova_02 tube awning installation instructions

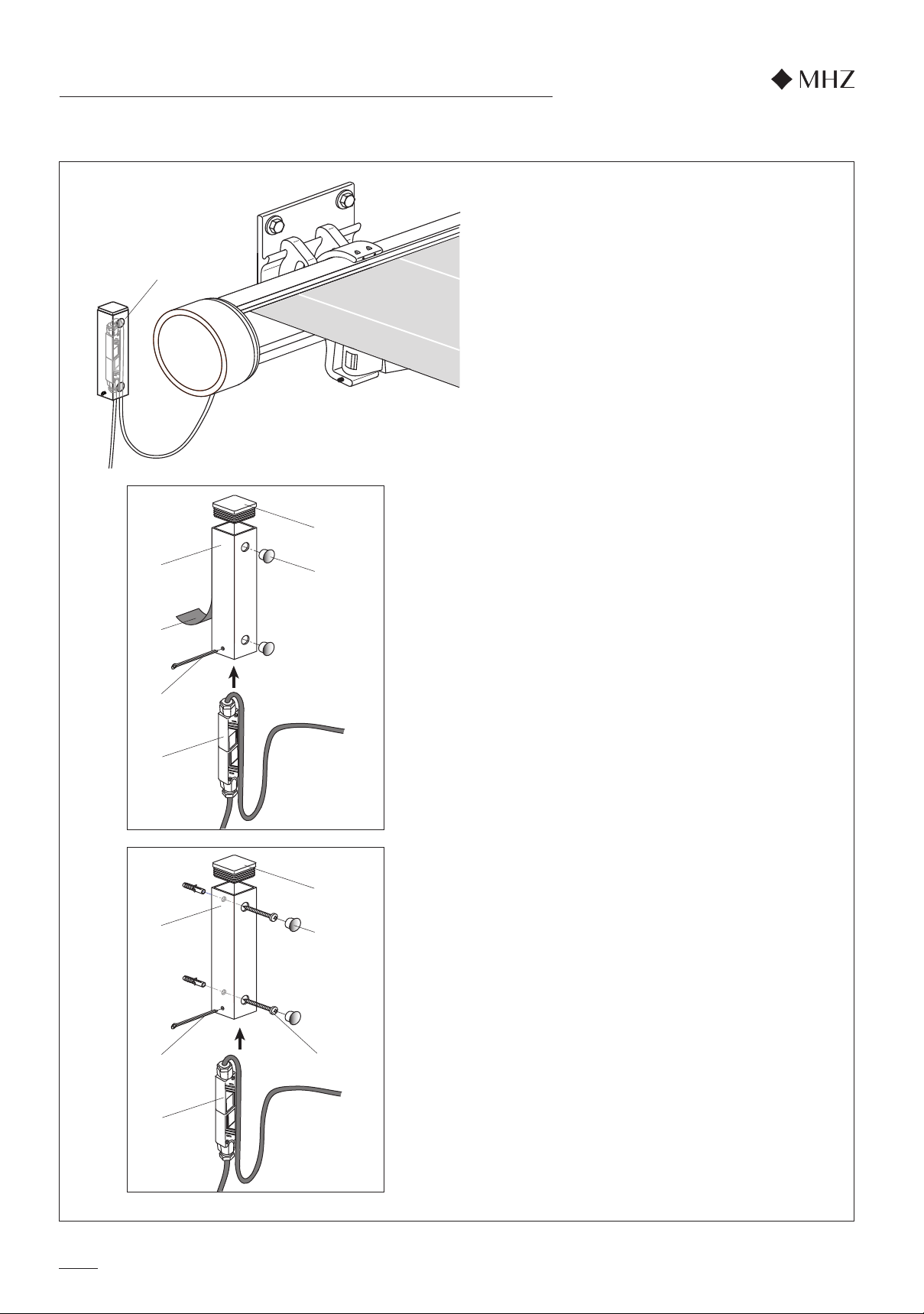

10. Protective sleeve installation for Hirschmann coupling (accessories)

Protective sleeve for Hirschmann coupling

(accessories)

The protective sleeve (38) for a Hirschmann coupling

can be screwed to the wall or ceiling. It should be

installed with the open side facing down. This ensures

that any incoming water or rain can drain away.

1. The protective sleeve can be secured to even and

smooth surfaces, such as a powder-coated carrier

bar, coated metal, and to stable and smooth plastic

substructures using adhesive.

Substructures such as plaster, concrete or wood,

and structured substructures, are not suitable for

adhesive.

Insert the plug-in caps (39) at the top of the

protective sleeve (38). Insert the two decorative

plugs (40) into the unused holes. Insert the

Hirschmann plug (41) into the protective sleeve

from below and secure with the splint (42).

Remove the protective film from the adhesive tape

(43) on the back of the protective sleeve. Stick the

protective sleeve in the required position on the

designated substructure and press down firmly

2. Screw fitting

Insert the plug-in caps (39) at the top of the

protective sleeve (38). Attach the protective sleeve

to the wall or ceiling using the S6 dowel and a

ø5x50 chipboard screw (44). Then insert the two

decorative plugs (40) into the holes.

Insert the Hirschmann plug (41) into the protective

sleeve from below and secure with the splint (42).

Step 1

Step 2

Step 3

Step 4

Step 1

Step 2 Step 3

Step 4

Subject to technical changes - Edition 10.2020

51

8

8

17

6

3

45

47

48

46

50

4950

nova_02 tube awning installation instructions

11. Coupling

Caution:

Only remove the arms' securing tapes after the

fabric tube's coupling.

Here is a lot of tension on the joint arms -

Risk of injury!

Install the awning section with the drive in the

same way as a single unit. Hook the joint arm

brackets (6) of the field, that is being connected, in

to the brackets (3) and push on to the coupling

bracket (45).

1. Connecting the fabric tube

Push the two spacers (46) on to the coupling

square (47). The fields, that are being connected,

must have the same number of fabric layers and

the piping channels on the fabric tubes must be

aligned.

When sliding on the field, that is being connected,

the coupling square (47) must be pushed into the

fabric tube insert (48) on the field being

connected. Do not forget the spacers (46). Press

the tube together gently and push into the

coupling bracket (45).

Secure the square with the threaded pin (49)

(SW3). Fix in place with a 3.9x14.5 countersunk

self-tapping screw (50) and a size2 Phillips

screwdriver.

2. Secure the connected awning section to the

brackets using the threaded pins on the arm

bracket (see installation instructions p.12, point3)

(SW4 Allen key).

3. Remove the retaining straps from the joint arms.

4. Extend the awning fully.

Check that the drop bars for both fields are at the

same height horizontally. If they are not level,

proceed as described in the installation instruc-

tions, p.13 “Tilt setting”.

Important for tension-free installation!

5. Retract the awning.

Check the fabric spacing. The spacing to the left

and right of the coupling bracket must be the

same.

Adjust if not.

6. Extend the awning fully.

7. Connecting the drop bar

Push in the top connector profile with the sliding

block (51) facing downwards until it is halfway into

the drop bar (8) groove. Then repeat this process

for the drop bar that is being connected. Align the

connector profile in the centre and screw tight

(SW6 Allen key).

8. Push the valance into the drop bar groove. Push

the end cap onto the drop bar and secure with

countersunk screws.

Subject to technical changes - Edition 10.2020

!

1.) 2.) 3.)

5.)

4.) 6.)

19

102

Winding

thermostatt

Electronics

Junction box

Switch box

Capacitor

Activation

button

L1

N

PE

Mains 230 V/50

Black

brown

blue

green/

yellow

3 1 42

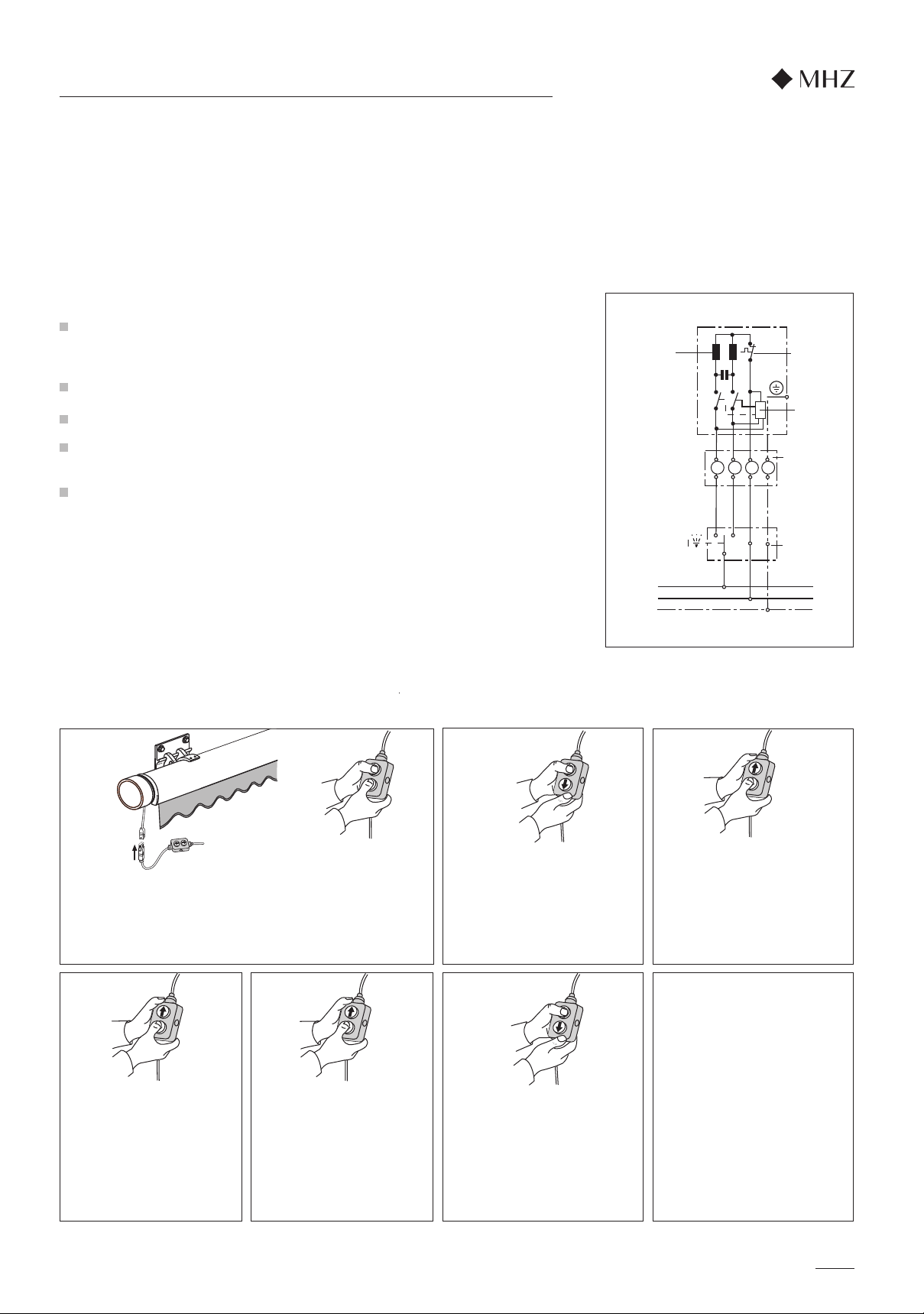

Adjustment instructions for Elero SunTop drives

Subject to technical changes - Edition 10.2020

nova_02 tube awning installation instructions

A. Note for the electrical installer

This awning must not be connected with the power live. Take fuse out beforehand!

There is a risk of the electronic end position setting being deleted. Resetting this is possible

only with the special Elero setting cable (prod. no. 99-1085).

The system is to be protected with an upstream FI circuit breaker in accordance with

VDE regulations. Only cables and connectors with a protection class of a minimum of

IP 54 may be used to supply power

B. Important Notice

This unit is fitted with an electronic SunTop motor. The special Elero setting cable has to

be used to set the end positions. A conventional test cable can be used to operate the

unit, but not to set it!

The electronics within the drive unit function only when built into the fabric tube!

Work on the mains power may be carried out only by authorised specialists!

After setting the drive's end positions, secure these installation instructions to the cable

for the electrician!

When using your own control systems not included with the product (e.g. wind/sun sensors

or similar), you must ensure that a switch-over pause from retract to extend command of at

least 0.5 seconds is set in the controller.

Where operation is via switches, only push-button switches with a 'dead-man' circuit are

permissible and they must mutually disable each other.

In accordance with VDE regulations, the motor may not be supplied with continuous current.

Otherwise the SunTop drive cannot be guaranteed to function reliably!

Note: It is possible to connect multiple SunTop drives in parallel (max. 430 W per drive).

If doing so, pay attention to the switching point's maximum switching capacity.

D. End position setting

The end position setting of the SunTop drive is set at the factory and does not normally need any correction. If you do,

nevertheless, want to set the drive's end positions differently, please note the following points:

C. Connection example

Press the DOWN button until the

drive automatically stops.

The top end position has now

been set.

Press the DOWN button again.

Run out the awning to just

before the desired bottom end

position. The drive starts with a

short STOP.

Move to the desired bottom

end position.

Corrections can be made via

the buttons.

The end positions are now set as

wished and the drive moves into

the respective end position.

Connect the Hirschmann

coupling to the control line again.

With this new drive there is no

need to simultaneously press the

UP and DOWN buttons after

resetting the end positions.

Pressing both buttons simulta-

neously would put the drive back

into programming mode (see

point 1).

Connect the Elero setting cable to the drive's Hirschmann coup

ling and run the unit out 30 cm. At the same time, press both

buttons on the setting cable. After c. 5 seconds, the drive goes

briefly up and down. The end positions have now been deleted

and can be reset.

Press the UP button again. Move

up to the top end stop. When the

stop is reached, the drive auto-

matically switches off.

Press the UP button until the drive

automatically stops.

The bottom end position has now

been set and the programming

finished.

s mfy

my

123

20

Up

Product no. 99 - 4196

In order to be able to operate the awning during installation, the drive must be connected to the Somfy

test cable. For power to be supplied to the drive, the test cable's 'Up' button has to be pressed.

The drive can then be operated via the hand-held radio remote control unit supplied with it.

The remote control unit has been paired with the drive. The top and bottom default end positions have

also been set at the factory and do not need any further programming. In the top end position the drive

automatically switches off when it reaches a set level of rated torque.

1. On the back of the transmitter already paired

with the radio-controlled drive press the

PROGramming button for c. 2 seconds.

The unit briefly moves and is thus 'Ready for

Pairing'

2. Briefly press the PROGramming button of the

transmitter to be newly paired (or deleted).

The unit again moves briefly back and forth.

3. The new transmitter has now been paired

(or deleted).

4. Trial run

1. Via the 'DOWN' button, extend the awning

completely (drive switches off automatically).

2. Press the 'UP' and 'DOWN' buttons simul-

taneously for c. 5 seconds until the unit

briefly moves back and forth.

3. Via the 'UP' or 'DOWN' buttons set the

awning's new, desired end position.

4. Press the middle 'Stop' button until the unit

again briefly moves back and forth.

5. The bottom end position has now been

reprogrammed.

6. Trial run

blue

( N ) black

( L1 )

empty

green/yellow

( PE )

Electrical connection

Pair further transmitters

(Or delete paired transmitters)

A maximum of 12 transmitters (including a maximum of 3 Sensor RTS

transmitters) can be paired with the OREA RTS radio-controlled drive.

In order to pair further transmitters (or to delete them), you always need a

transmitter that has already been paired.

If no such transmitter is available to you, contact your specialist retailer to

get further information.

The OREA RTS must be connected according

to the terminal assignments.

When making connections ensure that there is

no supply of power.

(Remove the fuse!)

Note: An electrician must perform the on-site

connection of drive system and controller.

Up / On

Stop

Down / Off

Back

Installation

NB: The awning's end positions are set at the factory. No alteration is necessary unless you want to

reset the bottom end position.

PROGramming

button

Adjustment instructions for OREA RTS drives from Somfy

nova_02 tube awning installation instructions

In order to prevent water running

along it into the motor, the connection

cable should always be laid with a

downward loop.

The system is to be protected with an upstream FI circuit breaker in

accordance with VDE regulations.

Only cables and connectors with a protection class of a minimum of

IP 54 may be used to supply power.

Subject to technical changes - Edition 10.2020

Special features of radio control systems

Features of the radio transmitters

Radio control systems' range is limited by the statutory regulations for wireless equipment and the

structural circumstances.

The control system should not be installed in the immediate vicinity of any metallic surfaces. Strong local

transmitter units (e.g. wireless headphones) that have a transmission frequency identical to the control

system can have an influence on its function. The transmission range is up to 300 metres in the open and

c. 20 metres inside buildings. The operating instructions of the Somfy radio transmitters being used must

be followed.

All suitable Somfy radio transmitters can be paired with and operate the OREA RTS drive,

e.g.: Telis 1 RTS, Telis 4 RTS, Telis Soliris RTS, Centralis RTS.

A maximum of 12 transmitters (including a maximum of 3 Sensor RTS transmitters) can be paired

with each OREA RTS drive.

Changing the lower end position

(Only necessary if the factory setting is to be altered)

The top and bottom end positions are set at the factory and do not

normally need any further programming.

If necessary, the bottom end position can be changed (the top end

position always stays the same).T.

Table of contents

Other MHZ Lawn And Garden Equipment manuals