Mi SUNMAN eArc SMF100F-3X12UW User manual

© Master Instruments Pty Ltd www.master-instruments.com.au page 1 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

INSTALLATION GUIDE

eArc SMF

Installation Manual

for RV & Marine Applications

© Master Instruments Pty Ltd www.master-instruments.com.au page 2 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

1.0 Summary

Thank you for purchasing Sunman eArc PV modules. This guide contains information regarding the installation and safe

handling of Sunman SMF100F-3X12UW, SMF175M-4X09UW & SMF215F-4X18UW Panels for RV & Marine applications. Users

and installers must read and follow the installation manual. Failure to follow these guidelines may result in panel or property

damage. Please read the safety and installation instructions before using and operating the modules.

1.1 Disclaimer

Master Instruments reserves the right to change this installation manual without prior notice. The changes and the latest

installation manuals after the changes will be published in the Sunman Installation Guides of the Master Instruments website.

Failure to follow installation guidelines may cause the warranty to be invalid.

Master Instruments does not guarantee any expressed or implied information contained in this manual.

1.2 Responsibility

Whether or not the installation of the modules is carried out in accordance with the instructions in the installation manual,

Master Instruments shall not be held legally responsible for any damages incurred during the installation process, including but

not limited to personal and property damage resulting from the operation of the modules and the installation of the system.

1.3 Copyright and Trademark Information

Copyright © 2023 by Sunman (Zhenjiang) Company Limited. All rights reserved. eArc and the SUNMAN logo are trademarks of

Sunman (Zhenjiang) Company Limited.

1.4 Warranty Warnings

WARRANTY VOID IF NON-SUNMAN-CERTIFIED HARDWARE IS ATTACHED TO eArc PV System.

© Master Instruments Pty Ltd www.master-instruments.com.au page 3 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

2.0 Safety precautions

WARNING: Please read and understand all safety instructions

before installing, wiring, operating, or maintaining modules.

DC power is generated when the module is exposed to

sunlight or other light sources. Direct contact with live parts of

the module, such as terminals, whether connected or not, may

result in personal injury or death.

Safety rules.

• All installation work must be in full compliance with local regulations and corresponding national or international

electrical standards.

• Use insulated tools to reduce the risk of electric shock.

• Use appropriate protective measures (slip gloves, overalls, etc.) to avoid direct contact with workers at 30V DC or higher,

while avoiding direct contact with sharp edges during installation to protect the operator’s hands.

• Do not wear metal ornaments when installing, to avoid puncturing the modules and causing electric shock.

• If the circuit breaker and overcurrent protection circuit breaker cannot be opened, or if the inverter cannot be turned o

during the module installation or wiring, cover the array modules with opaque material to stop the power output.

• Do not use or install damaged modules.

• If the module surface is damaged or worn, direct contact with the surface of the module may result in electric shock.

• Do not attempt to repair any part of the module, there are no user-accessible components within the module.

• The cover of the junction box should remain closed at all times.

• Do not split the modules or move any part of the module.

• Do not artificially condense light on modules.

© Master Instruments Pty Ltd www.master-instruments.com.au page 4 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

3.0 Mechanical / electrical properties

The rated electrical performance data for the modules is measured under standard test conditions (STC) of irradiance of 1000

W/m2, AM 1.5, and cell temperature of 25 °C. The specific electrical and mechanical performance parameters of Sunman eArc

modules are included in Annex A of this installation manual. The main electrical performance parameters under STC conditions

are also marked on the nameplate of each module. The maximum system voltage for all modules is 1000V.

In some cases, the current or voltage generated by the module may be greater than the optimal operating current or voltage of

its standard test condition (STC). Therefore, when determining the component rating and load value, the module open circuit

voltage and short circuit current at STC should be multiplied by 1.25. Please check with your local rules and regulation.

SMF100F-3X12UW SMF175M-4X09UW SMF215F-4X18UW

Maximum Power (Pmax)100 175 215

Maximum Power Voltage (Vmp)21.2 19.5 21.0

Maximum Power Current (Imp) 4.75 8.98 10.24

Open Circuit Voltage (Voc) 25.2 23.9 24.9

Short circuit Current (Isc) 5.12 9.50 10.72

Module Efciency (%) 15.7 17.3 19.1

Number of eyelets No 6 No

Operating Temperature -40°C to 85°C

Maximum System Voltage 600VDC (IEC)

J-box IP68 rated (each j-box have one bypass diodes)

Output Cables Photovoltaic technology cable 4.0mm2, (+)150 / (-)450mm

Connector MC4 compatible

Maximum Series Fuse Rating 20A

Application Class Class A

Power Tolerance 0/+5W

Solar Cell Mono (166mm half) Mono (6 inches) Mono (166mm half)

Number of cells 36 (3 x 12) 36 (4 x 9) 72 (4 x 18)

Dimensions 1093 x 552 x 2mm 1504 x 673 x 2mm 1610 x 700 x 2mm

Weight 2.1kg 3.0kg 3.8kg

STC: Irradiance 1000W/m2, cell temperature 25°C, AM=1.5

© Master Instruments Pty Ltd www.master-instruments.com.au page 5 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Storage and unpacking

• Precautions and general safety rules

• Store modules in a dry and ventilated environment.

• The modules must be transported in the package provided by Sunman and stored in the original package before

installation. Please protect the packaging from damage. Open the package according to the recommended unpacking

steps. Care must be taken during unpacking, shipping, and storage.

• Do not apply excessive loads on the modules or twist the modules.

• Do not carry the modules via the wires or junction boxes of the modules.

• Do not stand, climb, walk or jump on modules.

• Do not allow sharp objects to touch the modules. Scratches can directly aect the safety of the modules.

• Do not place the modules in an environment where there is no reliable support or is not fixed.

• Do not change the wiring method of the bypass diode.

• Keep all electrical connections clean and dry.

Product identification

• Barcode: each individual eArc has a unique serial number. The serial number has 21 digits. The 1st to 4th digits are the

module type for internal use, and 5th to 8th digits are the year code, and the 9th and 10th digits are the month code, and

the 11th and the 12th digits are the week code, and the 13th and 14th digits are the month code, and the 15th to 17th digits

are order number, and the 18th to 21st digits are the sequence codes. For example, xxxx20210415xxxxxxxxx means the

module was made in the 15th week of 2021. Each module has only one bar code. It is permanently attached to the interior

of eArc and is visible from the top front of eArc. This bar code is inserted prior to lamination.

• There is a nameplate, which shows the model number, main electrical properties, safety specifications and certification

indicator, on the back of each module.

4.0 Installation

Precautions and general safety rules

• Before installing the modules, please contact the relevant department to obtain information about the installation site

and the construction permit, and comply with the installation and inspection requirements.

• Check the applicable building codes to ensure that the building to be installed and its structure (roof, facade, load-

bearing, etc.) has sucient load-bearing capacity.

• During installation, make sure that the modules are installed on a fire-resistant roof. According to UL790 standards,

Sunman eArc modules are rated as fire rating C.

• The eArc modules are compliant with application level A (equivalent to safety level II, IEC 61730-1). This type of modules

can be used in systems where the public is likely to come into contact with voltages greater than 50V or power greater

than 240W.

Environmental conditions

The modules are suitable for general climatic conditions, ie with reference to IEC 60721-2-1- Classification of environmental

conditions Part 2-1: Environmental conditions occurring in nature - temperature and humidity.

• The modules must not be installed near flames or flammable objects.

• Do not expose modules to artificial condensing light sources.

• Failure to follow the above precautions may result in the Sunman Warranty being voided.

Maintenance & Cleaning

• Inspect all modules annually for safe electrical connections, sound mechanical connections, and freedom from

corrosion.

• Periodic cleaning of the modules will result in improved performance levels, especially in regions with low levels of annual

precipitation.

• To clean a module, wash its surface with potable, non-heated water. Normal water pressure is adequate. Some

fingerprints, stains, or accumulations of dirt on the surface may be removed with over-the-counter cleaners (such as

Windex® or equivalent), or with a 3% soap-and-water solution. Wet the module surface with the solution, let it stand for

five minutes, and then wet them again and use a soft sponge or seamless cloth to wipe the surface in a circular motion.

Do not use harsh industrial-strength cleaning materials such as aggressive chemicals, scouring powder, steel wool,

scrapers, blades, or other sharp instruments to clean the module. Use of such materials will void the product warranty.

© Master Instruments Pty Ltd www.master-instruments.com.au page 6 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Installation requirements

• Ensure the modules meet the overall technical requirements of the system.

• Ensure that components of other systems do not cause damaging mechanical or electrical performance eects on the

modules.

• Connect the appropriate number of modules according to the voltage specifications of the MPPT used in the system.

Even at the lowest local temperature conditions, the connected modules must produce no more than the voltage

allowed by the system.

• In order to avoid (or reduce) the mismatch eect of the array, it is recommended to connect modules of similar electrical

performance on the same string.

• In order to reduce the risk of indirect lightning strikes, loops should be avoided when designing the system.

• The modules should be securely fastened to withstand all possible loads, including wind and snow loads.

Series & Parallel Connection requirements.

• Connect modules in series to increase voltage or in parallel to increase current. When connected in series, the positive

pole of the module is connected to the next negative pole. When connected in parallel, the positive pole of the module is

connected to the positive pole of the next module.

• The number of bypass diodes provided varies depending on the module model.

• If overcurrent protection devices (fuse) are not used in series within each string of modules, up to two strings of modules

can be connected in parallel. If a suitable overcurrent protection device is connected in series with each string of

modules, three strings or more modules can be connected in parallel.

Optimal orientation and inclination

• In order to achieve maximum annual power generation, the optimal orientation and inclination of the PV module should

be determined first. The maximum electrical energy is typically generated when sunlight is directed onto the PV module.

Avoid shadows

• In systems with shading, it may be preferential to have multiple smaller systems with networked Victron MPPT’s.

4.1 Module wiring

Correct electrical wiring

• Check that the wiring is correct before starting the system. If the measured open circuit voltage (Voc) and short circuit

current (Isc) do not match the specifications provided, there may be a wiring fault.

Correct connection of the MC4 connector

• Make sure the MC4 connector is secure and properly connected. The MC4 connector must not be subjected to external

pressure. The MC4 connector can only be used for circuit connection functions and should not be used to turn the

circuit on and o.

• The MC4 connector should be kept dry and clean to prevent rain and moisture. Avoid direct sunlight and water soaking

of the MC4 connector.

Use appropriate materials

• Depending on local fire, construction and electrical standard, use dedicated solar cables and suitable MC4 connectors

to ensure the electrical and mechanical performance of the cable.

Cable protection

• Secure the cable to the mounting system with a cable tie that is UV resistant. Appropriate measures should be taken to

protect the exposed cable from damage (eg. in a plastic sleeve with UV aging resistance). Avoid direct exposure of the

cable to direct sunlight.

4.2 Grounding

• With adhesive on the back of SMF modules, there is no metal conductor for the module or the bracket, so no grounding

of module is required.

© Master Instruments Pty Ltd www.master-instruments.com.au page 7 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

5.0 Installation instructions

5.1 Module and tools

5.1.1 Module Handling

Applicable module models: SMF100F-3X12UW, SMF175M-4X09UW & SMF215F-4X18UW. The electrical performance

parameters are detailed in Annex A.

Use gloves when handling modules. The module is sensitive to oils and abrasive surfaces, which may lead to scratches and

irregular soiling. Do not place modules such that the module encounters abrasive surfaces and minimize any contact with the

module in general. Do not place anything on the modules, even for a moment. Never lift or move the module using the cables or

the junction box under any circumstances. Remove any fingerprints by washing the module as described in the Maintenance &

cleaning Section.

Modules should be handled without excess bending or bending at sharp angles or twisting of the panels. The panels are

designed to withstand a 30-degree bend in the panel, top to bottom where the top is the side with the junction box. This is

approximately 8cm of deflection. Additionally, no sharp objects should be placed in contact with the panel. This can result in

puncture of the panel and/or damage to the solar cells or connectors in the panel, resulting in decreased power output and

potentially a safety hazard.

Junction boxes, cables and connectors should never be subject to a sharp or blunt force.

This can result in a broken or cracked junction box, cable, or connectors such that the panel

should not be used.

Module Mounting: The Sunman Limited Warranty for PV Modules is contingent upon modules being mounted in accordance

with the requirements described in this section.

• Site Considerations: Sunman modules should only be mounted in locations that meet the following requirements.

• Operating Temperature: All SunPower modules must only be mounted in environments that ensure they will operate

within the temperature range of -40° C to +85°C.

Care should be taken to provide ventilation behind or underneath the modules, especially

in hot environments. In cold environments of less than 0° C (32° F), care should be taken to

avoid flexing of the panel or impact to the panel. Do not silicon around the perimeter of the

panels.

© Master Instruments Pty Ltd www.master-instruments.com.au page 8 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Module stacking and handling operations are as follows:

Unpacking precautions

Avoid operating in rainy weather when opening cartons outdoors. Secure the modules when operating outdoors in windy

conditions.

Stack components in a ventilated, rain-proof, and dry area before unpacking them.

Do not to damage the front or back of the module when using scissors or hobby knife to cut the outer packing tape.

Confirm the number of modules in the box promptly after unpacking.

The unpacking area needs to ensure that the box is placed horizontally and stably to avoid tipping of the modules.

© Master Instruments Pty Ltd www.master-instruments.com.au page 9 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Mounting Considerations:

Modules mounted over a roofing system must be mounted over a fire-resistant roof covering rated for the application. To

reduce soiling, modules should be mounted at a minimum of 10 degrees.

Modules may be mounted flexed

in either Longitudinal or Traverse

orientation.

The flexing in the Longitudinal (width)

axis can be either convex or Concave

not both simultaneously.

The flexing in the Traverse (Length) axis

can be both Convex and Concave.

The flexing in all axis simultaneously

will cause undue stress on the panel

substructure causing reduced service

life.

To prevent water from entering the junction box, which could present a safety hazard, modules should be oriented with the

junction box in the uppermost position. The junction box should not be mounted in a depression when mounted on a flat

surface. Note that the junction box manufacturer rates this junction box with an ingress protection rating of IP67.

Installation

In full sun applications, these panels may get up to 85°C. The expansion & contraction of both the panel and surface being

mounted to must be considered.

• Cleaning the contact surfaces: To ensure proper adhesion, all surfaces (mounting surface, back of panel and strips if

being used) must be cleaned and degreased. Not doing so will weaken the bond and can cause the bond to fail.

i. Clean the surfaces as per maintenance & Cleaning instructions above to remove excess grime/dirt.

ii. Check the surface for any loose paint or blemishes, if required rub the mounting surface with a fine or medium grit

emery.

iii. Use a suitable degreasing product such as industrial alcohol or isopropyl alcohol.

© Master Instruments Pty Ltd www.master-instruments.com.au page 10 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Solid Backings

Method 1.

Polycarbonate Twinwall 10MM

This method creates a 15mm air gap under the panels to maximise eciency.

Cut the Polycarbonate Twinwall into 30

mm strips.

To be fixed across the width of the

panels.

Use two (2) strips at the top and bottom

of the panels.

A single strip is also required to be fixed

in between each row of cells.

Use the Polycarbonate Sheet Joiners to

join panels.

Use the Polycarbonate Sheet Ends to

provide additional support to edges.

Fixing: Avoid using Polyurethane

Adhesives.

Use either:

• Fixtech 15 High Bond Marine

adhesive

• 3M VHB 4910 tape Very High

Bond Form Tape

Method 2.

Sealed Marine Ply

Cut Strips of 12 MM Marine Ply and seal.

Fixing:

Cut Strips of 12 MM Marine Ply and seal.

Avoid using Polyurethane Adhesives.

Use either:

• Fixtech 15 High Bond Marine adhesive

• 3M VHB 4910 tape Very High Bond Form Tape

Installation as per Polycarbonate Twinwall 10MM

© Master Instruments Pty Ltd www.master-instruments.com.au page 11 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Gluing

Gluing nozzle cutting

The standard nozzle cutout is 10.5mm x 6mm, which is made by cutting about 20mm from the original nozzle and flattening it to

the required size, as shown in the figure below.

Ensure the Fixtech 15 High Bond Marine adhesive is applied across the full width of PV panel.

The Bonding spacing should be Top & Botton & Central between each row of cells of the panel.

Please see below for proper bead application of Fixtech 15 High Bond Marine adhesive.

Operation steps

1. Use a straightedge or tape measure to measure the

length of the head of the nozzle 20mm, confirm the cutting

position, and then use the tool to cut in addition.

2. It is recommended to use a lighter to heat the tip of the

rubber nozzle for about 2s to prevent it from springing back

after being flattened.

3. Squeezing of the nozzle to the desired size using a

flattening die of the tool shears.

© Master Instruments Pty Ltd www.master-instruments.com.au page 12 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Gluing parameters

Gluing length: 10.8m/600ml on average Gluing speed: about 10cm/s

Gluing angle: the glue gun is at an angle of about 40° with the ground, as shown in the following figure:

Adhesive size and standard dosage: at least 10*5mm; 5 strips/1 module (adhesive along the width of the PV module); 3 strips/1

module (adhesive along the length of the PV module)

The correct form of structural adhesive after pasting modules.

© Master Instruments Pty Ltd www.master-instruments.com.au page 13 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Method 3.

Double Sided Very High Bond Tape

Use 3M VHB 4910 tape Very High Bond Form tape.

Apply double-sided acrylic high bond foam tape to both sides of the Polycarbonate or

Marine Ply strips and attach to the panel (leave the top layer of red plastic intact for now).

Finger pressure must be used to push the tape into the surface to make sure that it has

sucient grip on the surface for adequate bond strength.

Once the strips are attached to the panel, proceed to carefully lay the panel into position and remove the red plastic layer.

Gently apply pressure in between the cells, along the strips, ideally with a roller. Ensure you do not apply excessive force or push

on the cells where there is no strip behind as this will damage the cell.

Wait time of tape to full strength:

20 minutes – 50% strength 1 hour – 75% strength 1 day – 90% strength 3 days – 100% strength

Canvas Backings

Ensure:

• Canvas is taut which is essential to avoid “flapping” induced mechanical stress on the panel.

• Panels are well supported by the canvas over the entire back surface of the panel.

• Slight bending of panel in one axis.

Bolt-On Canvas Mounting: Use this method in conjunction with 3M VHB 4910 tape.

© Master Instruments Pty Ltd www.master-instruments.com.au page 14 of 14

Sunman_RV-Marine-Flexible-Panel_Installation_Guide_2023

Zip -On Canvas Mounting:

• Use polyester or PTFE based thread.

• Attach zips in opposite directions so the sliders are at opposite corners of the panel.

Canvas / Solid Backings

• Loxx fasteners mounting

Specifications in this manual are subject to change without notice.

This manual suits for next models

2

Table of contents

Popular Solar Panel manuals by other brands

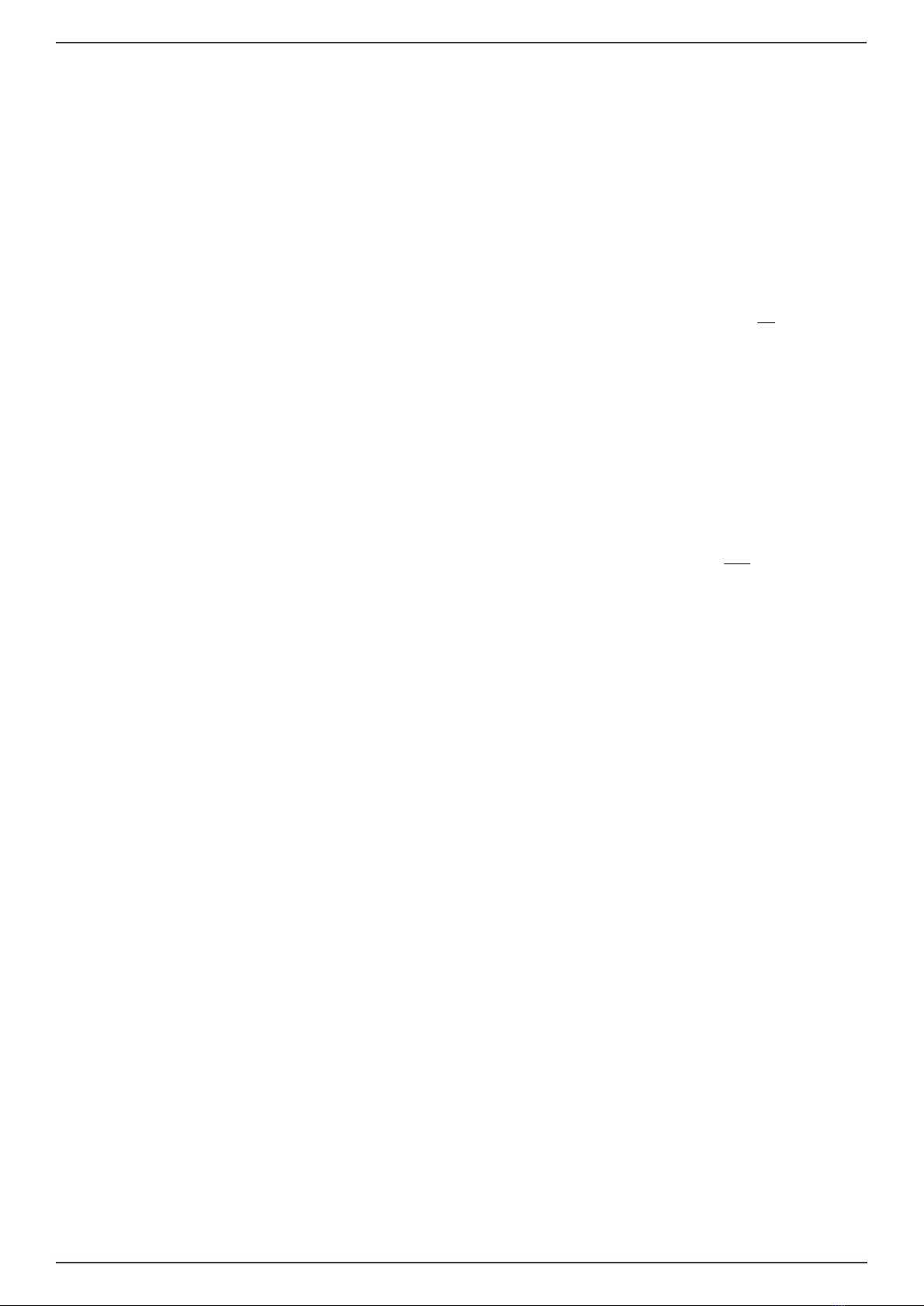

Floe

Floe 511-01351-00 Assembly instructions

Plug-In Solar

Plug-In Solar Sheet Metal/Flat Roof Mount Kit installation instructions

RAKwireless

RAKwireless 7249 installation guide

Horizont

Horizont 14499 instruction manual

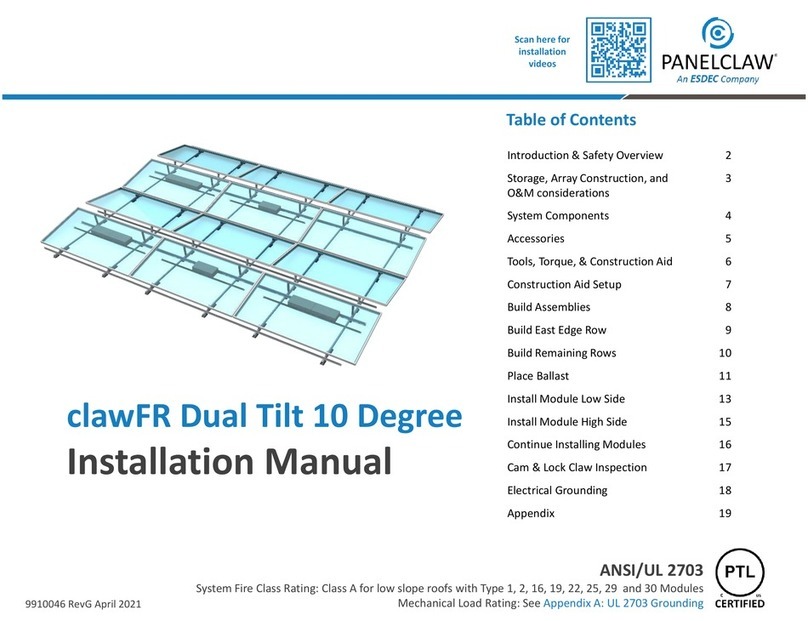

ESDEC

ESDEC Panelclaw clawFR Dual installation manual

Sonnenkraft

Sonnenkraft RKA2500 manual

Carbest

Carbest SC100 User instruction

Xstream

Xstream Flat Plate Collector Mounting Installation Instructions

SLK SOLAR

SLK SOLAR PV MODULE Assembly instructions

Schletter

Schletter PvMax3 Mounting instructions

Enersol

Enersol Solar Panel installation guide

Megasun

Megasun ST-2000 Installation instructions and owner's manuals