Miatech Bio Turbo 100i Owner's manual

SPECIFICATION SHEET | MAR ,

TECHNICAL INSTRUCTIONS

Bio Turbo 100i User Guide

Specication Sheet ..........

Installation Guide. ...........

Layout Diagram. .............

Maintenance Guide ..........

Wiring Diagram..............

MAR ,

AIRBORNE BACTERIA & ETHYLENE REMOVAL

MIATECH TECHNICAL INSTRUCTIONS | BIO TURBO I USER GUIDE SPECIFICATION SHEET | MAR ,

Features

• Smart LED’s for easier service

• Easy service

• Easy changing of ozone plates and lters

• Four models for proper coverage

• Aluminum and Stainless Steel

generation chamber

• Easy to install and operate

• Low maintenance

Model BIO TURBO i

Maximum volume up to ³ ( m³) per hours

Airflow CFM (. CMM)

Location Requirements

Electrical Source V AC

Circuit breaker A

Maintenance

Air Filter Change every months

Ozone Plate(s) Change every months

Number of Ozone Plates

Specications

Size:

Height inches ( cm)

Width inches ( cm)

Depth inches ( cm)

Weight lb ( kg)

Construction

Materials:

Unit cabinet Aluminum

Perforated Generator Plate Stainless Steel

Controls

Remote control: N/A

Power Switch

Bio Turbo 100i

Specication Sheet

MIATECH TECHNICAL INSTRUCTIONS | BIO TURBO I USER GUIDE INSTALLATION GUIDE | MAR ,

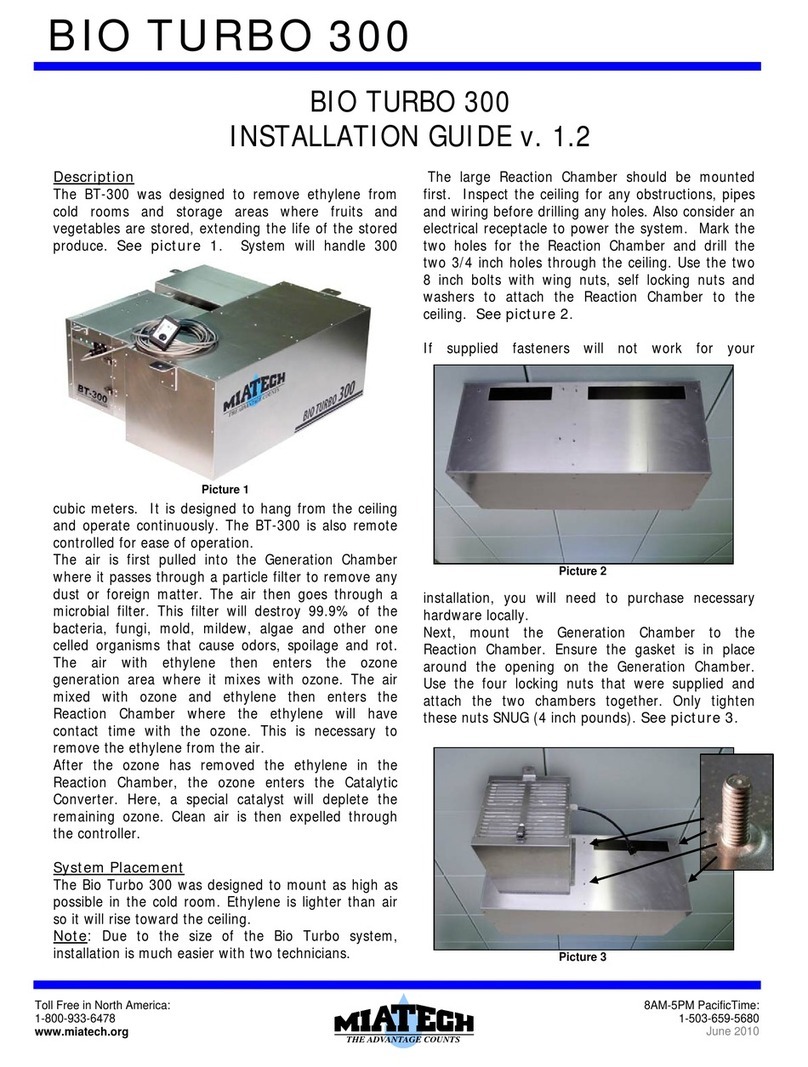

DESCRIPTION

The BT i was designed to remove ethylene from cold rooms and

storage areas where fruits and vegetables are stored, extending the

life of the stored produce.

System can cover up to m³ per hours. It is designed to

operate continuously.

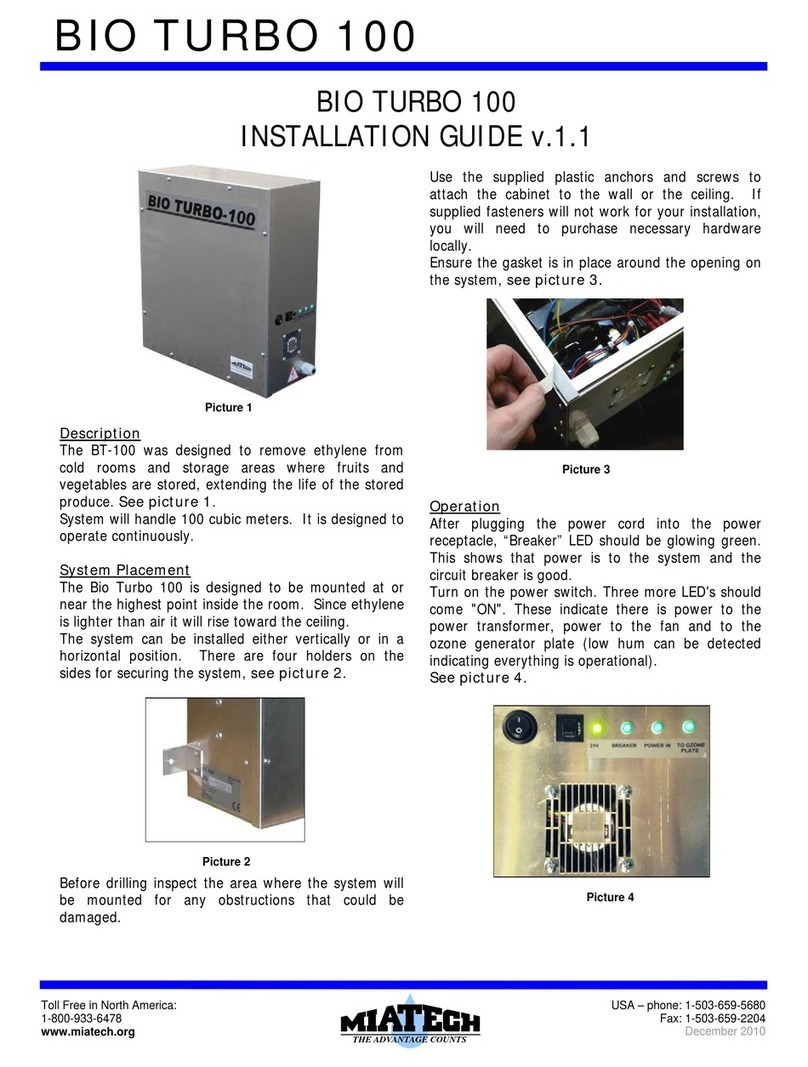

SYSTEM PLACEMENT

The Bio Turbo i is constructed to be

mounted to the ceiling of the truck. Since

ethylene is lighter than air it will rise toward

the ceiling.

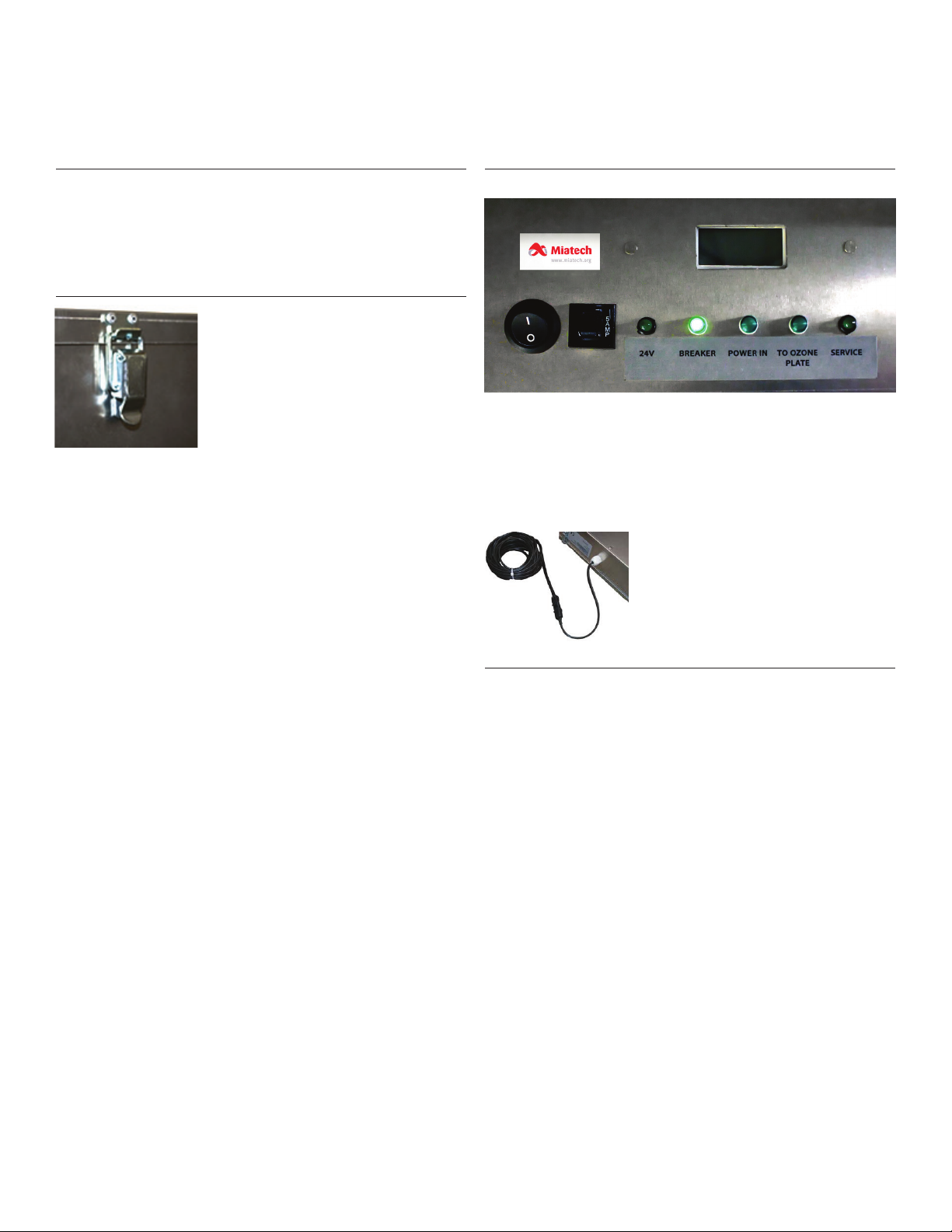

There are four snap clips on the sides for

securing the system to its holding frame

that can be easily installed to the ceiling

(see picture ).

Before drilling inspect the area where the

system will be mounted for any obstructions that could be damaged.

Use the supplied screws to attach the holding frame to the ceiling. Aer

the holding frame is installed you can easily secure the system to its frame.

OPERATION

Picture 2

Aer supplying the V power to the system, “Breaker” LED should

be glowing green. This shows that power is to the system and the

circuit breaker is good. Turn on the power switch. Three more LED’s

should come “ON”. These indicate there is power to the transformer,

power to the fan and to the ozone generator plate (a low hum should

be detected aer the unit is plugged in) (see picture ).

Picture 3

In case you want to remove Bio Turbo i

from the truck, please disconnect the

unit’s power cable using quick connector

(see picture ).

: Plus on the power cable is

marked with red.

COUNTDOWN SERVICE TIMER

System is equipped with the Service Timer which is counting down

days to the next maintenance when system is operating. Timer

is set to days and when it gets down below days it starts

beeping and Service LED light on the system will flash, signaling

maintenance is due. Service Timer has to be reset back to days

aer maintenance is completed.

Bio Turbo 100i

Installation Guide

Picture 1

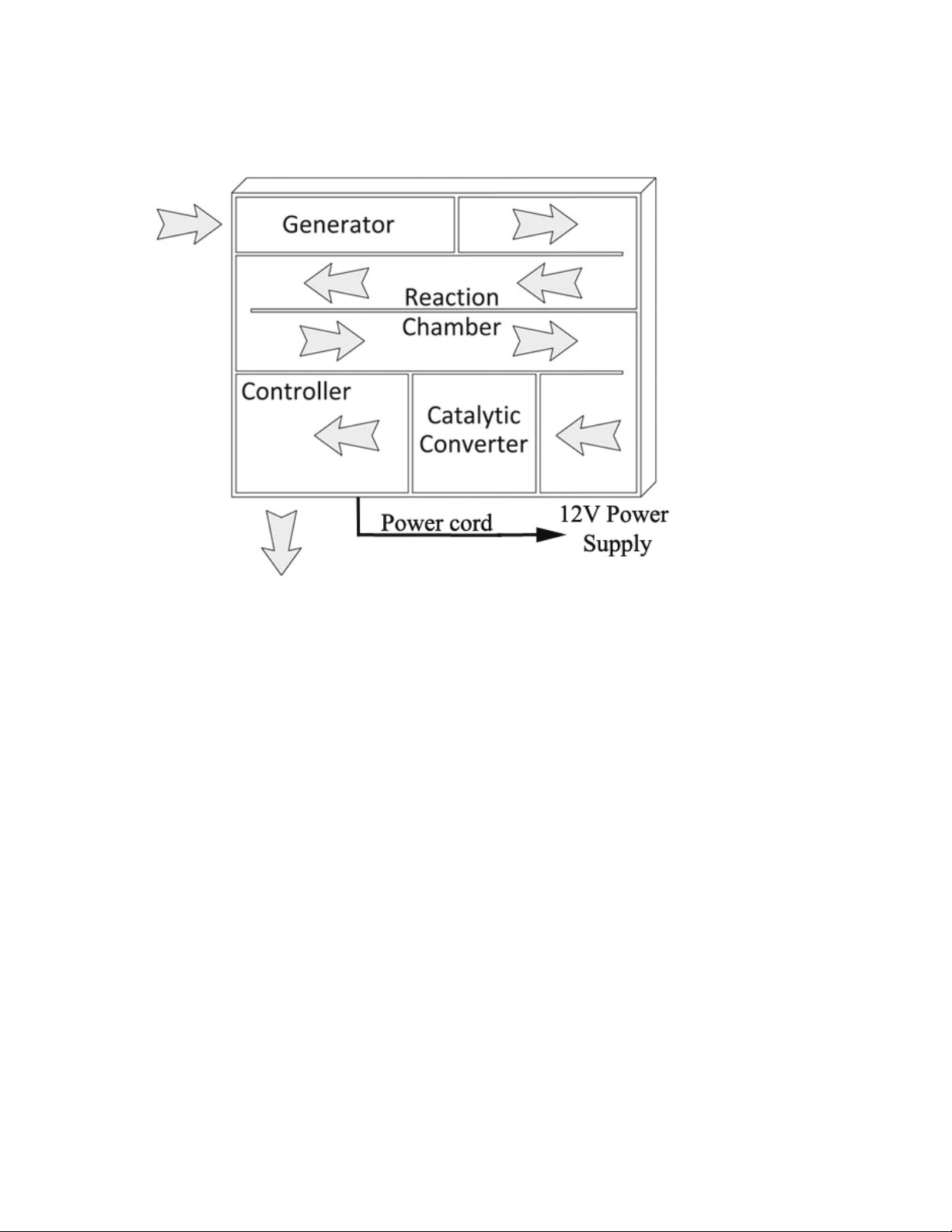

MIATECH TECHNICAL INSTRUCTIONS | BIO TURBO I USER GUIDE LAYOUT DIAGRAM | MAR ,

Bio Turbo 100i

Layout Diagram

BIO TURBO 100i

Toll Free in North America:

1-800-933-6478

www.miatech.org

USA –phone: 1-503-659-5680

Fax: 1-503-659-2204

MAY 2014

THE ADVANTAGE COUNTS

BIO TURBO 100i

LAYOUT DIAGRAM v. 1.1

MIATECH TECHNICAL INSTRUCTIONS | BIO TURBO I USER GUIDE MAINTENANCE GUIDE | MAR ,

Bio Turbo 100i

Maintenance Guide

:

ALWAYS UNPLUG POWER BEFORE SERVICE!

Maintenance Requirements

Annual service requires the replacement of Air Filter

(more oen if environment is very dusty) and the

replacement of the Ozone Generation Plates.

To replace the Air lter and the Ozone Generator Plates:

• Disconnect the unit’s power cable using quick connector.

• Unlatch four snap clips on a holding frame and put

a system on a ground.

• Unscrew the system lid (opposite from holding frame).

• Remove and replace the air lter (#).

• To replace the Generator Plate (#) disconnect the

power cables from plates, release from the holder,

remove and replace with new one.

System is equipped with the Service Timer (#) which

is counting down days to the next maintenance when

system is operating. Timer is set to days and

when it gets down below days it starts beeping

and Service LED light on the controller box will flash,

signaling maintenance is due. Service Timer has to be

reset back to days aer maintenance is completed.

To reset the Service Timer:

• Unscrew two nuts that are holding the timer (from

the inside of the controller box). Remove the timer,

press and hold the reset button until numbers start

flashing. By pressing the same button select

and wait until it denes (numbers will stop flashing).

Place the timer back and secure with nuts.

. Power switch (#)

. amp breaker (#)

. V LED (#)

. LEDs V (#), V (#)

. Service V LED (#)

. Air lter (#)

. Lifetime lter pad (#)

. Generator plate (#)

. Door switch (#)

. Ozone transformer (#)

. BT service timer (#)

. Solid state relay (#)

. Fan V DC (#)

. Alarm board for fan (#)

. Power Inverter (#)

. Transformer

V / V (#)

. Catalyst container

Diagnostic LED’s Name Description

“Breaker” (on the Controller Chamber) Power to the Unit

“Power IN” (on the Controller Chamber) Power to the Power Supply

“ V” (on the Controller Chamber) Power to the Fan

“To the Generation Chamber”

(on the Controller Chamber)

Power to the Generation Chamber

“Service” (on the Controller Chamber) When the service is needed

Table of contents

Other Miatech Air Cleaner manuals