Mic ETS2228 User manual

ETS2228 Maintenance Manual

All right reserved Page 1, Total 43

ETS2228 Maintenance Manual

ETS2228 Maintenance Manual

All right reserved Page 2, Total 43

Contents

Chapter 1 Overview...................................................................................................................................3

1.1 Brief Introduction of Product...............................................................................................3

1.2 Specifications of the Software and Hardware ..............................................................................4

Chapter 2 ETS2228 Principles.................................................................................................................5

2.1 Principles.......................................................................................................................................5

2.1.1 ETS2228 principle structure.................................................................................................5

2.1.2 Detailed Introduction to Functional Circuit Unit......................................................................6

Chapter 3 Detailed Introduction of Functional Module..............................................................................15

3.1 Power Part(including power supply and power management).............................................15

3.2 Base Band Part............................................................................................................................20

3.3 Power Management Part ............................................................................................................20

3.4 RF Part........................................................................................................................................23

Chapter4 Engineering Mode and Test Mode.............................................................................................29

4.1 Entrance to engineering mode and test mode.............................................................................29

Chapter 5 Troubleshooting.......................................................................................................................30

Chapter 6 Nam Programming......................................................................................................................40

Chapter 7 Appendix....................................................................................................................................41

7.1 Damageable Spare Part List.......................................................................................................41

7.2 Schematic Circuit Diagram.........................................................................................................42

7.3 Mainboard Structure Diagram...................................................................................................42

7.4 Test Point Location Diagram......................................................................................................42

7.5 Abbreviations..............................................................................................................................43

ETS2228 Maintenance Manual

All right reserved Page 3, Total 43

Chapter 1 Overview

1.1 Brief Introduction of Product

Based on the protocol IS-2000 and CDMA technology, supporting 450M/800M/1900M with jointing

different RF modules in PIPU, HUAWEI ETS2228 Fixed Wireless Terminal has the following features:

Working on frequency 800M;

Voice services;

Call ID display, Call forwarding, Three-way calling, DTMF, Emergency calling;

SMS

Supporting CDMA2000 1X PS data service (MSM6025);

Being compatible with internal antenna or external antenna(external antenna connected with the

standard RF-connector, which can be disassembled);

Power supply with charge battery or linear power adapter;

Supporting ROMSIM ;

ETS2228 Maintenance Manual

All right reserved Page 4, Total 43

1.2 Specifications of the Software and Hardware

1.2.1 Introduction to software functions

Functional modules within software structure as follows:

(1)Application processing module: Management of voice service.

(2) Protocol shed processing module: to support the CDMA2000 1X standard and being compatible

with the protocol IS-95.

(3)Platform service sub-system: there the common platform to run the software, which includes starting,

diagnosing, downloading, watch-dog etc.

(4)Driver modules: to control the hardware, like RF modules, environment detecting, storage

equipments. In additional, to control modulation and demodulation, to control user interface.

(5)Background Software Management Modules: to write the user configuration information into flash

and to replace configuration parameters to different software versions ,which to meet different operater’s

requirements.

1.2.2 Specification of hardware

Working Frequency Band: Uplink: 824MHz~849MHz;Downlink :869MHz~894MHz

Max. transmitting power: more than 23dBm;

Max. inputting power: -25dBm;

Receiving sensitivity : -104dBm;

Interfaces: Date serial port: DB9 (female), for parameters configuration;

Antenna interface: for installing indoor or outdoor antenna;

Power interface: for power supply;

Common power consumption while calling: 1.2W

Common standby power consumption: 40mW

Dimension: 185 mm × 162 mm × 79 mm

ETS2228 Maintenance Manual

All right reserved Page 5, Total 43

Chapter 2 ETS2228 Principles

2.1 Principles

ETS2228 Fixed Wireless Terminal (FWT) is composed by two boards, keypad and LCD etc. one board

is Terminal Communication Process Unit (TCPU), the other one is Phone Interface Process Unit(PIPU).

The TCPU includes MSM6000 subsystem, Power supply and power management subsystem, RF

subsystem and TCPU interface subsystem; the PIPU includes user interface subsystem(Serial port

protection module, AF channel 1, AF channel 2, Environment monitoring module and PCB version

number check module ), power supply and power manager subsystem(Primary power supply module,

Primary power supply check module, Battery charge/discharge module, DC/DC power module, Power

switch control module).

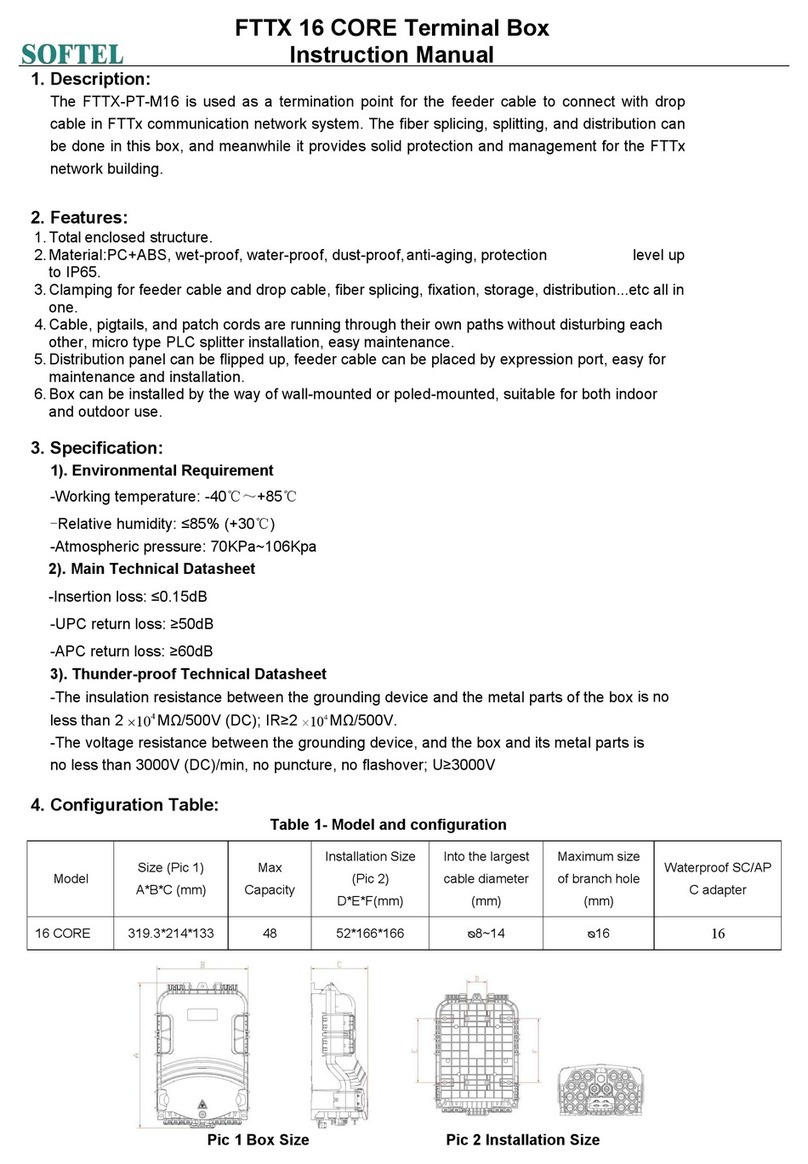

2.1.1 ETS2228 principle structure

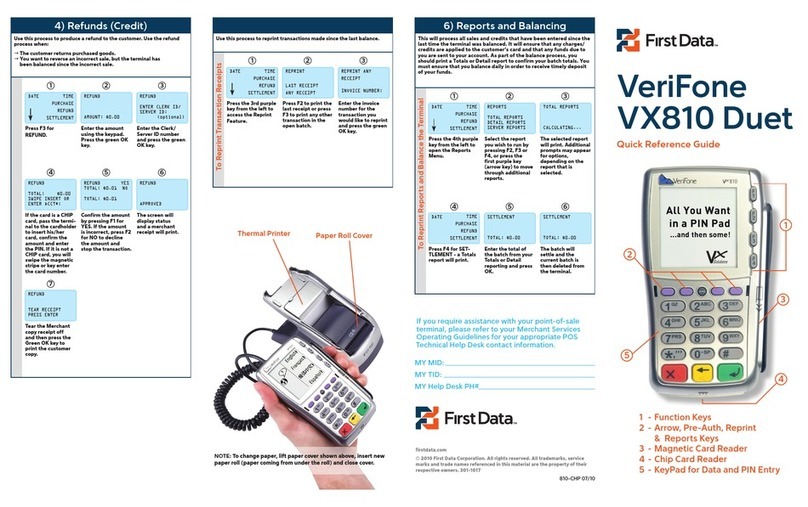

Figure 1: ETS2288 FWT Structure

HUAWEI ETS2228 Fixed Wireless Terminal is composed of two boards and keypad & LCD. One

ETS2228 Maintenance Manual

All right reserved Page 6, Total 43

board is Terminal Communication Process Unit (TCPU) and Phone Interface Process Unit (PIPU). The

hardware architecture of FWT is shown in Figure 1.

The TCPU is the core of an FWT, including a radio frequency (RF) receiving and transmitting unit,

a central processing unit and a power module.

The PIPU and the TCPU are connected through a 72-pin weld-pads (72 weld-pads locates around

the TCPU, which to connect the PIPU in the castellation form). The PIPU provides functions of power

conversion from the external power into the power needed by system, battery charge/discharge

management, voice signals processing. Besides the PIPU is the bridge between the TCPU and keypad &

LCD.

2.1.2 Detailed Introduction to Functional Circuit Unit

Power-on Circuit(Battery and Power adapter)

When powering on WL71PIPU, the whole process as follows:

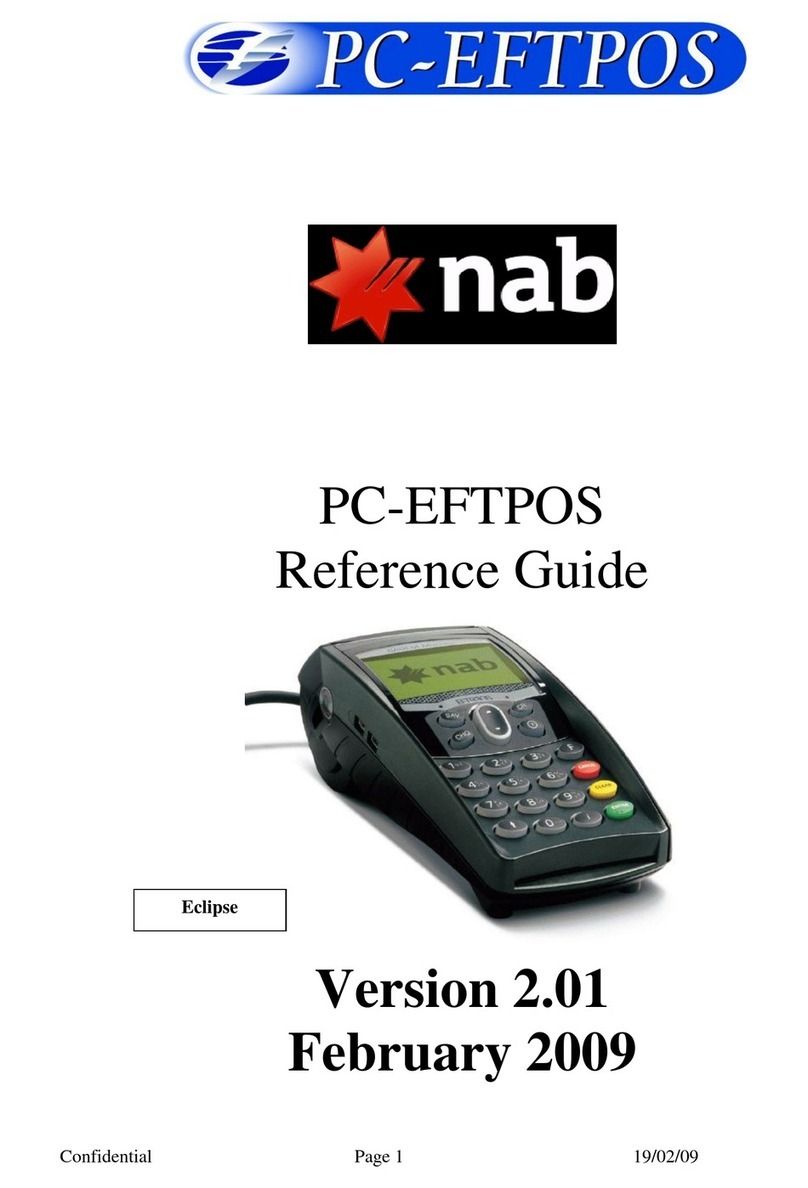

There are two ways of power supply: one is battery, the other is external power. When using the

later one, VEXT_DC up to 5V, then PM6610 begins to work and software startups. At this moment,

some functions of software have been running and the system begins to detect and charge the battery, the

display of LCD in charging status. If holding the Power-off key for 4S (keeping down the voltage of

TERM_ON), the process of Power-on will be closed, the software all in running, searching the net and

being in idle status.

When using the battery, there is only the voltage of VREG_PHONE, the system keeping down the

signal Term_on, PM6610 begins power conversion to the one needed by other modules and software

started up. The programme is the same if we turn on the Power-on switch: when turning it on, PM6610

and software starts up. The software only detects the Power-on switch being holding over 4S, it means

the normal power-on. If not, the process will be closed.

ETS2228 Maintenance Manual

All right reserved Page 7, Total 43

Figure 2 Power-on Circuit With Battery

Charging Circuit

When charging or discharging to battery, the management module is controlled by MSM6000 in TCPU.

MSM6000 detects the voltage of the battery to output the signal CHG_EN, which control the charging to

battery or not. If needed, the system will charge the battery.

1. Battery discharging: If there is no external power, MSM6000 control PM6610 to power supply the

system by battery.

2. Battery charging: if there is external power, MSM6000 control PM6610 to charge the battery or not.

The battery is charged or not, which by controlling the output current form the secondary power.

When the battery in fast charging status, the grid of Q303 is low and not through. The internal

differential amplifier (TL494) will control the pulse duty ratio of PWM, which the current output of

switch power supply will be restricted to 830mA; when the battery in slow charging status, the grid of

Q303 is high and through. The internal differential amplifier (TL494) will control the pulse duty ratio of

PWM, which the current output of switch power supply will be restricted to 75mA. Finally the fast

charging operation will be stopped and replaced by the slow charging operation. The feedback loop is

accomplished by the internal differential amplifier (TL494).

ETS2228 Maintenance Manual

All right reserved Page 8, Total 43

Signal Modules Function Description

VREG_PHONE the secondary power conversion module the output of the secondary

power:4.44V

V_BATT Battery->PM6610 the battery output voltage

CHG_EN PM6610->TL494 PM6610:control the output

List 1 Battery Charging/Discharging Module Signals

Figure 3 Battery charging Circuit

Battery is connected to the output of the secondary power supply(4.4V) directly. When there is no

external power supply, battery powers the system supply through the signal VREG_PHONE, and there is

no special discharging control circuit.

Audio Interface Circuit

ETS2228 audio interface includes handle receiver (the microphone and earphone is included),

speaker interface and hands-free MIC interface. The power of speaker is quit bigger than the others,

which must be amplified through the audio amplifier, but for hands-free MIC interface and handle

receiver can be connected directly.

1)Handset MIC Interface。Bead and capacitor constitute the filter circuit.

ETS2228 Maintenance Manual

All right reserved Page 9, Total 43

Figure 4 Handset MIC Circuit

2)Handle Receiver Interface. Bead and capacitor constitutes the filter circuit.

Figure 5 Handle Receiver Interface

3)Hands-free Interface Circuit

The audio amplifier amplifies EAR2 signal to speaker, the switch of speaker is controlled by the bias

voltage of MIC2_P. And when the bias voltage of MIC2_P is zero, the voice channel and the audio

amplification is shut-down, which the system is in idle status. Possible faults of the hands-free channel:

no ringing, then check whether U603 is wrong or not.

ETS2228 Maintenance Manual

All right reserved Page 10, Total 43

Figure 6 Hands-free Interface Circuit

LCD unit

In the ETS2228 FWT, LCD is a peripheral component. If wrong with LCD, it can be replaced

directly. The PIPU is compatible with the lattice LCD and the segment LCD, ETS2228 adopt the

lattice LCD.

ETS2228 Maintenance Manual

All right reserved Page 11, Total 43

Figure 7 LCD Hardware Interface Circuit

PIN NO. FUNCTION DESCRIPTIONS SYMBOL

1 This is the chip select signal. /CS1

2 /RES

3 A0

4 R/W

5

E

ETS2228 Maintenance Manual

All right reserved Page 12, Total 43

6~13 DATA BUS DB0~ DB7

14 Power supply VDD

15 Ground VSS

16 VOUT

17 CAP3P

18 CAP1N

19 CAP1P

20 CAP2P

21 CAP2N

22

DC/DC voltage converter.

CAP4P

23 V4

24 V3

25 V2

26 V1

27

This is a multi-level power supply for the liquid crystal drive. The voltage Supply

applied is

determined by the liquid crystal cell, and is changed through the use

of a resistive voltage divided

or through changing the impedance using an op.

amp. Voltage levels are determined based on Vss,

and must maintain the relative magnitudes shown below.

V0 ≧V1 ≧V2 ≧V3 ≧V4 ≧Vss V0

List 2 Lattice LCD Signals

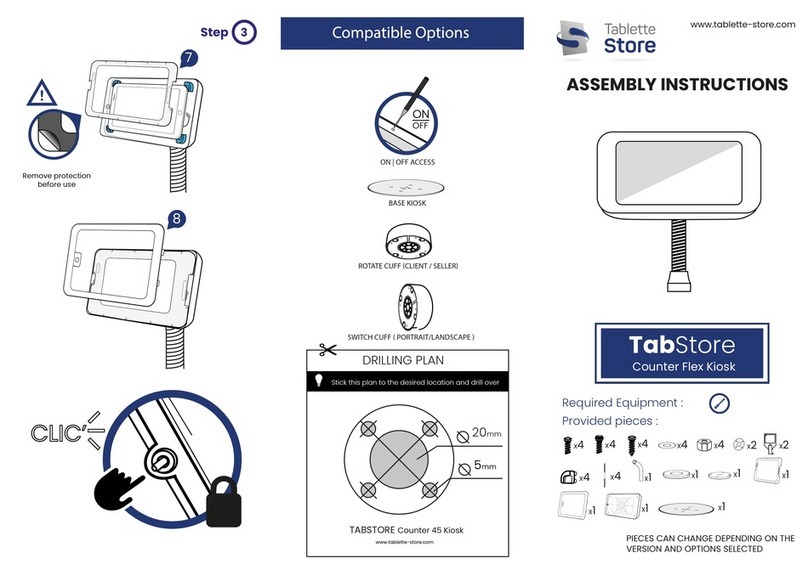

Keypad unit

In the ETS2288 series FWTs, the keypad is a peripheral component. If it is broken, it can be

directly replaced. And 72PIPU veneer uses 5×5 keypad。

ETS2228 Maintenance Manual

All right reserved Page 13, Total 43

Figure 10 keypad implements circuit

Figure 1 keypad back facet circuit

Asynchronous serial port drive circuit

We put the drive of the serial port onto the serial port line. The output power level of

the serial port drive does not match the MSM6000 power level---The high power level of MSM6000 is

2.8V, while the high power level of the serial port drive is 4.4V. Thus, what is needed is to make a

power-level conversion and protection circuit for the transistor to convert the power level of the serial

port circuit. The dual transient suppression diode protects the serial port and prevents the damage

towards the system from abnormal power level input such as ESD.

Serial port signals are divided into 5 groups:

1) Data receiving signal RS_RD (Input); Data sending signal RS_TD (Output).

2) Traffic signal clearing/sending RS_CTS(Input); Request sending RS_RTS (Output)

3) Modem status signal (modem refers to FWT); Carrier wave detection UART1_DCD (Output);

Data terminal ready UART1_DRT (Output)

4) Serial port indicating UART1_IND (Output). The power level (high/low) is determined by the

serial port line. The power level differentiates debugging data line and high-speed data line. Low power

level indicates high-speed (230400BPS) and high power level indicates low speed

(115200BPS).

5) External serial port drive power supply VDD1_RS. The power switch is controlled by the

MSM_P voltage.

The circuits are shown by the following diagrams:

ETS2228 Maintenance Manual

All right reserved Page 14, Total 43

Input power level conversion circuit:

Figure 2 Input power level conversion circuit

Output power level conversion circuit:

Figure 3 Output power level conversion circuit

Data receiving signal power level conversion circuit. The power level conversion of signal

UART1_RX is accomplished by clamp circuit. The reason lies in that the signal power-level needs to be

lowered to detect whether or not the serial port line is connected when there are no data lines.

ETS2228 Maintenance Manual

All right reserved Page 15, Total 43

Figure 4 Data receiving signal power level conversion circuit

Chapter 3 Detailed Introduction of Functional Module

3.1 Power Part(including power supply and power management)

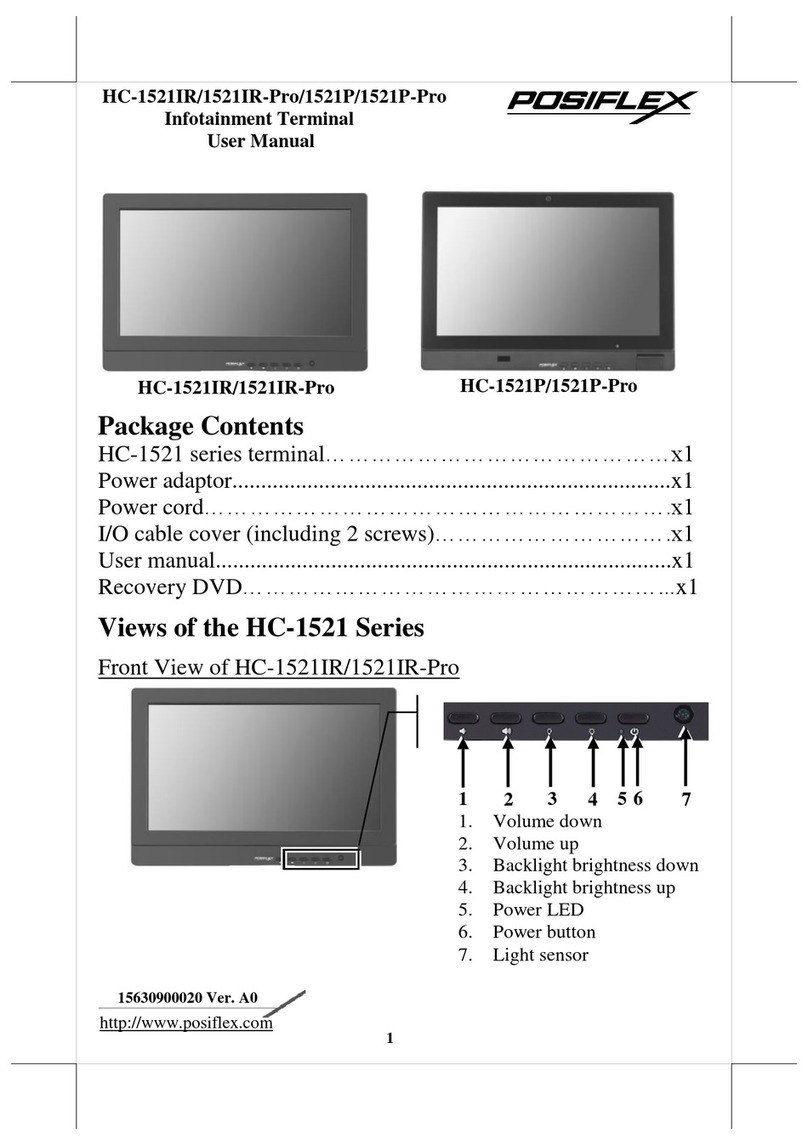

1 .DC/DC power protect module

This part is chosen joint circuit .the external power over voltage protection module protects the

input power. When the input voltage exceeds 30V, the protection circuit will function. Then the silicon

controlled thyristor is in the continuity status and the self-healing fuse F301/F302 (we only need to joint

one of them and now we joint F301) will be blown. Thus, the power protection circuit will be cut.

ETS2228 Maintenance Manual

All right reserved Page 16, Total 43

Figure16 External power over voltage protection module

2. DC/DC power module

The DC/DC power module generates 4.4V main power necessary for the operation of the whole

machine. It also fulfills the constant current charging function. The maximum output current is 830mA.

We mainly use the PWM control chip (U302) and the switch transistor (Q301) to complete the

second-time switch power circuit. It is the switch power supply that converts the external power into

4.4V.

Figure 5 DC/DC Power transfer circuit

The PWM control chip adopts TL494, including 2 differential amplifiers, 1 external adjustable

oscillator, 1 pulse comparer, 1 time overflow controller, and 1 output control circuit.

ETS2228 Maintenance Manual

All right reserved Page 17, Total 43

Figure 6 TL494

The differential amplifier can work within the range from AC -0.2V to 0.2V. The time overflow

controller has a fixed offset to assure the stable output in case of the changed external input. The external

oscillating circuit can be set through Rt/Ct (The working frequency to be set is 100KHZ).

3 .Power supply anti-reverse-insertion circuit and external

interface

D305 and D301 fulfill the anti-reverse=insertion function of the external power supply. EXT_DC

signal: Whether or not the external power supply exists; V_BATT signal: Battery voltage;

VREG_PHONE signal: Voltage of the second-time power supply.

ETS2228 Maintenance Manual

All right reserved Page 18, Total 43

Figure19 Anti-reverse-insertion circuit

4 .Second-time power voltage-limiting module

The second-time power voltage-limiting module limits the second-time power voltage to 4.4V.

When the constant current charging operation is ended, the second-time power output is stabilized to

4.4V to provide power for the back-level circuit.. The feedback loop is accomplished by operational

amplifier 1 of TL494.

ETS2228 Maintenance Manual

All right reserved Page 19, Total 43

Figure 7 Second-time power voltage-limiting module

5 .Battery temperature switchover module

The temperature’s measure is finished on TTPU veneer, and the battery’s ID measure is finished on

PIPU veneer.

This module converts the thermistor into voltage and sends the voltage to ADC on the TCPU board

to be measured. Thus, the battery temperature will be measured.

See the following figure for the circuit.

Figure21 Battery temperature switchover module

ETS2228 Maintenance Manual

All right reserved Page 20, Total 43

PM6610 PIN NO. Function Description Signal Name

HKADC5 Veneer temperature

sampling PHONE_THERM

HKADC8 Battery temperature

sampling BAT_TEMP

HKADC9 Battery identify(Battery ID)

BAT_ID

Table 1 Environment variable measure PIN

3.2 Base Band Part

The MSM6000 sub-system includes voice coding/decoding unit, baseband signal processing unit,

and CPU system on which protocol software runs. All these functional units are integrated into the

MSM6000 chip. The main function of the voice coding/decoding unit is to conduct compressing and

coding operations over 64K voice and digital code traffics like EVRC codes, to let them be suitable for

being transmitted in wireless environment. The baseband signal processing unit mainly includes

functions like baseband modulation/demodulation and channel coding/decoding. It also includes the

CPU system through which protocol software runs, as well as FLASH for storing software and SRAM

for running software.

3.3 Power Management Part

Power management sub-system mainly fulfils DC-DC converting of external input power

and managing power voltage which is used by inside circuit.

The function of power management can be divided to two parts: battery management and veneer

circuit’s power management. Battery management mainly supplies the functions of charging/discharging

management and temperature protect etc. veneer circuit’s power management manages power of veneer

unit circuit in order to reduce equipment’s power consumption according to operation state .Such as user

interface circuit ,RF transmitter,MSM6000 all can be set dormancy state to reduce equipment’s power

consumption a lot.

See the following table for Power management module interface signal:

Table of contents