MicaSense Altum Quick setup guide

MicaSense Altum™ and DLS 2

Integration Guide

Revision 10

June 2020

Seattle, WA

© 2020 MicaSense, Inc MSPN 900-00021-01

June 2020

Page 1 of 21

Table of Contents

Table of Contents 1

Introduction2

Firmware 2

What’s Included? 2

Lens and Imager Information 3

Center wavelengths and bandwidth 4

Cameras with serial number AL05 or higher 4

Cameras with serial number AL04 or lower 5

Imager/band number and output 5

Measurements and Attachment Points 5

Recommendations for Installation 7

Configuration Options 8

Default + Overlap mode 8

Default + trigger by HTTP API 9

MAVLink with PixHawk or similar flight controller 9

DLS 2 with Aircraft GPS 10

HTTP Connection 10

Serial Connection 10

Input and Output 11

Host Interface Connector (Power and Data I/O) 12

Power supply specifications 12

Input and Output 13

USB Storage and Ethernet 13

Capture Rate 14

Accessory Port (ACC) 14

Automatic Capture/Triggering 14

Overlap (recommended) 14

Timer 15

External Triggering 15

External Trigger 15

HTTP API (Ethernet and Wi-Fi) 15

Serial API 16

© 2020 MicaSense, Inc

June 2020

Page 2 of 21

Disabled 16

Thermal Non-Uniform Calibration (NUC) 16

Downwelling Light Sensor 2 (DLS 2) 17

Measurements and Attachment Points 18

DLS 2 Connectors and Buttons 18

DLS 2 Installation Guidelines 20

Fixed-wing 20

Multirotor 20

Example Integration 21

Introduction

MicaSense Altum provides multiple options for integration - from stand-alone (where you only

provide power to the sensor) to fully customized integrations. Advanced integrations take

advantage of flexible interfaces including Ethernet, serial, and PWM/GPIO trigger, for seamless

integration with any aircraft.

Firmware

It is important to have the latest version of firmware installed on your sensor. Please see the

following page to get the latest version and learn how to update your firmware:

https://www.micasense.com/firmware-updates

What’s Included?

For the most up-to-date information on what’s included with the Altum sensor kit, please see

the Altum packing list.

© 2020 MicaSense, Inc

June 2020

Page 3 of 21

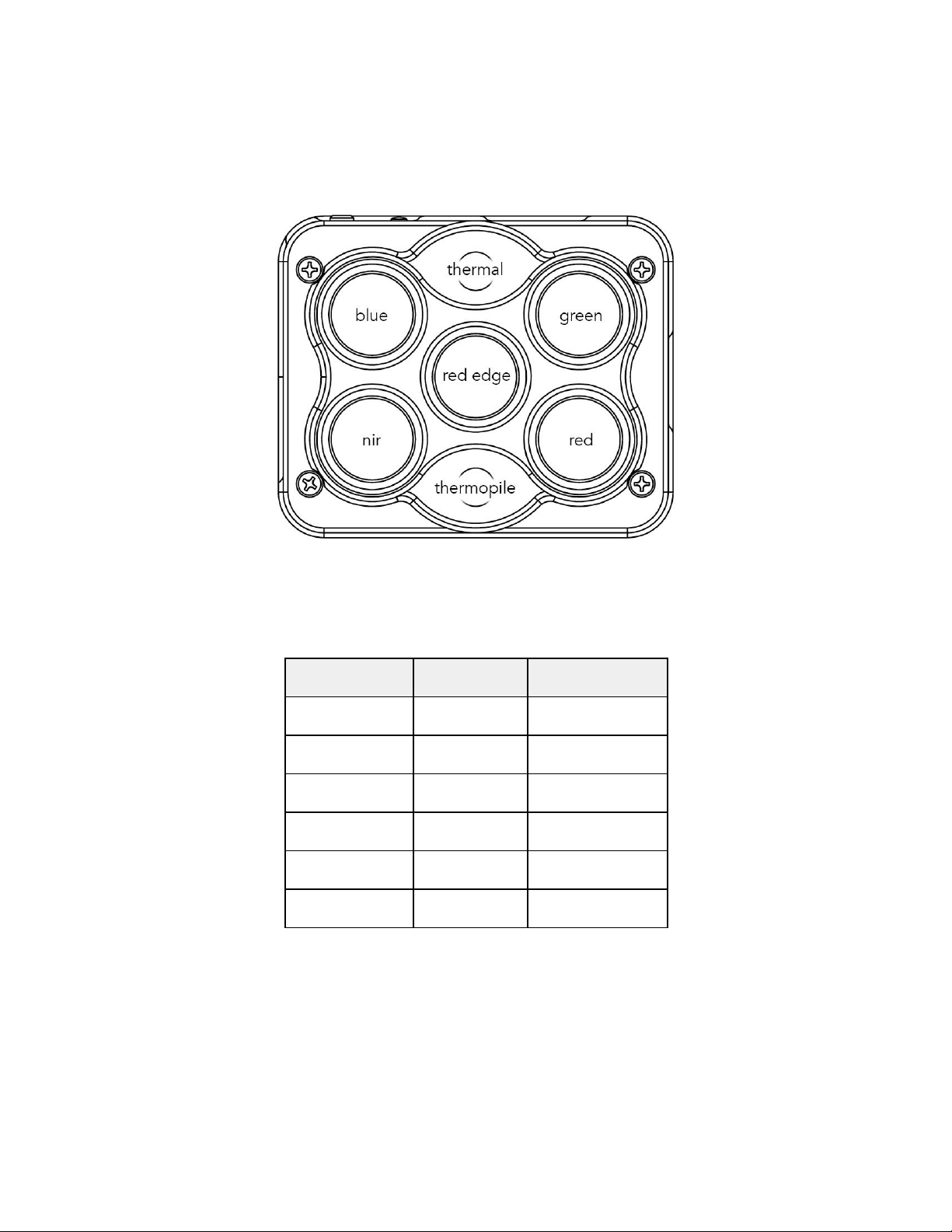

Lens and Imager Information

Multispectral

Thermal

Pixel size

3.45 μm

12 μm

Resolution

2064 x 1544 px

(3.2 MP x 5 imagers)

160 x 120 px

(0.01 K)

Aspect ratio

4 : 3

4 : 3

Sensor size

7.12 x 5.33 mm

(8.9 mm diagonal)

1.92 x 1.44 mm

Focal length

8 mm

1.77 mm

Field of view (h x v)

48º x 36.8º

57º x 44.3º

Thermal sensitivity

n/a

< 50 mK

Thermal accuracy

n/a

+/- 5 K

Output bit depth

12-bit

14-bit

GSD @ 120 m (~400 ft)

5.2 cm

81 cm

GSD @ 60 m (~200 ft)

2.1 cm

41 cm

© 2020 MicaSense, Inc

June 2020

Page 4 of 21

Center wavelengths and bandwidth

Cameras with serial number AL05 or higher

Name

Center

Bandwidth

Blue

475 nm

32 nm

Green

560 nm

27 nm

Red

668 nm

16 nm

Red edge

717 nm

12 nm

Near infrared

842 nm

57 nm

Thermal

11 μm

6 μm

© 2020 MicaSense, Inc

June 2020

Page 5 of 21

Cameras with serial number AL04 or lower

Name

Center

Bandwidth

Blue

475 nm

20 nm

Green

560 nm

20 nm

Red

668 nm

10 nm

Red edge

717 nm

10 nm

Near infrared

840 nm

40 nm

Thermal

11 μm

6 μm

Imager/band number and output

1

Blue

2

Green

3

Red

4

NIR

5

Red edge

6

Thermal

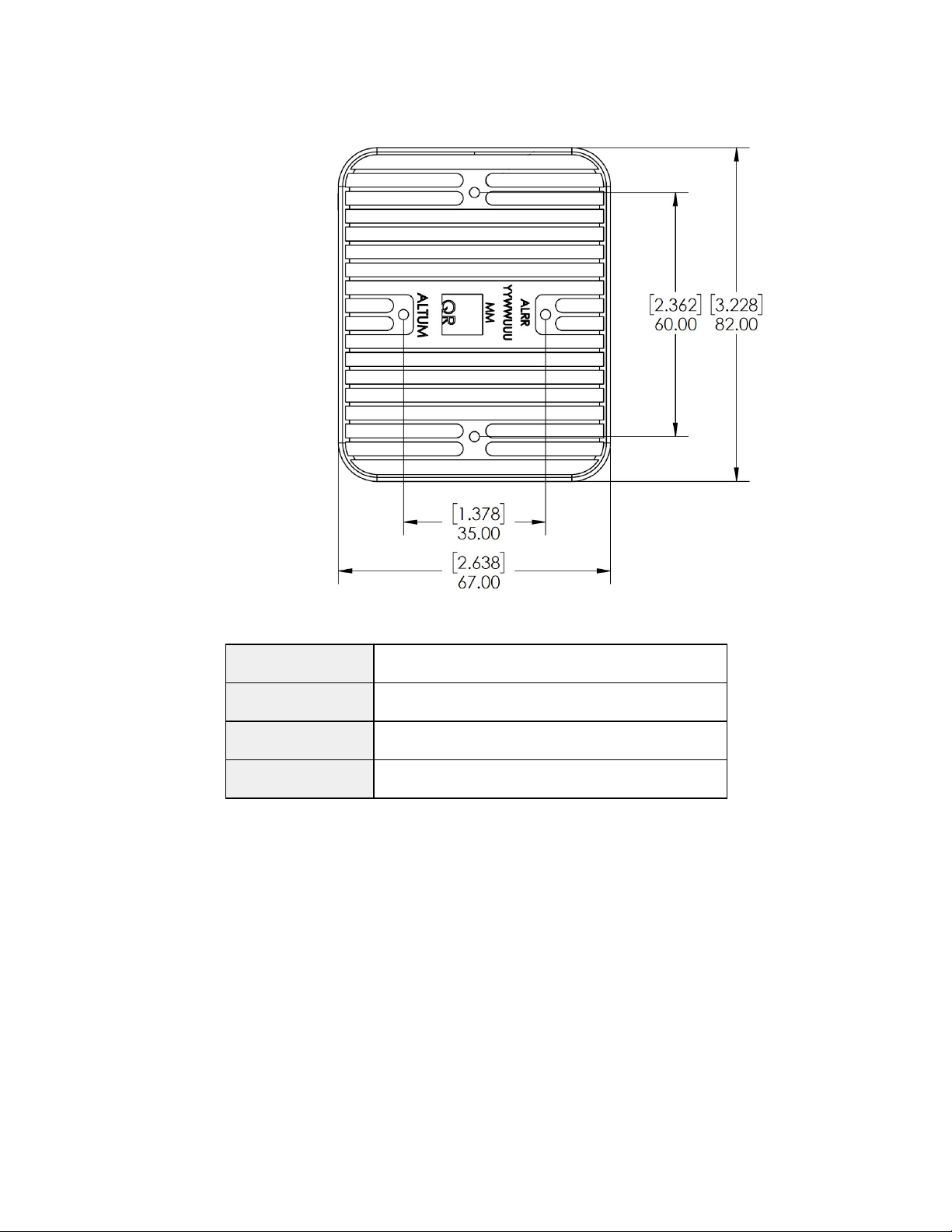

Measurements and Attachment Points

There are four M3 screw holes at 60 mm x 35 mm on-center. The sensor can be attached to

the host aircraft using at least two of the four provided threaded mounting points and M3 x 0.5

screws. If using only two mounting points, it is important to choose two threaded points

opposite of each other.

© 2020 MicaSense, Inc

June 2020

Page 6 of 21

Length

82 mm

Width

67 mm

Height

64.5 mm

Weight

357 g

© 2020 MicaSense, Inc

June 2020

Page 7 of 21

Recommendations for Installation

The Altum should be installed such that it has a clear view of the area directly below the

aircraft. The “cone” of the lenses, especially thermal, which has the widest field of view (57º

HFOV), should be considered in the process of deciding where to mount the sensor on the

aircraft or payload bay.

Avoid putting windows or covers in front of the thermal sensor. Many materials that are

transparent in visible bands are opaque in LWIR (thermal), so any coverings may prevent data

collection. Even materials that are mostly transparent in LWIR will negatively affect the

radiometric accuracy of the sensor output.

The multispectral sensors feature a global shutter and can withstand some vibration without

degrading image quality; nevertheless, we recommend vibration isolation between the sensor

mounting platform and the aircraft.

Make sure the sensor points straight down (with respect to the earth) at all times during flight.

The best way to ensure this is to use a gimbal.

Airflow over all surfaces of the sensor is necessary for proper heat dissipation. Do not run Altum

on the bench or in the field for extended periods of time without airflow. Do not completely

cover or insulate the back surface of the sensor.

Normally, the sensor should be in landscape orientation. If you plan to mount the sensor in a

portrait orientation, remember to swap the vertical and horizontal parameters in your mission

planner.

Ensure that the sensor is completely protected during landing. Note that we do not

recommend using a lens cover during flight as it can filter the wavelengths that the sensor

measures. Instead, protect the sensor with a recessed installation or by using landing gear.

Use the provided lens cover when storing Altum, and do not set Altum lens-side-down as it will

rest on and scratch the lenses.

More integration guidelines for the DLS 2 are in the DLS 2 section of this guide.

© 2020 MicaSense, Inc

June 2020

Page 8 of 21

Configuration Options

There are many ways to configure Altum. The following summaries will help you choose the

one that meets your needs. Many other options are possible. If you have any questions about

your integration, please contact [email protected]

Default + Overlap mode

The default configuration uses the DLS 2’s integrated GPS. Use the provided cable to connect

the DLS 2 to the DLS 2 board on the HOST connector. Ensure the DLS 2’s physical installation

meets the requirements outlined later in the DLS 2 section of this guide. Connect a compatible

power supply to pins 1 and 2 on the HOST connector. For more details about power, see the

Input and Output section of this guide.

Once attached to the aircraft, use the Flight Calculator to determine the necessary overlap

percentage for your desired Ground Sample Distance and Target Altitude, then input the

parameters into the Overlap settings, outlined in the Triggering section in this guide. The

sensor will begin capturing once it is within the Target Altitude Tolerance of your Target

Altitude. It will capture often enough to maintain your overlap percentage at your desired

altitude. This will ensure enough coverage to create a mosaic of your flight area with your

preferred photogrammetry software.

© 2020 MicaSense, Inc

June 2020

Page 9 of 21

Default + trigger by HTTP API

With this configuration, instead of automatically capturing with an automatic triggering mode,

the HTTP API (see below) is used with an onboard computer to trigger the camera at intervals

determined by your computer. See examples of the HTTP API here: Integration examples for

MicaSense sensors.

MAVLink with PixHawk or similar flight controller

The Altum can be triggered with a PixHawk flight control system using the serial API.

MicaSense cameras currently use the MAVLink v1.0 messaging protocol for the serial API,

which the camera uses to interact with PixHawk. You can read more detailed information here:

Guide for MicaSense Sensors and PixHawk.

© 2020 MicaSense, Inc

June 2020

Page 10 of 21

DLS 2 with Aircraft GPS

For more control, advanced users can communicate with Altum by HTTP (Ethernet, Wi-Fi) or

serial (MAVLink) using the MicaSense APIs (Application Programming Interfaces). The APIs can

be used in lieu of the DLS 2 GPS to provide the sensor with a position and attitude data (from

the aircraft GPS, for example). Anytime GPS data is sent to the sensor via the API commands, it

will be written to the image metadata, overriding the DLS 2 internal GPS data for five seconds

(or until another update is sent via the API).

HTTP Connection

Attach a USB Ethernet adapter or USB Wi-Fi adapter to one of the USB 3 ports. See the User

Guide for MicaSense Sensors for connection details and information. For HTTP API details, visit

https://www.micasense.com/api

Serial Connection

Use the provided pigtail from the host connector cable to connect to your serial device. See

the Input and Output section of this document for pin layout and details. Visit

https://www.micasense.com/api to learn more about communicating with the MAVLink API.

© 2020 MicaSense, Inc

June 2020

Page 11 of 21

Input and Output

The Altum & DLS 2 sensor kit includes all necessary cables for integration. If extending the

cables, ensure that the voltage at the camera is at acceptable levels as outlined in the

“Powering” section of this guide.

© 2020 MicaSense, Inc

June 2020

Page 12 of 21

Host Interface Connector (Power and Data I/O)

Connector type/part number: (provided as pigtail assembly with every Altum integration kit from MicaSense)

Samtec - 14pin, 2.00mm Tiger Eye™: PN# T2M-107-01-S-D-RA-WT

13

DLS RX

CAM TXF

11

DLS AUX OUT

CAM INF

9

DLS

POWER

7

CAM HOST

PPS IN

5

CAM RX

HOST TX

3

CAM

PPS OUT

1

POWER

14

DLS TX

CAM RXF

12

DLS PPS OUT

CAM PPS IN

10

DLS

GND

8

ISO GND

6

TRIG IN

4

CAM TX

HOST RX

2

GND

Power supply specifications

Voltage

5.2 V - 25.2 V

Standby

5.5 W

Average

7 W

Peak

10 W

© 2020 MicaSense, Inc

June 2020

Page 13 of 21

Altum requires 5.2 V DC for operation, with a maximum operating voltage of 25.2 V. The

supply must be able to provide 10 W peak. Power can be provided to the sensor in two main

ways:

●shared power from aircraft's main battery pack

●a rechargeable Lithium-Ion battery pack (a two-cell LiPo will provide optimal efficiency).

Ensure the power source conforms to the specifications listed above and can supply the

required voltage at the power port of the camera, accounting for any losses in the wiring.

Input and Output

Nominal IO Voltage*

3.3 V DC

IO Voltage Range*

0.0 V DC to 5.5 V DC

Absolute Maximum IO Voltage*

5.6 V DC

PWM Trigger Expected Range

1.0 ms to 2.0 ms

VIH High-level input voltage*

2.0 V to 5.5 V

VIL Low-level input voltage*

0.0 V to 0.8 V

*All 3.3V HOST IO lines are referenced to ISO GND (Pin 8). To ensure proper operation of

Trigger, Serial, and PPS lines, make sure ISO GND is connected to your host system’s IO

ground. This ground is isolated from the Altum power supply ground and must be connected

for the IO to function properly.

USB Storage and Ethernet

Altum features two high-speed USB 3 ports which support USB 3 compatible devices. Tested,

compatible devices include:

●Samsung MUF-64BA 128 GB flash drive

●Edimax Wi-Fi adapters:

○EW-7811Un

○EW-7611ULB (requires Altum firmware version 2.0.0 or higher)

●AmazonBasics USB 3.0 to 10/100/1000 Gigabit Ethernet Internet Adapter

●Cable Matters USB to Ethernet Adapter (USB 3.0 to Ethernet)

© 2020 MicaSense, Inc

June 2020

Page 14 of 21

Most USB external flash storage devices (thumb drives, hard drives, and others) should work,

but you should perform a thorough bench test before flight.

For details on how the sensor writes files to the storage device, see the File Storage section of

the Sensor User Guide.

Capture Rate

Altum’s capture rate is heavily dependent on the storage device. The Altum kit includes a 128

GB flash drive which has a maximum capture rate of about 1.5 seconds per capture. Using a

USB 3 drive with a fast write rate, such as a 2242 M.2 SATA USB 3 drive, will ensure the fastest

capture rate possible (about one capture per second). When setting up a mission or flight plan,

adjust the desired overlap, flight altitude, and speed so that the capture interval does not

exceed the maximum capture rate.

Accessory Port (ACC)

The accessory port can be used with the Altum SD Card Adapter. When other uses of this port

are available, we will update this guide.

Automatic Capture/Triggering

Altum supports three methods for capturing images: Overlap, Timer, and External Trigger. To

learn more about how to configure these settings, please see the User Guide for MicaSense

Sensors.

Overlap (recommended)

In Overlap mode, when the aircraft climbs to within your chosen Target Altitude Tolerance

below your Target Altitude, Altum will start capturing and only take a capture if it has traveled

forward enough distance to ensure the overlap percentage you have specified. Prior to Altum

firmware release 2.0.0, the Target Altitude Tolerance was fixed at 50 meters, but this can now

be specified by the user. When the sensor's altitude is below the Target Altitude Tolerance

from the Target Altitude, the sensor stops capturing. Overlap mode only calculates the forward

overlap, and cannot account for the side overlap, which must be calculated in a flight planner,

using the sensor’s field of view to create an appropriate row spacing.

We recommend this mode because it helps ensure proper overlap (75% or higher), which is

essential in order to produce high-quality output when processing the data in standard

photogrammetry software.

© 2020 MicaSense, Inc

June 2020

Page 15 of 21

Timer

When in timer mode, Altum will capture according to the timer period, which is every two

seconds by default. If the timer period is set to capture faster than the storage device can write

the captures, inconsistent capture intervals may result. The capture rate is heavily dependent

on the write speed of the attached storage device, and is prone to unreliable physical capture

spacing if the aircraft does not travel at a constant ground speed. See the USB Storage and

Ethernet and Capture Rate headings in this guide for more details.

External Triggering

For more control, you can enable external trigger mode to talk to Altum by PWM or edge

triggering. See the Host Interface Connector section of this document for detailed pin

information.

External Trigger

The sensor can be set to trigger by the rising-edge of a pulse, the falling-edge of a pulse, or a

PWM signal (such as is typically used with standard servos). When using a PWM signal as the

trigger, the sensor detects a transition from a “long” PWM to a “short” PWM (or vice-versa).

When using PWM, rising-edge, or falling-edge, ensure that the input signal’s ground is

connected to the isolated ground pin 8 on the Altum.

HTTP API (Ethernet and Wi-Fi)

The HTTP API is the most powerful way to interface with the Altum. You can use this API using

either the Ethernet connector or the camera’s Wi-Fi access point.

The API is accessed via HTTP connection to port 80 at the sensor IP address. Most data is

exchanged in the JSON format.

The actual value of the IP address depends on the configuration. When accessing the sensor

via its Wi-Fi access point, the sensor IP address will be 192.168.10.254. When the sensor is

connected to an Ethernet network, the sensor IP address will be 192.168.1.83 by default.

The sensor can be commanded to take a capture by either a GET or POST request to the

/capture URL.

For more information, please see https://www.micasense.com/api

For examples, please see these articles:

●Integration examples for MicaSense sensors

© 2020 MicaSense, Inc

June 2020

Page 16 of 21

●Inputs and outputs for MicaSense sensors

Serial API

The Serial API provides a MAVLink interface to the Altum. You can use this API by connecting

your MAVLink-capable system to the host serial port on the sensor.

The API is accessed via serial messages in the MAVLink format. MAVLink provides an open

data format for interaction as well as a suite of tools to assist the programmer in developing

and testing the interface. Altum uses MAVLink v1.0 messages and communicates with the host

at 57600 baud.

For more information and examples, please see https://www.micasense.com/api

Disabled

“Disabled” should be set when triggering via Skyport (PSDK), HTTP API, or the serial (MAVLink)

API. This mode disables the camera’s automatic triggering functions, and will require trigger

commands directly from the drone via PSDK, HTTP, or MAVLink, depending on the integration.

Thermal Non-Uniform Calibration (NUC)

Performing Non-Uniform Calibrations on (NUCing) thermal images helps reduce image noise,

resulting in better thermal image quality. The auto-NUCing feature is enabled on boot, and

ensures that the calibration is up to date with NUCs occuring every five minutes or when the

temperature of the camera changes by 2 Kelvin. Altum firmware version 2.0.0 and newer has a

manual NUCing feature available through the HTTP API and through the serial API, which

allows the user or autopilot to request a NUC, instead of depending on the auto-NUCing

feature. Once a manual NUC is commanded, auto-NUCing will remain disabled until the

camera is turned off and then back on again. Manual NUCing can ensure that NUCs don’t

occur at inopportune times during data collection, but may lead to poor data quality if NUCs

aren’t performed as often as needed.

© 2020 MicaSense, Inc

June 2020

Page 17 of 21

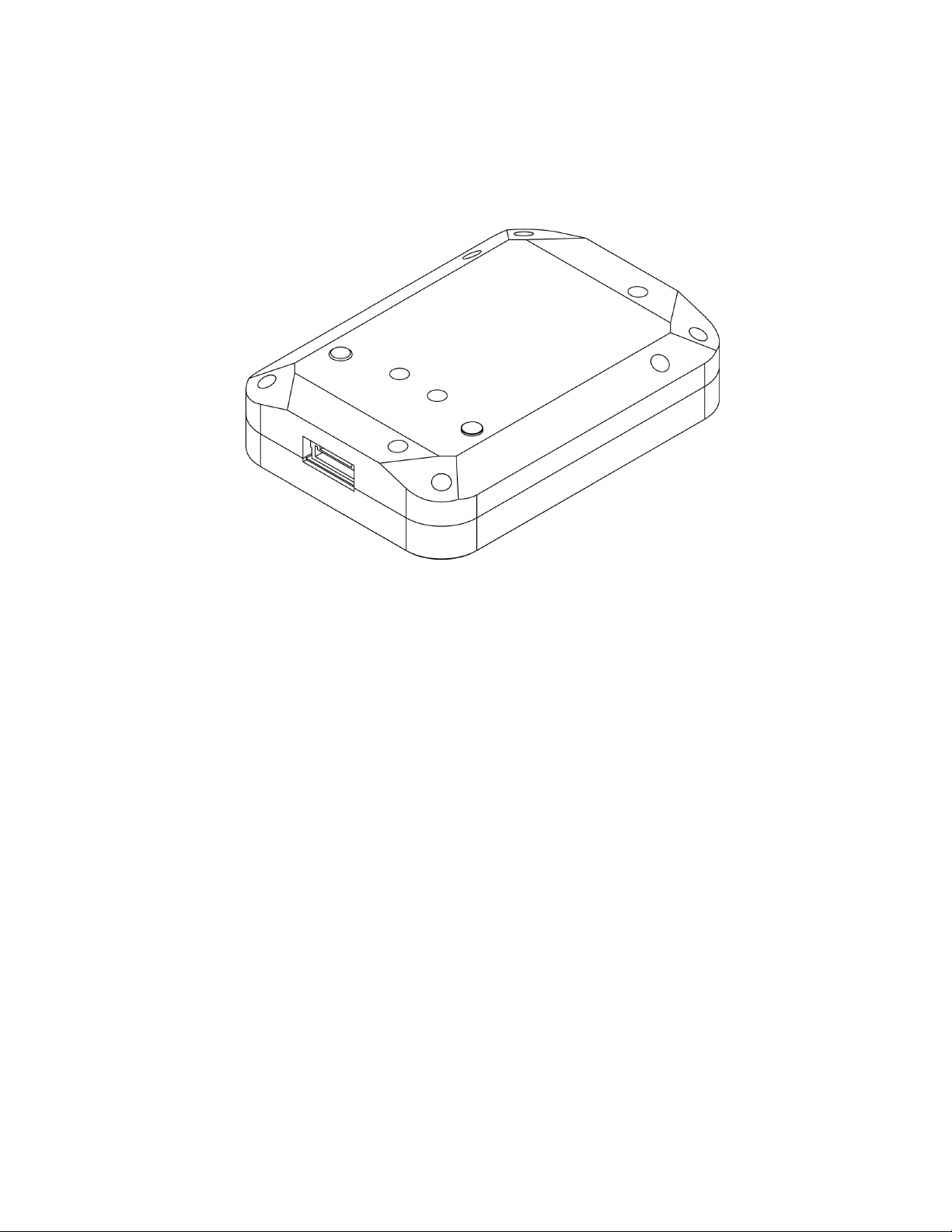

Downwelling Light Sensor 2 (DLS 2)

The Downwelling Light Sensor (DLS 2) is an advanced incident light sensor that connects

directly to Altum. During a mission, the DLS 2 measures the ambient light and sun angle and

records this information in the metadata of the TIFF images captured by the camera. This

information can then be used by specialized processing tools (like Pix4Dmapper) to correct for

global lighting changes in the middle of a flight, such as those that can happen due to clouds

covering the sun.

In addition, the DLS 2 provides GPS data to Altum unless GPS data is provided from an

external source as outlined earlier in this guide. If using an alternative GPS source, the GPS

receiver will remain on at low power.

© 2020 MicaSense, Inc

June 2020

Page 18 of 21

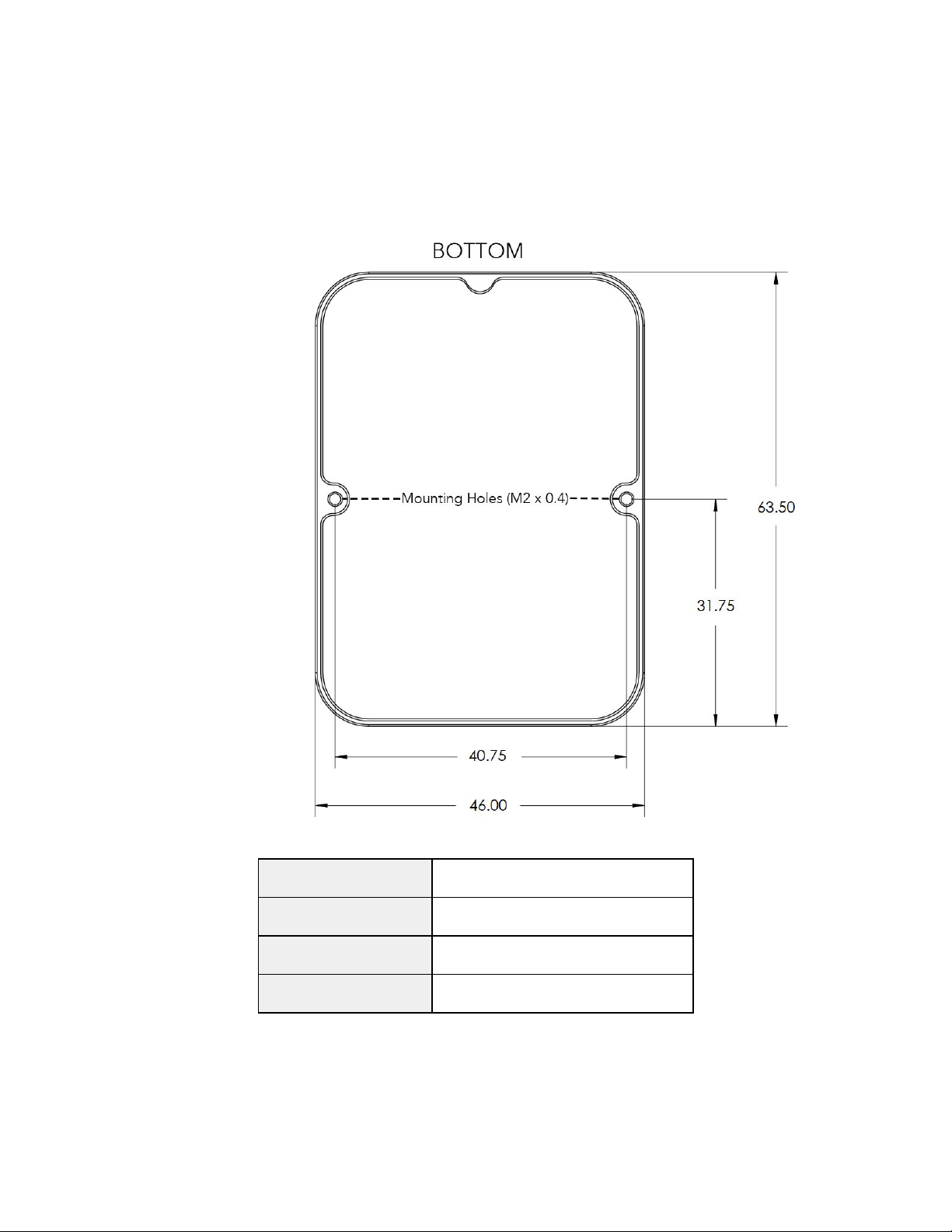

Measurements and Attachment Points

Height

14.03 mm

Width

46.00 mm

Length

63.50 mm

Weight

49 g

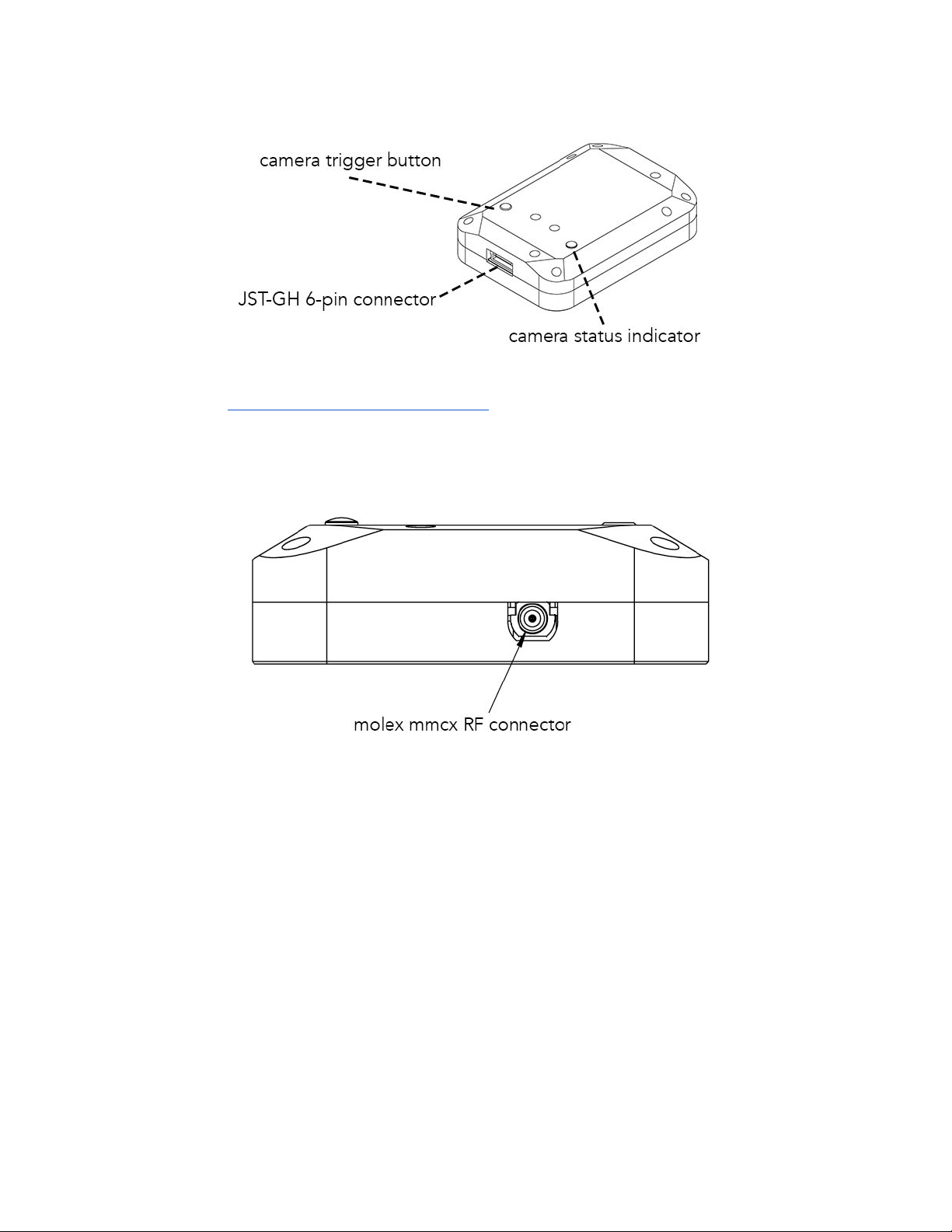

DLS 2 Connectors and Buttons

The sensor kit includes all required interface cables to connect to the DLS 2.

© 2020 MicaSense, Inc

June 2020

Page 19 of 21

The LED camera status indicator mimics the LED signals on Altum. The signal types are

outlined in the User Guide for MicaSense Sensors. The camera trigger button will command a

capture on the Altum. This is useful for capturing a preflight image of the calibration panel, but

care should be taken not to cover or shade any of the light sensors when pressing the button.

Older DLS 2 have an RF connector. This connector is not used by the DLS 2 or camera.

© 2020 MicaSense, Inc

This manual suits for next models

1

Table of contents

Other MicaSense Accessories manuals