Product Description

The lcs+ sensor offers a non-contact

measurement of the distance to an

object which must be positioned

within the sensor’s detection zone.

The switching outputs are set condi-

tional upon the adjusted detect dis-

tances.

The sensors can be adjusted via Teach-

in procedure using two buttons. Two

LEDs indicate operation and the states

of the switching outputs.

Optionally all Teach-in and additional

sensor parameter settings can be

made using the LinkControl adapter

(optional accessory) and the LinkCon-

trol software for windows®.

Note

The housing was updated with Batch

number XXXXXX. The assembly dia-

gram and installation height are iden-

tical to the old housing.

Safety Notes

Ԏ

Read the operating manual prior

to start-up.

ԎConnection, installation and ad-

justment works should be carried

out by expert personnel only.

Ԏ

No safety component in ac-

cordance with the EU Machine

Directive, use in the area of per-

sonal and machine protection

not permitted

Proper Use

lcs+ ultrasonic sensors are used for

non-contact detection of objects.

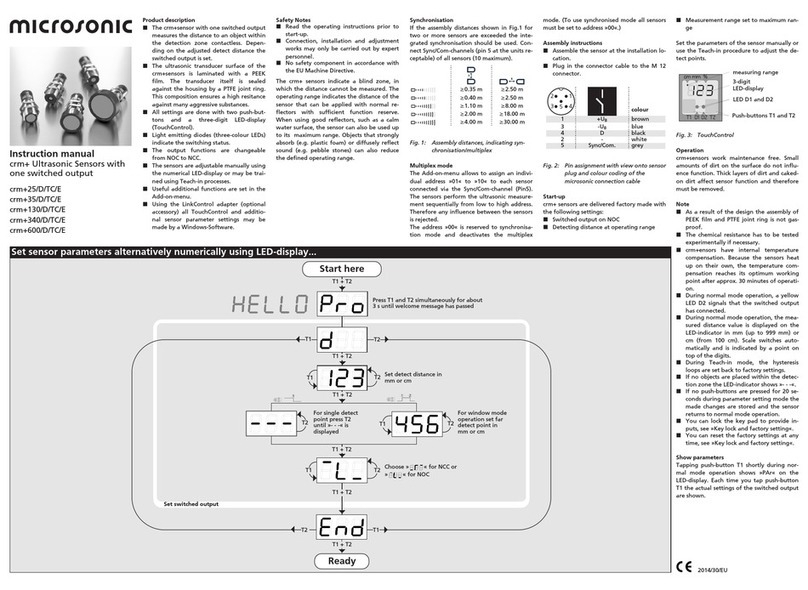

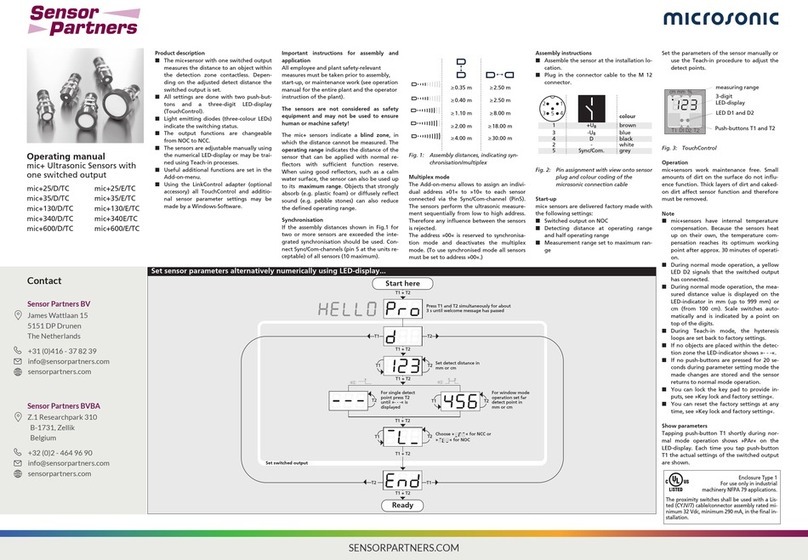

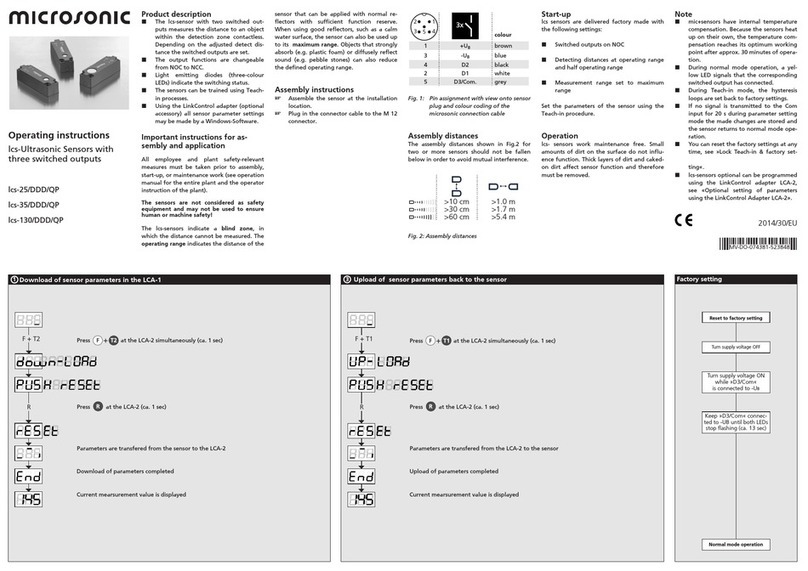

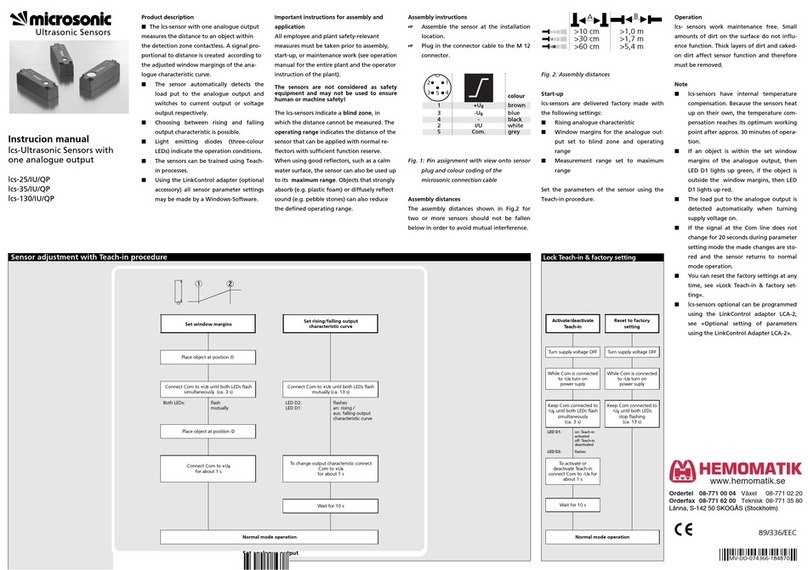

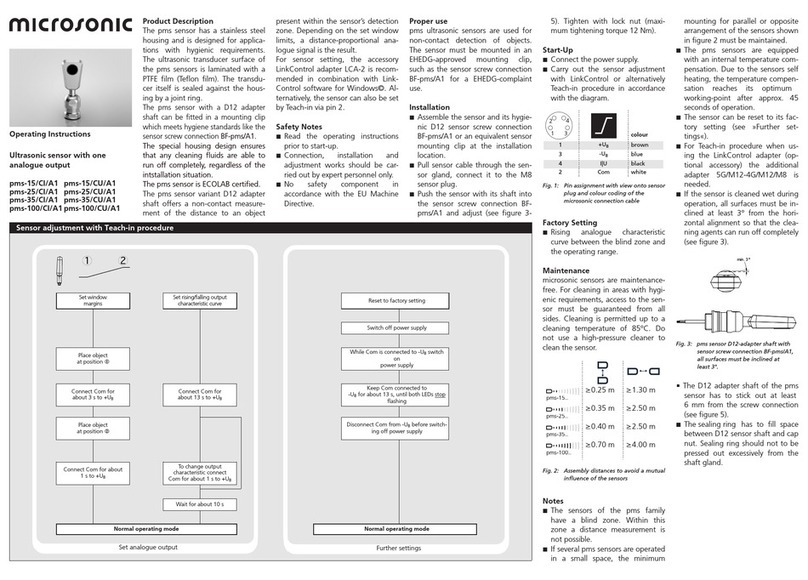

Installation

Î

Mount the sensor at the place of

fitting.

ÎConnect a connection cable to the

M12 device plug, see Fig. 1.

1

5

2

colour

1 +UBbrown

3 –UBblue

4 D2 black

2 D1 white

5 Sync/Com grey

Fig. 1: Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cables

Start-Up

ÎConnect the power supply.

Î

Set the sensor parameters using the

Teach-in procedure, see Diagram 1.

Factory Setting

ԎSwitching outputs on NOC

Ԏ

Detect distance D1 at operating

range and D2 at half operating ran-

ge

Synchronisation

If the assembly distance of multiple

sensors falls below the values shown

in Fig. 2, the internal synchronisation

should be used to avoid mutual inter-

ference between them. To do this in-

terconnect each pin 5 of the sensors

to be synchronised (max. 10 sensors).

lcs+340... ≥2.00 m ≥18.00 m

lcs+600... ≥4.00 m ≥30.00 m

Fig. 2: Minimal assembly distances without

synchronisation

Maintenance

microsonic sensors are maintenance-

free. In case of excess caked-on dirt

we recommend to clean the white

sensor surface.

Operating Manual

Ultrasonic sensor

with two switching outputs

lcs+340/DD

lcs+600/DD

Notes

ԎPin 5 (Sync/Com) of the sensor may

only be connected for synchronisa-

tion.

ԎThe sensors of the lcs+ family have

a blind zone, within which a dis-

tance measurement is not possible.

ԎThe lcs+ sensors are equipped with

an internal temperature compensa-

tion. Due to the sensors self hea-

ting, the temperature compensati-

on reaches its optimum working-

point after approx. 30 minutes of

operation.

ԎIn the normal operating mode, an

illuminated yellow LED signals that

the corresponding switching output

is set.

ԎIn the »Two-way reflective barrier«

operating mode, the object has to

be within the range of 0 to 85 % of

the set distance.

ԎIf no push-buttons are pressed for

5 minutes during parameter setting

mode the made changes are discar-

ded and the sensor returns to nor-

mal operating mode.

Ԏ

In the »Set switching point – me-

thod A« Teach-in procedure the

actual distance to the object is

taught to the sensor as the detect

point. If the object moves towards

the sensor (e.g. with level control)

then the taught distance is the level

at which the sensor has to switch

the output (see Fig. 3).

Set switching point -

method A

Set switching point

+8 % - method B

Fig. 3: Teach-in for different directions of

movement of the obcject

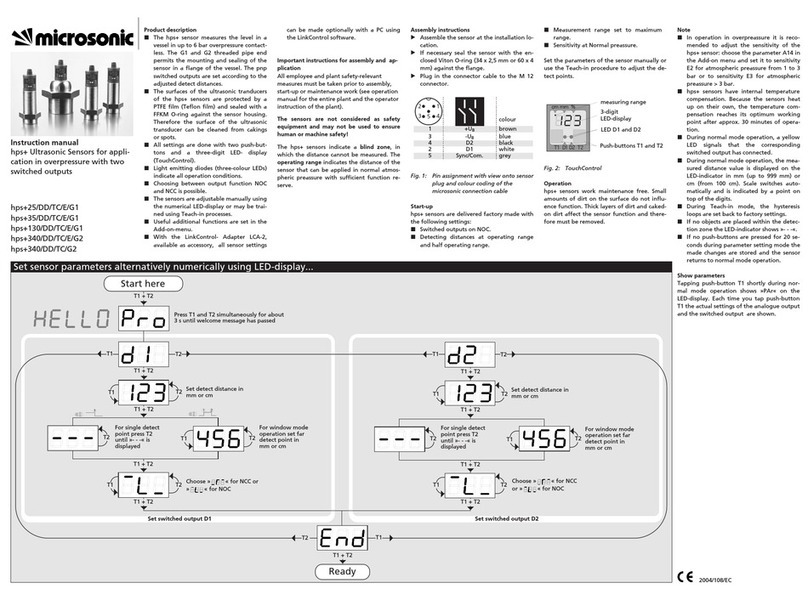

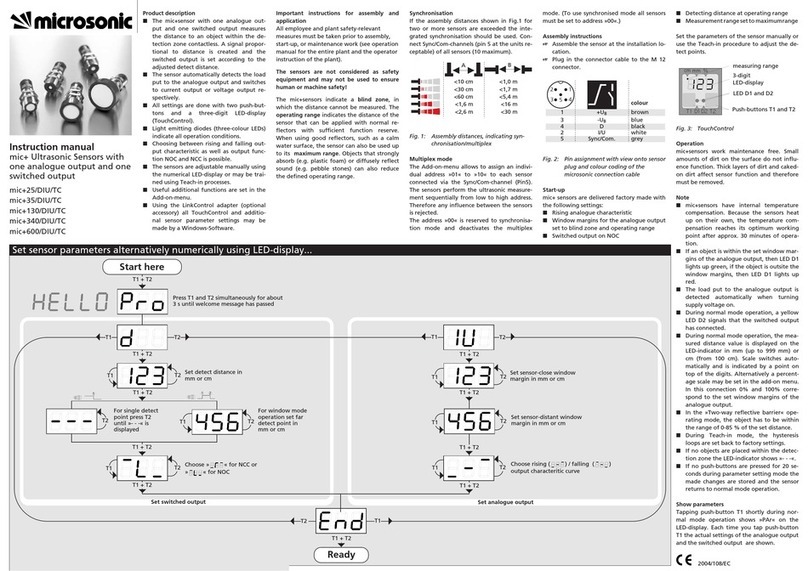

Diagram 1: Set sensor parameters via Teach-in procedure

Set switching point

D1/D2 – method A

Set switching point

D1/D2 +8

% – method B

Set window mode

D1/D2

Set two way reflective

barrier D1/D2 Set NOC/NCC D1/D2

Press T1/T2 for about 3 s,

until both LEDs flash

simultaneously.

Press T1/T2 for about 3 s,

until both LEDs flash

simultaneously.

Press T1/T2 for about 3 s,

until both LEDs flash

simultaneously.

Press T1/T2 for about 3 s,

until both LEDs flash

simultaneously.

Press T1/T2 for

about 1 s.

Press T1/T2 for

about 1 s.

Press T1/T2 for

about 13 s,

until both LEDs

flash alternately.

Place reflector at

position .

1

Place object at

position .

2

Place object at

position .

1

Place object at

position .

1

Place object at

position .

1

Both LEDs: flash

alternately Both LEDs: flash

alternately Both LEDs:

Both LEDs:

flash

alternately

flash

alternately

Wait for 10 s.

Both LEDs: flash

alternately

Press T1/T2 for

about 3 s,

until both LEDs

flash alternately again.

Press T1/T2 for

about 10 s, until

both LEDs stop flashing.

To change output

characteristic press

T1/T2 for about 1 s.

Normal operating mode

Set switching outputs

Output D1:

LED D2:

LED D1:

flashes

on:

off: NCC

NOC

Output D2:

LED D1:

LED D2:

flashes

on:

off: NCC

NOC

11 1 2

%85

1

Reset to factory

setting

Switch on or off

Teach-in

Keep T1 pressed for

about 3 s, until

both LEDs flash

simultaneously.

Keep T1 pressed for

about 13 s, until

both LEDs flash

alternately.

To change operation

mode press T1

for about 1 s.

Wait for 10 s.

LED D2:

LED D1:

flashes

on:

off:

Teach-in on

Teach-in off

Normal operating mode

Further settings

Switch off

operating voltage.

Switch on

operating voltage.

Switch on

operating voltage.

Switch off

operating voltage.

Press and hold T1. Press and hold T1.

Release T1.